Practical Sailor has been researching ground tackle for nearly 40 years, but in the controversial world of anchoring, there are always new firestorms to light. Heres one that is sure to spark a lively debate (as if we need another one).

A while ago, when we were researching large oil-rig anchors, we noticed that these rigs were anchored with a spider-web of stranded wire, or in some cases, Dyneema, a rope made of ultra-high molecular weight (UHMW) polyethylene, a low-stretch, high-strength synthetic fiber.

Lighter and potentially more compact than either chain or metal cable, Dyneema offers several advantages over chain in deep-water drilling operations, but not so many for sailboats. Sailboats don’t anchor in the depths that some of the new drilling ships operate in, they must spin around to face the wind, and they rely on the weight of the chain to provide shock-absorbing catenary, or slack, in the anchor rode. Nevertheless, we began to wonder whether Dyneema or a similar fiber might have some application in recreational sailboat anchoring. After all, sailboats are already using these new high-tech fibers for critical above-the-waterline tasks-in everything from standing rigging to shackles and lifelines.

Some of the pros and cons of using a high-tensile fiber or wire-rope are self evident. The most obvious is the potential weight savings. Using a UHMW fiber rope like Dyneema instead of chain would dramatically reduce the weight carried in the bow, making the boat drier when sailing in rough weather and potentially faster and better balanced in light to moderate winds. As our previous article on anchor lockers pointed out, many contemporary sailboats are ill-equipped to handle large quantities of chain (PS, March 2011). Resistance to corrosion is another obvious benefit of a fiber rode.

But using a super-strong fiber substitute for chain is inadvisable for many reasons, and it entails certain risks. Disadvantages of a fiber rode include susceptibility to abrasion, incompatibility with conventional anchor windlasses, and, as mentioned, the loss of shock-absorbing catenary. Although a fiber rode may take up less overall space in a locker, chain can automatically lock onto the wildcat of a windlass and drop effortlessly into the bottom of an anchor locker, making it much more reliable with a windlass.

In our view, one of the biggest disadvantages of a high-tech fiber rope rode is that it has no shock-absorbing characteristics and can fail without warning. Although galvanized chain rusts as it is reaching the end of its lifespan, the condition of a fiber rode is harder to assess. As we saw in our test of nylon rodes (PS, December 2007), the load-cycling and weathering that a rode undergoes can drastically reduce its tensile strength.

Despite these serious concerns, we decided to go forward with more testing. It seemed that some of these shortcomings could be overcome in the future, and we hoped that, as frequently occurs when we roll up or sleeves, our testing might reveal some less obvious advantages of an ultra-high-strength fiber rode. Foremost in our minds was the question of how a fiber rode might affect the anchors ability to set.

Assuming that the cross-section of the fiber or cable rode is much smaller than that of chain, we suspected that the anchors with fiber or cable rodes would penetrate faster and deeper. As many of our previous anchor reports demonstrate, the makers of new-generation anchors emphasize their ability to set deeper and quicker. Some of the claims are so amazing that if a landlubber looked at the marketing materials, he might think these contraptions were designed to carve a path to Earths core, not hold a boat in place. It stands to reason that a lower-profile rode would enhance an anchors ability to set.

The idea of using wire cable instead of chain with a recreational marine anchor isn’t new. The U.S. manufacturer XYZ used cable leaders on some production models that we tested (PS, January 2008).

The purpose of the cable was two-fold. As we saw in our report on anchor shank strength (PS, April and May 2013), an ability to dig deeply into a sand bottom is a terrific characteristic-

allowing a relatively lightweight anchor to sustain extreme loads-but it can be a problem for anchors with long shanks made of weaker steel. When the anchor is so deeply set that it doesn’t rotate and reset in a sudden wind shift, such a shift could easily subject the shank to lateral loads that it isn’t designed to withstand. So after just one afternoon squall in the sandy-bottom Bahamas, youd have a bent anchor.

The XYZ anchor we tested had a very short shank with less lever arm to resist bending. The anchors cable permitted it to dive deeper into the sand-according to the designer. The anchor held well in our tests, but we had other concerns about the design. And we were curious. How much deeper does an anchor on cable (instead of chain) actually dive?

