We recently learned that Spinlock RP25, one of our favorite cordage treatment used to prevent chafe and to improve grip in jammers has been discontinued. Another favorite, Yale Maxijacket, is sold only in more expensive, larger volumes—more than we’ll ever need alone.

Industries that use large volumes of these coatings—towing companies, commercial fishermen, and arborists—can still buy 1- to 5-gallon containers of the stuff. But it seems that the slow acceptance among sailors made it hard for companies to justify the marketing effort. We can relate. As much as we enjoy seeing our treated halyard lock down in a jammer without budging or chafing, we find far more uses for these coatings off the boat.

Yale Maxijacket has become a favorite for protecting the bottoms of backpacks, fabric tool bags, the cuffs of our Carharts, and the corners of high-use luggage. We’ve coated the corners of hot-meal fabric bags used by the local meals-on-wheels group. For each use, we marvel at how a nearly invisible treatment can greatly extend the life of almost any soft goods (bags, cushions, etc.).

STOPPING SLIP

On boats, a principal use for these rope coatings is to reduce slippage and wear in rope clutches. But before you reach for the Maxijacket or one of our DIY formulations described below, you’ll want to check a few things.

First, make sure the jammers are properly sized for the rope, adding a cover or bulking up the core as needed. Next, inspect the cams for excessive wear and replace as needed.

If these fixes don’t solve the problem, try an impregnating treatment. These treatments increase friction between the core and cover, and reduce core slippage in Dyneema-core lines. When the Dyneema core slips, the polyester cover tries to hold the entire load on its own, resulting in rapid wear and cover failure.

Treatments also stiffen the core so that it doesn’t flatten under the cam on a jammer and loosen the grip. Dyneema lines flatten more easily than polyester, particularly after they’ve been in use for a while. Because the treatment stiffens lines and makes them harder to handle, only the portion of the rope that will be in the jammer should be treated.

We have used RP25 to coat the forward 10 feet of jib furler lines, eliminating wear on guides and furler drum edges. We also coated lines that passed through jammers. We used Yale Maxijacket where dock lines rub on rails or chocks.

With RP25 gone and Maxijacket only available in large quantities, we decided to search for another home brew.

ROPE TREATMENTS

Treatments can’t restore a worn line, so apply any rope treatments as soon as wear patterns become apparent. The goal is to prevent further wear. If chafe is caused by sharp edges or burrs, eliminate the offenders or use a heavy chafe cover that allows the rope to slide inside it. These treatments are very good, but there are limits to what they can do.

During our initial rope chafe testing (see “UV, Chafe Protection,” PS March 2015) we tried protecting rope with latex paint, latex varnish, liquid electrical tape, and several dip-coatings intended to whip the ends of ropes. All quickly wore away. The products that lasted (Maxijacket and RP25) worked by bonding the fibers together from the inside, preventing the shedding of worn fibers. We knew we were looking for a strong, but flexible adhesive that could be diluted so it would soak in.

WHAT WE TESTED

We re-tested RP25, even though it has been discontinued, to establish an acceptable baseline. We tested Maxijacket at full strength and diluted 30-50 percent with water. We also tested a variety of adhesives diluted in solvents: Gorilla Spray Adhesive, Shoe Goo, and Gorilla Glue. Based on our initial success, we recognize that there are surely more possibilities.

HOW WE TESTED

We coated 12-inch sections of new StaSet polyester double braid and put them on our pendulum abrasion test rig. (This rig operates just as it sounds; a weight is suspended from a rope that passes over a rough surface. The weight is swung into motion, and the tensioned rope drags repeatedly across the surface.) We also tested the coatings on synthetic leather gloves to see if they improved grip and helped prevent wear.

DILUTE AS NEEDED

For best performance and to conserve product, you should vary the dilution as needed. For heavy duty protection—docklines in chocks, for example—use a higher concentration. If flexibility is important, thin with water or solvent as described below. The diluted coating will penetrate to stiffen the rope’s core, and the grip and chafe resistance of the rope’s cover will also improve. Recommended dilutions follow below. You can always practice on a sample rope before treating.

Generally, you need only a few milliliters per foot of rope, depending how much you allow to soak in and how you are diluting the product. More product will increase stiffness, and potentially provide more protection, but in our testing heavy or multiple coats didn’t make much difference. Apply only as much as will soak in within about 60 seconds and then wipe off all excess. If you’re using a 50-percent solution and want less stiffness, wipe off the excess after about 30 seconds. Allow to dry for at least 3 days.

