Over the years Practical Sailor has conducted dozens of anchor tests, and like many publications, we’ve repeated the common guidance that cruising sailors should buy an anchor that is at least one size larger than what the maker recommends for your size vessel.

During the last two decades, however, the tremendous holding power of some newer generation anchors have caused us to re-think this guidance. Are we paying more for an anchor, rode, and the requisite anchor handling equipment than we need? How accurate are the makers size recommendations? How much insurance are we really getting for the price of a bigger anchor?

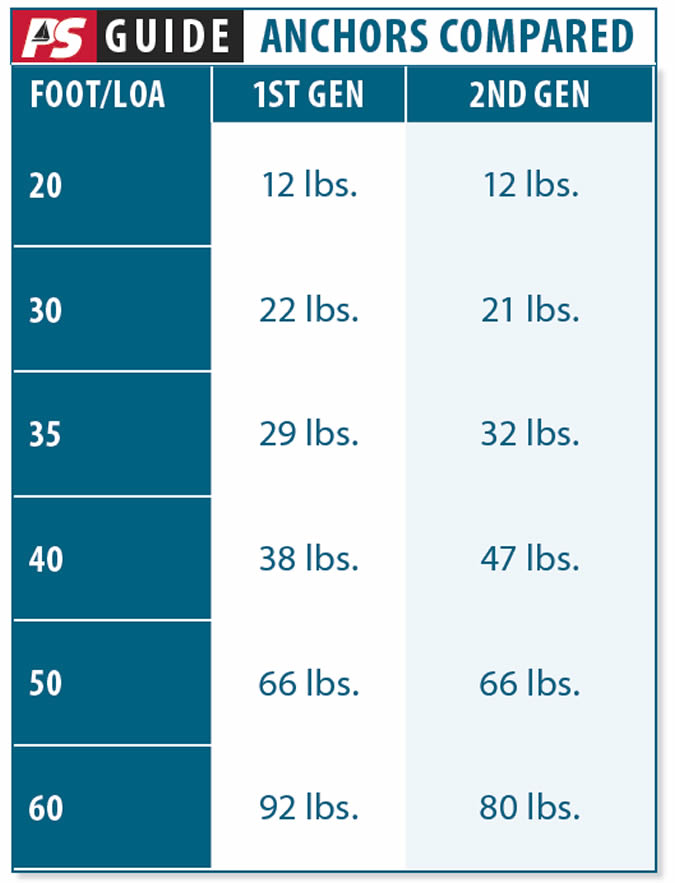

For this report we took a range of modern, sometimes called new generation anchors, and their predecessors and averaged their weight vs. vessel size recommendations (see accompanying table). Much to our surprise, the weight recommendations for the new designs, Rocna, Excel, Supreme, etc. are very similar to the weight recommendation for the older, traditional models, CQR, Delta, Bruce etc. In both cases, the recommendation for a 35-foot yacht is approximately a 30-pound anchor. The exceptions are aluminum anchors from Fortress and Spade.

Most of the new generation anchors have been tested to international standards established by the RINA (Registro Italian Naval) or some other internationally recognized society. Rocna, Fortress, Supreme, Excel, Spade have been found to meet standards of Super High Holding Power, SHHP. The older anchors, CQR, Bruce, Delta are rated as High Holding Power. The difference between the two categories is that the SHHP have been tested and found to have a hold, comparing anchors of the same weight, that is two times that of the HHP anchors.

So if we’re getting double the holding power, does that mean we can use an anchor that is half the weight? Not necessarily. Nor can you expect another doubling of holding power by doubling the weight of an SHHP anchor.

Despite the sales pitch that the new anchors have greater holding capacity pound-for-pound, the anchor makers are suggesting that you replace your old CQR with the same weight new anchor. It appears that manufacturers are, in effect, doubling the historic safety factor. And for a cautious sailor, there is nothing wrong with this.

However, consider the advice that is often repeated on internet forums, or the local scuttlebutt, that cruising sailors should increase one size over the makers recommendation. So instead of a 33-pound Rocna for your Tartan 37, you buy a 44-pound Rocna-now with potentially three times the safety factor of an old school anchor. Apart from the added significant expense, this obsession with upsizing – more anchor, more chain, bigger windlass-can also add potentially unnecessary weight and concentrate it in the bow.

