Photos by Ralph Naranjo

As the volatile weather of fall approaches, harbors and marinas are more likely to feel the effects of tropical and extra-tropical low pressure systems. The wind and waves linked to these unwelcome weather events put extra loads on dock and mooring lines. Fortunately, we can increase our odds of weathering the storm simply by making sure that these vital lines are well protected against chafe.

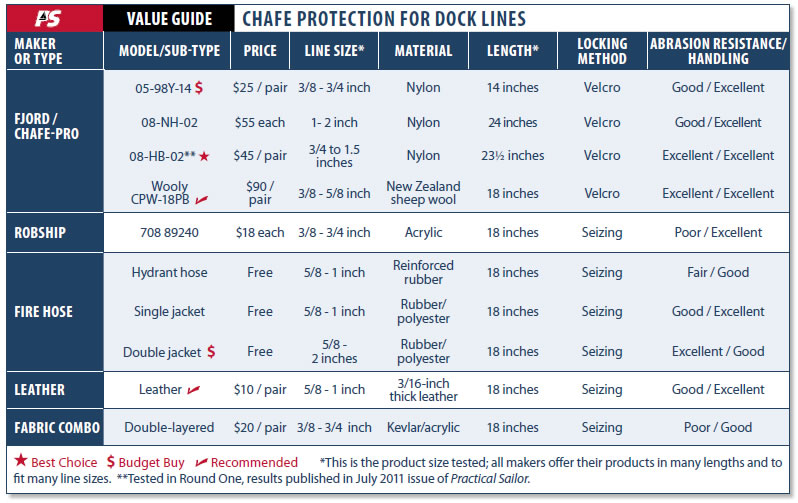

In the July 2011 issue of Practical Sailor, we evaluated rope chafe protection, and Fjords Chafe-Pro commercial chafe guard (model number 08-HB-02), a product used by commercial mariners and the U.S. Coast Guard, trumped all competitors, including two products from Taylor Made, one from Fiorentino, and one from Davis Instruments.

Our testing revealed that skin toughness was a primary factor, and the more resistant a product was to abrasion, the better. However, we also looked at flexibility and dimensional constraints that controlled whether or not a specific product would fit into smaller chocks seen on so many boats. (See the March 2010 issue of Practical Sailor for a discussion of chock placement and design.)

The article on that test prompted several requests that we expand the field to include some products we overlooked, some products introduced since that test, and some popular homemade chafe guards. In this second round of anti-chafe testing, we put four over-the-counter favorites and a handful of home brew alternatives to the test. Our updated field of products included some Chafe-Pro models that wed missed in the first round, a new rope protector from Robship, and three DIY alternatives-fire hose, leather, and a homemade esoteric Kevlar/Acrylic sandwich of our own design that we felt held great promise. The outcome reinforced Chafe-Pros prior win, endorsed a visit to a local fire department, kept leather in the running, and proved that our Kevlar-acrylic break-through had one fatal flaw.

How we tested

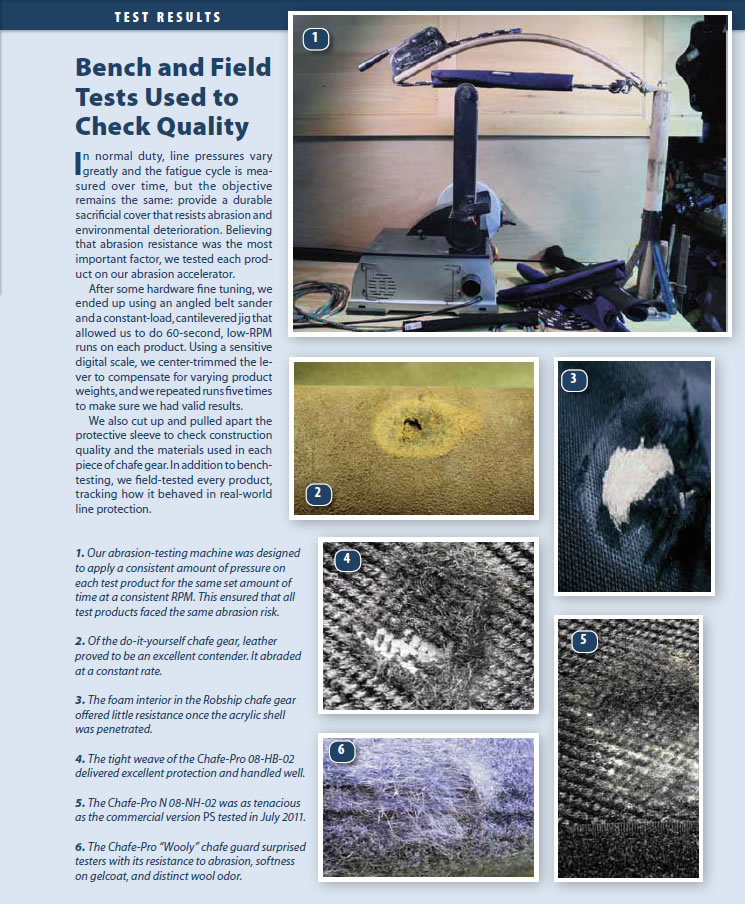

In order to maintain consistency in our accelerated abrasion testing, we once again set up a belt sander and used a rheostat to reduce the RPM and provide a uniform level of destructive friction to abrade each sample. (See Test Results on right for photos and additional details on the testing.) The multiple tests carried out on each product resulted in very similar damage, indicating that the careful control of time and pressure produced valid and repeatable results.

