Water, water, every where, and all the boards did shrink; Water, water, every where, nor any drop to drink. Who can read those lines from the seafaring classic, The Rime of the Ancient Mariner without thinking Man – those guys couldve used a watermaker!?

Reverse-osmosis, DC-powered watermakers have been available for use aboard mid-sized cruising boats for years, but as noted during our last look at watermakers (PS, November 2005), they just keep getting better. Todays units are more efficient, reasonably compact, and in many cases, modular in design.

What We Tested

Our 2005 article on watermakers was simply a market scan of available units. This go-around, we decided to take a more in-depth look at two popular brands that offer DC-powered units and to put a couple of them to the test.

There are basically three choices for powering the watermaker on a sailboat: AC electric power, DC electric power, and direct drive from the main engine. If you have a separate generator, AC power is a rational solution, but that usually means a boat over 40 feet to justify the space, weight, and cost of a generator.

Driving the high-pressure pump from the boats main engine can maximize output, but it may require a fairly complex installation involving custom brackets, custom pulleys, and modifications to the engine box. Also, the engine may have to be run within a narrow RPM band to properly drive the watermakers high-pressure pump. Then theres the risk of a soaked engine room, if something goes wrong.

Although the third option, using DC power, can put significant demands on a 12-volt system-often requiring an alternator upgrade and added battery storage capacity-it is the most appropriate choice for a typical mid-size cruiser, in our view. Fortunately, there are a wide variety of DC watermakers on the market to select from.

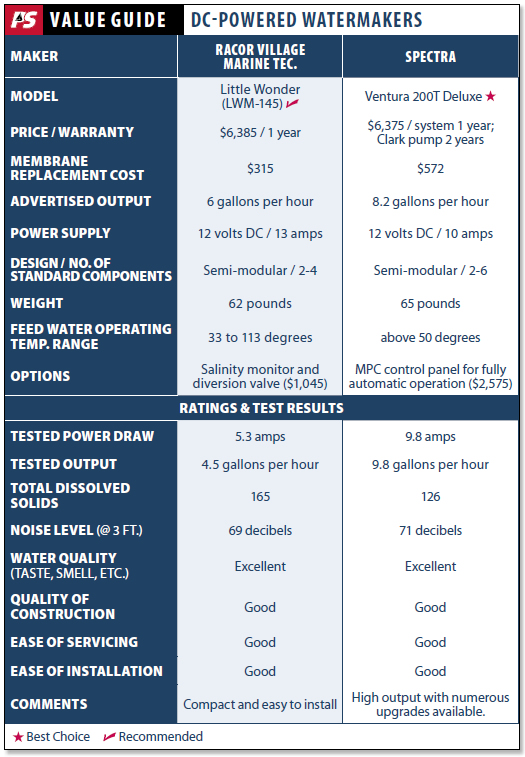

From Spectra, a global leader in reverse-osmosis desalination systems, we tested the new Ventura 200T (Tropical). We also tested the Little Wonder (LWM-145) from Racor Village Marine Tec., developers of innovative water desalination and purification plants for more than 30 years.

Watermakers are designed in one of two configurations: frame-mounted and modular. The frame-mounted system secures all components to a pre-plumbed, pre-wired, drop-in chassis, making for a straightforward, neat installation. Modular designs separate the bulky components, allowing for more installation options aboard space-challenged vessels and making it easier to service the system. However, installing a modular system may require that a fair amount of time be spent fabricating mounting arrangements for the various components, as well as having to deal with more wiring and plumbing.

Both the Ventura 200T and the Little Wonder are considered to be semi-modular.

How We Tested

In addition to more obvious factors such as output capacity and cost, both watermakers were tested and rated for water and construction quality, noise, power consumption, heat generated, and ease of installation and maintenance. Warranty and price were also considered.

Each unit was installed in a bench-test setup and operated per the manufacturers instructions. Although not actually required for our test, to ensure an accurate representation of unit performance (output, power draw, etc.), all intake filters and auxiliary components were also installed.

To maintain a constant, equal power supply, testers connected the test units to a regulated power supply set to provide 13.8-volts DC. Power leads were kept as short as possible and were sized according to manufacturer recommendations; each unit also was properly fused.

