We have a love-hate relationship with nylon rope. When it comes to absorbing shock, it offers the best available combination of strength, elasticity, and economy. On the downside, it is sensitive to UV, abrasion when wet, has a low working load limit, and is weakened over time by internal wear.

We can deal with UV damage by replacing dock lines every five years or so and keeping anchor rodes and snubbers out of the sun when not in use. Careful use of anti-chafe gear and minimizing bend angles goes a long way toward eliminating chafe and internal friction damage. That leaves us with the twin problems of a relatively low working load limit and heating during cyclical loading. These also can be solved with careful application.

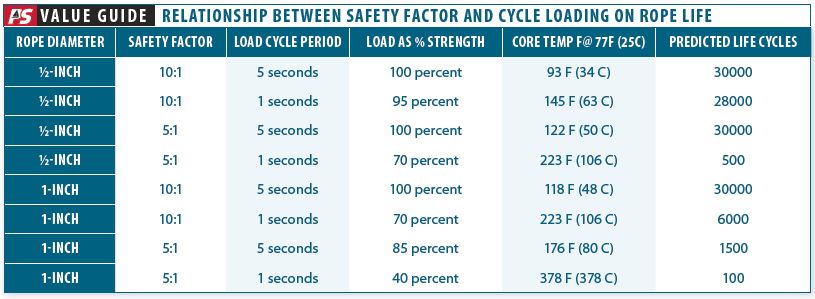

Fatigue. Steel has a well-known fatigue limit of about half its tensile strength. Although aluminum has no specific fatigue limit, so long as the stress remains below about 1/3 tensile strength, the average cycle limit and life expectancy is beyond that required of any mooring or deck gear. Likewise, ropes are always subject to internal wear of the fibers and damage due to strain and flexing, with no specific fatigue limit. Even within a specific fiber type, the exact relationship depends on the weave, spinning lubricants, and any applied coatings. A typical range of results are summarized in Table 1.

So how does this relate to the working load limit? First we must decide what we consider an acceptable life-span. Take climbing ropes, jack lines, and safety tethers as examples. For these, the design basis uses a safety factor of only about 3:1 based on the absolute worst-case event. For a climber, this might be a fall from 10 feet above his anchor point, right past it to 10 feet below it. The rope is only expected to survive a half dozen of these extremely severe falls and will be retired after just one. Most impacts will be much less than that.

If we consider the normal use of the rope, including the minor falls and bumps it will experience daily (about 500 pounds), the safety factor is about 13:1, and if we use only the climbers weight, the safety factor is nearly 40:1. Similar calculations are used for jacklines and tethers; two sailors taking a hard fall on a jackline or being thrown against their tether in a knockdown will strain the gear to within 1/3 of the breaking point, the balance being a safety factory against UV damage, cuts, and abrasion. Thus, climbers and savvy sailors inspect their gear regularly and replace critical fiber equipment year every few years.

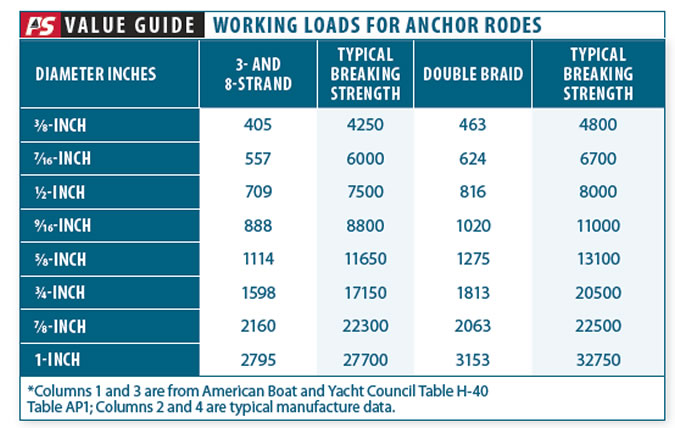

If we need a long service life-enough for an anchor rode or a set of dock lines to get us through stormy season, or for shrouds to hold the mast up-we need lifespan on the order of 100,000 to 1,000,000 cycles. In the case of Dyneema or polyester, a 5:1 safety factor is sufficient. However, nylon must have a safety factor of between 10:1 and 12:1 if we expect it to last very long. This is supported by the ABYC anchoring guidelines, adapted in Table 3.

Internal Heating

Ropes gain heat when repeatedly pulled and then relaxed. This is true of all rope, not just nylon, but it more important in nylon because it can stretch farther and because we often use it in applications where it is exposed to repetitive loads. The heating results from the fact that nylon rope is not a perfect spring; most of the energy is returned on the rebound, but some is absorbed by the rope through a combination of internal friction and the inherent nature of the fibers.