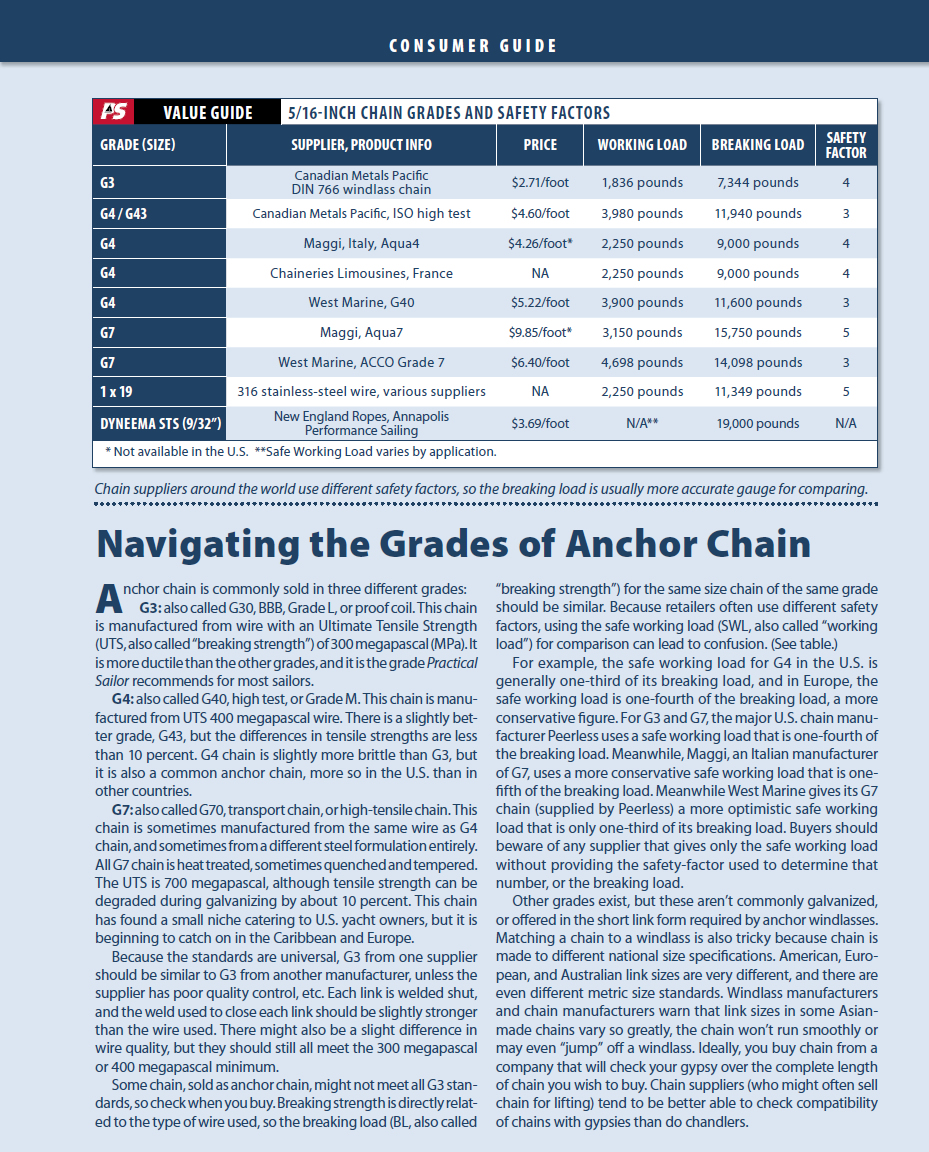

The thin, lightweight fiber versus thicker, heavier chain question is relevant, even if we intend to stick with chain. For many years, sailors have asked whether downsizing from a heavier Grade 30 (G3) chain to a smaller-diameter, but higher tensile-strength Grade 43 chain would offer enough weight savings to be worth the added expense. For comparison, 5/16-inch high-test Grade 43 (G43) chain weighs about 25 percent less than 3/8-inch Grade 30 proof coil chain, and it has nearly 30 percent higher safe working load. It also costs about 40 percent more. See the accompanying Consumer Guide.

Previously, arguments against a smaller-diameter, higher tensile-strength chain have cited price, less catenary (due to the chains reduced weight), and the brittleness of the higher-tensile metal as reasons to stick with Grade 30. However, if the smaller-diameter chain allowed newer anchors to set quicker and deeper, and we could compensate for the loss of catenary with a kellet (a weight that rides on the rode) or by attaching an effective snubber (PS, November 2013), would that tip the scales in favor of the lighter, but more expensive high-tensile chain? There are even high-tensile G70 varieties coming on the market that could permit more dramatic downsizing.

