Your vessel’s battery selector switch is probably one of the first things that you reach for each time you step aboard your boat. And after you’ve left, it’s the switch that plagues your mind: Did I turn that @$*^ thing off?

A battery selector switch’s primary purpose is to help manage the flow of electrical power onboard your vessel. This is accomplished by providing a selectable circuit path between your vessel’s batteries and the primary branch circuit, such as the main DC distribution panel or engines.

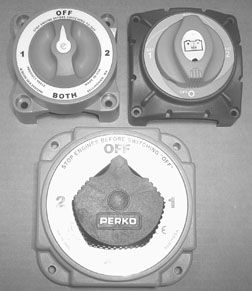

The difference between a battery switch and a battery selector switch is the number of positions on the switch. A battery switch is normally a two-position (On/Off) switch. A battery selector switch is normally a four-position switch (Off, Bat 1, Bat 2, Both).

The selector switch provides the means for isolating the vessel’s battery banks to prevent battery drain when the vessel is not in use. In addition, it acts as a master switch capable of shutting down the entire electrical system during an emergency. The battery selector switch also gives you a method of distributing charging currents from generation sources back to the vessel’s batteries while providing electrical separation of battery banks.

In pre-1940 vessel construction (the age of mahogany planks, oakum and sump pumps), the battery “Disconnect” was a simple knife switch. Everything that could be considered wrong about a switch could be associated with the knife switch. Its unprotected terminals were an easy target in the engine compartment to be shorted out to ground during engine maintenance by the bump of a wrench. This switch was prone to constant corrosion and ignition protection was best supplemented with your Class B/C fire extinguisher.

Then, in the early ’40s, the Cole Hersee Co. out of Boston, MA, made a marked contribution to marine safety with its introduction of the Rotary Battery Switch. No longer were the contacts of the switch exposed, and with the new rotary design it was now easy to parallel a second battery bank for engine starting.

The battery selector switch is not a particularly glamorous device. It’s usually mounted in some dark recess of the cabin or in some surplus space in the engine room. On older vessels, these switches were consistently sited at ankle height and you almost always needed a flashlight to positively identify the switch’s position. But things change. No longer are we finding battery switches limited to the standard colors of bright red, safety orange, or industrial gray. There are switches on the market that now come with white cases that color coordinate with the engine room, ones with red and green faceplates, and even ones with luminous dials. The latest trend is towards mini battery switches that can be cluster-mounted directly into the vessel’s DC electrical distribution panel.

How We Tested

In determining our evaluation procedure for this test, we felt that the engine start/surge portion of the UL test, which involves loading a switch for only 10 seconds of engine start load, isn’t a good indicator of real-life conditions.

We are all aware that it could easily take more than 10 seconds of cranking to start an engine in cold weather or if it has a fuel delivery problem. We’re not the only ones that find the bar on the UL’s test a little low. The Blue Seas Systems Co. has come up with its own in-house test, called the “Engine Starting Standard.” This test consists of subjecting the battery switch to 10 cycles of an inrush current spike of 1/4-second duration, then a cranking duration period of 9.75 seconds, followed by a two-second rest, repeated for a total of 120 seconds. We feel this type of test would be more representative of the load imposed on a battery switch in the starting circuit under difficult starting conditions, so we made it the basis of our evaluations.

We asked each manufacturer that participated in our test to provide two sample switches for each model tested. For a full cycle of our engine starting standard test, one of their representative battery selector switches was connected to a carbon pile (0-800 amp) load tester and subjected to an amperage load equal to the switch’s intermittent rating. At the end of the test’s two-minute period, we then removed the carbon pile load tester and measured the temperature of the switch’s rear terminals with a Blue Point digital infrared thermometer. Terminal temperatures were logged and noted as an indication of the switch’s actual rating.

The second sample switch provided from each manufacturer was fully disassembled to gain interior access to the switch’s contact plates. We evaluated the design of the switch and rated the quality of the components used in the construction.

What We Tested

BEP Marine Inc. offers a smart-looking, Euro-styled line of battery selector and disconnect switches manufactured in New Zealand. All of the company’s battery switches are watertight-rated to two meters and feature self-cleaning contacts. These switches feature a red and green color-coded dial plate that is visually appealing. The heavy weight of the BEP switches speaks to the quality of the materials incorporated into each switch.

All BEP switches come with a removable back plate. A back plate is required by the American Boat and Yacht Council (ABYC) whenflush-mounting a battery switch to protect the switch’s rear terminals from coming into contact with other objects. BEP Marine informed us that no other switch on the market comes with a back plate.

