If we used our boats like the family car, back and forth to work each day, fuel would never sit for more than a few weeks and it would never age. Instead, boats sit for weeks at a time in-season, and for months during the off-season. Water, oxygen, bacteria, metal ions, and even instabilities in the molecules themselves combine to turn fresh fuel into a soup that will clog filters, corrode fuel systems, and leave us stranded. Fuel refineries have long known this, and all products are dosed with inhibitors at the refinery; however, these dosages are calculated for the normal distribution and storage times, not half-full tanks that will sit for months or even years.

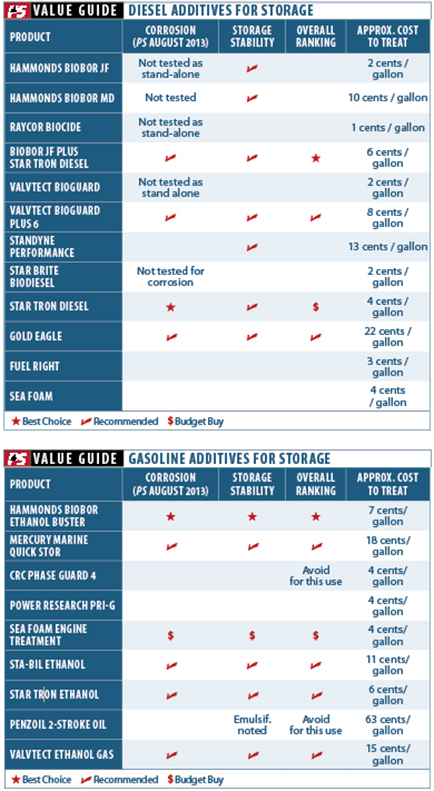

We’ve studied the impact of aftermarket additives on corrosion (PS November 2012 and August 2013) and biological bugs (PS July 2009). And we’ve reported on how silica-gel fuel-vent filters reduce corrosion, separation, and oxidation (PS January 2013 and January 2014). Here, we examine long-term storage stability in both gasoline (E-10) and ultra low sulfur diesel (ULSD). In the accompanying Value Guide table, we’ve combined these new findings with a summary of prior testing and presented our top picks for overall additive effectiveness. No more mystery claims; only measured results.

For this test, we followed standard test methods for fuel storage stability. Diesel was tested using American Society of Testing and Materials Method D 4625, Standard Test Method for Middle Distillate Fuel Storage Stability at 43C. For more details on the test procedure, see the accompanying How We Tested.

What We Tested

Our test focus was on products claiming to improve storage stability, and there are many. We also tested some additives that do not make this specific claim, but we included them because performance additives are often used as storage additives.

Giving these products a grade for overall performance wasn’t easy. Some products werent tested in all categories. Some are single-purpose additives-biocides, for example-and would typically be combined with other products to give multi-function protection. Some were simply not considered or available during prior testing. In one sample, we combined two additives (Star Tron and Hammonds BioBor JF) to confirm that they would work together against corrosion. They did, and we don’t foresee any problems combining additives to treat distinct problems, although a single product might be just as effective-and is probably less expensive.

Lab Observations

Even under accelerated aging conditions, our fuel samples aged very, very slowly. Without treatment, all diesel samples survived the equivalent of three years storage (in optimal conditions) with no changes that would disturb engine operation or render the fuel off-specification. Under our labs optimal storage conditions, diesel can be stored for three years, but the temperature, humidity levels, and tank conditions that meet our definition of optimal are extremely difficult to replicate at sea.

Gasoline deteriorated more quickly. Some of our untreated control samples and some treated samples only slightly exceeded specification after the equivalent of two years. Any sample treated with products that we rated as Recommended remained in specification throughout the test period and should allow safe storage up to two years.

