In decades past, many sailmakers manufactured their own spinnaker sleeve or snuffer—the tubular devices often favored by shorthanded crews for facilitating the setting and dousing of spinnakers. Materials and designs varied considerably in these products, and the results were mixed. Today, spinnaker sleeve manufacturers have more or less settled upon a common design solution. Moreover, all major sailmakers in North America except North Sails have ceased producing spinnaker sleeves, opting instead to resell sleeves from companies specializing in them.

We found two such makers in the U.S.: ATN, Inc., builders of the ATN Spinnaker Sleeve, and the V.F. Shaw Co., producers of the Chutescoop®. Local sailmakers do occasionally take on the job of building custom spinnaker sleeves because the fundamentals of the design are well known and not patented by anyone.

ATN, based in Hollywood, FL, sees itself as the innovator in spinnaker sleeve design, having introduced many of the design features that are now considered standard. The company claims to have built more than 17,000 sleeves to date. V.F. Shaw Co., based in Bowie, MD, first introduced the Chutescoop in 1979 and takes a minimalist approach to spinnaker sleeve design, eschewing the elaborate systems found in competing products. The SnufferPlus™ spinnaker sleeve by North Sails is strikingly similar to that of ATN, but with a more streamlined design and simpler materials. We tested the three spinnaker sleeves on the water. But first, we had a good look at them on the dock.

Design Fundamentals

The basic elements of a spinnaker sleeve are fairly simple: a tapered fabric sleeve attached to a rigid opening at the bottom, with control lines rigged for raising and lowering the sleeve over the sail. Additional design features—now nearly universally adopted by the designs we tested—include:

• A separate sleeve for the control line, sewn externally to the main sleeve, to keep the control line from fouling the sail;

• A pendant between the uppermost attachment point of the sleeve and the shackle for the head of the sail, to allow room for the sleeve to gather when raised;

• Upward- and downward-facing bridles on the rigid opening of the sleeve, to ensure a fair pull;

• A swiveling shackle within the sleeve for the head of the sail;

• A low-friction block over which the control line runs, to raise and lower the spinnaker sleeve;

• A stripe of contrasting color, to help indicate if the sleeve is twisted.

Low weight is also an important consideration—both at the top of the rig, and on deck as one maneuvers the sail and sleeve in and out of the cabin or locker. An important engineering consideration is the fabric of the sleeve. It should be smooth enough so it doesn’t create excessive friction between itself and the fabric of the sail. The fabric of the sleeve must also be chosen so that it does not bleed color onto the spinnaker when wet. Finally, it is important to keep the control line block firmly anchored in its downward position at the top of the sleeve. We have seen firsthand the damage to a sleeve’s stitching and fabric that can occur when the control line does not have a fair lead. Two out of the three spinnaker sleeve manufacturers in our test have taken steps to address this issue—North and ATN.

ATN

The primary fabric of the ATN spinnaker sleeve is white, knitted polyester, which the manufacturer claims slides well over spinnaker material, even when wet. The bottom of the ATN spinnaker sleeve ends in a fiberglass bell, molded with Kevlar for weight savings and impact resistance. The bell mouth is a smooth radiused diamond shape, measuring 20 3/4″ by 11 5/8″ and 2″ high. The quality of the finish on the bell we examined was poor, with pockmarks and an overall dull appearance. Though merely cosmetic, this flaw did mar the otherwise polished appearance of this product.

The ATN sleeve has a rather complicated system of upper and lower bridles for hauling the bell up and down the sleeve: the lower bridle is pulled aside with shock cord, and the upper bridle is covered entirely by a sewn pocket. The continuous control line is tapered, with a 3/8″ polyester braided outer cover for hauling, spliced to a 5/16″ nylon line within the sleeve. The control line runs within a secondary sleeve of a contrasting grey polyester cloth sewn on the exterior of the main sleeve. The control line runs over a Wichard cheek block at the top of the sleeve. This block is through-bolted twice to a stainless steel rod, 9″ long and 5/16″ thick, inside the top of the sleeve. The rod acts as a pendant between the halyard attachment point and the shackle for the head of the spinnaker. We noticed one bolt had an extra thread or so standing proud above the nylon lock nut—presenting the potential for tearing fabric.