Along with the bench testing, we evaluated each product by fitting it to various diameter lines, testing its ability to be locked in place, and noting how easy or difficult the attachment process happened to be.

During this process, it became clear that to some extent, lines will surge inside the chafe gear as well as cause the chafe guard to surge inside a chock or against the rail it passes over. This inner-and-outer rub effect will vary according to how well the chafe gear is attached to the line and how much of a bend occurs at the point of contact. Chafe-Pros use of a full length of hook-side Velcro on the inner surface of its products acts to lock the line in place over the full length of the chafe protection. This minimizes surge inside the guard and maximizes the friction between the chock and the outer layer of the chafe guard.

In some situations, however, it may seem desirable to allow the surging to take place between the rope and the inner chafe protection surface. But because line failure usually involves a thermal melting effect caused by inter-filament stretch, we feel adding thermal insulation around a surging line will have even more of a negative effect on its breaking strength. This has proven to be the case when PVC tubing was used to act as chafe protection on pennants for moored vessels facing fall storm conditions in the Northeast.

Chafe-Pro 05-98Y-14

This tough, durable nylon chafe protection is designed to fit braid and three-strand line, ranging in diameter from 3⁄8-inch to -inch. Like the entire line of Chafe-Pro abrasion protection, it is secured using a hook-and-eye (Velcro) closure seam. On the inside of the heavy-denier nylon is a lengthwise hook-sided strip of Velcro that locks lines in place. The ribbed texture of Chafe-Pros proprietary weave has proven to be a very durable material.

Bottom line: Good everyday chafe gear for small to medium-size line diameters, Chafe-Pros 05-98Y-14 is the new PS Budget Buy, edging out the Davis Secure (no. 395) featured in the July 2011 test.

Chafe-Pro 08-NH-02

The big brother, turbo version of the product mentioned above, this heavy-duty line protector is as ruggedly constructed as the commercial (HB) product we tested in Round One. The NH line retains the Velcro closure and line-locking design of the smaller line guard, but it also incorporates a durable, ballistic nylon inner layer thats well stitched.

The composite is supple enough to slip into modest-sized chock slots. Its as rub-resistant as its commercial cousin, and the one we tested is designed for lines 1 to 2 inches in diameter.

Bottom line: The 08-NH-02 is an excellent option for those working with larger-diameter lines.

Chafe-Pro Wooly CPW-18PB

Thinking we had seen it all, testers were pleasantly surprised by Chafe-Pros new dockline/fender line. This fuzzy wool line guard uses New Zealand sheeps wool and was designed to protect gelcoat and paint as well as provide chafe protection. At first, it seemed more fashion than function-at least until we turned on the Chafe-O-Matic test jig and laid the wool-clad rope on the belt. At the 30-second pull-off point, we lifted the lever arm and had a hard time identifying any damage.

The material is so resistant to abrasion, that even when we doubled the dose of run time on the belt, the resulting damage was the least we saw on any test sample enduring half the punishment. We don’t have data on the effect of long-term UV, high moisture content, and atmospheric deposition, but New Zealand sheep seem to cope with these factors just fine. The manufacturer claims that the products durability is very good.

Concerned that something this tough couldnt be good for gelcoat or paint, we attempted to use it as an abrasive to damage LPU gloss, but after considerable rubbing, the shine remained bright and unmarred.

Bottom line: With high marks for its resistance to chafe, supple handling, and gelcoat-kind demeanor, the Wooly was another big winner. It gets our Recommended rating for the price-is-no-object sailor.

Robship 708 89240

Robship products are distributed by the Teufelberger Group and include a rope chafe protector thats easy to attach to dock or anchor lines, very lightweight, and the least resistant to abrasion of all of the products we have tested thus far. The acrylic outer cover affords good UV protection, but once abrasion cuts through the material, the closed-cell foam core affords little abrasion resistance, and the last stop before the rope makes contact with the wear point is the inner single layer of acrylic cloth.

Our testing has shown that while acrylic cloth is a great choice for awnings, dodgers, rope bags, and lee cloths, it just doesn’t have enough abrasion resistance for long-term chafe protection.

Bottom line: Although this new chafe guard is fine for preventing scuff-marks from rope in calm-water marinas, it lacks the ruggedness and durability required for chafe protection in a storm or in exposed waters.