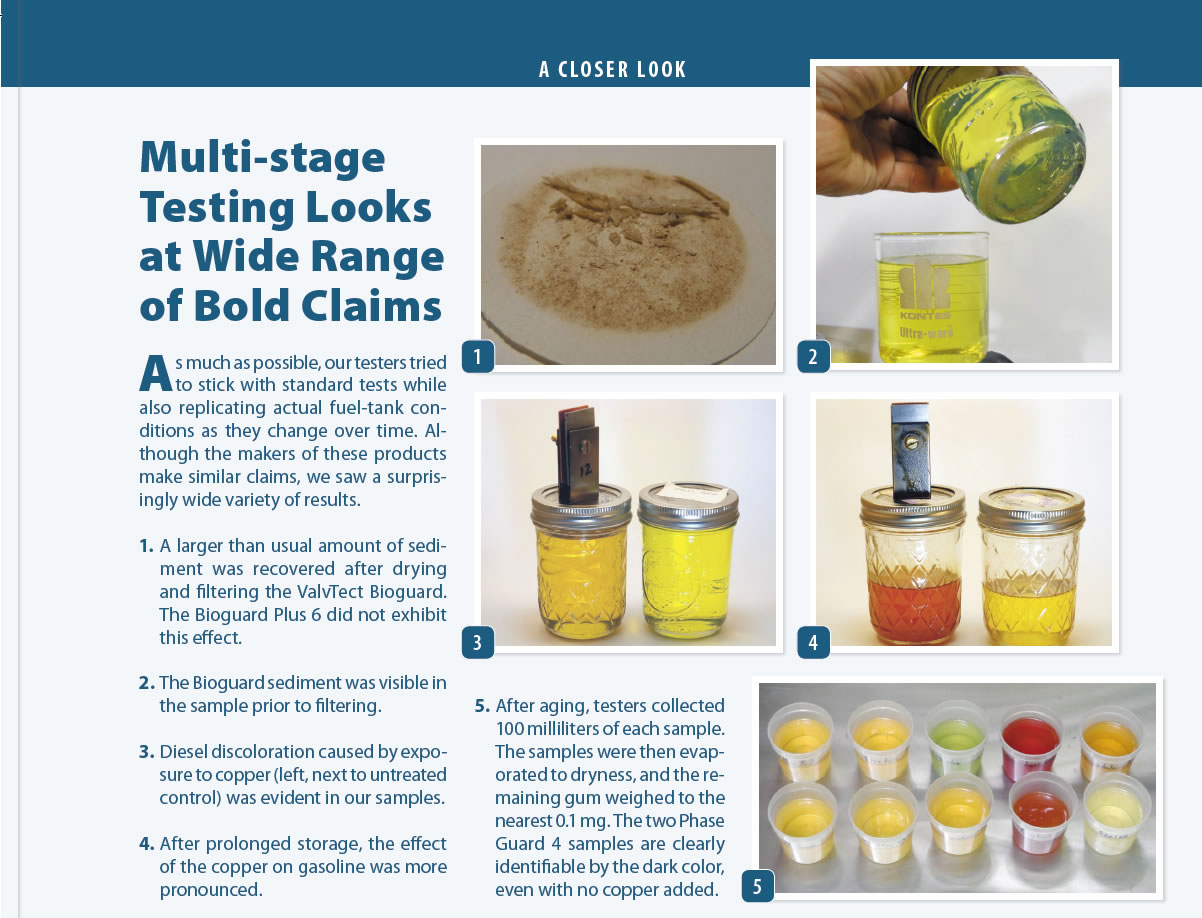

Ironically, components in the fuel system itself can accelerate aging. In previous PS additive tests, we saw catastrophic aging of fuels that were exposed to copper and zinc. Our testers witnessed this again in this round of testing. The only samples experiencing significant aging were those with brass and copper coupons, and the effects were dramatic. In the gasoline sample, color and visible cloudiness appeared within a week. Diesel was less affected, but since it is often stored for longer periods, and is exposed to more copper as the fuel recirculates, exposure to harmful metals is still a concern.

Both gasoline and diesel were rendered off-specification after 75 days of testing (with copper coupons), the equivalent to seven to 10 months of storage, or a single off-season in some chillier climates. The diesel was barely off-specification, while the gasoline sample contained filter-clogging sediment and very high gum levels. This test intensified the conditions in the tank, because the ratio of copper to fuel was exaggerated. Even so, the scenario was not unrealistic for some systems with brass jets and copper fuel lines, especially when you consider that the fuel in our test was refinery treated and of the highest quality-something seldom found at a dockside pump.

Although we have pointed out the importance of keeping ethanol-blended gasoline tanks full (or completely empty, where practical) during storage, diesel is different. We saw no difference in the aging of diesel samples that were 90-percent full versus 25-percent full. Thus, leaving the diesel tank partially full during winter storage and topping off in the spring is acceptable. This is not a valid approach for gasoline, whether or not it is an ethanol blend.

Copper and Zinc

Scientists have long known that copper and zinc are catalyzing agents that can foster fuel polymerization, the gum and varnish buildup that can clog carburetors. Land diesel storage tanks don’t experience this because steel and aluminum are the only acceptable materials. Although our tests could not quantify the risk posed by copper and zinc valves and fittings in the fuel system, other studies suggest that this is a legitimate worry.

The American Society of Testing and Materials (ASTM) clearly states that stored fuel should not be exposed to copper and copper-containing alloys and that zinc coatings can react with water or organic acids to form gels, which rapidly clog filters. British Petroleum (BP), Caterpillar, Cummins, Yanmar-the list goes on-offer similar warnings.

