Some nights, Im still jolted awake by an image from our cruising days. Im wedged into the crawl space beneath the bottom of one of

288

Knowing you are about to get drenched in diesel fuel is a singularly unsettling feeling. Despite meticulous pre-filtering, the religious use of anti-biological additives, and many improvements to the 60-year-old ketchs fuel system (including the installation of a fuel-polishing system), I found myself in this position once every couple of years. Part of the problem was our sketchy fuel supply. (My other recurring nightmare is refueling on the island of Obi in Indonesia, which involved ladling-yes ladling-100 gallons of drum-stored diesel fuel into jerry cans, which were then lugged a mile back to the boat.)

So the article on fuel tank construction and design in this months issue (“Replacing the Diesel Fuel Tank,” page 18) was of particular interest to me. One of the most telling side-notes to that article is that even the manufacturers of plastic tanks readily admit that this material is not the best choice for replacing an existing diesel fuel tank on a cruising sailboat. Here are some of the drawbacks we heard from the makers of these tanks:

Plastics do “weird” things when exposed to the chemicals in todays fuels.

Expansion and flex make it tricky to install a plastic tank. Ideally, they should be supported on all sides.

Multiple cleaning ports and baffled chambers that cruisers need on a large tank are not possible.

In a fire, plastic melts.

Custom ordering a single tank to fit your boat is not an option. Most manufacturers don’t even sell single orders of their tanks.

From a boatbuilders perspective, however, plastic tanks offer many advantages. They are light, inexpensive and can be mass-produced in virtually any shape. Fit isn’t a big issue, since the boatbuilder can design space below for an existing tank in production. And when it comes to installing the tank, you can foam it into any corner of the boat without corrosion worries.

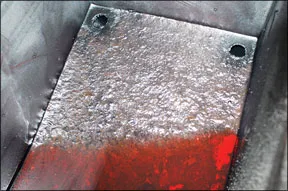

A corrosion-free fuel tank is a plus for owners, too, since this is a chief cause of tank failure. But, in our view, the corrosion resistance of a plastic fuel tank isn’t worth the hassles mentioned above. With proper material selection, design, and installation, the owner can protect against corrosion in an aluminum tank, which is still the best diesel tank material for the money.

There is far more involved in tank replacement than any single article can cover, so please feel free to write or e-mail any additional questions you may have. This project is probably one of the most trying ones that the owner of an old boat will face, but when done at a time and place of your choosing, it is far more pleasant than suddenly losing your engine in a coral-strewn pass, staring at your reflection in a pool of diesel in the bilge . . . or waiting for the spigot to open for your bi-annual diesel shower. This much I know.

Darrell Nicholson

Editor