How do we reduce and even eliminate our sailboat’s carbon dioxide emissions when using auxiliary propulsion and electrical HVAC systems?

Just like with automobiles, how will the range anxiety issue be lessened or resolved and how will the present high-cost issue be lessened or resolved?

Some would argue the future is now in terms of options to lessen or eliminate diesel fuel consumption in sailboats and therefore carbon dioxide emissions.

Yes, the availability of diesel-electric hybrid and full electric systems has definitely progressed to the point, if you want a system for your sailboat auxiliary power, it is available for most sailboats and sailing yachts.

However, such systems costs are for most sailors, too high compared to conventional diesel engines systems and range that can be travelled under auxiliary power (electric power only) is too limited compared to a liter of diesel fuel.

The reasons are; low energy density in battery storage systems and relatively low recharge capacities available from onboard systems (solar, wind and hydro).

The amount of energy stored in diesel fuel versus the best battery technology currently available for sailboat (lithium iron phosphate) can be better understood when thinking in real world practical terms.

Suppose you have a 45-ft. cruising sailboat with a 50-hp. diesel running at 2,200 rpm (6 knot cruising speed) and are consuming about 4 liters (just over 1 gallon per hour). The mechanical power being delivered to the propeller is about 15 kW (20 hp). About 38 percent of the energy available in the diesel fuel being consumed is being transmitted to the propeller shaft as mechanical energy to rotate the propeller and move the sailboat in this example forward at 6 knots speed. In one hour, the energy consumed is 15 kilowatt hours (KWh).

Now image this same 45-ft. cruising sailboat with no diesel engine and only an electric propulsion system. Electric motors are very efficient and for simplicity, in this example we will assume 100 percent efficient. This means the electric motor will need 15 KWh of electrical energy to power the sailboat forward for one hour at 6 knots. For this one hour of cruising at a power consumption of 15 KWh, you will need three 5 KWh lithium iron phosphate batteries. Each battery will weigh about 80 pounds and will require about 1.6 cubic feet of space to install (240 lb. and 4.8 cubic feet total). Each battery will cost U.S. $5,000.

Now let us look at how we are going to recharge this 15 KWh of energy our example sailboat consumed during one hour of cruising at 6 knots. The average sailboat solar panel installation will produce about 1.2 KWh per square meter of solar panel each sunny day. So, we will need 12.5 square meters (134 sq ft) of solar panels to recharge the batteries based on only one hour cruising at 6 knots. That is 22 solar panels like I have on my small sailing catamaran (each panel is 42-in. by 21-in. and rated for 100 watts power output).

Does an electric only propulsion system that requires U.S. $15,000 of lithium iron phosphate batteries and 22, 100-watt solar panels (U.S. $3,500) explain the battery low energy density and solar panel recharge low capacity issue?

In reality, to be useable, this theoretical all electric propulsion system would require as a minimum two times the battery capacity (U.S. $30,000) and would need shore power recharging after even two hours of cruising at 6 knots, even if we could find room for 22 solar panels.

From a cost perspective, we have yet to account for a 40-hp. electric motor and overall systems installation costs.

The 40-hp. electric motor would be another U.S. $30,000, not including installation costs.

At this point we are double a new 50-hp. diesel engine cost and we only have two hours of cruising time (12 knots distance) before needing shore power to recharge.

DIESEL-ELECTRIC HYBRID AUXILIARY POWER

We should now be at the point where practical reasoning prevails over or desire to be 100 percent carbon dioxide emission free and a diesel engine has to be brought back into the options. Diesel-electric hybrid auxiliary power systems have a place in our sailboats the same way gasoline-electric hybrids have a place in the automobile parked in your driveway.

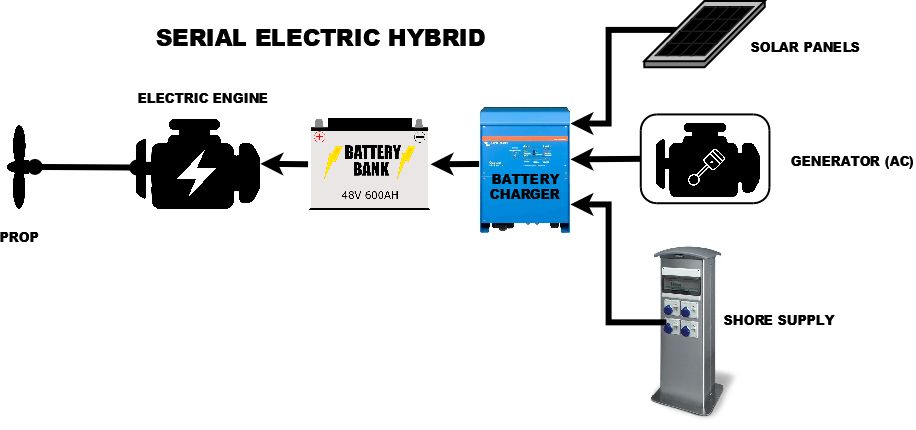

There are essentially two types of hybrid configurations. The serial system, where the diesel engine only powers a generator, not the sailboat propeller shaft. Only the electric motors are connected to the propeller(s). The below system is a serial system and is based on the Oceanvolt saildrive electric motor system combined with a single diesel DC power generator.