So what do we really get with that bigger anchor? There is an idea that if you double weight of an anchor you will double holding power. Except with extra-large commercial anchors and some specific tests, we’ve found no data to support this.

No independent test, as far as we know, has taken a series of different sized anchors of the same design and tested them in the same seabed for ultimate holding capacity. Tests have been conducted on commercial oil rig anchors like the Bruce, and the best scaling is about 90 percent-double weight and you increase hold by 1.8 times.

The only recreational anchor that we are aware of that has undergone some testing to determine the relationship between weight and holding is Fortress (in mud only, see Anchoring in Squishy Bottoms, PS February 2015). An analysis of all their tests on a complete range of their anchor sizes suggest that if you triple weight you increase hold by slightly more than two times, approximately an 80 percent efficiency as size is scaled up.

Ultimately, this means that when someone tells you they can calculate the increase in holding power as you move up in size, be careful not to read too much into this conclusion. For one, the ratio used deserves close scrutiny. Surely, the bigger anchor will provide better holding-but how much? This hard to quantify, even with computer modeling. And no matter how accurate your calculation-a ratio based on performance in one type of bottom might not apply in another.

One reason you can’t claim that doubling the weight doubles the holding is that as anchors increase in size, the stress on the construction increases. To compensate for the increase in stress, the steel thicknesses must be increased – and more steel weighs more. So in an anchor whose holding power relies greatly on surface area and how it is distributed, adding more weight doesn’t necessarily result in a commensurate increase in surface area that provides holding power.

And as we’ve shown in our past tests-anchor dimensions (especially the fluke area) and shape can play a significant role in performance. It might be possible to double weight and double the holding power without beefing up the steel, but the resulting anchor would be less strong relative to its designed holding power.

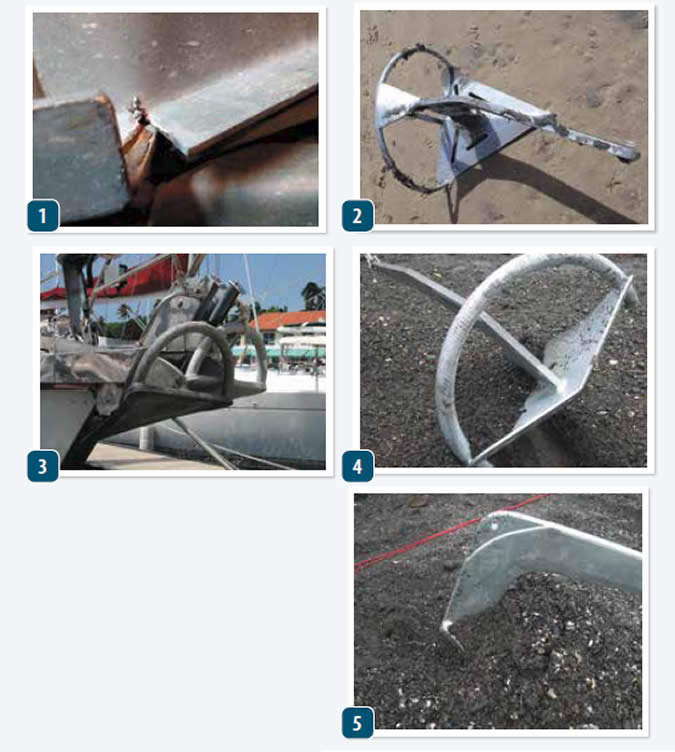

Weaker construction might not matter on an over-engineered anchor. However, we have seen how the use of inferior materials has resulted in anchors that bend more easily at designed loads (see Anchor Tests: Bending More Shanks, PS May 2013).

Anchor Angles

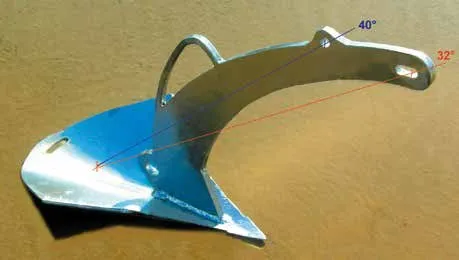

In past reports, we’ve discussed in detail how anchor design can impact holding, especially with the new generation anchors (see An Inquiry into Anchor Angles, PS February 2017). As you consider which design best suits your needs, here are some things to consider.