Testers used a Fluke multimeter to monitor supply voltage, while amp appetites were noted with a clamp-on ammeter. Pump noise was read on a sound-level meter placed 3 feet away from each unit. Although the noise levels listed in the accompanying Value Guide are not radically disparate, it should be noted that the racket the pumps made on our open, wood test platform is greater than the noise they would make when tucked away in an enclosed compartment on a boat. However, the primary object here was to compare the sound levels in like circumstances.

When measuring power usage, testers ignored high start-up amperages and took amp readings once the units had settled down to work. Even so, there were often noticeable variations in amp usage as part of the pumps normal cycling.

To ensure water-source control and uniformity, the raw water supplied to each unit was simulated sea water made using Instant Ocean, a product used by leading aquariums throughout North America. Our simulated seawater solution was mixed to provide a supply-water salinity of 32,000 parts per million (ppm), the accepted average representation of seawater. The supply-water temperature was kept between 65 and 70 degrees.

With most watermakers, output can be affected by changes in feed-water temperature, pressure, and salinity. You can maintain a constant output despite variations in feed-water temperature and salinity by manipulating system pressure. For example, as output flow decreases, you can increase system pressure, which would in turn increase output, mitigating the effects of a decrease in temperature or increase in salinity. Conversely, an operator would want to reduce pressure (and permeate flow) in areas of excessively high supply water temperature or low salinity. In any case, all such changes in pressure must stay within the watermakers recommended operating parameters to avoid damaging the unit or membrane.

Each unit was connected to a 30-gallon feed tank of simulated sea water. Before testing, both units were allowed a 30-minute break-in period, and then, each unit was put through three 15-minute test runs. Water output and quality was measured after each test run. Total hourly output was determined by averaging the output of the three test runs.

Water samples produced by each unit were tested using an HM Digital COM-100 Water Quality Tester to determine total dissolved solids. Seawater contains numerous dissolved solids in solution. Sodium chloride (common table salt) is the most prevalent; however, there is plenty of other stuff as well, much of which contains calcium and sulfate compounds. The sum of all of the solids dissolved in a particular sample of water is referred to as Total Dissolved Solids, or TDS.

The goal of a watermaker is to remove as much of these dissolved solids as possible (TDS compounds can’t be removed by traditional filters); however, no unit is capable of removing 100 percent of them. The target then is to produce water with less than 500 parts per million (ppm) TDS, which falls within the World Health Organization standard for drinking water.

Its not surprising that high levels of TDS in drinking water (greater than 1,200 mg/liter) may be objectionable to some; however, its also interesting to note that water with extremely low TDS concentrations may also be unacceptable due to its ?at, insipid taste.

The more subjective taste, smell, and clarity characteristics were also noted.

Spectra Ventura 200T Deluxe

Known globally for their energy efficiency, Spectra watermakers are semi-modular in design and engineered for use aboard smaller vessels. The new Ventura 200T (the T means the unit is designed for tropical-water applications only) is advertised as being energy efficient, lightweight, compact, and easy to install. Depending on supply-water temperature, advertised output is up to 8 gallons of fresh water per hour.

The 200T features an exclusive Spectra-Clark Pump High-Pressure Intensifier, which the maker claims is able to maintain proper membrane pressure throughout a wide range of temperatures and water conditions, without adjustments or loss of freshwater output.

Constructed of corrosion-resistant composite materials (a combination of Acetal, Teflon, and nylon plastics and fiberglass composites), the Clark pump requires no routine maintenance and can be mounted in any position.

Service life is entirely dependent on how well the system is maintained, explained Spectra technical supports Michael Anderson. We have Clark pumps that were built in the 90s that are still working to specification and have never been rebuilt. Obviously, these systems have meticulous owners and may not be seeing a lot of use, however the typical service life on a Ventura system is about 2,000 to 3,000 hours before a rebuild of the Clark pump is required.

Anderson added that while its rare for a pump to suddenly fail in the field, if it does, it can typically be repaired if the owner has a seal and O-ring kit ($94) on board. He recommends owners keep a log of the units performance, which will help identify when it is time for the pump to be rebuilt. Spectra offers an exchange/upgrade service for the Clark pump, with a typical rebuild costing $425.

