An inspection of storm-damaged boats reminded Practical Sailor editors that sailboats are designed, engineered, and built to handle sailing loads, and the point-loading that occurs during collisions or fetching up make all promises of ruggedness and survivability a tenuous crapshoot at best. Fiberglass hulls have many redeeming qualities, and it’s these positive traits as well as their limitations that boat owners need to understand. One thing’s for sure: It’s easier to become a proficient navigator, install a secure storm mooring, or transit to safe shelter before a storm, than it is to build or buy a catastrophe-proof vessel.

****

Contrary to the testing-oriented automotive industry, sailboat builders seldom willingly destroy boats to validate construction quality. High per-unit cost and limited R&D budgets cause destructive evaluations of new sailboats to be relegated to laminate samples, test coupons, and small subsections of new models, rather than experimenting with the sacrifice of a complete vessel. Just the thought of taking a brand-new, marketable sailboat and subjecting it to an intentional grounding, dismasting, or capsize is enough to give most yacht brokers chest pains.

Instead, baseline scan’tlings, laminate schedules, and building practices, such as those promulgated by the American Bureau of Ships (ABS), help to guide pre-construction engineering. Some companies voluntarily comply with the International Standards Organization (ISO) system of certification, while others use finite element analysis to digitally analyze the structural features of a new vessel. Past production results and owner feedback also help a builder define just how “strong” a new boat should be. The goal is to create a vessel for a specific type of use that is capable of withstanding the associated natural forces, and some degree of operator error. The wear and tear associated with time is also factored into the equation, as are the designers and builders usually unstated views of the lifespan of the boat.

Because real-world destructive testing goes beyond the scope of most builders R&D efforts, the results of storm damage and operator error have become the next best alternative to controlled destructive testing. Insurance companies, standards bodies, and others involved in the big question of just how strong a recreational vessel should be made, look carefully at broken boats. Such after-the-fact analysis provides valid engineering feedback. A close inspection of critical failures and the factors that lead to their occurrence can explain how a boat should be built and what should be changed or maintained.

Marine surveyors and other industry experts employ a forensic approach to post-storm damage evaluations, noting easily observable as well as hidden problems that lead to or become apparent after an incident.

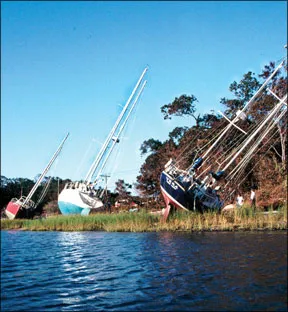

Practical Sailor recently toured a yard that contained numerous storm-damaged vessels with the intention of finding areas of potential concern in FRP construction. It wasn’t pretty. We saw shorn-off keels, ripped winch-base pedestals, AWOL chainplates, and bent rudder stocks. The boats came from a broad spectrum of production builders, yet its difficult to draw definitive conclusions about how one maker deals with unusual stresses over another absent an understanding of what these boats actually endured.

Accordingly, its impossible to state that any of the boats pictured here are “defective,” because the treatment each received was catastrophic, highly variable, and well outside the conditions they were designed for.

Nonetheless, understanding failure points can give us a better picture of common vulnerabilities and how builders might address them.

What’s Reasonable?

The first of many lessons learned is that sailboats are designed, engineered, and built to handle sailing loads, and the point-loading associated with collisions or fetching up on a coral reef, granite ledge, or surf-swept sandy shoal make all promises of ruggedness and survivability a tenuous crapshoot at best. Just one look at what happens to FRP when its elastic deformation ability is exceeded, and critical fracturing of the hull skin results, conveys much about recreational boating’s most favored material. Its inability to survive heavy point loads is one reason why there aren’t many FRP tugs, workboats, or warships. Fiberglass has many redeeming qualities, and its these positive traits as well as their limitations that boat owners need to understand.

Fiberglass molding revolutionized recreational boatbuilding not simply because the new material was rot resistant and offered a good strength-to-weight ratio, but because it provided a means of generating smooth curves and complex shapes that could be reproduced cheaply and efficiently.