Fluke/shank angle. The fluke/shank angle is the angle between fluke and shank. It is one of the determining factors in how quickly and deeply an anchor sets. For a simple design with flat plate fluke and a straight shank (like a Guardian) the angle is a line down the center of the shank to the hinge and then along the fluke. In shanks with curves or angles, the first line is usually drawn from the shackle pin to the point there the shank meets the fluke.

For three-dimensional flukes (as found in most new generation anchors), you have to estimate where the top of the fluke plate lies. The ballast chamber or shank support that might protrude from the sole, such as with Spade, or Vulcan anchor should not be used to determine shank/fluke angle.

It is the fluke top surface that is important. In previous tests we reported that in thin mud an anchor with a fluke angle of around 45 degrees will outperform an identical anchor with its fluke angle set at 30 degrees. But a firmer sand seabed is entirely different, and research demonstrates the ideal fluke angle for a typical sand bottom is around 30 degrees (see Small Anchor Reset Tests, PS February 2013).

Fluke-seabed angle. This is the angle of the fluke to the seabed during the phases of anchoring-most importantly, during the initial penetration into the bottom, and when the anchor is set.

Penetration angle. When an anchor is aligned ready to set, or engage with the seabed (it might need tension on the rode to achieve this) then the fluke will usually be at an angle of 60-70 degrees to the seabed. Commonly the anchor is on its side.

Setting angle. Once the anchor starts to penetrate it will self align and the fluke plate tend quickly toward its setting angle, usually of about 30 degrees. It is coincidence that the fluke/shank angle and setting angle are similar though most anchors tend to show the similarity of the two angles. Center of gravity can have a great effect on penetration angle. This is why many new generation anchors, like the Ultra, have weighted flukes. Having a 30-degree fluke/shank angle is irrelevant if the center of gravity is in the wrong place.

Shank length

If you imagine a Fortress with a shank/fluke angle of 30 degrees but a shank three times longer than its original design, then you can visualize how the anchor will probably simply slide along the seabed when tensioned. The throat opening will be too small. Similarly if you chop the shank in half, the toe of the anchor will simply scrape along the seabed. In both case the anchor will find difficulty in engaging because the penetration angle will be wrong.

Conclusion

Are the makers of new generation anchors over-stating the need for bigger anchors, thus requiring boat owners to pay much more than they might need in order to be secure at anchor? Possibly. Would going with a larger-than-required anchor actually hurt your anchors performance? Unlikely. As is often the case with our anchor reports, it is hard to come with some firm answers regarding both of these questions. Anchor studies are fraught with variables.

In our view, it is no crime to go up one size over the manufacturers recommended size, if your boat and crew can handle it. The anchor may require more reverse throttle to set, but ultimately, it should provide the holding you require. Likewise, it is reasonable to assume that the anchor makers guidance for sizing is reasonable. However, if an online advocate starts telling you that youll get x times more holding power by going up one size, ask him for the data.

Extra weight in an anchor is your insurance policy. Yes, you can almost always get more security with the heavier anchor, but whether or not you will every need that extra holding power is not conclusive. In our view, conservative sizing is added insurance-but until the data is in, we remain skeptical of any absolute claims that attempt to quantify the advantages of more weight when choosing an anchor.

Based on average recommendations from leading anchor makers, the weight savings of upgrading to a second generation anchor doesnt really pay off until you get into the larger size vessels.

In an anchor whose holding power relies greatly on surface area and how it is distributed, adding more weight doesnt necessarily result in a commensurate increase in surface area that provides holding power. To compensate for the higher loads, the steel must be thicker, resulting in different surface area/weight ratios.

- As fluke size increases, so do the loads. But if the construction isnt beefed up to handle the loads, the result is failure. Flat plate steel in this Danforth fluke sheered.

- The shaft of an Excel anchor bent during veer testing.

- The flat flukes of the Bugel anchor makes it easy to calculate the shank-fluke angle.

- Here a Rocna anchor is in the initial setting angle, still capsized on one side, with not enough of its toe is dug into the soil to dig in. Bottom shape and center of gravity (some designs are weighted to control CG), helps to determine this angle.

- This Manson Ray anchor has rolled upright and assumed the angle of penetration that will help the anchor to bury into the bottom.