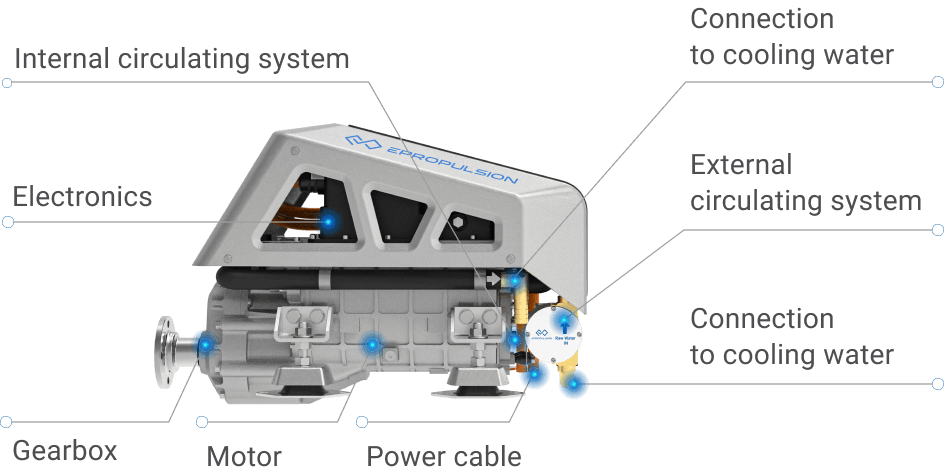

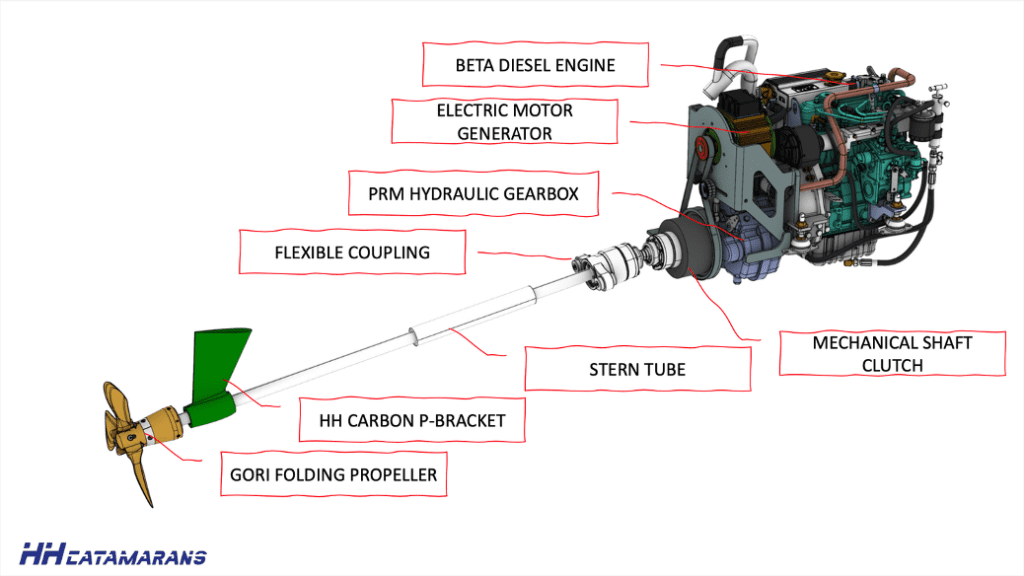

More flexible and capable, in my opinion is the parallel system, where the diesel engine(s) are connected to the propeller shaft(s) via a gear transmission and the electric motor/generators are connected to the same propeller shaft(s) via a cogged belt drive system.

The electric motors can function as generators to charge the batteries when the diesel engines are running and turning the propeller shaft. When there is sufficient wind for sailing with no diesel engine running, the motors can be engaged by the spinning propeller shaft and utilized as generators (running in regen mode) to charge the batteries while sailing under wind power.

For periods of no wind or during times when it is preferred not to be running a diesel engine, such as docking, the motors can be engaged as propulsion units without diesel operation.

HH44 catamarans have such a diesel-electric parallel hybrid system. This is a very innovative design with the added benefit of straight shaft propeller drive system.

Aside from the above explained battery power density and charging constraints faced by full electric propulsion versus diesel engine systems and the cost challenges of complex diesel-electric hybrid systems, below is a table showing pros and cons of each system.

CONCLUSION

To answer the questions at the beginning of this article, there will only be a matter of time for continuing innovation to solve the power density issue for batteries and charging capacity of solar panels. Battery technology continues to evolve and likely solid-state batteries will one day achieve higher energy density than the current lithium iron phosphate batteries. Bifacial and other solar panel technology advances will boost solar panel efficiencies.