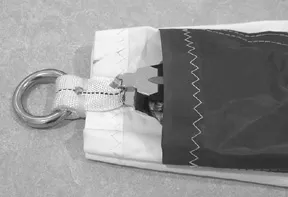

A fixed U-shackle with a 3/8″ inside diameter is bolted to the top of the steel rod as the halyard attachment point, while a shackle for the head of the sail swivels around the rod at its bottom. The bottom shackle has an 11/16″ jaw opening, an 11/16″ clearance, and closes with a clevis pin and split-ring. The bottom shackle is accessible through a flap closed with Velcro that spans the entire length of the stainless rod.

The overall fit and finish of the ATN sleeve is excellent, with strong stitching throughout. At an all-up weight of 14 lbs., the ATN spinnaker sleeve is the comparative heavyweight of the three spinnaker sleeves we tested. Of the total weight, the control line accounts for about 5 pounds and the bell almost 2 pounds.

Chutescoop

The primary material of the Chutescoop spinnaker sleeve is white, unfinished, 1.5-oz. nylon. The bottom opening of the sleeve has a 12″ hoop of 1/4″ stainless steel sewn inside a Dacron pocket. Two 3/16″ lines attach to the hoop on opposite sides. Instead of forming a bridle, these two lines run full-length inside a secondary sleeve to the top. The secondary sleeve, also of white, unfinished nylon, has a ¼” strip of green nylon sewn full length along one of its seams, to provide the contrasting color for users to detect any twists in the sleeve. We feel that having the entire secondary sleeve in a contrasting color would be much more effective at showing twists.

The dual control lines turn over a single 1″ Race-lite block that is suspended inside the top of the secondary sleeve; they then exit to the exterior through a single brass grommet in the top cuff of the secondary sleeve. Running two lines over a single sheave certainly goes against conventional wisdom. We are also concerned that the grommet takes some of the load, potentially stressing over time the stitching that secures the secondary sleeve to the main one. The block is lashed to the head thimble with a single loop of 1/8″ line, but nothing secures it in its downward position inside the sleeve. We found that the block can come out of the sleeve quite easily, which will lead to trouble as the twin control lines would make two sharp turns over the top cuff of the secondary sleeve. This invites significant friction.

Once external to the sleeve, the twin lines are tied with bowlines to a 3/8″, 12-strand braided line that is hauled on to raise the sleeve over the sail. Unlike the other two spinnaker sleeves reviewed here, the control line travels down to the deck completely external to the sleeve. The purported reason for having the control line arranged in this fashion is so that a user can raise the sleeve from various locations on the boat and not just the foredeck. The product’s accompanying literature mentions that the Chutescoop can be converted so that that the control line remains entirely within the secondary sleeve.

Inside the head of the Chutescoop sleeve is a 12″ pendant of 5/16″ Spectra line, spliced around a 5/8″ inside-diameter thimble at the top for the halyard attachment, and a swiveling shackle at the bottom for the head of the sail. This swiveling shackle is a substantial piece of hardware from Suncor, stamped with “2,000 lbs.” The shackle opens with a hex key, which we like for its snag-free profile.

We found the overall quality of construction in the Chutescoop unimpressive. There were loose threads and uneven edges in many places on the sleeve. Because it lacks a heavy fiberglass bell, the Chutescoop is the lightest of the three spinnaker sleeves we tested. The total weight of the 47′ Chutescoop we tested is 8 3/8 lbs., 3 1/2 lbs. of which is attributable to the large control line.

North Sails

The primary sleeve of North’s SnufferPlus is a white nylon material. The sleeve ends in a PVC-coated nylon cuff that is drawn tight with a drawstring around the upper flange of an elliptical fiberglass bell measuring 20 1/4″ by 12 3/4″ across its mouth, and approximately 3″ in height. The gelcoat finish of the SnufferPlus bell is far glossier than that of ATN’s product. For a control line, North uses a blue, braided, 10 mm, polypropylene line. This is a good choice of line, as a braided line does not kink easily, and polypropylene does not absorb much water.