Anderson noted that if a problem occurs, its important for owners to follow Spectras diagnostic protocols to correctly identify the problem and replace the correct part (saving both time and money).

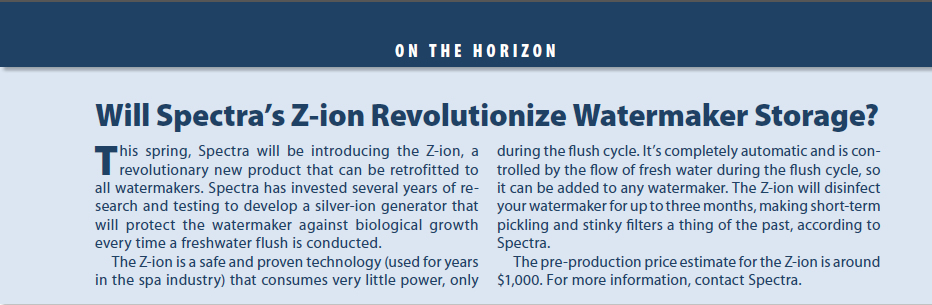

Ventura 200T units are available in both deluxe and Micro Processor Control (MPC) models. The deluxe unit features analog controls (pressure gauge, flow meter, on/off switch, and flush valve), while the MPC units are completely automatic. The MPC unit can be setup so that a single button push will fill the tank, do a freshwater flush at the end of each production cycle, and perform a freshwater flush every five days until the system is used again. This not only eliminates the need for storage chemicals (pickling), it keeps the unit ready to go as well. The electrical control box has a built-in manual override so the watermaker also works without the MPC-5000 electronic control.

Were not big fans of having unsupervised, energized pumping equipment onboard (particularly when the system is connected to a below-the-waterline through-hull), but the automatic self-cleaning feature is handy and will be attractive to many.

Other options include the Z-Brane system, which is designed to permanently eliminate chemical cleaning and preservation steps while prolonging membrane life. (Each time a membrane is chemically pickled, it reduces its service life.) The Z-Brane module creates an environment that is unfriendly to bio-film and bacteria, allowing the system to be shut down or decommissioned for extended periods of time without chemicals or preservatives.

The Manual Deluxe Version that we tested comprised a Clark pump membrane module; a feed pump module with a cooling fan, integral filter, and service valve. It also included an instrument panel with a feedwater pressure gauge, product flow meter, handheld salinity monitor, and an additional three-way valve for diverting to a water-quality test port.

Testers were impressed with the completeness of the Spectra package from an installation standpoint. The Ventura Deluxe comes with most everything youll need for the installation, from 25 feet of 5/8-inch hose to fittings, hose clamps, and even Teflon tape. Items that will need to be purchased include through-hull fittings (intake and discharge), a seacock for the intake, wiring, and mounting hardware.

With more components than the Village Marine Little Wonder, the Ventura 200T is still compact and well-constructed. The added parts made installation a bit more arduous than installing the Little Wonder, but overall, it was fairly easy to set up.

The Clark pump membrane module is pre-mounted and plumbed together, which the manufacturer states reduces installation time and adds reliability. The Ventura feed-pump module is bulkier than the individual components of the Little Wonder we tested, but it has a more finished, robust look to it.

The Ventura 200T drew considerably more power than the Little Wonder in our tests, but its tested output of 9.8-gallons per hour (gph) was also more than double the Little Wonders output.

The TDS readings for the 200T were lower than the Little Wonder unit, but the difference was imperceptible during taste tests, for which both received Excellent ratings.

Bottom line: With an output of more than 8 gallons per hour, the Ventura 200T delivers big on value, performance, and available convenience. It gets PSs Best Choice pick in this head-to-head comparison.

Village Marine Little Wonder

Since our last article, Parker-Racor acquired Village Marine Tec. (VMT) and its Little Wonder watermaker. The Little Wonder brand is the companys original high-output DC watermaker line, and it has remained a popular choice with cruisers for nearly two decades. The 12-volt Little Wonder systems come in both 6-gph and 8-gph models.

All Little Wonder watermakers come with pre-filters, manual freshwater flush, and a low-pressure boost pump. (The latter adds about one amp to the total current consumption.)