We expected to feel obvious differences between the products. RP25, diluted Maxijacket, and diluted Gorilla Spray Adhesive are more flexible, and undiluted Maxijacket stiffens the rope noticeably. Improvements in grippiness (slip-resistance) were slight, but the Gorilla Spray Adhesive did improve this slightly. Even after six months, halyards treated with the spray adhesive resisted slipping in jammers. Gloves also showed less abrasion.

Treat only the rope sections subject to severe abrasive wear or core slippage. The rope fibers are lubricated during manufacture, partly to facilitate the rope-spinning process, but also to reduce friction between fibers when the rope is under load.

The coatings reviewed here lock the fibers in place, which increases abrasion resistance, and improves grip in clutches by firming the core and eliminating core/cover slippage. However, they also stiffen the ropes, which can increase friction around blocks and probably reduce resistance to fatigue caused by repeated loading. There is a tradeoff.

SPLINLOCK RP25

Now discontinued, this solvent-based, product stiffens the rope slightly and increases wear resistance by several times. It was developed to reduce core/cover slippage and improve jammer holding with high modulus ropes, and it does this beautifully.

Bottom Line: If you can find it (try eBay), this is still recommended for jammers, and chafe-prone sections of halyards and furler lines.

YALE MAXIJACKET

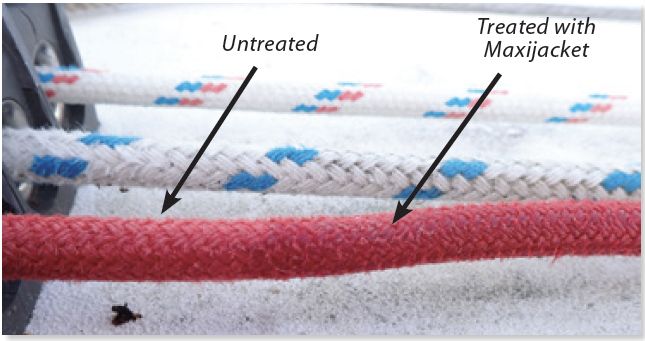

A water-borne polyurethane, Maxijacket proved astoundingly effective at decreasing wear in polyester and nylon (both rope and fabrics), polyurethane suede, and synthetic leather. Coated materials were 5-10 times more resistant to chafe than uncoated. Used full strength, ropes and fabrics are considerably stiffer. This is acceptable for heavy duty applications such as dock lines and the bottoms of backpacks.

For less stiffness, mix thoroughly 1:1 with water. This solution delivers performance very similar to RP25, providing 3-5 times better chafe resistance and much less stiffening. It will work for chafe-prone furler lines and halyards sections held by jammers. We like the diluted product better for most applications. Less is more. Do not treat rope portions that are handled or wrap around winches. We recommend clear; colors can rub off on the deck. A 1-quart container is about $70.

Bottom Line: This is our Best Choice for dock lines, jammers, and for halyard ends.

FLEXDEL ROPE DIP

In prior testing and in our experience, this is the most protective and stiffest of the rope treatments, but it is no longer available.

Bottom Line: Rope Dip is similar to Maxijacket. If you can find it, dilution is recommended for most applications.

GORILLA SPRAY ADHESIVE

At first we thought this tacky contact cement was going to make a mess, but in fact it is a stiff moisture-cure polyurethane which becomes very strong and quite hard after a few days of drying. The manufacture reports 4,050 psi tensile strength (80 percent of epoxy). In our own shear testing, it took 1,600 psi to break the bond between two fiberglass test coupons (an adhesive bond eight times stronger than polyurethane adhesive sealants).

For treatment in jammers and spinnaker halyards we recommend a 10:1 dilution with a 10% acetone/90% xylene blend. Brush it on heavy and wipe off all excess within 20 seconds to avoid excessive stiffness. Wear gloves.

With the acetone/xylene blend, the rope samples were slightly stiffer, grip slightly better, and resistance to wear was at least four times better than unprotected rope. For dock lines and heavy wear points we recommend a 5:1 dilution. Because it increases surface friction, we do not recommend treating sections that pass through low friction rings or fairleads at a significant angle.

Bottom Line: Recommended to prevent slipping in jammers.

ORIGINAL GORILLA GLUE

This gel-like liquid is also a polyurethane, but stiff and slippery when cured. We tried it in two solutions with xylene (5:1 and 10:1). The rope was considerably stiffer. We preferred Maxijacket.

Bottom line: Not recommended.