We can wait for more innovation and lower costs or become early adopters of the current technology, which will help the pace of innovation and economies of scale in production cost reductions. If you are lucky to have the means, it is a great way to help improve the environmental challenges being faced today.

Are you buying a used sailboat or new sailboat and the particular model you are interested in, has both inboard and outboard engine options available? The intent of this article is to explore the pros and cons of inboard versus outboard internal combustion (IC) engines. Fuel types for inboard auxiliary IC engines will be primarily diesel, although some older sailboats may have gasoline inboard auxiliary engines. Universal Atomic 4 being the most common gasoline inboard auxiliary engine found in some older sailboats up to 1984. The best place to start exploring the pros and cons of replacement auxiliary engine options is what is your starting point. For sailboats with existing IC outboard engines as the starting point, generally due to cost and likely space restrictions, the best replacement will be another IC outboard(s). Where your options for replacing sailboat auxiliary engines become more interesting is in the case of monohulls and multihulls with originally fitted with IC inboard auxiliary diesel engines. Generally, for monohulls (and trimarans), once the length is greater than 30 ft., inboard diesel engines will, for the most part, be the starting point. In the case of catamarans, the assumption is that above 38 ft., for the most part the starting point will also be inboard diesel engines. Although inboard diesel auxiliary engines are available in much smaller monohulls and catamarans, this is not the only option available by sailboat manufacturers. Both inboard diesel and outboard gasoline auxiliary engines have been installed as original equipment in many sailboats under these particular size ranges. The starting point is important as, for the most part, staying with an inboard or an outboard that is already installed will generally be the most economical from an initial cost perspective, but not always the lowest cost of ownership and best user experience as a sailor. Your personal preferences and how you intend to use your sailboat are also important considerations. Safety concern over gasoline versus diesel. Most sailboats will have some gasoline on onboard due to dingy engine fuel, which is predominantly gasoline. So disqualifying gasoline outboards as sailboat auxiliary engines due to concern over gasoline only has validity for cases where dinghy motors are electric and there is truly no gasoline onboard. Gasoline outboard auxiliary engines and associated fuel storage can be designed, installed, handled and stored in a safe manner. Keeping gasoline fumes and fuel out of bilges, or any other unventilated spaces, and away from electrical spark and other ignition sources is critical. The outboard engine, by design, in most cases accommodates an installation where ventilation is plentiful and fuel lines/tanks can be kept away from unventilated spaces. To determine what is best for your sailboat when planning to rebuild or replace your auxiliary engine(s), the inboard versus outboard question needs to be evaluated in terms of pros and cons versus your goals, budget, skills (if a do it yourself project), future plans for your boat. Are you selling it, are you planning coastal cruising, blue water sailing, live aboard, etc. One consideration with outboards, especially for monohulls is careful placement and shaft height to ensure the propeller stays in the water as the hull is lifted by waves passing amidship. Some older monohulls, originally designed for outboards, will have an engine well just astern of the cockpit as opposed to a transom mounted outboard engine set-up. For blue water sailors, inboard diesels are going to be the best option for reliability, range per volume of fuel tankage onboard and seaworthiness. For coastal cruisers and island hopping, outboard gasoline engines can be a good option. The other consideration for inboard auxiliary diesel engines is straight shaft drives versus sail drives. This article will not dive into this question, other than to say, my personal preference is straight shafts over sail drives due to the improved reliability and lower maintenance associated with straight shafts versus sail drives. Sail drives are popular with monohull and catamaran manufacturers who need to place engines as far aft as possible, and therefore optimize boat interior living space for given hull designs. For this reason, sail drives are found on many used and new sailboats, irrespective of the additional maintenance requirements that results. You have to admire the simplicity of a straight shaft drive system. Cutlass bearing and shaft packing are really the only maintenance items. As with the straight shaft drive for inboard diesel engines, one has to appreciate the simplicity of a gasoline outboard auxiliary engine system for sailboats. The below two 9.9-hp. high-thrust Yamaha outboards have about 1,500 hours operation since 2017 and have propelled this catamaran from Florida to Nova Scotia, Canada and back to Florida again in 2023. Electric start and power tilt are a must for this type of application.

Are you looking to replace the auxiliary engine in your sailboat?

The initiative to reduce emissions is appreciated but more often advertised for the sales bias.

Let’s start with a sailboat set of sails-and the hours under sail vs motoring. Then clearly explain the expectations- racing, cruising, day sailing locally.

Only then may the green effort be real numbers and described as efforts to reduce greenhouse or health emissions.

Sails are sourced from dinosaurs as well as diesel and gas. – so what is the comparison? Only then can the feel good politics be truly comparable.

Let’s think deeply about this….how much CO2 is released when these batteries are manufactured? What is their reasonable life span? Where does shore power come from? What emissions does that create?

Perhaps the quick and easy, and certainly the cheapest way to ‘green up’ a sailboat is to sail more and motor less!