If youve ever struggled to retrieve a balky rope-to-chain back splice with your windlass, youve probably wondered if there wasnt a better approach. The problem becomes especially acute if youve upgraded to higher tensile chain and want to use nylon rode with the same approximate tensile strength.

The solution relies on a bit of 19th-century splicing technology. Back in the days of weak chain and hemp rope, a two-strand splice was developed to allow bulky rope to fit through a link.

The Two-Strand Splice

In a two-strand, long chain splice, one strand is unlaid far back up the rope and the remaining two strands are fed through the link in opposite directions, lying flat and sharing the load evenly. One of these strands is wound back along the rope in place of the unlaid strand and then terminated in the manner of a long splice. The other strand is back-tucked as one would do when making a three-strand eye splice. The splice was common in the 19th century, when weaker hemp ropes were the norm

Three-strand backsplice

The introduction of stronger nylon made possible the three-strand splice, which should be familiar to most sailors. In this splice, the rope is unlaid a much shorter distance, and all three strands are passed through the last chain link in alternating directions, and tucked back into the rope as you would do when making an eye splice. The cross sectional area of the rope doubles, but it is still compact enough to fit in a windlass gypsy, and it is simpler to learn. The back splice is less efficient and slightly weaker than the rope itself, but the nylon rope is ultimately still stronger than the hypothetical 1/2-inch BBB chain that it would be paired with.

If you are using BBB chain or G30, getting a rope that fits the windlass and also matches the chains strength is not a problem. However, with introduction of G43 and G70 high tensile chain, modern sailors face the same rope-to-chain dilemma that tall ship sailors did. To match the strength of the new chain we need a much larger-diameter rope, and this has proven too bulky to feed though some windlass gypsies. So, at least in the case of G43, we find ourselves returning to the 19th-century solution: the two-strand, long chain splice.

The problem is more complicated with G70. Even when using the long chain splice, any nylon rope that matches the strength of G70 chain can’t be formed into a splice that will fit the corresponding gypsy. It is simply too large in diameter. Or to put it the other way around, any nylon rope that will fit your G70 gypsy isn’t nearly as strong as the chain. If you opt for a smaller diameter nylon rope that fits the gypsy, it will only be about 65 percent as strong as the chain. Any margin of safety you thought you had by purchasing more expensive G70 chain-and possibly the new gypsy to use with it-is lost.

Given the many vulnerabilities of nylon rode, the ultimate strength of the nylon rope should be at least 130-percent greater than that of the chain it is spliced to. With G70 chain, this is something you can’t achieve without resorting to an oversized nylon rode.

What We Tested

In our search for a reliable way to splice a rode that matches G70 chain and still fit on its relatively tiny gypsy, we made up samples of three different rope-to-chain splices using three-strand rode-a chain back-splice, a chain long splice, and a shovel splice.

The chain back-splice is like a basic eye-splice except that the strands are separated before threading through the last link (two strands in one direction, one in the opposite direction) and subsequently interwoven back up the rode. The chain long splice (two-strand splice) is a hybrid splice with only two strands passing through the last link in the chain and the strands gradually tapered as they are woven back up the rode. The shovel spice is made by unlaying the rope and weaving the strands through 12 to 14 links of chain, and locking them in place with a few wrappings of twine.

How We Tested

We tested the splices by pull testing them for strength and checking their ability to pass through the windlass. Although one splice-the shovel splice-was not as strong as the rope itself, the other two splices reduced strength by an equally small margin-about 10 – 20 percent. So the question that remained unanswered was: Which one feeds through the windlass most easily?

Splicing Instructions

The following instructions are for 1/2-inch nylon rope. For larger sizes, just scale up the measurements proportionately. Its okay to unlay too much rope, you will simply have more excess to trim. You can find more detail on the common chain back splice at Animated Knots (www.animatedknots.com), the long chain splice is detailed in Brion Tosss The Riggers Apprentice (available at www.practical-sailor/books), it also appears in Ashley’s Book of Kntos as #2858) and the shovel splice readily turns up in a Google search (we used this illustration at www.whsyc.org/).

Shovel Splice

Wrap seizing around the rope about 24 inches from the end and unlay. Weave the strands through 12-14 links of chain and secure at each link with a binding of whipping twine. The splicing itself is quite simple but our testers could not get it to feed through a windlass. No amount of urging, tapering, or fiddling would convince it to work, and it occasionally snagged on the windlass body.

The simplest to make, this splice also the weakest and the least friendly to windlasses. It simply would not pass through the Lewmar V700 windlass on our test boat. Its also pretty weak, only about 70 percent of the strength of the rope, and we wonder how long the lashings holding it together will last. We suppose it could be used for a rode that was retrieved manually, but even so its a mess, always bringing up mud.