SHOE GOO

A familiar shoe repair aid, Shoe Goo is thick and gooey, so it would seem like an odd choice for soaking ropes. But when dissolved 10:1 with a 90% xylene/10% acetone blend (mix very well) it becomes thin and soaks in deeply. We found it to be very abrasion resistant, very elastic, and quite firm once dried. Rope stiffness compared with Gorilla Spray Adhesive, but it proved less effective at reducing wear.

Bottom line: Keep it for your shoes.

GLOVE TREATMENTS

We have always favored Ronstan Sticky Race Long Finger gloves. The extra grip really helps aging fingers, particularly when gripping a sheet in gusty weather. The synthetic leather is impregnated with polyurethane, but this wears away within a few seasons.

TESTING

A decade ago we had great success applying Yale Maxijacket to a pair of Amara (synthetic leather) cycling gloves. Wear effectively stopped, but the gloves became more slick, which is unacceptable for sailing gloves.

Since the sticky treatment in the Amara synthetic leather is an infused polymer resin, we tested dilutions of two similar polymer resins: Gorilla Adhesive Spray and the Shoe Goo.

Gloves infused with Gorilla Spray Adhesive do not feel sticky like football receiver gloves or even golf gloves. This is good because a sticky glove can make it harder to coil lines quickly. Still, the infused gloves will easily lock onto a rope tail with half the effort, which is just what we were looking for. Wear is reduced considerably.

We also tested a dilution of Shoe Goo. It had less effect on grip, stiffened the glove, and didn’t improve wear as much.

Bottom line: Gorilla Spray adhesive is great for gloves. Shoe Goo is for shoes.

APPLICATION

Dilute Gorilla Spray Adhesive 5:1 with a 90 percent xylene/10 percent acetone blend. Paint a little onto the severely worn areas of the fingers,

allowing it to soak in, then paint very lightly over all leather areas, and then wipe off immediately (you don’t want to stiffen the gloves).

Allow the gloves to dry for several days. The result is gloves that look better, grip better, and will last a few more seasons. This treatment can also be used to protect worn fabric areas, for example, around the wrist.

CONCLUSIONS

If you will be coating a lot of dock lines, some backpack bottoms, or have some friends to share with, you won’t go wrong with a quart can of Maxijacket. For heavy duty applications, including docklines and mooring pendant splices, use it undiluted. For reducing jammer slip and wear, dilute 30 to 50 percent. Well sealed, the shelf life is at least 5 years.

If you have a furler line, the masthead end of a spinnaker halyard, and the jammer portion of a few halyards that need treatment, snap up a can of RP25 from eBay before they’re gone forever. If you have a worn glove or two, properly diluted Gorilla Spray Adhesive is just the trick, and it also works well for a few lines that are slipping in jammers and firming up and protecting high-wear splices.

CONTACTS

SHOE GOO, www.eclecticproducts.com

GORILLA GLUE, www.gorillatough.com

SPINLOCK, www.spinlock.co.uk

YALE CORDAGE, www.yalecordage.com

VALUE GUIDE: TREATMENTS TO IMPROVE ROPE GRIP AND RESISTANCE TO CHAFE

| MANUFACTURER | GORILLA | GORILLA | GORILLA | SPINLOCK** J | YALE | YALE | ECLECTIC PRODUCTS |

|---|---|---|---|---|---|---|---|

| PRODUCT | Heavy Duty Spray Adhesive | Original | Original | RP25 | Maxijacket | Maxijacket | Shoe Goo |

| DILUTION | 5:1 xylene/acetone blend | 5:1 xylene | 10:1 xylene | Full | Full strength | 1:1 with water | 5:1 xylene |

| STIFFNESS 1 | 2.5 | 5 | 4.6 | 2.2 | 2.6 | 1.8 | 2.4 |

| STIFFNESS 2 (AFTER BREAK-IN) | 2.3 | 5 | 4.7 | 1.8 | 2.3 | 1.6 | 2.2000000000000002 |

| CHAFE (% OF BASELINE) | 30% | 20% | 20% | 35% | 20% | 35% | 35% |

| WINCH GRIP | Improves | Improves | Improves | No change | No change | No change | Improves |

| JAMMER GRIP | Improves | Improves | Improves | Improves | Improves | Improves | Improves |

| COMMENTS | Use very sparingly on winches | Too stiff | Too stiff | Discontinued e-Bay only. | Stiff if over done. | Stiff if over done. | Difficult to dissolve |

| PRICE* | $13/14 oz. | $22/18 oz. | $22/18 oz. | $54/8.5 oz. | $68/32 oz. | $68/32 oz. | $5/3.7 oz. |