Standard features include a hi-rejection Aqua Pro membrane, magnetic drive raw-water boost pump (for extra feed pressure), adjustable 316 stainless-steel pressure-regulating valve, product-water (freshwater) flow meter, and a glycerin-filled gauge for reading the high-pressure pump level. Manual freshwater flush and product sampling and cleaning valves are also part of the system. Other supplied items are cleaning and preservative chemicals plus a spare pre-filter cartridge.

The heart of the Little Wonder (LWM-145) is a single-piston, belt-driven, low-RPM titanium high-pressure pump, which is advertised as being reliable, impervious to corrosion, field serviceable, quiet, and designed for maximum efficiency, producing more water with less battery power.

We have units that have been on the market for 18-plus years and are still in operation, reported VMT Technical Services Manager Greg Newman. The Aqua Pro Titan series pump has an expected 40-plus year lifecycle.

Although both units are modular in design, the Little Wonder is split up into more individual system components (pre-filters, flush valve, etc) than the Ventura, so it offers more mounting versatility.

While the standard lift pump is rated to lift up to 6 feet, the maker recommends that the system, up to and including the high-pressure pump, be installed below the waterline. If thats not possible, users can purchase an optional high-lift, low-pressure pump ($290) that allows the high-pressure pump to be mounted up to 12 feet above waterline.

There are no height installation limits (within reason) for the pressure vessel tube or instrument panel. As the high-pressure pump is the driving force behind the feed to the pressure vessel, it has the potential to push for long distances.

Ive personally installed a unit with a 20-foot horizontal, 10-foot vertical lift with no issues, Newman added.

Routine maintenance of the high-pressure pump includes monitoring oil level and routine oil changes. As the high-pressure pump has a vented crank case, the unit must be mounted fairly level, with a permanent list of less than 15 degrees and a fore and aft trim of 30 degrees or less.

Should a major failure occur, the manufacturer said, the pump is easy to service and typically can be repaired by the user. The unit manual provides a breakdown of general maintenance and expected frequency. Routine service kits for the high-pressure pump are available for $107, while crankcase and manifold rebuild kits run $104 and $175, respectively. No special tools are required.

The Little Wonder has a wider feed-water temperature operating range (33 to 113 degrees) than the Ventura (greater than 50 degrees), and it drew considerably less power. That being said, the output for the Little Wonder during our test was 4.4 gallons per hour, less than half that of the Ventura-which makes them more or less equal in terms of power-use when looking at gallons per amps.

Bottom line: If space is at a premium, and you need maximum installation flexibility, the Little Wonder has a lot to offer. Its simplicity, compact design, lower power draw, and installation options were its strongest attributes in our tests. We recommend it for those who use less water and those with very limited available mounting space.

Conclusion

The percentage of sailboat owners who really need a watermaker is fairly low-particularly for those cruising in North America, where free potable water is normally included in slip fees or when taking on fuel. Even in places such as the Bahamas (where water is expensive), youd be able to buy a lot of water before you would actually recoup the purchase and operating cost of any watermaker. As noted in our 2005 article, even if you have very small water tanks, it will probably prove cheaper to install additional tankage than to buy a watermaker.

In This Old Boat, author Don Casey points out that if you spend $4,000 on a watermaker system-plus $1,000 for fuel and engine wear, solar panels, or a windgen to power it-your water cost for the first year will be $14 per day, everyday, whether you use the watermaker or not. The per diem cost will decrease as the purchase cost is amortized over several years.

That being said, the convenience factor can weigh heavily when deciding to purchase a watermaker-particularly for those forced to dinghy jerry cans of water to an anchored boat. To help decide whether purchasing a watermaker is in your best interest, check out Practical Sailors buyers guide with this article online and in the November 2005 article.

The Little Wonder and the Ventura performed similarly in our tests, and the difference in price is negligible-as was water quality, warranty periods, quality of construction, ease of installation, etc. One big difference, however, was their freshwater outputs, where the Spectra Ventura had the definite advantage.

If onboard space is the deciding factor in whether to buy a watermaker, wed definitely recommend the Little Wonder. If not, the Ventura 200T, by virtue of its production output and available upgrades, is the PS Best Choice.