Diesel

Hammonds Biobor JF

One of Hammonds most popular products, Biobor JF (jet fuel) is perhaps the most widely used biocide for diesel and jet fuel, and thus is among the most available. It rated highly as a biocide in our tests, but it did little to protect against corrosion. In a previous test, we paired Biobor JF with Star Tron Diesel, and corrosion was very well controlled.

Bottom line: This wasn’t the top overall pick, but its the Best Choice for a biocide.

Hammonds Biobor MD

Hammonds multifunction additive Biobor MD is intended to compliment Biobor JF, specifically as a storage additive. Unfortunately, it is a new product, so it was not available during our initial anticorrosion trials; although this prevented it from getting an overall rating, it did well in our storage testing.

Bottom line: We will be looking at Biobor MDs anticorrosion performance in future tests. For now, it is Recommended for storage.

ValvTect Bioguard

Although ValvTects Bioguard proved to be an effective biocide, it produced higher than normal levels of precipitate in our tests. If there is any significant amount of bottom water (water that has been separated by gravity and settled to the bottom of the tank), this precipitate should stay in solution and will evaporate, or burn through the engine without harm. The sample also yielded a higher than normal amount of sediment.

Bottom line: Not recommended for storage. If you like the ValvTect brand, go with Bioguard Plus 6.

ValvTect Bioguard Plus 6

ValvTects Bioguard Plus 6 includes the same biocide used in Bioguard, along with extra additives to control corrosion and reduce sludge formation. It did not produce the sediment that the plain Bioguard did.

Bottom line: This is a good multifunction additive that can be used for storage and/or routine treatment. A Recommended product for overall use.

Star Tron Diesel + Biobor JF

A top performer in anticorrosion tests and anti-aging tests, Star Tron Diesel also performed well when used in combination with Biobor JF. In biocide testing trials (Star Tron is not marketed as a biocide), it showed properties that complimented Biobor JF (killed different strains), making the pair a powerful one-two punch.

Bottom line: While this blend requires adding two products, based on our testing, it is the Best Choice overall.

Star brite Biodiesel

Using the same basic chemistry as ValvTect Bioguard, Star brite’s Biodiesel also produced an unacceptable level of precipitate, rendering the diesel off-specification. As with the Bioguard, in the event of any significant bottoms water, the precipitate should stay in solution and evaporate or be so minor that it wont harm the engine, but it is still an undesirable condition.

Bottom line: There are better choices.

Sta-Bil Diesel

Although not the top performer against corrosion-it allowed slight surface corrosion of steel samples-this product did a respectable job of preventing serious corrosion. There was no pitting in the test coupon, while the control and several other additives allowed countless small craters in the steel sample. In storage testing, the filterable solids value was average for the test group. The sample appeared more turbid than others in the group, although this might be attributed factors that have no detrimental bearing on performance.

Bottom line: Recommended.

Gasoline

Hammonds Biobor EB

A top performer in PSs gasoline corrosion tests, Hammonds Biobor EB is a comprehensive gasoline fuel treatment that claims to prevent phase separation, although we have yet to see any product achieve this. During phase separation a concentrated water/ethanol layer can collect in the bottom of your tank, accelerating tank corrosion and possibly harming the engine. It also claims to stabilize gas to prevent gum and varnish buildup and prevent corrosion. In our tests, it preserved the clearest samples with the lowest gum levels.

Bottom line: A clear winner in this category, Biobor EB is our Best Choice for overall gasoline treatment.

ValvTect Ethanol

ValvTects Ethanol additive proved to be a good anti-corrosion product with acceptable anti-aging properties.

Bottom line: Recommended.

Star brite Star Tron Ethanol

We previously tested Star Tron Ethanol for its ability to delay or prevent phase-separation in ethanol fuels, and its ability to burn cleanly without leaving behind any ash residue. In that test, the product came out with a Recommended rating. Although its anti-corrosion protection did not impress testers, its anti-aging performance was good, which nudged it higher in terms of overall performance.

Bottom line: Star Tron Ethanol offers acceptable anti-corrosion and anti-aging properties at a good price. Recommended.

CRC Phase Guard 4

CRC Industries Phase Guard 4 has been a disappointment. In both corrosion testing and stability testing, our results seemed to indicate that this additive has the potential to do more harm than good under certain conditions.

Bottom line: We do not Recommend this product.

Two-stroke oil

Some claim that adding common two-stroke oil to gasoline can offer all the storage and corrosion protection you need. We categorize this myth as busted. In corrosion testing, the oil actually increased corrosion due to increased water absorption. We saw cloudiness in the aging test as well.

Bottom line: Dont expect two-stroke oil to protect gasoline during storage or use; use one of the Recommended additives.