Unfortunately, the material was anything but ideal, and its the downside to FRP construction that tends to get little press. Far from a perfect composite, glass fiber and resin have little affinity for each other. To make the bond work, a chemical coating must be added to the glass filaments and other synthetic fibers used as reinforcement in the resin matrix, whether its polyester, vinylester, or epoxy resin. This water-soluble chemical finish allows the resin to form a covalent bond with the fiber, and when solidified, the composite forms a hard but flexible skin just a little denser than hardwood. The finish used to link glass filaments to resin is the weak link in the adhesion process. This is why when destructive loads cause an FRP structure to tear, the ragged, resin- free filaments look as if they were never properly “wet out,” making it appear as if the failure was due to poor lamination. In reality, the shearing likely occurred at the critical interface between the glass filaments and their chemical finish.

Axes of Attack

In order to achieve a lighter but stiffer structure, low-density foam or other core material may be sandwiched between inner and outer FRP skins. In essence, these laminates are stiff and can have a great strength-to-weight ratio in two of the three planes often referred to with X, Y, and Z coordinates. The X and Y planes are aligned with the warp and weft of woven or stitched reinforcing fabrics, and they cope nicely with loads aligned in the same plane. The nemesis of FRP construction is the Z axis, a plane that is solely reinforced by the resins adhesive quality rather than by reinforcing fibers aligned with the axis. Metals, on the other hand, are isotropic in nature showing equal strength in all directions. Bond failure due to stress along the Z axis is one of the most common causes of FRP deterioration, and the term “de-lamination” is part of the boatyard lexicon all over the world. Boats driven hard at sea, or inadvertently grounded, often display critical failures that are partly due to the physical nature of the material from which they are made and partly due to the actual building process.

It’s important to note that high loads migrate through a structure and focus where the stiffness is the greatest. For example, global sailing loads create energy hot spots around the keel stub, mast step, chainplates and rudder bearing points.

Most skilled marine surveyors carefully inspect these locations, especially when storm damage or grounding-related problems are an issue. Point loads associated with collisions and grounding can subject FRP structures to loads that they may be incapable of weathering. When it comes to toughness and abrasion resistance, a resin-fiber composite will prove to be less than an ideal material. Ironically, its often an external lead ballast keel that saves a fiberglass sailboat in a serious grounding. As long as the hull pounding is mitigated by malleable lead making contact with a hard, tough planet, the chance of survival is good. Once the FRP hull skin starts taking the punishment, the odds for survival drop significantly.

Aluminum, though tougher than FRP and wood, also has a proclivity to tear eventually. Compared with wood and fiberglass, its tolerance for pounding against a hard surface is superior, but its durability is also directly linked to design scan’tlings. Sailboats with thicker plate and closer spaced frames do better than lighter alternatives. But, as the military and commercial sides of the marine industry have long known, steel is the only material that can give those prone to hitting things a fighting chance.

Ductility is one reason that steel resists being holed. It is known as a high-yield material, which means that there’s a wide range between the point where its elastic quality ends and where its plastic deformation ability finally ceases and a crack occurs. This property of steel is much greater than what’s found in wood, FRP, and even aluminum.

The engineering term “yield” is a measure of a materials ability to cope with loads that exceed its “spring back” point, and defines how much permanent distortion it will go through prior to failure. This range of deformation leads to dents and caved in sections of the hull, but often keeps a boat from being holed. Ironically, in engineering terminology, steel has a greater range of plastic deformation than fiber-reinforced plastic happens to have. Unfortunately, steel is heavy, rust-prone, and expensive to keep in Bristol fashion, not to mention its unsuitability for fast production-boat building. Consequently, it remains on the fringe of recreational boating – more of the material of choice for high-latitude expeditionary cruisers than for casual inshore sailors.

Designers use computer-aided design and finite element analysis to engineer increases in baseline laminates for hull and deck areas where highly focused loads occur. For example, carbon-fiber deck beams and chainplates, molded grid structures bonded to the keel stub, and rebated cores with solid laminates can be added to stiffen and strengthen specific areas. One of the most important tricks of the trade is the art of building it in accordance to the design specs, and over the years, there have been many examples of errors between the “as designed” and “as built” aspects of boatbuilding.