Another nice feature of this line of switches is that all four sides have large removable side plates. This allows for the battery cable to enter not just from the bottom of the switch, but also from the side and top. The potential disadvantage of the removable side plates, in our opinion, is that they simply slide onto the switch body and do not snap into place. We can foresee these plates falling off if you are wrestling the switch into position with the heavy battery cables attached.

The theme of BEP’s product line is modular. All switches are designed to have the ability to be tightly clustered together to form a nice modular-looking distribution point.

Blue Sea Systems of Bellingham, WA, manufactures a line of battery selector and disconnect switches. All Blue Sea battery switches are moisture-sealed with O-rings and feature luminous dial labels for low-light readability. Another nice feature is the tactile texture imprinted on the switch’s knob, which helps indicate the position by feel only.

Starting in April, Blue Seas began adding luminous labels to the rear of its switches. This addition helps make it possible to properly identify each rear terminal position when troubleshooting an electrical problem in a low-light situation.

The tin-plated copper terminal connection studs on these switches are cold-welded to the switch’s copper contact plate by use of a high-force press. This manufacturing process eliminates the need for a retention backing nut, which is what usually holds the stud in place. These press-studs have a nice large collar, which maximizes the conductive surface with the battery cable lug.

Blue Sea Systems manufactures its 9000 series battery selector switch for West Marine. We felt that Blue Sea’s website offered the best technical and reference information.

Charles Marine imports a standard-duty battery selector switch that is designed in the U.S. and built in Asia. This is the only manufacturer to offer its switches in a pure white case with a black knob. Although this feature may seem trivial, plenty of battery switches on smaller craft get mounted in the cockpit in plain sight, so a choice other than a bright red or orange switch is welcome.

The Charles selector switch is ignition-protected and comes packaged with screw cover caps that dress up the final installation. The 3/8″ terminal studs on the back of the Charles switch are made of brass. Copper is 250 percent more conductive than brass, which means that an electrical device made with copper is capable of handling higher amperages at lower temperatures.

The downside of copper is that it will corrode and turn green in a marine environment, introducing poor conductivity. The solution is to tin-plate the copper. Adding a tin plating over copper will preserve the conductivity while fending off corrosion. Brass terminal studs, although acceptable, are indicative of cost cutting.

The Cole Hersee Co. has been manufacturing a full range of electrical switches since 1924. Its product line includes switches specific to the automotive, marine, heavy industrial, and agricultural markets, with battery switch ratings as high as 2,000 continuous amps.

Cole Hersee’s most popular marine battery selector switch—the M-750—is designed in the U.S. and assembled in Mexico. At 5″ round, available in white or black, this industrial strength switch is a favorite among the commercial fishing fleet. This popularity is due in part to the M-750’s case. It’s moisture-sealed with a flexible O-ring, and has a selector knob large enough to be gripped easily while wearing commercial work gloves.

The 3/8″ terminal studs on the back of the M-750 are made of copper. Although we prefer copper studs to the lower-cost brass, we would have liked to see Cole Hersee use corrosion-resistant tin-plated copper studs instead. We noticed that the M-750’s retail blister pack did not have any markings to denote the length of its warranty. Upon further investigation, we learned that Cole Hersee Company offers neither a specific nor implied warranty but does “stand behind the quality and workmanship of our product line. Each situation is evaluated and treated on an individual basis.” Still, we prefer written warranties.

Guest, a division of the Marinco Company, offers almost 20 different marine battery selector switches— the largest selection on the market. All of the battery switch products are made in the U.S. and all are UL-Listed. Guest switches feature an innovative “sweep contact” design, which Guest claims provides up to 60% more contact area than standard designs. Guest says it machines each of its sweep contacts to guarantee an electrically sound path, and that its contacts are self-cleaned each time the switch is rotated.

The terminal studs on all of the switches are made of brass, which is a bit of a disappointment. Also, we found some misinformation on Guest’s website. When we searched the site to verify the momentary rating of the Guest 2300A battery selector switch, the site offered a picture of the 2303 On/Off disconnect switch and listed the rating as 800 amps. When we looked up the ratings for the 2303A On/Off disconnect switch, we found the correct picture but the wrong rating (600 momentary amps).

