Its called ground tackle-mooring weights, chain, lines, snubbers, shackles, swivels, anchors-all intended to hold your boat still when moored or anchored.

The vulnerable spot is where the anchor rode or mooring line climbs aboard the boat via a bow chock, which the French call a galoche davant and the Germans, whose marine terms surely are the most comical-looking, say, Bug-Aufklotzung.

The chock may have straight or angled horns, can be let into the toe rail, can be open or closed or even equipped with rollers, maybe a sliding latch to lock the line in place, anything to prevent the line from lifting out of the chock. Its trouble if it does and it usually happens not from the boats pitching but because the line gets stiff. Out of the chock, the line is almost guaranteed to get quickly chewed up by some other bow hardware.

The chock should have a very fine finish. Any rough or sharp spots, however minute, are guaranteed to chew up a line. An annual inspection is a good idea.

Peace of mind in this perilous situation is having good chafing gear.

In ye olden days, the drill was worm, parcel and serve, meaning that small line was fitted in the groves of the anchor or mooring line, the bundle was wrapped with canvas and the whole thing was tightly bound (or marled) with serving line. Sometimes the layers were tarred to make the whole section waterproof. The outer layer-the marling-was considered sacrificial and was redone as needed.

You can get an approximation of that old-fashioned chafing gear by just worming the standard three-strand nylon line and covering it with several layers of good quality marine tape. The worming should be big enough to make the bundle as smooth and round as possible, with the worming standing a bit proud. The roundness doesn’t reduce wear, but it discourages the wear from concentrating on one strand.

Types of Chafe Gear

As substitutes for the old-fashioned way, we tested 10 other approaches.

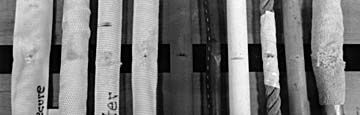

Eight are commercial products-two hoses, four made of woven fabric, a sewn leather cover and an expensive marine tape. Also included was a piece of common garden hose and a cover made of strips of an old towel, taped in place.

The hose-type guards come either as slip-on tubes that must be positioned before any eye splices are constructed or as split extrusions that can be applied any time. (The tubular hoses can be cut, of course, to permit installation but, if done so, the line should be taped to preclude any sharp edges from sawing the line.)

The woven material guards come as tubes or shapes considered removable because they are fixed in place with hook-and-loop edges. These are particularly useful when anchoring.

The Test

Basically, the test might be considered a shoot-out between marine or garden variety hose and fabrics woven of very modern material. (Neither the tape, the leather nor the towel treatment was in the same league-as far as chafe protection is concerned.)

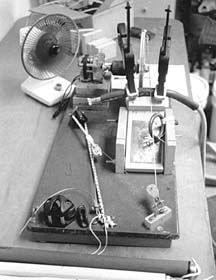

Positioned and secured on properly sized three-strand nylon line, each piece of chafing gear was subjected to Practical Sailors chafing machine.

In the first phase, the machine was set up to pull a piece of 1/16″ 1 x 19 stainless wire 7″ linearly across each piece of gear under a load that reached 8 lbs. The stainless wire might simulate what could happen to a chock if the anchor rode dragged up a stone or sand and roughed up the chocks finish at the wear point.

The load was vastly less than would be exerted by an anchor line or mooring line. Any wear seen in the test would be greatly multiplied in actual usage.

Each piece was cycled for four hours. Because the rotation is but 3 rpm, there is no heat build-up.

The 1 x 19 wire did not do much damage, but it appeared that the grooves worn in the woven fabric guards were less pronounced than on the rubber-type guards. The wire wore out before the home brew chafe guards could be tested.

Looking for more emphatic, realistic action, the chafe machine was reconfigured to scrape a rod blade made for a hack saw back and forth across the chafe guard. The blade moved perpendicular to the chafe guard. The round hack saw blade is embedded with bits of tungsten carbide. Although it seemed unlikely that the tungsten carbide bits could be dulled by wear on such soft materials, the contact portion of the rod was checked frequently for clogging.

In one direction, the stiff rod blade was lightly drawn sideways over a chafe guard. The pressure on the return stroke was much heavier. The rod blade also moved linearly about 3/8″ before resuming its perpendicular movement. The action was no substitute for what might happen in a real situation. If moored or anchored in difficult conditions, it seems likely that this much damage could be done in a few minutes.

Except for those that couldnt take it, each chafe guard was run for eight hours, meaning that the rod blade scraped back and forth 1,440 times-2,880 strokes.

The initial wall thickness, the wear and the percentage of wall thickness worn away are shown on the chart.

The Bottom Line

Which fared best? Solid hose, woven fabric, leather, tape or toweling?

In a little more than four hours, the leather was sawed through, in a narrow slit where the rod saw blade settled in, to the enclosed nylon line.

The two layers of tape, applied in a spiral, lasted an hour.

The toweling wore through in six hours-probably because it had some flexibility to slip back and forth.

What of the hoses and fabric tubes?

The chart indicates which best withstood the abrasion.

The fabric guards fuzzed up; strands broke until the material was tattered and worn-sometimes completely through. The best of the fabric guards was the Davis removable, whose woven nylon was backed by a solid layer of hook material (part of the hook-and-loop fastening. Its wall thickness loss placed it second.

Aside from the Davis removable, the natural or synthetic hoses generally performed considerably better than the fabric guards. Each behaved somewhat like a pencil eraser. Tiny bits of rubber were shaved off with each pass of the abrasive rod. After a few hours, the bits made a neat pile. They lost the lowest percentage of wall thickness, with the neoprene Perma Buoy sample suffering less percentage loss than the rubber Seafit or the common garden hose.

For placement as needed to protect an anchor rode, it would be nice to have aboard the removable version of the nylon Davis guard. Its particularly helpful on lines with eye splices, over which you can’t slip a tube. If it was a rough night aboard, wed inspect the guard fairly often.

For a mooring or permanent docking lines, the test strongly suggests that flexible rubber or neoprene hose is by far the best. And, of the several versions, the Perma Buoy seems preferred-not only because of its thicker wall but because it tested best against abrasion. Just check first to make sure it fits in your chock.

Contacts- Davis Secure, Davis Instruments, 3465 Diablo Ave., Hayward, CA 94545; 510/732-9229. Perimeter, Perimeter Industries, 1532 W. 132nd St., Gardena, CA 90249; 800/225-6636. Perma Buoy, 121 River Rd., Ware, MA 01082; 413/967-7700. Seadog, Sea-Dog, Box 479, Everett, WA 98206; 425/259-0194. Seafit, West Marine, Box 50070, Watsonville, CA 95077-0070; 800/262-8464.