Ever since some ancient mariner broke a toe tripping over the killick stowed in the bow of his curragh, sailors have sought to solve the mysteries of ground tackle stowage. The solutions have been endless, and as a rule compromises. A significant portion of the interior volume of a 19th century warship was given over to the storage of anchor rode.

Even aboard modern boats, the search for the proper stowage of several anchors and chain, plus hundreds of feet of sometimes slimy nylon anchor line, is one that occupies both designers and boat owners.

288

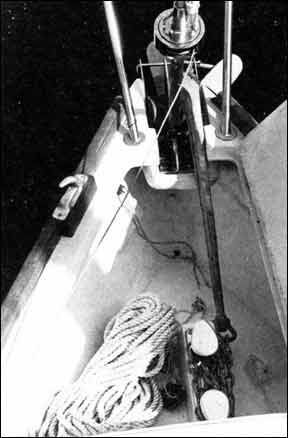

Two “modern inventions” — the anchor well, and the bow roller — have greatly eased many of the problems of ground tackle stowage. But even these developments vary greatly in quality and design, some creating more problems than they solve.

Of course, neither the anchor well nor the self-stowing bow roller are new. In some form or another, they have existed since time immemorial. But it is only in the last decade that they have become standard features on production boats, and it will probably be still another ten years before most of the wrinkles are ironed out, to judge by some of the boats we’ve recently examined.

We don’t know who gets credit for the modern anchor well. Like the development of the wheel and the discovery of fire, the anchor well lacks a specific point of origin. Whatever its source, most of those condemned to handling anchors on the pointy end of the boat will rank improvements in ground tackle handling right up there with the wheel, the ice cube, and Mt. Gay and tonic.

Anchor Wells

Making an anchor well is easy. Making a good one is less so. Most early anchor wells were created by installing a bulkhead in the bow of the boat about three feet behind the stem. A large hatch cut in the deck and hinged on one side provided access. Usually, a small hole was drilled in the stem to provide a drain for water finding its way into the well through the deck hatch.

While this may be the simplest form of enclosed anchor well, it has a number of shortcomings. With a deep anchor well, all the gear ends up in a tight little pile at the bottom, wedged into the vee formed by the stem and the topsides at the bow.

A deep anchor well invites back problems, as it is almost impossible to avoid bending over into the well to retrieve the anchor and chain. In heavy weather, the anchor and chain can pound hard against the hull of the boat, and could conceivably cause structural damage in some conditions. And to top it off, many boats carry a significant amount of water in the well in heavy weather, water located in the worst possible part of the boat when handling is the hardest.

288

Surprisingly, many production boats still have this type of anchor well. Fortunately, it may not be too difficult to improve upon it.

The ideal anchor well is no deeper than is necessary to hold a single anchor and its rode. Unless the well is compartmented in some way, storing more than one anchor in the well is likely to result in a rat’s nest of tangled line, complicating — perhaps dangerously — both the setting and retrieving of the anchor.

If you have a deep anchor well, it may be possible to improve it by glassing in a triangular piece of heavy plywood to serve as a false floor. Unless the access hatch is very large, it will be necessary to cut this plywood floor into two pieces to wrestle it into place. The two pieces can be rejoined with a simple strip of wood on the underside, screwed into one half of the plywood before it is inserted, into the other once both pieces are in place.

It will then be necessary to drill a new drain hole in the stem, just at the height of the new floor. Draining will be made easier if the plywood floor is angled downward slightly at its forward end.

If two anchor rodes are carried in the well, a removable plywood partition can be installed to keep them separate.

A cleat much larger than you would be willing to mount on deck can be mounted to the new plywood floor, but only if the floor is heavy, rigid, and very strong ly fiberglassed to the hull. Otherwise, cleat, anchor, and rode may take leave of the boat when she is anchored in heavy conditions.

The well should also include one or two large padeyes, through bolted to either the floor or the adjoining

bulkhead, to which the bitter end of the anchor rode can be secured. If you are clever enough to have spliced a thimble into both ends of the anchor rode so that it can be swapped end for end yearly, the bitter end is simply shackled to the pad eye in the well.

288

It’s also a good idea to mount several smaller eyes that can be used for lashing down anchors. Otherwise, it could be possible in a severe knockdown to lose the anchor and rode.

Boats carrying large quantities of chain would do well to stow the chain further aft than a foredeck anchor well. If there is a chain locker under the forward berths, a PVC pipe can be run from the inside of the anchor well to the locker. This pipe must be substantially larger in diameter than the chain links, and should be run without sharp turns. It is possible to form PVC pipe to curves if it is heated. The pipe should project far enough above the floor of the anchor well to minimize the chance of water in the bottom of the well finding its way into the chain locker.

Realistically, the lid of the anchor well is going to be a pain. Lids are heavy, hard to secure positively, and always seem to be in the way. Strong hinges are required, and heavy sliding bolts or some other means of latching. In areas where theft is a problem, a staple and hasp for locking it may be in order.

Another type of specialized anchor well is the molded fiberglass vertical well fitted for a particular size and type of anchor. We first saw this on the J/30, which has a well on the side deck designed to carry the Danforth anchor that is the class standard. The well has molded recesses for the stock of the anchor, so that it is securely held in place. The advantage of this arrangement is that the vertical well takes up less deck space, so that its location is more flexible. The disadvantage is that there is little flexibility in the ground tackle you can carry. You’re pretty much stuck with whatever anchor the locker is molded for.