With those questions in mind, we set about testing. For details on the testing, see the accompanying How We Tested.

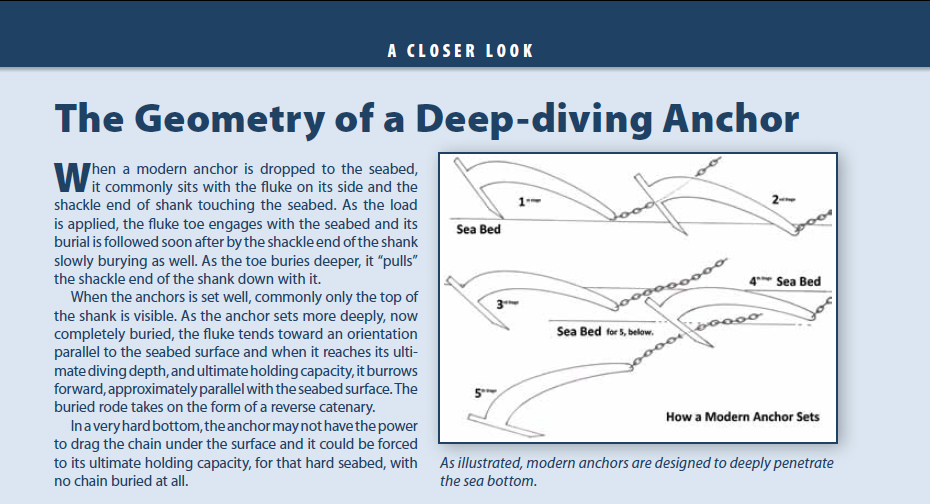

Rode only disappears below the seabed surface if it is pulled downward by the anchor. The ability of the anchor to pull the rode down is based on the load applied (the boats engine or the wind/windage) and the anchors design.

Our assumptions regarding the effect of rode dimensions on setting ability generally proved correct: The smaller a rode, the deeper the test anchor dove, effectively giving it more holding capacity. Its important, however, to put this finding into the right context. (Taken to an extreme, this finding suggests that we use Kryptonite piano-wire on our anchors so they can provide better holding power.)

The fundamental question was, how much smaller should the rode be to provide a noticeable advantage? To determine this, we started measuring. The cross-sectional area of the wire strops was easy to calculate. We estimated that 39 inches of our 3/16-inch wire cable had a cross-sectional area of about 8 square inches. The chain cross-section was more difficult to calculate. We estimated that the cross-sectional area of 39 inches of the 3/8-inch chain was about 42 square inches. For this calculation, we assumed that sand would squeeze through the holes in the chain. In reality, however, the holes add resistance, so the practical cross-sectional area is probably much larger.

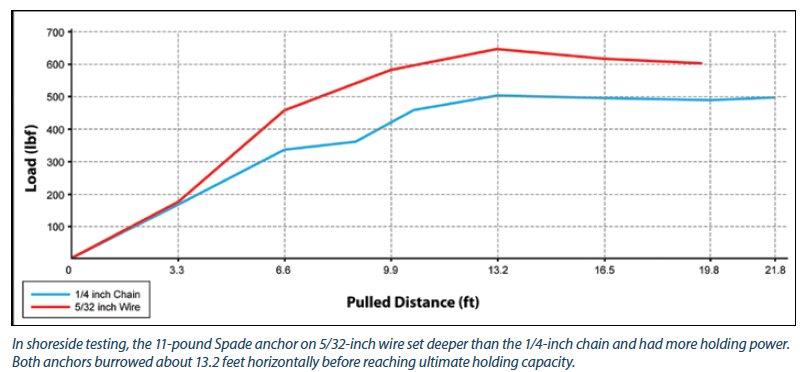

During beach testing with an 11-pound Spade anchor (surface area of the Spade is about 62 square inches), switching from the 5/32-inch wire to the quarter-inch chain rode reduced holding capacity from an average of about 610 pounds with the wire to 495 pounds with chain, a drop of about 20 percent. The anchor on wire rode set 26 percent deeper than the anchor on chain (15 inches versus 11 inches), but we saw no significant difference in the speed at which the two rodes set. This was checked by measuring the horizontal distance the anchor dug through the seabed before it reached its ultimate diving depth. Just as we predicted, the wire rode clearly allowed the anchor to penetrate deeper.