VALUE GUIDE: PROTECTIVE TREATMENTS ON SYNTHETIC GLOVE LEATHER (AMARA)

| BRAND | PRODUCT/SOLUTION | GLOVE GRIP*(5= TACKY, 0=AMARA) | WEAR RESISTANCE | STIFFNESS** | PRICE (UNDILUTED) |

|---|---|---|---|---|---|

| GORILLA | Diluted Spray Adhesive (diluted with 10:1 xylene) | 3 | 20% wear | 2 | $13/14 oz. |

| GORILLA | Original (5:1 xylene) | 0.5 | Not tested | Not tested | $22/18 oz. |

| GORILLA | Original (10:1 xylene) | 0.5 | Not tested | Not tested | $22/18 oz. |

| SPINLOCK | RP25 | 0 | Not tested | Not tested | $54/8.5 oz. |

| YALE | Maxijacket | -0.5 | 10 percent wear | 1 | $68/32 oz. |

| YALE | Maxijacket (1:1 water) | Not tested | Not tested | Not tested | $68/32 oz. |

| ECLECTIC PRODUCTS | Shoe Goo | 1 | Not tested | 5 | $9/3.7 oz. |

| AMARA | No treatment | 0 | 100% wear (holed) | NA |

We tested Maxijacket on our favorite winter bike gloves, and the reduction in wear was impressive, but it was too slippery for sailing gloves. We went looking for a DIY glove treatment that would restore grip and fight chafe.

After testing several products, including our own concoctions, we settled on Gorilla Spray Adhesive mixed with Xylene. Not only did the DIY solution help prevent wear and tear, it also improved grip. Maxijacket, by comparison, did little or nothing to improve grip. Our DIY version is cheaper, too.

We tested the treatment on the various popular brands of gloves shown here. All of the gloves showed improved grip.

1. Testing the Ronstan Three-finger Sticky Race glove.

2. Testing the Gill Pro, half-finger sailing glove.

3. Testing Harken Black Magic, half-finger sailing glove.

1. The diluted Gorilla Glue rope was considerably stiffer and more resistant to wear.

2. The rope samples treated with Gorilla Glue spray were noticeably stiffer, grip was slightly improved, and resistance to wear was significantly improved.

3. Maxijacket diluted 1:1 with water delivers performance very similar to RP25, providing 3-5 times wear improvement and delivering a much more flexible rope. It will help prevent wear on chafe-prone furler lines and halyards sections held by jammers. We found the diluted product to be better for most applications.

4. RP25 was developed to reduce core/cover slippage and also to improve jammer holding with high modulus ropes, and it does this very well. Unfortunately, it is now discontinued.

5. The rope with no treatment showed obvious wear.

1. Drysuit treatments. Our growing interest in drysuits, either as a supplement or even as a substitute for foul weather gear (see InsidePS Blog “Details to Look for in Drysuits for Sailors,” inevitably led us to treatments to prevent odor buildup. Products from Nikwax and Gear Aid, as well as our own DIY formula, proved effective in our testing. Many of these products were also good for foul weather gear (see “Taking the Stink Out of Drysuits,” PS Dec. 2020).

2. Rope treatments. As we found years ago, a machine wash is one of the most effective way to clean halyards, sheets, and docklines (see “What’s the Best Way to Clean Marine Ropes,” PS July 2011). But how can we protect them? We were especially interested in ways to keep mildew at bay and to prevent stiffening in freezing temperatures. Products from Granger and Nikwax rose to the top (see “Aftermarket Cordage Treatments” PS April 2020).

3. Sunbrella. During our summer-long comparison of products designed to protect and preserve Sunbrella, we compared compatibility with clear vinyl, water repellency, and stain resistance. Products from GoldEagle (303), Star brite, and NikWax stood out. All the tested formulas repelled water for at least two months; some lasted for as long as six months. Soil and mildew repellency was effective as long as the water repellency lasted (see “Keeping Canvas in Tiptop Shape,” PS April 2020.)

A few clarifications on using diluted Gorilla Glue:

We collected the glue by spraying into a 100ml disposable polyethylene cup, holding the nozzle close to the side to maximize spray capture. We determined the amount of glue captured by weighing the cup before and after. We then quickly diluted to either 20% glue or 10% glue, the balance being a solvent blend (by weight or volume is not much different) of the 10% acetone/90% xylene. Mix vigorously. The amount of dilution depends on the desired result and how much stiffness you can tolerate or even desire. Experiment. You can also reduce stiffening by quickly wiping off the excess or just applying less. This is a thin solution that penetrates deeply and quickly.

You cannot spray into the solvent, because the solvent will go everywhere. Keep in a small tightly capped jar.