Unfortunately, the material that offers immense stiffness, light weight, and high yield plus construction simplicity is jokingly referred to as “unobtainium.” Chemists continue their quest for the ideal boatbuilding materials, but in the meantime, racing sailors want light, stiff sailboats, cruisers want rugged, easy-to-maintain hulls, and when either fetch up on a rocky ledge, they wish they had a stout steel boat. The right compromise continues to be debated, and each builder promotes his own solution to the challenge of structural adequacy. Building a boat to take surf-swept groundings in stride would lead to a sailboat that behaves like a boulder, and at the other end of the spectrum are race boats that simply lose their keels under the load of sailing.

For the average cruising sailor, there’s value in a reasonable length of garboard joint that allows keel loads to be dissipated through a larger portion of the hull. This can be aided with floor frames, grid structures, and a well-tapered laminate build-up near the keel stub. Cored hulls that continue all the way to a keel stub create a stress riser that does not dissipate loads as effectively as a heavier, more gradually tapered laminate.

Lessons Learned

For too long, there’s been an enduring misconception that rudders attached to the trailing edge of a keel are more protected in grounding situations and consequently suffer less damage. The truth is that these rudders reach down almost as deep as the keel itself, causing both the heel gudgeon and rudder to be quite vulnerable in a grounding situation. Shoal-draft vessels also have rudders extending nearly as deep as the keel, and they too will collide with the bottom, even in minor grounding scenarios. Ironically, deeper-draft vessels tend to have a larger offset between their max draft and the draft of a separate rudder. This offset often prevents bottom contact by the rudder during serious groundings.

Some older cut-away forefoot designs had their fore-and-aft center of gravity far enough forward to cause the vessel to rotate bow down as the tide ebbed, and the vessel would heel and rotate forward, holding the rudder out of harms way. Centerboarders with a separate rudder face the same grounding problems affecting shoal-draft vessels and can suffer serious rudder damage in a grounding.

Keel attachment has proven to be a critical factor in surviving a heavy-weather grounding. Wave action causes the full weight of the hull to act like a jackhammer, creating massive energy transfers between the keel and hull. Lead and iron keels are well-suited to such pounding, but hull skins do not have the same tolerance for intense impact loads. In addition to the forces generated, the hulls of modern sailboats often have a near-90-degree change in shape exactly where the keel/hull interface occurs. When these modern hull shapes pound on hard bottom, the critical junction between the hull and keel becomes a focal point for stress loads. The shearing that occurred at the keel-hull interface on the Beneteau on page 24 shows the location of stress risers on a flat-bottom, fin-keel hull when subjected to pounding that is far from ordinary. Wayne Burdick, of Beneteau USA, commented that, based on his observations of other storm-damaged boats, the photographed boat was clearly the victim of a “remarkable force.”

“This is, for the most part, the standard keel attachment for the majority of the industry,” Burdick said.

High-stress areas such as winch base pedestals and chainplates must be well-engineered and able to take significant loads. A well-made yacht is capable of being lifted by its chainplates – the loads imposed are equal to the displacement of the vessel.

Practical Sailor believes the chainplate structures should be the strong point in the rig, able to support any load that the rig might be capable of transferring to the hull before some other element of the rig itself fails. FRP-bonded chainplates, like those that are missing from the Island Packet 44 pictured on page 25, can present a special engineering challenge in this regard. Island Packets Bill Bolin pointed out the extreme conditions that led to the rigs demise, and that not too many hulls would have survived being crushed beneath the steel beams of a bridge and pounded stern first against rocks, the event that befell the IP44.

Similarly, winch pedestals, bow cleats, and mast partners must be heavily reinforced because these structures may be called on to keep a vessel off a surf-breaking reef or to tow it to safety.

