Because a fairly large segment of our readership has expressed interest in a ‘blue-water trailerable’ sailboat, a PS subscriber shares here the philosophy and plans for just such a boat. In fact, he’s building one now, based on a successful 15-foot prototype he sailed for two years in the Santa Barbara Channel.

Trailerable sailboats can be cruised safely on long ocean passages. Reader commentary in Practical Sailor suggests that they have become a hot topic of discussion.

Believers in the concept point to the major advantages trailering offers—no slip or mooring costs, dry storage, home maintenance, and an almost unlimited choice of cruise starting locations.

Skeptics argue that boats of trailerable size (typically in the 22- to 26-foot range and of shallow draft) are too light and too small for safe, comfortable cruising. Are these opposing views irreconcilable?

I think there is a meeting ground in the form of a water-ballasted boat design that I started working on 15 years ago.

To understand the principle, consider a thinshelled sphere filled with enough water to float about half-submerged, then has been fixed inside with a horizontal bulkhead that exactly covers the interior water. To give this picture some scale, assume that the sphere is about a tall man’s height in its diameter. We know intuitively that this is a seaworthy form of craft. It can withstand external crushing forces that are large relative to its shell material strength, it is inherently stable, self righting, and, even if breached and flooded, it won’t sink if the shell material is slightly buoyant.

Now, stretch the sphere along its waterline to make it as long as a very long trailer (30′ to 35′). Shape it at the ends to define a bow and stern, add a rudder, and add just enough keel to give it reasonable directional stability under sail. Expand the beam to the maximum allowable for trailering without a special permit (8′ 6″ in California). To provide standing headroom, build a dry well in the water ballast chamber that is wide enough to walk in. Add sufficient hard ballast to the keel to replace the water ballast weight lost to this headroom well. For trailering, build hatches into the bottom of the craft that permit the water ballast chamber to flood or drain as the boat is ramped into or out of the water.

That’s the concept in theory. In practice, however, even with today’s improved materials and building methods, the arithmetic of weights and displacements prevents us from ever realizing a trailerable boat that will sail at the preferred half-submerged condition of our hypothetical craft. But you can get a trailerable hull by this scheme that will sail about one-third submerged, which probably is close enough, and that boat will have more than enough righting moment for reasonable sail-carrying. You also can get a boat that weighs relatively little out of the water compared to its displacement in the water—exactly the characteristic you want in a blue-water trailer sailer.

I describe this design as “Ultra Water Ballasted.” In 1982, I gave up working on a Westsail 32 bare hull, because we lived too far from the ocean to ever be able to conveniently maintain and cruise the boat. I then began experimenting with all sorts of trailerable cruiser ideas and in 1986 hit on the UWB. I formed a small company to further develop the concept. We built a half-scale model for proof-of-principle purposes and launched it in 1990. Two years of intermittent testing in the waters around Santa Barbara followed, then in late 1993 we began construction of the full-scale proof-of-design boat that is the subject of this article.

The Design

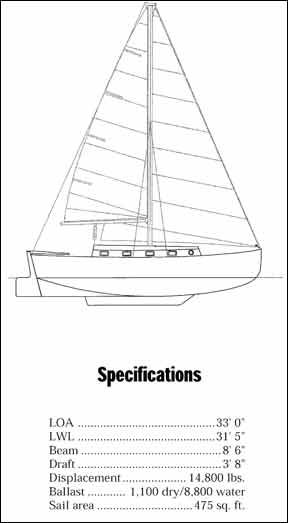

The UWB 333, is 33′ LOA, 8.5′ at the beam and draws 3.7′. About 1 foot of her draft is in the keel. The projected weights are about 6,000 pounds dry and 14,800 pounds displaced. She has a plum bow above the waterline, a slight sheer at the waist, a small transom and an outboard rudder.

In midship cross-section, she tries to be round bottomed, but only to the extent that her doublechine construction permits.

In profile, she looks like a moderate draft, moderate- to-heavy displacement cruising boat. In top view she looks the same, except perhaps for her relatively narrow beam.

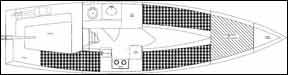

The water ballast chamber is easier to visualize if you think of it in four sections. The Fore Chamber is a beam-width section that starts from the chain locker bulkhead and ends at the forward cabin bulkhead. The Port and Starboard Middle Chambers are narrower banana-shaped sections on each side of the cabin footwell; they span the entire cabin length. Berths/seats are on top of these chambers in the fore cabin; in the aft cabin, housekeeping structures (nav table, kitchen counter, sinks, etc.) are built over them. The Aft Chamber is a beam-width section that runs from the aft cabin bulkhead to the lower transom edge. The cockpit structure is built over it. The main flood door for filling and emptying the chamber is located at the aft cabin bulkhead, under the ladder. A supplementary flood door may also be located at the mid-cabin bulkhead, if that proves necessary.

There are sub-bulkheads spaced about every 2′ in all four flood chamber sections, but they are primarily for structural strength and not for baffling. Baffling really isn’t needed because of an important feature that was built into the design. Her weight and balance, when launched dry, are such that her outside waterline and her interior ballast waterline are at the same level. That turns out to be an optimum condition for water-ballasted boats. It also means that when UWB 333 is launched, her ballast chambers will fill completely, with no airspaces left in them, and without the aid of pumps. Then, when her flood hatch is closed, the ballast water effectively becomes a sold mass, incapable of sloshing.