Bottom line: The shovel splice has proponents, and it still appears in some textbooks, but in our view it is not a viable option.

Chain Back Splice

Place a seizing around the rope about 18 inches from the end and unlay. Feed the strands through the last link in alternating directions, and then work backward tucking into the rope. Dont try to tighten the strands around the last link in an effort to eliminate chafe, since this isn’t necessary and will contribute to uneven loading on the strands and thus reduce strength. In fact, the entire splice should not be too tight or it will be overly stiff, larger in diameter, and will not bend around the gypsy. Also, pay careful attention when tapering the splice. Roll the completed splice underfoot on the deck to make the diameter as smooth and as small possible.

Any sailors who can make a three-strand eye splice can manage this on the first try. Do not make it too tight, taper carefully, and if the rope is a relatively tight weave, it might just pass the windlass. Strength is about 85-90 percent of line strength.

Bottom line: Recommended if it will pass your windlass with a properly sized nylon rode … difficult to achieve if you use G43 or G70 chain.

Chain Long Splice

This is a more time-consuming splice, requiring attention to detail, but it is not beyond the capabilities of a novice. Place a seizing around the rope about 48 inches from the end. Take any strand-well call this the first strand-and carefully unlay it all the way to the seizing, leaving a neat vacan’t groove. Seize the remaining two strands about 30 inches from the end and carefully unlay them.

Feed the two strands through the last link of chain in opposite directions up to the point of the second seizing. Take strand two, the one that now lies closest to the vacan’t groove from the missing first strand, and lay it back up the groove, re-laying the strand by twisting slightly in the reverse direction to restore the original twist and tension.

When this strand meets the 48-inch seizing, lock it to the first strand with an overhand knot, untwisting both strands so that they are loose and can lie flat, and then weave it back up the rode in the manner of a long splice.

Finally, take the third strand, loosen the twist out of it and the tuck it back up the rode six times and taper, as though finishing an eye splice. Roll underfoot and trim to finish. There should be very little noticeable bulging. In a well finished splice, the tension on both strands is equal and hardly larger than the base rope and without stiffness.

This is the most complex splice of the three, and attention to detail is required for good results. However, if made neatly it will pass the windlass as smoothly as chain. It tested at 86 to 94 percent of rope strength even with our meager splicing skills; professional riggers achieve 100-percent strength.

Bottom line: Best Choice if you are willing to learn a new skill.

Conclusions

If you use BBB chain matched with the appropriately sized rope, you shouldnt have much trouble making a dependably strong splice that will fit your gypsy. Upgrading to higher test G43 or G70 chain in a rope-to-chain rode will let you use a longer chain leader without adding weight, but before you invest too much money on shedding chain weight, keep in mind the consequences.

If you are using a rope-to-chain rode, you don’t want to make the leader so short that you lose all catenary. Catenary, the sag in the chain, reduces the angle of pull on the anchor and absorbs shock from waves or wind gusts. In a rode with a short leader-30 feet is the bare minimum for a cruising boat-the extra weight of short-link G30 (BBB) can be important advantage.

If you have upgraded to G43 chain, matching the strength of the nylon rode to the strength of the chain requires mastery of the chain long splice. If youve upgraded to G70 chain, youve paid for expensive protection against abrasion that is stronger than it needs to be. The rope will part, most likely at the splice, long before the chain does.

It is true that you probably wont ever test your anchor rode to its breaking strength, but this risk will become greater to those who anchor on a mixed rode for extended periods or in rough weather.

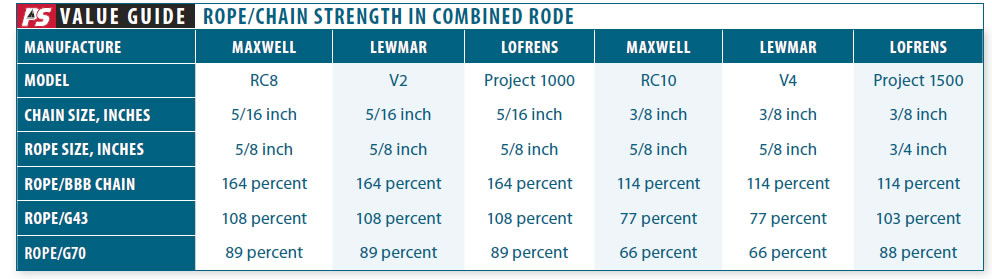

This table shows the ultimate tensile strength (UTS) of nylon three-strand as a percentage of chain UTS in combined rodes in sizes specified by windlass makers Maxwell, Lewmar, and Lofrens. The calculations assume a 100-percent efficient splice, although the norm is between 85 and 90 percent. Note the reduction in overall strength in the rodes that incorporate G70 grade chain.