No boat can be built to withstand the worst of a stormy pounding on an unforgiving reef, jetty, or breakwater, but every designer and builder should give serious thought as to how the garboard region of a vessel should be structured in order to endure more than just average sailing loads. Thickening panels or plate, removing core, and adding more units of FRP in this region, and bonding in or welding up a reinforcing grid are options that can make the hull-to-ballast keel connection the most rugged part of the vessel. External lead ballast can act as functional shock absorber, accepting the cutting and grinding effect on the keel and spreading the load over the entire garboard joint. A thick FRP hull skin and sealed, encapsulated ballast effectively transfer the rig and righting moment forces throughout the hull, but FRPs lack of toughness in comparison to external lead or iron make it a poor material to put in contact with a reef or rocks.

CONCLUSION

Its easier to become a proficient navigator, install a secure storm mooring, or transit to safe shelter before a storm, than it is to build or buy a catastrophe-proof vessel. And with the busiest part of the hurricane season dead ahead, followed up by the promise of violent fall nor’easters, its time to make sure that mooring pendants are in tiptop shape and anti-chafe gear is used wherever line contacts the rail or other hard surface.

Whenever there’s a warning of severe weather, all efforts should be made to double up lines, beef up chafing gear, and reduce your boats windage. More and more sailboat damage is associated with unfurling headsails and the windage that they create. Stripping headsails from furling foils during the proverbial calm before the storm ups the odds of survival and helps keep your boat where it belongs. And with some luck, in one piece.

shock absorbers. A car’s suspension redistributes forces, that would ordinarily bend axles, frames and transmissions. A sailboat is forced to flex, based on wind direction, sail area, wave angle and butting up against heavy surf. the Hull-Deck lag attachment system is suppose to limit over torquing, while maintaining water tight integrity. Wooden ships were thick and robust, but fiberglass and resin depreciates almost immediately. Sailboat suspension with flex compensation across X-Y-Z axis, is similar to a gimble. But Sailboats of the future will fly, so who cares about the water. if it were me, bring back wooden ship kits, made from processed or composite fibers. Sailing and ship building is a vocation, not an insurance claim. how long does fiberglass and resin take to decompose anyway? Great article!

Hobie Alter conducted crash testing of the Hobie 33 a long time ago. He was eager to show the world that he could build a light, fast, and strong sailboat. He punished the Hobie 33 by running it aground at 6 mph and dropping it into the water from a crane 12 feet above the water. The boat survived quite well. It was given more abuse than most owners would ever give it. You can see the video here: https://www.youtube.com/watch?v=ZdVHhg5600Y I know of one local skipper that successfully races a Hobie 33 in all, but the most severe weather and has an exceptional race record, including a class win in a brutal Miami to Key West race a few years back.

Yachting Monthly, a UK based publication, also conducts occasional crash tests which have included holing the hull and a dismasting, among other tests. In many cases the boats have proven much stronger than once thought.

When we purchase a boat it is a love story and the budget allow for this avenue is limited we believe the popular boat at the marina is a descant choice. Popular builder make boat for charter business with a expected life of 5 years. It is common to see a 20 years steel or aluminium boat in top shape. Many peoples lost life due to lost keel in the past 10 years and boatbuilder continue to build weak boat. Remember Cheeki Rafeki. /Users/jean-claude/Downloads/Cheeki Rafiki MAIBInvReport_8_2015.pdf

Good article. A concern that I have with the design of many modern fiberglass sailboats is the absence of a robust rub rail. I have sailed on Lake Erie, Lake Huron, Lake St. Clair, Texas Gulf Coast, and San Francisco Bay. Most boats in these areas are kept on docks with pilings, not mooring balls or at anchor.

Much of the damage to medium to large fiberglass sailboat hulls could be reduced by the re-introduction of stout rub rails to mitigate the damage caused by mishaps at the docking. It used to be that Beneteau and other sailboat manufacturers designed their boats with perforated aluminum toe rails that acted as rub rails as well as toe rails and attachment points for blocks and fenders.

It seems that today robust rub rails are not as common as they once were.

Is there a way to apply a new rubrail over my existing 1977 e27 w/ out removing original ?

Why a beached steel boat on the cover photo? The story is mostly about glass boats.

Where are pages 24 and 25 with pictures that are referred to in the article?

The links at the bottom of the article.