Because so much of her volume belowdecks is in water, storage space is in very short supply. We plan to provide some form of drainable and refillable compartment at various locations in the tops of the ballast chambers to help offset this loss. You can see how such compartments might work very well as regular storage on the boat, so long as they are made small enough that no one or two of them standing nearly empty at any time would significantly affect the boat’s ballast condition, and so long as they were only filled with goods (diesel fuel, or densely packed canned goods, for example) that weighed nearly the same as the water lost. We’ve found at least one neat way to mechanize these compartments without the need for pumps or elaborate drain systems, but that’s beyond the scope of this article.

Because the unflooded space below the waterline is very limited, the design doesn’t really lend itself to a big auxiliary engine. Instead, we plan on using twin outboards (say, two 15-hp. Yamahas or Hondas) that would “pop out” of the transom on either side of the rudder.

Because this engine configuration will prohibit, or at least inhibit, battery charging on demand, we are also toying with the idea of putting a separate power generator in its own well, either in the skeg part of the Aft Ballast section, or in the Fore Ballast section.

Construction

UWB 333 is being built as a double chine hull, using marine plywood panels of Douglas fir that are bent to the transom, the four main bulkheads and the stem piece.

The basic building block in her construction is two 3/8″ thicknesses of 5-ply plywood epoxied together into a 3/4″ panel. We chose this approach over full 3/4″ sheets because it would make bending sharply curved sections easier, and it allows us to form the bulkheads and transom more truly flat. All of the planar sections are of the basic 3/4″ dimension, except the transom which is 1-1/8″ thick (three sheets laminated) and the inner sides of the Mid Chambers, which are 3/8″ thick (a single sheet). There is extensive framing and stringerwork throughout, as dictated by the fairly conservative scan’tlings. All stringers and timber pieces are epoxy-laminated clear Douglas fir. All the wooden parts of the hull, deck and cabin are glued and filleted with epoxy, then the entire outside of the boat is glassed.

We put four main (full cross section) bulkheads in the boat to make it structurally strong, but it also allows us, at least in theory, to divide most of the interior into water-tight compartments. That would be a definite boon to the boat’s seaworthiness. But as a practical matter, making the compartments truly watertight would probably be prohibitively expensive. A compromise would be to completely seal all the bulkheads around their perimeters and install solid, tightly fitting doors. That will result in about half of the boat’s interior volume being nearly watertight. The keel structure is concrete cast in a foil shape, around a fabricated steel girder core. The keel is hung from the hull by long bolts passing through vertical wood logs that have been epoxied and glassed in place. The keel adds longitudinal strength, and also provides a large flat shoe that can bear much of the weight of the boat when it is out of the water.

The spars and the rigging are slightly oversized, although the mast height and the sail plan is smallish for a boat of this length. We have designed a “one pull does all” system that will be used for setting up the cabin-stepped mast and rigging at launch time. It operates from the tow vehicle.

Performance

UWB 333 hasn’t been tested yet, but we have sea tested the UWB concept, at least in a half-scale version.

The proof-of-principle model was a 15′ boat very similar in construction and arrangement to UWB 333, except that it had no cabin and a proportionally wider beam (6′). It weighed about 800 pounds dry and 1,600 pounds displaced. To thoroughly test its seaworthiness, we purposely overpowered it with a 22′ mast and sails from a 19′ kit boat. (We had to mount a 3′ bowsprit to accommodate all the sail.) In two years of sailing in the Santa Barbara Channel, this 15-footer showed itself to be very stable. It never came close to a knockdown, even under full sail in 6′ seas and 20-knot winds. In controlled tests, it was quickly and strongly self-righting. It was definitely not a racer going upwind, but did seem to fly when sailing off the wind.

According to stability data we’ve developed by computer, UWB 333 will produce a maximum righting moment of about 22,000 foot-pounds at any angle between 60° to 90° of heel, with positive stability apparent through 140°. It should be able to carry 500 square feet of sail in moderate winds. That’s at the low end for a typical 33-footer, but not bad for one with narrow beam.

Note that with so much of the total displacement accounted for by internal water, UWB 333 will be easy to make unsinkable. Providing about 95 cubic feet of sealed airspace inside the hull will do it, and that’s less volume than the forepeak.

But, even if it is blue-water seaworthy, with so little space onboard available for storage, can this boat really be considered a long-range cruiser? The answer is definitely yes if you’re considering a twoperson cruise, and probably yes if you’re considering a cruise with three adults, or two adults and two children.

We haven’t done the detailed analysis yet, but back-of-the-envelope calculations suggest that the extra stowage available from those drainable compartments in the ballast chambers will be sufficient.

Will a boat this large really be trailerable?

Well, not by a Honda or an old Ford LTD, or even a Chevy 1/2 ton. But the cattle people around the farming community where I live regularly use 3/4- ton pickups to pull 10,000 pounds of beef on the hoof in 4,000-pound trailers. A Chevy 2500 or Ford 250 should suffice.

A slight worry is how the trailering rig will behave in initial retrieval, when the boat still weighs almost 15,000 lbs.

Will a 3/4-ton truck be able to tow nearly 20,000 lbs. even the few inches up the ramp needed to start the ballast water draining?

If not, we may have to provide for winching the boat up those first few inches. Or we may have to pump out some of its ballast before beginning the retrieval.

My purpose in writing this article was twofold: I particularly wanted to see what the reactions of thePS readership would be to the blue-water trailer sailer that we’re building; and I wanted to encourage free thinking on the practical and technical merits of ultra water ballasting.

As you may have guessed, UWB 333 is something of a back-burner project. We occasionally dream about going into production with a family of UWB trailerables, if the present experiment proves the concept. But then we confront the basic questions: Would there be a market? Could such boats be produced for what the market would bear?