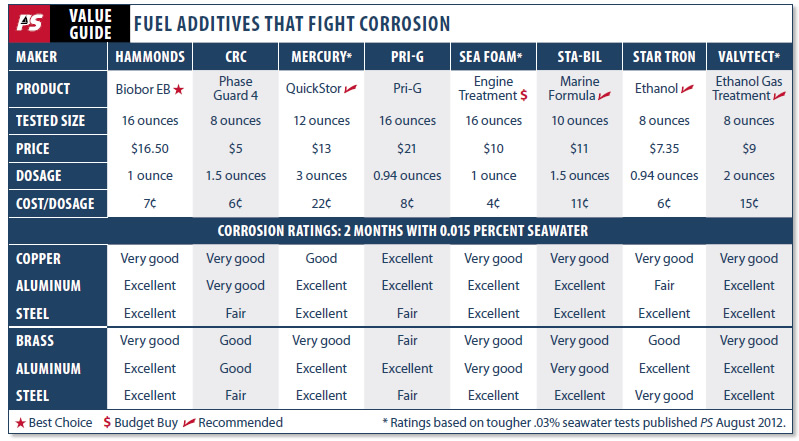

In the August 2012 issue, Practical Sailor reported on the effectiveness of eight common fuel additives in reducing salt-induced galvanic corrosion in E-10 fuel systems. Some makers suggested our test was too tough and too short, so we have repeated the test, for five products, reducing the amount of seawater from 0.03 percent to 0.015 percent (equivalent to four drops of water in a 1-quart tank) and increasing the exposure time to two months. Included in this round are three products that under-performed in the first test, along with the two top performers, Biobor EB and Sta-Bil Marine Formula. We also tested Pennzoil two-stroke oil to see if it helped fight corrosion.

How We Tested

We added each additive as directed to samples of E-10 fuel contaminated with .015-percent seawater. We also included two control batches with no additives-one sealed, one vented to the air. We then introduced a bundle of metal coupons into each sample. The coupons were grouped for simultaneous testing: brass/aluminum/steel; and copper/aluminum/steel. Two months later, we checked on the samples and compared corrosion. For a detailed discussion of the test procedures, see the August 2012 article at www.practical-sailor.com.

What We Tested

The tested products included Hammonds Biobor Ethanol Buster, CRC Phase Guard 4, PRI-G, Sta-Bil Ethanol, Star Tron Ethanol, and Pennzoil Two-Stroke Oil. All made similar claims: The additive prevents phase separation in ethanol fuel, gum formation, keeps carburetors and injectors clean, inhibits corrosion of metals, and promotes easier starting. The makers said the additives should be used on a regular basis, particularly before long-term storage. This test only tested the anti-corrosion claims, and we only tested products marketed as storage additives. In November 2008, we tested the ability to prevent phase separation in ethanol fuel, and results are also available at www.practical-sailor.com.

Observations

The sealed control sample appeared not to age at all and there was no corrosion or staining of the metal coupons. Clearly, anything you can do to minimize water gain and breathing will help.

The vented control with seawater addition showed fast corrosion, particularly on the aluminum and steel coupons. Brass and copper showed heavy staining but no pitting. The extent of discoloration and pitting resembled that of the worst carburetors and fuel components we have seen after 15-plus years of marine service.

Inhibitors varied in their effectiveness. All did better in this test than they did with the higher salt levels of the previous test, but some were still disappointing. In those samples with significant corrosion, the gasoline was clearly discolored, contained particles, and was clearly unusable.

Biobor EB

From Hammonds-the makers of Biobor JF, the most widely used biocide for diesel and jet fuel, and a top recommended product in our test of diesel fuel additives-Biobor EB (ethanol buster) was a top performer in the first round. It again provided Excellent protection. Biobor EB is a top-performing additive that had no metal damage and only the slightest staining. Its available in 16- and 32-ounce bottles.

Bottom line: Reasonably priced and the top performer. It is our Best Choice.

CRC Phase Guard 4

Phase Guard 4 failed badly in the first round, but it did much better this time around with the lower seawater level. However, it still allowed significant corrosion of aluminum and steel. We believe it would do fine in fresh water. It is available in 8-, 16-, and 32-ounce bottles. Adam Seilisker, vice president of technology for CRC, was among those who took issue with our initial test.

We are confident that CRCs Phase Guard 4 product meets all of the performance criteria for its intended purpose, he said. (There is a link to the full text of CRCs comments in the August 2012 report.)

Bottom line: Not recommended.

PRI-G

PRI-G also performed better at the reduced seawater level, but it still allowed unacceptable corrosion; we believe it would do fine in fresh water. It is available in 16-ounce, 32-ounce, and 1-gallon bottles. Ralph E. Lewis, a vice president with PRI-G, pointed to the products extensive standards-based testing and record with commercial clients, including more than 1,500 oceangoing vessels-both distillate and heavy fuels as evidence that PRI-G works.

Bottom line: Not recommended.

Sta-Bil Ethanol

Sta-Bil Ethanol performed very well at lower seawater levels, allowing none of the corrosion we saw on aluminum in the higher-concentration seawater test. It is available in 8-, 16-, and 32-ounce dispenser bottles.

Bottom line: Recommended.

Star brite Star tron

Star Tron is made by Star brite, a company that markets a range of boat maintenance products. Star Trons ability to delay or prevent phase-separation in ethanol fuels, and its ability to burn cleanly without leaving behind any ash residue, earned it a Recommended rating in previous PS testing. Star brite doesn’t make any specific anti-corrosion claims for Star Tron, but it performed acceptably in the first round of testing and even better at lower seawater levels, allowing no pitting. It is available in 8-, 16-, and 32-ounce dispenser bottles.

Bottom line: Recommended.

PENNZOIL Two-Stroke Oil

Conclusion

Keeping saltwater out of gasoline or fuel is critical. Even tiny amounts cause trouble that additives may not be able to protect you from.

Check out our maintenance tips with the online version of this article. Some additives really help, stopping corrosion dead in its tracks. Others fight corrosion as long as the amount of salt is limited. For year-round corrosion protection, we see a strong case for using Biobor Ethanol Buster, Mercury Quickstor, Sea Foam, or Valvtect Ethanol Gas Treatment, or Sta-bil Marine Formula.