Continuing with our recent evaluations of marine sanitation systems, Practical Sailor tested eight marine-grade diverter valves, or Y-valves. Y-valves are a means of controlling the flow of liquid from one source to two different outlets or from two sources to one outlet. On boats, one use is to control waste management. The Y-valve directs toilet waste to either a holding tank or directly overboard through an appropriate seacock.

Many states require that the valve be locked in the holding tank position while sailing lakes or inland waterways. Under federal regulations, no overboard holding-tank discharge is allowed within three miles of shore.

A Y-valve can also be reversed and used in a bilge-pump arrangement to select between two separate bilge areas using only one bilge pump.

What we tested

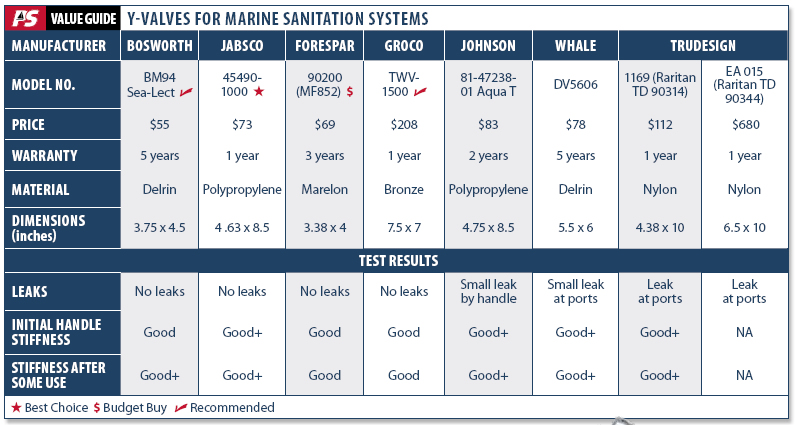

The test field for this evaluation comprised seven manual diverter valves and one electric valve from seven manufacturers. The Bosworth Co. is a family-owned, Rhode Island company, while Gross Mechanical (Groco brand) is a third-generation maker of marine hardware and is head-quartered in Maryland. Jabsco, Forespar, Johnson Pump, and Whale are all worldwide players in the leisure marine market. (Jabsco is now part of Xylem Flow Control, a new spinoff from ITT Industries.) TruDesign, the maker of the only electric diverter valve in this test, is a New Zealand-based manufacturer of marine composite fittings.

How We Tested

Practical Sailor tested the diverter valves to determine which were the top picks for marine sanitation systems or for installations where a manual or electric pump may be used in conjunction with the valves.

All of the Y-valves tested were new, never used, and dry. Testers mounted them to a piece of lumber for the bench tests. Ambient temperature during testing was about 72 degrees, and there was no wastewater or matter present in the test-bench setup.

To rate how easily each valve’s handle turned, we attached a Manley bronze spring scale (calibrated to 50 pounds) to the hole in each handle (designed for locking the handle) and measured the amount of pull needed to release inertia and move the handle. The placement of the holes in the handles was not consistent, with some at the end and a few near the handle center, so some mechanical advantage was lost for those with holes closer to the center. Testers kept this in mind when calculating the ratings.

The ratings listed under “initial handle stiffness” in the Value Guide are the averages of 10 pulls. The “stiffness after some use” ratings are the average pounds of pull required after the handle’s seal was loosened up.

Some valve handles were stiffer to turn than others. Several manufacturers advise you to keep the valve seals lubricated, recommending silicone grease or even Vaseline, and suggest operating the valve frequently, at least once a month, to prevent the seal from seizing up. Several units loosened up after we did the pressure test.

To test resistance to odor and water leaks, we attached appropriately sized sanitation hose to one outlet port and capped the other end of the hose. To the other outlet port, testers connected a garden hose with 55-pounds per square inch (psi) of water pressure. We worked valve handles back and forth for 30 seconds each and left them in the closed position for two minutes with the water running. We evaluated the smoothness of operation, the feel for a positive stop in both positions, and leaks from the outlets, base, or handle.