Also With This Article…

Special Report

Special Report Hull Damage

Or you can download August 2007 issue from the archives.

https://www.practical-sailor.com/category/full-issue/page/20

I hit the bridge and the rocky point (separate events) amazing how my Bristol 35.5 held up!

Fiberglass Boats – Hugo du Plessis (5th ed) Adlard Coles Nautical isbn 978-1-4081-2274-7

Yacht design and building is an art of modeling materials we do not wholly understand into shapes we cannot properly analyse to withstand forces we cannot properly assess in such a manner that the general public has no reason to suspect the extent of our ignorance. Anon

The Mariners Library (44 vol) pub – Rupert Hart-Davis, Adlard Coles

Having worked in the rubber/plastics industry fo over thirty years as a products liability national counsel I spent much of my time analyzing failures.

All materials will fail, so the key is to mitigate the risk of failure.I live in Florida whose waters are littered with shipwrecks since the 1500s.

I keep my sailboat in San Diego. Step one.

Weather watching and nav skills are essential everywhere. Step two.

I could go on but approaching mariner activity requires objective understanding of all these factors and applying them non emotionally.

This is a very good article that exposes engineering risks associated with FRP. Sail within limits? Eh

I believe a wide, thick, keel stub laminate that slopes fore and aft from high to low making the attachment surface for an external lead keel, is the best design to survive a straight-in hard grounding on a rock reef where the contact point is the leading edge of the lead keel. Rather than shearing keelbolts the impact actually lifts the boat compressing the keel to stub joint as the boat does a hand stand and stops. As long as the hull laminate is properly thick at the aft end of the keel to absorb the compression, the likelihood of significant damage is small. Even at hull speed.

I looked in depth at a lot of hurricane damaged boats in the process of purchasing my hurricane damaged Antares 44. Between that and the repair of my boat, I have learned a lot about what makes a boat strong. The problem is that boat design and building is a compromise; lightweight, strong, low-cost and easy to build while not totally mutually exclusive, are difficult to find a balance. In production boats low-cost and easy to build always win out.

My 1962 Alberg 35 went through the ultimate test. Hurricane Andrew. Cat 5. Gusts over 200kts. A 135’ steel barge was anchored up wind of my marina. It smashed and plowed through the marina sideways, beam on. It went right into my Alberg and trounced it right to the bottom. When we raised it 3 weeks later the boat was completely whole! The hull deck joint was chaffed at the Turn of the stb bow, and that was about it. The 2” SS schedule 40 custom built anchor roller was bent 90 degrees. But the boat was completely whole. All the boats around us were pulverized into pieces. NO, we were not on board and YES, some of these older heavy FRP boats were damn strong. The only reason that it was totaled was that it sat underwater for more than 3 wks destroying the all plywood interior and systems. The military would not let us near anything as they were pulling dead bodies out of boats and the water in the immediate area. When it come to a major storm like this NO boat is worth your life.

Yes, a great article by a noteworthy voice of experience. Even if the original is 15 years old, little has changed. But as Ralph indicates, the least expensive solution in the long term is to avoid the damage from ‘storms that find you’ in the first place. is by better preparation and location.

But most damages reviewed here, were not from a boat hitting something during actual navigation and in addition, were monohulls with solid keels. These can take a huge impact ,.. but it’s their attachment that more typically fails and of course, exposed rudders are super vulnerable all the time. In fact, the rudders of boats in general are one of the weak links for most boats with even more failures-per-boat that masts.

As Ralph points out, steel is super tough and resistant and in the 1960’s I was a guest speaker at a conference on Material Choices for Fishing Vessels with the task of defending steel as Choice #1. It was not difficult …. with the competition being alumimum, fiberglass and back then, even ferro-cement, for many of the reasons Ralph mentions.

But since 1990, I have turned my attention (as a naval architect) to multihulls, and steel is just NOT a viable option for a lightweight cat or trimaran .. with my preferred specialty becoming the trimaran. So is there an answer to surviving high impacts with such boats in practical use at sea and near shore? Well, I have been working on this for the last decade and here is where I am.