Bow Rollers

If the design of many anchor wells leaves something to be desired, stemhead fittings designed to stow anchors or ease the handling of ground tackle are really in the dark ages.

288

Bow rollers began to proliferate about the same time as the anchor well, and many suffer from the same shortcomings as anchor wells: in the boatbuilders’ attempt to have something to meet the competition, they stick something “cruisey” on the pointy end of the boat.

For a boat doing a fair amount of coastal cruising, where anchoring daily is a part of the routine, some kind of self-stowing anchor holder on the bow is a real blessing. In the stranger than fiction world of family cruising, the person handling the heavy ground tackle on the bow of the boat is usually a woman, while the male assumes his dominant position at the controls of the boat. (“Just swing that 35 pound Danforth with 25 pounds of chain on it over the side when I tell you little lady, and don’t scratch the topsides.“) Handling heavy ground tackle is a backbreaking chore that should be left to the strongest member of the crew, whether male or female.

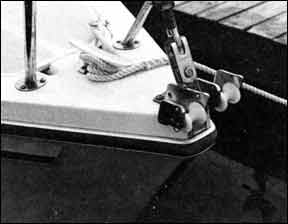

Bow rollers fall into two categories: those designed to stow anchors, and those whose only function is to provide a low friction pivot point for retreival of the anchor.

If the bow roller is not used to stow the anchor, its design requirements are fairly simple.

The roller itself should be large enough in cross section to handle both the anchor line and the lead chain. It should roll freely on its axle. Dense urethane is a good roller material, since it will not chafe the anchor line.

Harder materials, such as bronze and stainless steel, can quickly wear the galvanizing off chain. Even hard plastic, such as nylon, can wear soft zinc galvanizing. Metal rollers also tend to be noisy at anchor, particularly if all-chain rode is used.

288

The cheeks of the roller housing are quite important. Forward of the rollers, they should be flared outward, with edges well polished, to prevent wear on the anchor rode as the boat sails around on the anchor. Most modern cruisers have too much windage forward and not enough displacement to lie quietly at anchor. Some, in fact, are far smarter sailers on the anchor than they are with the sails up. Once during our brief career as a charter boat captain, the rather delightful but exceedingly drunk wife of one of the charter party spent an entire evening at the helm, tacking the C&C 42 Landfall through about 80” for hours on end. The boat, unfortunately, was at anchor with no sails up. It never did manage to tack through 80” under way. In addition, the roller cheeks should project far enough above the roller to hold the line in position as the boat swings and pitches. There should be a removable pin through the cheeks above the rode to serve as a keeper, in case the rode has a tendency to pop out. It is important that there be little or no space between the cheeks and the roller, to prevent the line from wedging itself in that space.

A fair lead from the aft end of the roller to the windlass or bow cleat is critical. Anchor line can chafe just as easily on the back of the roller as on the front. Obviously, the lead should not foul the headstay, the roller furling pennant, or the lid to the anchor well.

The same requirements hold when the bow roller is incorporated into some type of bow fittings which actually Serve to house the anchor. There are, in addition, even more caveats.

First, the fitting must project far enough forward to keep the anchor from banging into the topsides. This problem i s most common with plow-type anchors, whose flukes pivot quite nicely when the anchor shank is in the horizontal position. If a plow anchor is snugged up against the stem, the stem must be fitted with a metal protecting plate.

288

There are several ways of mounting Danforth-type anchors at the bow. The problem with stowing a Danforth at the bow is that the long flukes and stock make a formidable projectile, guaranteed to snag errant sheets, docklines, and the custom teak rubrail of the boat in the neighboring slip. In addition, the stock of a Danforth can poke wonderful holes in your new Mylar genoa.

Stowing the anchor vertically in the bow pulpit still requires handling the anchor and chain, something you’re trying to avoid. Instead, if at all possible, use an anchor roller specifically designed for the Danforth anchor, making sure that it mounts far enough forward to keep those sharp flukes away from your tender topsides.

If the fitting is used to house a CQR plow, it should incorporate a cross pin through the cheeks that passes through the trip line eye just above the flukes of the anchor. This serves the dual purpose of holding the anchor firmly in the fitting, and preventing the flukes from beating a hole through your topsides.

A considerable amount of leverage is exerted on the projecting anchor roller when the boat pitches at anchor. We’ve seen these fittings twisted like pretzels on several occasions. Be sure that the material is heavy enough for the job it must perform. Don’t skimp either on the sire of the bolts or the backing plate used to secure the fitting.

Conclusions

The primary disadvantage to stowing anchors in stemhead rollers is their effect on the boat’s pitching moment. The longitudinal center of bouyancy of most modern boats the point about which they pivot when pitching -is usually slightly aft of the middle of the boat. The further forward the weight of ground tackle is, the greater the tendency of the boat to pitch.

For long passages, therefore, you’re better off removing anchors from stemhead fittings, stowing them further aft. Whenever possible, keep the ends of the boat light to reduce pitching.

This is, of course, contradictory to the idea of handy stowage of ground tackle for in-use convenience. That’s not too surprising, for like almost everything else associated with boats, there’s no free lunch -just a neverending stream of trade-offs.

Would love to see some testing when it comes to anchor rollers. There’s a lot of variability that has come into designs with some really low cost and really high end options.