Practical Sailor recognizes that a Y-valve in a marine sanitation installation during normal operation would be less than 55 psi (more like 2 to 10 psi) and there—ideally—would be no blocked outlet, but we consider the pressure to be a fair amount for the purpose of our tests. Diverter valves are also used in other systems—sometimes in conjunction with a manual or electric pump—and those installations would see greater pressure than a valve in a waste-disposal setup; also these systems do become clogged.

Unlike seacocks and through-hull valves, there are no industry standards for Y-valves related to pressure. According to Forespar’s Bill Hanna, the company shop-tests each of its valves to 45 psi. Similarly, Groco tests its valves to 30 psi, and Forespar also randomly leak-tests its valves to 50 psi but does not move the handle during tests. Whale tests its valves to 17 psi but does so with them in a traditional installation setup.

For this test, PS also considered the valves’ prices, ease of installation and maintenance, construction quality and materials, and whether they could be easily locked in accordance with some areas’ laws. Most units come with holes or feet for mounting the base to a deck or bulkhead and offer handle extensions for allowing the handle to be on the front of a bulkhead for easier access.

Bosworth Sea-Lect

The Bosworth Co.’s BM94 Sea-Lect valve was the most simple and compact of our test samples. It was the only one with ports to 1-inch ID hoses, and they are smooth and fixed to 120 degrees. It is also available for 1½-inch hose, NPT tapped ports, and flush mounting.

The body is made of Delrin, and the handle is epoxy-coated aluminum. Delrin is an acetal resin that is as strong and hard as a metal but is easily molded and resistant to salt, solvents, and friction. Bosworth offers a whole series of polypropylene and nylon-barbed fittings and adapters for hoses from ½ to 2 inches.

Although the Bosworth’s handle has a hole, there are no corresponding holes in the housing into which you could insert a padlock, so it’s unclear how you would lock the valve closed. The handle was well-marked with molded arrows for the flow direction.

Handle operation was stiff at first but became smooth. Bosworth re-designed its valves in 2011 to make them easier to turn and more resistant to the freeze ups that sometimes occur with Y-valves. The Sea-Lect came with a tube of Dow Corning No. 44 grease and was unique in explaining how to lubricate the inside of the body completely, at least once a year.

Bottom line: The Bosworth Y-valve was trouble-free in testing, has a compact design, and at $55 (with a five-year warranty), it was the least expensive of the products tested. It gets PS’s Recommendation for a valve in this size range.

Jabsco

Jabsco’s 45490-1000 has a larger footprint than some other valves because it comes with two curved, 120-degree, 1½-inch discharge ports that can rotate in any direction to make plumbing it easier. It comes with both 1½- and 1-inch screw-in inlet port adapters.

The body and handle have holes for accommodating a padlock to prevent discharge and comply with discharge regulations. The valve body is made of chemical- and corrosion-resistant polypropylene with stainless-steel bolts, screws, and bright silver, inlaid flow arrows. The ports and diverter shaft have replaceable O-ring seals.

Made in China, the valves came with a well-written four-page instruction sheet. The unit is easy to disassemble for cleaning and lubricating, and testers found operation to be very smooth, with positive stops and no leaks.

Bottom line: The Jabsco performed well in our tests, and its rotating outlet ports and easy locking arrangement were bonus features. Priced at $73, it gets the PS Best Choice in this test field.

Forespar

Forespar, established in 1967, has an extensive line of sailing hardware and marine plumbing parts. The Forespar MF852 (No. 902000) Y-valves we tested are made of Marelon, a proprietary formulation of polymer composite compounds designed for use in marine plumbing systems and use below the waterline. Marelon is lightweight, easily molded, and resistant to the ravages of saltwater corrosion and electrolysis.

The Forespar Y-valve is available in four sizes with hose barbs from ¾ to 1½ inches. The valve has a small, rounded handle, which enables it to have a small footprint: 3.5 inches wide by 4.5 inches tall.

The smooth handle moves only 120 degrees and includes a hole for a padlock, but there are no corresponding holes in the valve base. The handle movement was quite stiff initially, and under pressure, it was even stiffer until it locked up. According to Forespar Sales Manager Art Bandy, this was likely a result of the high pressure used in testing, which could have forced the valve’s internal seals to seat beyond normal use.