What we found

When this second round of testing was completed, the results didnt significantly alter testers opinions. For price, ease of use, and durability, good-old leather was hard to beat. Testers especially liked the way it could be custom cut, hole-punched, and secured to a line. While fitting a leather chafe guard isn’t as easy or convenient as fitting the newer, Velcro-closure types, the process of making these chafe guards reconnected us with an ages-old maritime tradition.

For those who develop and enjoy the practice of marlinspike seamanship, this is a sensible approach to protecting dock and mooring lines. Its a skill that can be adapted to other uses onboard as well, providing an aesthetic means of eliminating chafe in running rigging or on the ends of spreaders to lessen damage to sails.

In an attempt to advance the art of DIY chafe protection beyond leather, we devised our own high-tech line padding that incorporated a doubled-up layer of woven Kevlar fabric (a 50/50 warp-to-weft weave). We stitched the Kevlar fabric inside a 10-ounce acrylic fabric sleeve and used Velcro as a means of closure.

We had hoped our invention would have the same sort of abrasion protection that you can find in epoxy/Kevlar composites. When you take a sander to this composite, the Kevlar is nearly impervious to sandpaper. But without the epoxy resin holding the woven cloth filaments in place, the belt sander plucked out clumps of Kevlar as if it were cotton candy sticking to a childs cheek.

In no time at all, the bullet-proof barrier was gone, and the inside layer of acrylic had a hole of its own. Our creation might have held on longer, with more stitching between the layers, but by the time we completed our testing, it was clear that we had outwitted ourselves with the high-tech Kevlar/acrylic sandwich.

Conclusion

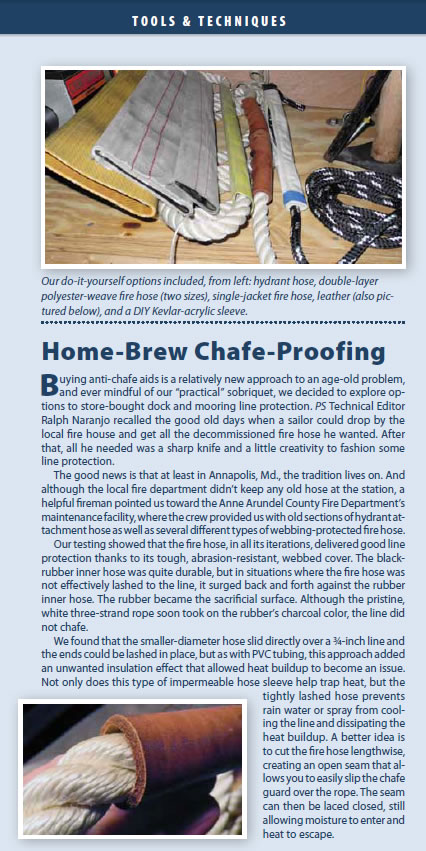

Practicality dictates that chasing down fire hose, hunting for thick leather, or sewing up your own alternative to commercial chafe gear isn’t the right answer for everyone. Those with less time for DIY projects and those hearing that tropical storm such-and-such is headed their way may prefer the expedience of an off-the-shelf alternative.

But when named storms are in the news, chandlery shelves are like supermarket aisles, and start to get pretty spare. Thats why an anti-chafe kit is handy to have on board. It comprises a sharp knife, sharpening stone, leather, heavy canvas, hole punch, lashing line, heavy thread, needles, a sailors palm, and a roll of omnipresent duct tape-plus some old fire hose or other patent barrier material.

Once again, our testing reiterated that Chafe-Pro gets the nod when it comes to off-the-shelf chafe protection. The NH line of recreational-craft products mimics the durability of the companys commercial protection, and the soft Wooly products will appeal to those who don’t mind paying more for a softer exterior finish. We were pleased to see that their proprietary, ribbed-weave outer skin prevails in Fjords recreational products line.

Fjords Velcro locking system is hard to beat, and installation is easy, whether its on an already tensioned line or one thats being made up prior to easing it into a chock or tensioning it over a hard spot on a rail.

Darrell: I recently discovered your articles while searching on the internet for information regarding rope failure from stand ropes used for boats to military parachutes and thread and rope climbing failures. I wanted to reach out to let you know of the most recent discoveries in long term fortification of polyamides and thermoplastic polyesters for rope. As you point out in one of your articles it starts with melt spinning of the Nylon fiber and 20 filament threads fed into the equipment to make three strand ropes. We know that fortification of Nylon and other ropes has been limited in the last fifty years and this includes fishing ghost nets made of nylon. However, what is not known and being suppressed due to business practices that continue to perpetuate failures was the discovery that we can now extend lifetimes of nylon rope from 10 year to 80 years without outer core rope failure of the filaments nor colorant fading. We now have the science and the data to illustrate that integration of this technology into the fiber spinning process will extend into ropes that will not degrade and are bleach resistant and have greater physical properties while inhibit intrinsic yellowing of the nylon on UV exposure. Suggest you look at Stabilization-technologies llc website.