Perko has the distinction of being the oldest manufacturer in our test group. Founded in the late 1880s by Frederick Perkins, Perko is located in Miami, FL. All of Perko’s switches are ignition-protected, UL-listed, and feature Perko’s trademark triangular selector knob. Perko’s 8500 series switches are the only ones on the market that use a short-throw selection pattern (90° partial dial vs. 360° full dial). We have never been big fans of this pattern as we find it hard to avoid turning past the selection we want. The in-line selection is just too closely spaced together and the triangular knob is not tall enough to grip comfortably, in our opinion. As a result, we end up squeezing the knob and turning it with pure finger power instead wrist action.

On the other end of Perko’s product line is the 8600 series heavy-duty battery selector switch. This is physically the largest switch in our test group and uses the conventional 360-degree full-dial-turn pattern. The large, thick, triangular knob on this switch has excellent ergonomics, and its texture is the best in its class. Perko’s 8603 switch is rated at 380 continuous amps, which is the highest continuous rating of our field.

West Marine is marketing the Blue Sea Systems’ switch under its own label. The only difference between the Blue Sea label and the West Marine switch is case color. The West Marine switch is housed in a black case while the Blue Seas switch ships in a red case. All other features are identical. The standard warranty is one year; however, West backs up all its products with a no-questions-asked return policy.

What We Found

As all of the switches that we tested were either UL1107-approved or rated, it was no surprise that all of the entries met their minimum rated capacities. In looking at the terminal stud temperatures, it is pretty evident that the switches with the copper studs ran the coolest. Thus it would be fair to say, based on terminal stud temperatures and our visual inspection of the interior of each switch, that the BEP and the Blue Sea Systems switches are overbuilt, and dissipate a far greater amount of heat than other standard-duty switches of similar rate capacity. In the heavy-duty category, the Perko 8603 switch is almost indestructible.

The interiors of BEP’s 721 switch and the Blue Seas Systems switch look similar, but there are noteworthy differences. The plate copper contacts inside the BEP switch are 1/3 thicker than the ones found in the Blue Seas switch. Also, BEP connects the selector knob to the contact plate with a 1/4″ solid brass shaft, while Blue Seas uses plastic.

The copper plates found inside Cole Hersee’s M750 are surprisingly thin; thus, the lower continuous amperage rating for such a physically large switch. Minimal components were found on the Charles switch, as well as Guest’s 2111A and 2101.

We thought we’d find a much closer comparison in the heavy-duty category between Perko’s 8603 and Guest’s 2300A. Guest advertises that its switch’s sweep design provides 60% more contact. However, after poking around inside both of these switches, we can say that Guest doesn’t provide 60% more contact area than Perko’s 8603. The selector plate on the 8603 slides through dual contact plates (one above and one below, much like an old knife switch) at each position stop. So there is twice as much copper plating inside Perko’s 8603 switch as compared to Guest’s 2300A. The sliding of Perko’s selector plate through the contact accounts for the smooth feel as the selector knob is rotated. Conversely, the selector knob on the Guest 2300A takes a good amount of force to turn, to the point that the switch often feels stuck.

Conclusions

The Blue Seas switch is our choice for best value in a standard-duty battery selector switch. It’s made in the U.S. with high-grade materials, comes with a lifetime warranty, and is the least expensive switch in our test.

When we factored in the Blue Sea’s luminous dial, high amperage rating, and the consensus that the switch is overbuilt, allowing cooler terminal stud temperatures, we had no qualms about putting this switch at the top of our list.

BEP Marine’s model 721 switch is the best-built standard-duty battery selector switch on the market, in our opinion. But, because it’s imported, it is often not as readily available at local retail stores as other switches. Officials at BEP Marine’s U.S. corporate headquarters in Georgia told us that the company is in the process of adding on-line shopping to its website and said that there is plenty of product in stock at its U.S. facility.

Perko’s 8603 easily takes top honors in the heavy-duty battery selector switch category. One look at the comparison photo (see pg. 25) and one turn of its selector knob tells it all. This is the switch to use where failure is not an option.

Also With This Article

“Value Guide: Battery Switches”

“Ratings & Standards”

“Choosing a Battery Selector Switch”

Contacts

• BEP Marine Inc., 877/730-3700, www.bepmarineinc.com

• Blue Sea Systems, 800/222-7617, www.bluesea.com

• Charles Marine Products, 847/806-6300, www.charlesindustries.com

• Cole Hersee Co., 617/268-2100, www.colehersee.com

• Marinco Recreational Group (Guest), 707/226-9600, www.marinco.com

• Perko Inc., 305/621-7525, www.perko.com

• West Marine, 800/262-8464, www.westmarine.com