A second sample was tested, and it worked better with no leaks and a smoother operation under pressure. It rated in the middle of the pack for ease of turning. We can only assume the difficulty with the first test valve was an anomaly.

The MF852, which comes with a three-year warranty, is designed for easy maintenance and repair, and repair kits are available.

Bottom line: The Forespar MF852 is compact and costs $69, a bit less than the top-rated Jabsco. It gets our Budget Buy pick for installs where its small stature is a good fit.

Groco

Groco, founded in 1918, manufactures a line of specialized bronze valves, seacocks, pumps, marine toilets, and holding tanks. The Groco TWV-1500 is a heavy-duty, bronze three-way valve with ports for 1½-inch threaded pipe fittings.

It’s important to use the correct pipe threads. Straight ones require a lot of space to bend the hoses, which can be a real problem in a tight space. Be sure to determine which way the hoses will run before mounting the valve. Groco markets a full line of threaded fittings that are available from West Marine stores.

The Groco is heavy and compact, but it has only two mounting holes, whereas the other test products had more. The handle mounts on the side and points to the flow direction with the center closed “off.” No instructions were included, but none were needed.

The valves are heavy-duty cast bronze with stainless-steel. The coated-stainless handle was initially quite stiff, but after some lubrication and working back and forth, it loosened up adequately.

The handle rotates a full 180 degrees. It does not have any indicators for flow direction, but it’s a logical design that’s intuitive to use.

Under pressure, the Groco, with its PTEF seats and seals, worked better than any other test product and had no leaks.

Bottom line: Although the $208 Groco is considerably more expensive than others, the cast-bronze housing is likely to outlast those made of plastic, and with only one bolt for the handle, it has few parts to worry about breaking. It gets the PS Recommendation for its bullet-proof design, top-notch performance, and smooth operation. Some things are worth the added expense, and the Groco is one of them.

Johnson Pump

Johnson Pump is a division of Sweden-based SPX Flow Technology, which is a leading manufacturer of marine pumps, marine toilets, and sanitation accessories.

The Johnson Aqua-T Diverter Valve (No. 81-47238-01) came with reducers and a handle extension for flush mounting. The valve looks very similar to the Jabsco we tested, but it came with no instructions.

The operation was smooth, but the handle has no marking to indicate flow direction, and it was a little confusing which position was open or closed.

In bench testing, the Johnson valve leaked under the handle when operated under pressure.

Bottom line: The Johnson valve’s leak and lack of flow indicators held it back.

Whale

Founded in 1810, Whale Water Systems manufactures fresh, gray, bilge, and wastewater pumps, showers, faucets, and accessories. The Whale diverter valve is made of Teflon-coated Delrin acetal composite that is manufactured in Ireland and comes with a five-year warranty.

The Whale DV5606 diverter valve is fairly compact and has smooth 1½-inch ports at 90-degree angles. When plumbing hose to smooth ports, be sure to secure it with two hose clamps.

The Whale has four mounting flanges and three holes in the body, but there is no hole in the handle for securing it to the body. It includes stick-on arrows and labels such as “Tank,” “Sea,” etc., and the handle points to the “open” position.

The unit is compact, its operation is clean and very smooth, but it did leak through the closed port when operated under pressure. We tested a second sample, and it also leaked.

Whale explained that leaks were rare, but in our case, it was likely a result of the high pressure used in testing. The valve is not rated to 55 psi.

“Our testing is carried out with a normal installation of an open head, i.e. an open seacock overboard or open inlet to black waste,” Whale Engineering Manager Richard Bovilli explained. “Typically, the pressure in this installation is only generated by flow of the pump, which is always less than a lift of 13.1 feet or 7 psi (0.4 bar).”

Bottom line: The leaks and lack of permanent flow indicators kept testers from favoring the Whale valve.

TruDesign Manual

TruDesign products are made in New Zealand and sold in the U.S. through Raritan Engineering Co. (www.raritaneng.com). We tested the Manual Aquavalve (Model 1169; sold by Raritan as No. 90314).