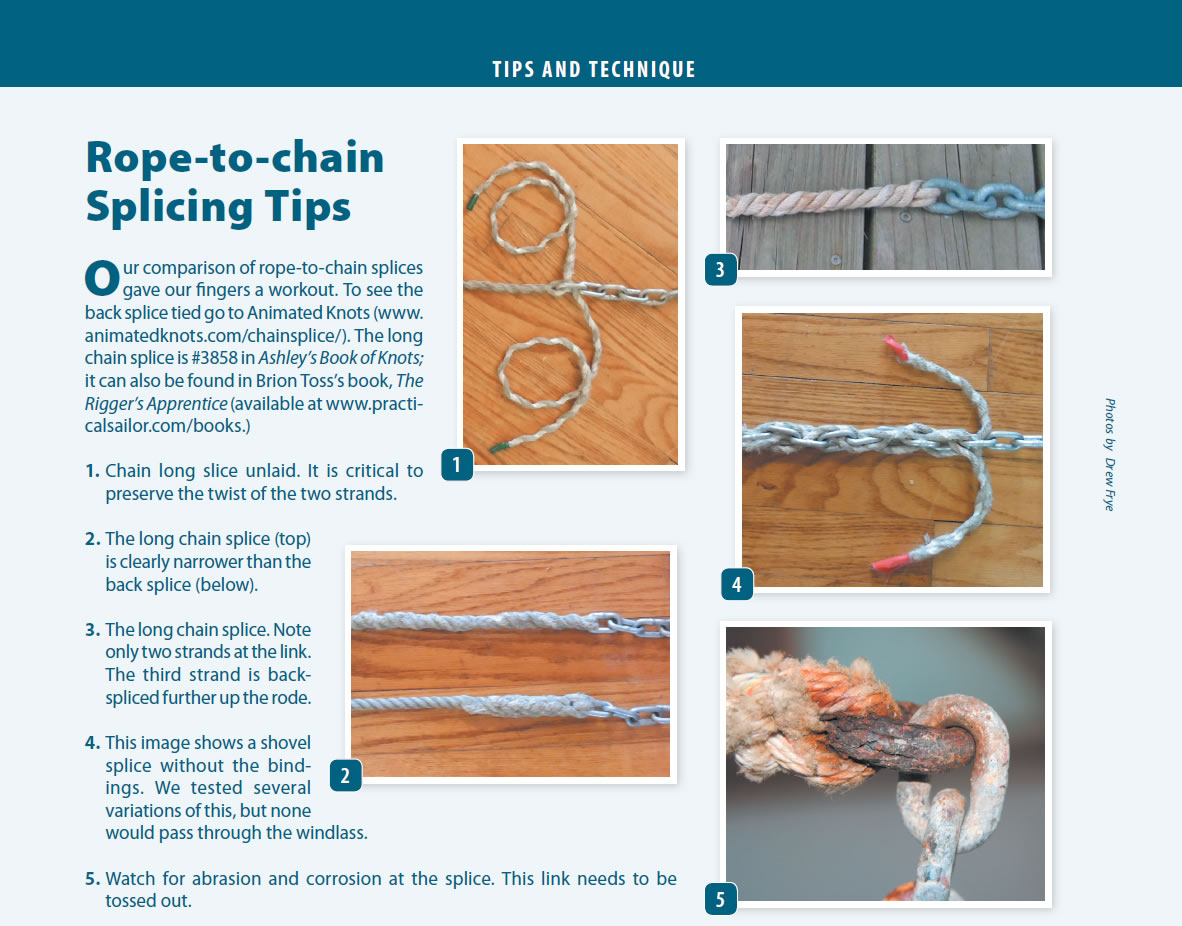

Our comparison of rope-to-chain splices gave our fingers a workout. To see the back splice tied go to Animated Knots (www.animatedknots.com/chainsplice/). The long chain splice is #2858 in Ashley’s Book of Knots; it can also be found in Brion Toss’s book, The Rigger’s Apprentice, second edition (available at www.practicalsailor.com/books.)

- Chain long slice unlaid. It is critical to preserve the twist of the two strands.

- The long chain splice (top) is clearly narrower than the back splice (below).

- The long chain splice. Note only two strands at the link. The third strand is back-spliced further up the rode.

- This image shows a shovel splice without the bindings. We tested several variations of this, but none would pass through the windlass.

- Watch for abrasion and corrosion at the splice. This link needs to be tossed out.