I am have been slowly developing a new ‘Wanderer’ 10m trimaran design that I want to be the safest and toughest such boat out there yet still be a performer that justifies the trimaran format choice. While I cannot afford full size tests that will have to wait real-life situations, I have tested small scaled-down components and become convinced that a lot can still be done to mitigate damage. Today, one of the PRIME risks for a trimaran that can often exceed 10k, is collision with some UFO (unidentified floating object), so I believe this must be taken more seriously by designers than it presently seems to be. Having personally run into an immovable 12ft dia. rock in 8ft of water and been thrown airborne a distance of 10ft, while my strong 26ft trimaran shuddered to a stop in just 100mm from 6 knots, I can also add that it’s not just boat damage we should be concerned about .. its human life and injury also. So after that, I started designing both daggerboards and even hull bows with shear off fore-tips (SOFT) and this concept was presented in an article in Multihull Magazine in March 2017 with the idea receiving the endorsement of 6 times circumnavigator Henk de Velde who was starting to see the risk from the increasing number of boats hitting UFO’s. Floating ’rocks’ that were mostly 20 plus ton containers that had not yet fully sunk.

So yes, the Wanderer 32 will have a SOFT bow. One that will shear off at a calculated light load, leaving an intact forefoot that looks more like the Icebreakers I used to design 40 years ago. The secret to surviving such brutal decisions is absorption … just as for your automobile. We MUST extend the time and distance of such collisions and in some cases provide secondary barriers. This will not cost a fortune either .. but it does take forethought and careful design. There is no reason why the shear off tip cannot be recuperated either, with a small but strong Dyneema line to attach the piece to the boat for reinstallation at a suitable time … but not reinstalled with carbon fiber as one owner did with a SOFT daggerboard tip I once built. The new owner hit something hard that broke the tip off but then totally defeated the concept by re-installing it to not ever shear off again. (Sure enough, he disintegrated the whole board the next time).

But then there is the risk of groundings and rock damage. For this, I have found one tough solution for a lightweight boat is to use materials that are really tough to tear and disintegrate, and combine these with a secondary back-up barrier.

For this, 7 ply plywood (or MDO**) with kevlar packing, tests out better than most practical fiberglass layups and is slightly lighter. So the bottom of my Wanderer, aft of the SOFT bow, will have a double bottom of MDO with a super tough Kevlar layer on both sides, with then 100mm of dense polyurethane foam being sprayed over this, with a secondary ply bottom over it, again with Kevlar on the inside. Altogether, this gives a secondary barrier, the proven resistance of bullet–proof Kevlar and the distance & time delay that will lower bottom penetration risk significantly. (This is NOT the place for carbon fiber, as its low elasticity just allows it to explode quite violently and with excessive shock). Perhaps these ideas will lead to further thought and application so that the potential terror of impacting a UFO at speed can at least be brought down to something a human can survive. Sadly, it will be long time before we will see much reduction in the number of containers lost overboard in our oceans, as statistically they are too low for shipping companies to pay much attention to. But this means, both ocean-going designer and sailors need to pay high attention to this growing threat.

Mike Waters, N.A.

** In case some readers are not familiar with it, MDO is a medium-density overlay – a phenolic coated fir plywood that is commonly used for exterior signs so very water resistant. It is less expensive than marine ply and epoxy bonds very well to the smooth surface. In the USA, many workboats are now built with it and it’s both tough and resistant to damage, but the thinnest available is 3/8” and even that is hard to find. The ½” specified for the bottom of Wanderer is easy to procure …. in the US anyway.

Yes, a great article by a noteworthy voice of experience. Even if the original is 15 years old, little has changed. But as Ralph indicates, the least expensive solution in the long term is to avoid the damage from ‘storms that find you’ in the first place. is by better preparation and location.

But most damages reviewed here, were not from a boat hitting something during actual navigation and in addition, were monohulls with solid keels. These can take a huge impact ,.. but it’s their attachment that more typically fails and of course, exposed rudders are super vulnerable all the time. In fact, the rudders of boats in general are one of the weak links for most boats with even more failures-per-boat that masts.