Made of glass-reinforced nylon composite, the white valve we tested had black lettering identifying it as a “Toilet Diverting Valve” and labeling the three ports as “Inlet,” “Overboard,” and “Holding Tank.” It clearly shows which port is closed and which is open, a feature testers liked.

TruDesign’s Aquavalve has holes to secure a padlock in one of two positions and includes three 1½-inch thread to 1½-inch hose nipple adapters (one straight, one 90 degrees, and one 120 degrees). They come with appropriate washers and a plastic wrench, but the threads are not standard PVC pipe threads. Installers must determine which fitting and washer each port should have before screwing in and screwing down the base.

The Aquavalve has a silicone seal, which Raritan said gives less resistance when changing the flow from one port to another. The silicone also will not bind to its housing when unused for extended periods, a common problem among diverter valves with rigid seals.

When we applied water pressure during bench tests, testers heard a “pop” inside the valve housing, which resulted in considerable leaking from the closed port. Raritan reported that in seven years of production, there have been no customer complaints of experiences like ours. The company carried out its own test, trying to replicate our problem, and found that it was related to the high pressure in testing.

“The pop sound comes from the silicone seal coming out of its seat and relieving all the pressure suddenly—just like a cork from a champagne bottle,” Raritan’s Kim Shinn explained. The silicone seal can be re-seated by moving the handle back and forth, if the handle does not offer resistance. If there is resistance, Shinn said, then the only safe way to re-seal the valve is to take the unit apart.

Shinn added that although there is no standard for Y-valve pressure ratings, the American Boat and Yacht Council and UL standards related to hull piping specify that sea valves tolerate 10 psi test during opening and closing. “We tested the Aquavalve with 10 psi applied and opened and closed (the valve) 25 times as per UL 1121 17.3, and there were no leaks. We also applied 45 psi for one minute in the closed position as per 18.1 of UL 1121, and no leak and no pop sound.”

Bottom line: The second most expensive ($112) manual diverter valve tested, the Aquavalve has some great features. However, its strong point—the silicone seal— may also be its Achilles heel in moderate- to high-pressure installations.

TruDesign Electric

TruDesign’s EA015 Electronic Aquavalve (sold by Raritan as No. 90344) uses a similar valve body as the manual valve, but the manual handle was replaced with an electric one, a small remote-control panel (2½ by 3½ by 5/8 inches), and a 15-foot data cable. It can be ordered in either 12- or 24-volt.

The 12-volt Aquavalve requires 3.3 amps to operate and 40 mA in standby. The valve housing and control panel are dust- and jet-spray proof. To insure seal lubrication, the valve automatically cycles between ports at regular intervals (so long as the power is on).

The top of the valve and control panel have colored LEDs to show the position of the valve. The control panel has three pushbuttons, two for the valve positions and one to lock it in place. The electrical hookup was very simple.

Testers experienced the same seal popping and leaking in the electric version as we did with the manual TruDesign. The remote panel flashed all three LEDS showing a “fault,” indicating there was a blockage in the valve’s rotation. When this happens—or if power is lost—the valve will not operate. To operate manually, you must disassemble the unit to access the rotor, then use parts that came with the unit to fit out the valve for manual operation. This does not void the warranty.

Bottom line: Priced at $680, the Electronic Aquavalve is overkill for most boats, and we’re hesitant to add an electronic device where a manual will serve just fine. This is more designed for boats where the skipper really needs the convenience of diverting the head without going below, in our opinion.

Conclusions

While only half the test valves passed our high-pressure test, any of them would likely perform well onboard. However, there were a few standouts in the group.

For small boat and other installations where space is a problem, the petite Bosworth is worth considering; it was the most compact and least expensive. But, for just $15 more, we’d go with the Forespar, which is also very compact and well made. It gets our Budget Buy pick. For those with a little more space, we’d opt for the Jabsco or Groco. The Jabsco was a smooth operator with no leaks; it also has the advantage of rotating outlets and would be the easiest to take apart for cleaning and lubricating. It’s the Best Choice. The PS Recommended Groco is more pricey, but it worked perfectly and the one-piece bronze housing has definite advantages for minimum service and longevity.