The control line runs through a secondary sleeve of blue nylon and over a Ronstan ball-bearing block with becket (RF 40111). The halyard attaches to a stainless steel ring (1 1/4″ inside diameter, 5/16″ thick). This ring is at the top of a 16″ long pendant made out of four layers of polyester webbing sewn together. At the bottom of the pendant is a Wichard bow shackle (No. 1444; 5/8″ jaw, 1″ clearance) with captive pin. The control block hangs from the head ring on an additional loop of webbing, and is sewn onto the webbing of the head pendant with whipping thread that passes over the strap for the becket. There is a slim chance that the block will come adrift of its downward pointing position. The becket of the Ronstan block is removable; it snaps out of a keyhole opening in the metal strap. Stuffing the spinnaker sleeve in a locker might produce just the right pressure to pop the becket out of the block. Without the becket, the whipping would be unable to secure the block in its proper position, and the block would be free to work its way out of the secondary sleeve. If this goes unnoticed, the control line could badly chafe the stitching and cloth at the head of the sleeve.

We brought this to North’s attention, and the company said that it has already changed the way the block is secured. Now, a piece of webbing keeps the becket under tension and facing down.

We found the construction quality in the SnufferPlus to be excellent. The product weighs in at a total of 9 1/4 lbs. The polypropylene line used is the lightest control line of the three sleeves tested, at under 3 lbs. The fiberglass bell is heavier than ATN’s by half a pound because of its larger overall dimensions and larger flanges.

Testing

Our tests were conducted using a Jeanneau Odyssey 40, an average size boat for double-handed cruising and one aboard which a spinnaker sleeve would truly be a useful aid to sailhandling. The asymmetric spinnaker on this boat has leech and luff lengths of 46 and 52 feet respectively, so we used spinnaker sleeves with overall lengths of 47 feet. A properly sized spinnaker sleeve should only extend as low as the clew patch. If a sleeve is so long that it fully covers the clew, the clew may get stuck and ride up inside as the sleeve is raised.

We conducted our test in 6 knots of wind on the beam. To allow us to switch sleeves rapidly and still be in the same testing conditions, we conducted our tests with the boat tied to the dock. Each sleeve was raised and lowered four times by two different testers. We were testing primarily to assess the effort needed to raise and lower the sleeves over the spinnaker, mindful of the potential sources of friction at the sleeve opening, at the control line block, and between the spinnaker sleeve’s material and the sail’s cloth.

The first task prior to testing was to load the sail into each sleeve in turn. We watched the 20-minute video on CD-ROM that came with the SnufferPlus, showing how to install, set, and douse the spinnaker sleeve. A DVD is also available from ATN.

Loading the sleeve was easiest with North’s SnufferPlus. The sleeve arrives from North with the inside pennant pulled out of the mouth of the bell and shackled to the head ring. This spares you from having to gather the sleeve over your arm when installing it on a spinnaker for the first time. ATN, by contrast, cannot ship its sleeve shackled onto itself because of its rigid stainless steel rod. The Velcro-ed flap on the ATN spinnaker sleeve makes it easy to attach the head of the sail to the shackle inside the sleeve, but you do need to gather the entire sleeve over an arm to do so. We would rate its ease of installation second to that of the SnufferPlus. Loading the Chutescoop also involved gathering the entire sleeve over an arm while being careful not to develop twists.

There is a lot of line to deal with when the Chutescoop is on deck. This is the result of the way the Chutescoop control line runs externally to the sleeve for half of its length. One must take care to ensure that the control line does not get twisted around the sleeve when stowed in a sail bag. The V.F. Shaw Co. markets a specially designed spinnaker turtle for use in conjunction with the Chutescoop, with a pocket dedicated to stowing the coils of the control line. We prefer the self-contained approach of the ATN and North spinnaker sleeves, both of which have considerably less external line to manage, simplifying the undertaking.

In our tests, the ATN spinnaker sleeve set and doused with ease. We did notice, however, that the thin portion of the tapered control line came into our hands near full-hoist. On douses, the leech tapes of the spinnaker followed the acute corners of the diamond opening of the ATN bell exactly as intended.