As Ralph points out, steel is super tough and resistant and in the 1960’s I was a guest speaker at a conference on Material Choices for Fishing Vessels with the task of defending steel as Choice #1. It was not difficult …. with the competition being alumimum, fiberglass and back then, even ferro-cement, for many of the reasons Ralph mentions.

But since 1990, I have turned my attention (as a naval architect) to multihulls, and steel is just NOT a viable option for a lightweight cat or trimaran .. with my preferred specialty becoming the trimaran. So is there an answer to surviving high impacts with such boats in practical use at sea and near shore? Well, I have been working on this for the last decade and here is where I am.

I have been slowly developing a new ‘Wanderer’ 10m trimaran design that I want to be the safest and toughest such boat out there yet still be a performer that justifies the trimaran format choice. While I cannot afford full size tests that will have to wait real-life situations, I have tested small scaled-down components and become convinced that a lot can still be done to mitigate damage. Today, one of the PRIME risks for a trimaran that can often exceed 10k, is collision with some UFO (unidentified floating object), so I believe this must be taken more seriously by designers than it presently seems to be. Having personally run into an immovable 12ft dia. rock in 8ft of water and been thrown airborne a distance of 10ft, while my strong 26ft trimaran shuddered to a stop in just 100mm from 6 knots, I can also add that it’s not just boat damage we should be concerned about .. its human life and injury also. So after that, I started designing both daggerboards and even hull bows with shear off fore-tips (SOFT) and this concept was presented in an article in Multihull Magazine in March 2017 with the idea receiving the endorsement of 6 times circumnavigator Henk de Velde who was starting to see the risk from the increasing number of boats hitting UFO’s. Floating ’rocks’ that were mostly 20 plus ton containers that had not yet fully sunk.

So yes, the Wanderer 32 will have a SOFT bow. One that will shear off at a calculated light load, leaving an intact forefoot that looks more like the icebreakers I used to design 40 years ago. The secret to surviving such brutal decisions is absorption … just as for your automobile. We MUST extend the time and distance of such collisions and in some cases provide secondary barriers. This will not cost a fortune either .. but it does take forethought and careful design. There is no reason why the shear off tip cannot be recuperated either, with a small but strong Dyneema line to attach the piece to the boat for reinstallation at a suitable time … but not reinstalled with carbon fiber as one owner did with a SOFT daggerboard tip I once built. The new owner hit something hard that correctly sheared the tip off but then totally defeated the concept by re-installing it to not ever shear off again. (Sure enough, he disintegrated the whole board the next time).

But then there is the risk of groundings and rock damage. For this, I have found one effective solution for a lightweight boat is to use materials that are really tough to tear and disintegrate, and combine these with a secondary back-up barrier.

For this, 5/7 ply marine plywood (or MDO**) with kevlar packing, tests out better than most practical fiberglass layups and is slightly lighter. So the bottom of my Wanderer, aft of the SOFT bow, will have a double bottom of MDO with a super tough Kevlar layer on both sides, with then 100mm of dense polyurethane foam being poured over this, with a secondary ply bottom over it, again with Kevlar on the inside. Altogether, this gives a secondary barrier, the proven resistance of bullet–proof Kevlar plus the distance & time delay that will lower bottom penetration risk significantly. (This is NOT the place for carbon fiber, as its low elasticity just allows it to explode quite violently and with excessive shock).

Perhaps these ideas will lead to further thought and application so that the potential terror of impacting a UFO at speed can at least be brought down to something a human can survive. Sadly, it will be long time before we will see much reduction in the number of containers lost overboard in our oceans, as statistically they are too low for shipping companies to pay much attention to. But this means, both ocean-going designer and sailors need to pay high attention to this growing threat.

Mike Waters

** In case some readers are not familiar with it, MDO is a medium-density overlay – a phenolic coated fir plywood that is commonly used for exterior signs so very water resistant. It is less expensive than marine ply and epoxy bonds very well to the smooth surface. In the USA, many workboats are now built with it and it’s both tough and resistant to damage, but the thinnest available is 3/8” and even that is hard to find. The ½” specified for the bottom of Wanderer is easy to procure …. in the US anyway.