The extent of the heating depends on a number of factors:

The size of the rope. The larger the rope, the more difficultly the rope has dissipating the heat.

Frequency of cycles. The faster the cycling, the more heat builds up.

The load factor. The closer to the breaking point the rope is loaded, the more heat builds up.

Slack. If the rope is allowed to go completely slack, the fibers kink on a micro scale when slack and more heat builds.

Thus, a large rope that is cycled every few seconds to 30 percent of its breaking point will experience significant heating, while a small rope kept below its working load limit and cycled slowly will experience virtually no heating at all.

In previous Practical Sailor reports we’ve used microscopic images of burned fibers on broken ropes as evidence of intra-fiber friction. It turns out that just observing melted fibers means very little. We have pulled brand new ropes at very low rate through just a single cycle, as one does in breaking strength testing, and learned that if the rope is relatively new and in good condition, the fibers almost always melt and fuse. The incredible amount of energy released at the instant of rupture is enough to melt the ends (428 F), even if the rope is cold.

On the other hand, if the rope is old and fails at a low fraction of its original strength, as older ropes commonly do, there will be no heating because the energy release was insufficient, and rope end will not fuse. In other words, melted fibers more often result from momentary over-load than the small amount of heating induced by cycling.

So how do we avoid internal heat buildup? Table 1 provides some clues. First, if the rope is relatively small, -inch or less, the rope will never heat enough to cause weakening unless it is so horribly overloaded that it would have failed within a few thousand cycles anyway. A properly sized anchor rope, for example, will never be loaded past its working load limit and heating will not be a factor. Dock lines, on the other hand, can be strained past the safe 10:1 working load if they are short or undersized. Larger ropes will only heat if cycled both hard and very rapidly, probably beyond safe working limits.

External Heating

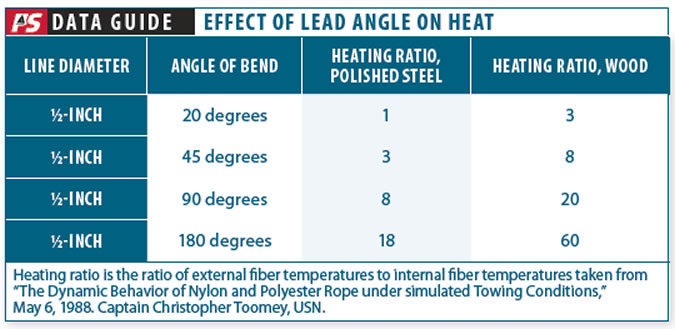

The hot theory is that nylon heats up due to cycling under high load. But lets not forget what we have known all along; simply rubbing your hands together creates heat. You’ve felt it right through your gloves when easing a line. On big race boats, the lines often have aramid covers to prevent the covers from melting when eased under extreme pressure. How much heating depends on even more variables than internal heating, including load and frequency like before, but also the coefficient of friction and the angle the line bends around the chocks.

The difference in tension around a smooth bend is given by the windlass equation:

T(out) = T(in)e^(a*c)

Where:

T(in) is the tension on the load side

T(out) is the tension between the bend and the cleat

Ais the angle of wrap, from 0 to 180 degrees for a return bend (in radians)

C is the coefficient of friction, a measurement of the sliding friction of the materials involved

e is the natural number, about 2.72

External heating is proportional to the mathematical product of the difference in tension on each side of the friction point and the distance the lines moves. We ran through these numbers for a variety of friction surfaces and observed that external heating is often the greater than internal friction.

Even when external friction is less than internal friction, it will prevent the line from cooling, leading to the common observation that lines get hot under PVC chafe gear. Of course they do, because in that location two heating mechanisms are at play.

In fact, external friction heating is generally the far more serious concern. In all of our impact testing, the obvious damage is always from external heating. This wont always be the case, but lets not forget our traditional enemy.

How do we limit external heating? Avoid sharp bends. When ropes bend excessively heating goes up exponentially, as do internal stresses on the rope. Use low-friction materials for chafe protection. Minimize stretch between the friction point and the cleat by minimizing the distance and by using non-stretch pendants as needed. Adding a polyester or Dyneema extension at the fairlead will stretch 5-20 times less than nylon and thus heat 5-20 times less.

Conclusions

Ropes greater than 1 inch in diameter are subject to internal heating if loaded past their safe working limit or loaded at high frequency. Ground anchor and sea anchor rodes are cycled at low frequency; although the core will see some increase in temperature, it will not progress to the point of weakening the rope unless the rope is loaded beyond the 10:1 safe working limit. If the anchor rode is sized right, it will never be over-strained or overheated.