The Chutescoop did its job smoothly, with just as little friction on sets and douses as the other products tested. The circular hoop functioned well, collapsing the chute in the windiest of our tests. The circular hoop showed no tendency to twist around the sleeve. However, it did tilt up on edge because the downward bridle attaches only at two points on opposite sides of the hoop. We are concerned that the metal hoop of the Chutescoop is too hard an edge for the sail to pass over, and we foresee the potential for wear on the sail’s stitching over time, particularly on the luff and leech tapes. One must also be careful when attaching the halyard to the top of the Chutescoop to make sure that the twin control lines are on the same side of the halyard. If not, one of the two control lines could take a half turn around the sleeve relative to the other, which will lead to unnecessary friction and wear.

We tested the theory of raising the Chutescoop from locations on the boat other than the foredeck, which is the reason why its control lines exit through the grommet and then run to the deck instead of traveling all the way down via the secondary sleeve. This feature worked as advertised. However, there are other ways of hauling on the control line from elsewhere on the boat. For instance, ATN recommends (and markets) a snatch block that can be attached to the rail on the foredeck and used to lead the line aft. In our opinion, spinnaker sets are rarely executed when the extra safety of being off the foredeck is required. Rather, it is spinnaker douses that are sometimes performed under pressure. The externally run control lines of the Chutescoop wouldn’t provide any additional safety in those circumstances.

Our testers felt that North’s SnufferPlus required slightly more effort to raise than the ATN sleeve, though this may have resulted from the textured surface of the braided control line rubbing over the lip of the bell on the way down to the deck. We also feel that the SnufferPlus could benefit from a swivel shackle within its head. In one of our four sets, the sail was twisted a half turn relative to the sleeve. Asymmetric spinnakers, with distinct luff and leech tapes, can easily develop a half-twist depending on which tack the sail is set on and to which side of the sail the control line is facing. The webbing pendant did absorb this twist, but when twisted, the pendant presents a potential source of friction for the control line.

Costs

ATN sells its sleeves by the foot—$10 per foot for sleeves up to 55′ in length, or $470 for the one we tested. In lengths between 55 and 100 feet, ATN sleeves cost $12 per foot, and the cost ascends accordingly. In the upper sizes, ATN appears to be in sole possession of the market (except for custom-built products), with nine bell sizes up to 9′ in circumference to accommodate the world’s largest megayachts. As for its warranty, ATN will fully refund the purchase price within 30 days, but the company says no customer has ever requested that.

The V.F. Shaw Company offers nine standard sizes for the Chutescoop, from 20′ up to 50′ in sleeve length. The cost of a Chutescoop is a function of the sleeve length and hoop diameter. Per foot, the pricing for the Chutescoop works out to fall within a range from roughly $5 per foot for smaller sleeve sizes to approximately $6 per foot for the largest sleeve size. The price of the Chutescoop sleeve we tested is $264.15. The maker of the Chutescoop offers a one-year warranty on the product.

North produces sleeves up to 70′ in length. Below 55′ in length, North’s pricing works out to be $8.50 per foot; at 55′ and above, the SnufferPlus is $12 per foot. The price of the SnufferPlus we tested is $399.50. North Sails does not have a written warranty policy on snuffers, but the company will accept and refund the return of a product that does not meet the customer’s satisfaction.

Conclusions

The ATN Spinnaker Sleeve is the most rugged of the three we tested, but at the cost of greater weight. It has a lot of design features, which is a sign that the manufacturer has put a much thought into product improvement. But the increased labor costs of its assembly make it the priciest of our group.

The Chutescoop is an economy product, perhaps best suited for casual use on smaller boats in coastal settings. We liked its low weight and low price, but some features were questionable, and we have concerns about how the Chutescoop (and the spinnaker used with it) will stand up to wear and tear in the long run.

Our winner—North’s SnufferPlus—is significantly lighter than the comparable ATN Spinnaker Sleeve, which is an advantage, and is more competitively priced for boats under 45 feet.

Also With This Article

“Value Guide: Spinnaker Sleeves”

Contacts

• ATN Inc., 954/584-2477, www.atninc.com

• North Sails, Inc., 800/724-5123, www.northsails.com

• V.F. Shaw Co., Inc., 301/262-5266, www.chutescoop.com