After several attempts to mathematically predict the depth of set achievable based on rode diameter, we reluctantly gave up. We simply didnt have enough data to pursue this angle. We also didnt attempt to generate anything more than some very rough predictive curves showing the relationship between holding power and depth of set. While accurate curves would be helpful in assessing the tradeoffs when choosing a rode, the wide variability in bottom conditions would make these sorts of formulas of limited use in practice.

During our on-the-water testing with the 13-pound Mantus anchor (surface area of 88 square inches, excluding roll bar), the wire rode took longer than chain to reach its maximum depth of set, but it also set noticeably deeper. With the wire rode, the anchor dug horizontally 48 inches before reaching a maximum set depth of 20 inches. By comparison, the 3/8-inch chain dragged 24 inches before reaching its maximum set depth of 15 inches. The half-inch chain dragged 19 inches before reaching its maximum depth of about 11 inches. Based on this test, there seems to be little performance advantage gained by moving downward from half-inch to 3/8-inch chain.

The anchor buried at a slightly steeper angle using the 3/8-inch chain, but this would not be enough to tilt our preference to one size chain over the other. Given the results of this test, we would expect to see little setting difference between 5/16-inch and 3/8-inch chain. So if you have 37-foot boat and are torn between these two sizes, then you can disregard setting performance as a factor. The old argument of bigger is better seems to prevail-so long as your boats bow can accommodate the extra weight (or you are comfortable with a shorter length of chain in a combination rope/chain rode).

Based solely on our shoreside testing, which has minimal statistical support, reducing the rode diameter by a factor of four with the Spade anchor increased its diving depth and ultimate holding capacity by 25 percent. In on-the-water testing, reducing the rode diameter by a factor of 5.5 increased the diving depth by 25 percent. Based on these rough calculations, it seems clear that to make measurable gains in performance simply by switching rode diameter will require a reduction in rode size that is much more drastic than the usual switch from half-inch to 3/8-inch (a roughly 50-percent reduction in cross-sectional area) or from 3/8-inch to 5/16-inch (less than a 25-percent reduction in cross-sectional area).

One might be able to drop down two sizes when switching to higher-tensile G70 chain. But, as well see in a future report on corrosion, downsizing chain diameter may not be a smart choice. And ultra-high tensile chains are also generally more brittle, a handicap when it comes to anchoring, which entails repeated cycles of dynamic or shock loading.

Although our data is limited, it seems to support what we already suspected: The burying ability of an anchor is impacted by the diameter of the rode, but not so much as to justify downsizing from one size chain to the other. In our view, the skippers skill and wisdom would more than make up for any advantage gained with a smaller chain.

If our choice was between a larger-diameter Grade 30 anchor chain or smaller-diameter, higher tensile steel anchor chain, we lean toward the bigger diameter. Our findings do suggest that a reliable, small-diameter, abrasion- resistant material like Dyneema or wire between the anchor and the chain would allow the anchor to bury deeper. At this stage, however, we don’t see any practical option that overcomes our natural reluctance to add more failure points such as swages, splices, knots, or swivels between the boat and the anchor.

The biggest unknown value in our test is how using a larger anchor might alter our findings. Larger anchors tend to dive deeper than smaller ones, but we are not prepared to speculate what difference an increase in anchor (and fluke) size might make.

Seabeds will clearly play a role in the rode-size decision as well. In harder seabeds, the impact of chain diameter on burying ability would seem to be less important as the anchor struggles to bury itself, much less pull a couple feet of chain down with it.

While the weight savings or added length of moving to a smaller chain size seems enticing, we are still not convinced this is a sensible move for most cruisers. Probably the most controversial modification that this study invites is the placement of a wire strop (of appropriate strength) between the chain end and anchor.

Because wire swages or Nicropress fittings used to join wire to an anchor will add a potential failure point, we don’t condone this modification, but if one were to experiment with this approach, the wire leader should be supplied by a qualified rigger. Buried wire, crimps, and swages will be prone to corrosion, so any such strop should be checked and/or retired on a regular basis. A high-tech fiber leader that is well insulated from chafe offers an interesting option as well, but at present, such modifications-in our view-have a place in future experiments, but not in practice among sailors.