Sea Foam

For years, recreational fishermen have been using Sea Foam Motor Treatment to resurrect balky outboards. We found it very effective against corrosion, good in aging tests, and inexpensive. Its available in 16-ounce cans through auto parts supply chains.

Bottom line: Sea Foam gets the Budget Buy pick.

Sta-bil Ethanol

Sta-Bils Ethanol additive performed acceptably in our corrosion test at lower seawater levels and earned a Recommendation. In terms of protection against aging,it meets all the industry standards for storage additives, including ASTM D525, the only stability test recognized by the petroleum industry for measuring the stability of gasoline and ethanol blended E-10.

Bottom line: A solid middle of the pack performer overall. Recommended.

Conclusions

While anti-oxidation additives logically help against fuel aging, it seems clear to us that copper and zinc ions are the main driver and that corrosion control additives are key. Keeping water out of the fuel system and avoiding the use of copper and zinc alloys in the system should be high priorities. Gasoline is more vulnerable to both atmospheric- and metal ion-induced aging, but if you follow our storage guidelines, use a good additive, and install a vent filter, you can expect fuel to still be good after two years.

See the Inside Practical Sailor blog post, Fuel Storage Tips for Sailors, (Sept. 21, 2015) for our storage guidelines and links to related articles.

Without taking any safe guards, fuel quality will deteriorate within months. Diesel will also require an effective additive and careful attention to our storage guidelines. If these are followed, you could see up to three years of storage life-although this may be an unreasonable expectation in the real world, especially warmer climates. In both cases, the stability of the base product and the effectiveness of the refinery additive treatment will affect results.

We launched our investigation into fuel additives five years ago, full of skepticism and expecting mostly snake oil. In the end, we’ve found products that can do remarkable things. However, each testing round reinforced a very simple maxim: Pure fuels are quite stable and only turn foul when contaminated-not uncommon in marine fuel systems. Water wont burn. Once it is in your system, it supports corrosion, biological growth (diesel only), and phase separation (E-10 gasoline only).

One of the most common entry points for water is the filler cap. Inspect the filler cap for leaks. A silica-gel vent filters provide further protection against moisture absorption in diesel and gasoline tanks, and prevent the loss of volatiles in gasoline tanks.

Diesel bio-sludge can clog filters, so we recommend regular use of biocides and multi-function additives to reduce corrosion and sludge formation. Copper and zinc greatly accelerate oxidation; try to use only stainless-steel, cadmium-plated steel, and aluminum fittings and valves. If the tank is dirty or contains free water, a pump-out and cleaning is the solution. No miracle additive can fix these problems.

Although our fuel storage tests-showing multi-year protection-are encouraging, they don’t mirror the real world. A better plan is to try to burn through your fuel in less than one year.

The accompanying Value Guide table tells the complete story. Unfortunately, a few products did not earn overall recommendations simply because they were not included in the past corrosion trials. When we revisit the topic of fuel additives in the future, we will work to fill in these blanks.

For gasoline, we like Biobor EB, Mercury Quickstor, and Sea Foam. For diesel additives, we like Star Tron and Biobor JF used together; Star Tron provides complimentary anti-bug activity (different chemistry from BioBor JF), good anti-aging properties, and superior corrosion protection. ValvTect Plus 6 was also impressive. Our on-the-water experience with these products tells the same story; combined with best management practices, our fuel system problems have been vanquished.

Suggestion… Please do an article on the need for diesel fuel additives other than biocides. I own a 34′ power catamaran with twin Yanmar 100 HP Turbo diesels. We recently had our local diesel experts handle some expensive repairs needed to the fuel pump/injection system on one engine. They also discovered that all of my fuel injectors were failing and needed to be repaired. What got my attention after the repairs were done, besides a hefty bill, was that they strongly recommended using one of two diesel fuel additives on a regular basis to increase lubricity. I asked them why…

They said the reason was that in 2000 the U.S. EPA agency changed the rules for manufacturing diesel fuel specifically to reduce the amount of sulfur in diesel fuel by about 97% (see: https://www.epa.gov/archive/epa/aboutepa/reduced-sulfur-content-diesel-fuel.html>). As a consequence, they said diesel fuel is less toxic to the environment BUT has far less lubricity. They said about 2 years ago virtually all of the major marine diesel engine manufacturers (Yanmar, Cummings, Volvo, etc.) started recommending using a fuel additive such as Stanadyne or Diesel Kleen. So they now recommend it to their customers. (Prior to 2 years ago, they never recommended this kind of additive.)

As far as I can tell, not one person in my local boating community is aware of the need for a fuel additive OTHER than a biocide. I think it would be helpful to all boaters with diesel engines to see a PS article on this topic.