Sea anchor rodes as well as tow lines for drogues, on the other hand, are often specified at about the same size as a ground anchor rode, even though they are often subject much greater forces than a boat anchored in a harbor. Instead of 10:1 safety factor, it could easily be operating at 5:1 or even less. Thus, a larger sea anchor rode can be weakened by internal heating.

Dock lines are more serious problem. If the boat is exposed to short period chop from the side, the frequency can be high and the force can exceed the 10:1 safe working limit. Core temperatures above the boiling point are possible in dry conditions, and even with spray to cool the rope there may be significant weakening. Add to this considerable frictional heating at contact points and special precautions are required.

Anti-chafe gear type. Avoid waterproof materials. Select materials that are inherently slippery, such as nylon webbing (see Chafe Gear for Mooring and Dock Lines, PS October 2012).

Anti-chafe gear positioning. Avoid sharp turns because these increase friction.

Minimize the run. Reducing the distance between the anchor point and the friction point will reduce the back-and-forth motion that will increase friction. Polyester or Dyneema pendants through the chock will combat friction here. Short non-stretch pendants attached to nylon snubbers and mooring pendants reduce rode motion over the bow rollers.

Avoid slack lines and bouncing. In a recent article on storm preparation we discussed motion control (see PS July 2016 Spring Lines for Storm Preparedness). A boat that is bouncing on its lines increases chafe, frictional heating, and forces. While it is necessary to maintain enough slack to accommodate changes in tide, excess motion should be controlled through the use of elastic devices or slender nylon tensioning lines. Stop the bouncing.

The correct size. When truly severe weather is expected, sailors like to double up lines and install oversize lines, but the average boat does not have cleats large enough to accommodate the required dock line size. We have taken to installing strong Dyneema loops over the cleats to allow attaching multiple large lines to a standard cleat. This should not overload the cleat if it is properly installed. This setup allows the use of multiple lines in multiple directions to control motion and to keep forces within the appropriate working load limit for nylon.

Table 1: This table illustrates the importance of having a conservative safety factor when sizing docklines (1-second cycle) and anchor lines (5-second cycle) to prevent overheating.

Table 2: This table illustrates how sharper bends contribute significantly to the external heat generated.

Table 3: The American Boat and Yacht Council uses a conservative 10:1 safety factor when calculating working loads for nylon rope. Our past study shows that some nylon rode that appeared serviceable had lost more than 70 percent of its strength.

Our investigation into interfiber friction and the role it plays in failure led back to a familiar enemy – poor fairleads. Under high loads, sharp bends can quickly wreak havoc with even top-of-the line double braids.

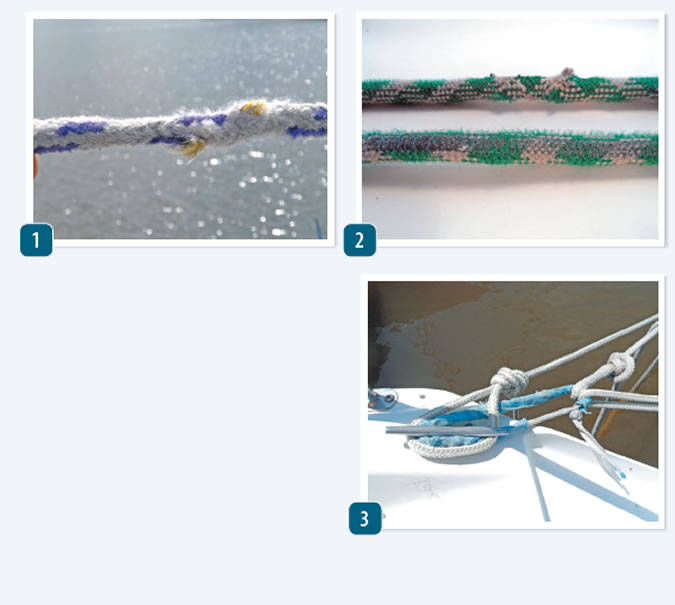

1. The interior of this line has a broken Kevlar core, greatly reducing its overall strength. Note that the polyester cover is still intact.

2. These 7/16-inch nylon rope samples were ruined by shock loading at only 20 percent of breaking strength. The top sample, ruptured at a sharp 90 degree bend through a chock on the fourth try, allowing the core to poke through. The lower sample was secured 4 feet away from a 2-inch radius 90-degree bend, which allowed considerable movement when the line stretched; it was covered with tubular nylon webbing chafe gear, which it welded itself to. With a 90-degree bend and with 4 feet of stretch at low frequency (5 second intervals), external friction was about 20 times greater than internal heating.

3. This cleat was hopelessly undersized for the three 1/2-inch lines this boat required to properly position the boat in all wind directions. The solution was a ¼-inch Dyneema soft Shackle covered with nylon webbing to spread the load (a Dyneema sling is just as suitable).