Tony Smith’s most recent design is the third iteration of a 34-foot catamaran that his company, Performance Cruising, Inc., of Annapolis, first introduced to the American market in the 1990s. The result of Smith’s continued tinkering, the 105Mc, is, he says faster than the original. Since this is our first review of the Gemini cat in any version, we can’t compare. But we can report that this boat is fast for a cruising catamaran. It’s also evidence that when a builder is willing to incorporate new and sometimes expensive ideas in design development, the results can be worth the investment.

Company History

Tony Smith is a British expatriate who, with wife Susan, formed Performance Cruising in 1980. Following graduation from the University of East Anglia with a degree in engineering, he studied the mechanics of boat performance while participating in singlehanded races, including the first 2,100-mile Round Britain race, in which he finished fourth.

He began his boatbuilding career by constructing a 24-foot Piver trimaran in a shed in England. Then, in 1969, he developed a method of integrating foam coring with fiberglass, and produced the Telstar, a 26-foot, folding trimaran. During a 10-year run, 300 of the boats were sold worldwide. Along the way, he also was involved in the construction of 30- to 70-foot custom yachts.

Eventually emigrating to the US, he introduced the Telstar to the US market. Following the loss of the molds in a fire in 1981, he re-emerged on the scene with the design for a new catamaran, appropriately called the Phoenix, the first Gemini.

In 1993, the company launched the Gemini 3400, the first catamaran with a lifting underhung rudder system. It was eventually modified and reintroduced as the 105M, and the 105Mc is the most recent upgrade.

With 800 boats on the water, the company claims to be the best-selling catamaran manufacturer in the US. In 2002 the company’s 20 employees built and sold 54 boats, valued at $8 million, in a 16,000-square-foot factory. An additional 25,000 square feet of production space are currently under construction.

Six dealers are located in Florida, Maryland, California and Washington. Though the company also sells directly to customers, there’s no price advantage, and a connection to a local dealer would be an advantage if warranty issues arise.

A prototype for a new Telstar trimaran is undergoing sea trials, and can be seen on the Performance Cruising website.

Appearance/Design

Smith’s perspective on sailing and yacht design fits the definition of a multihull advocate. From his standpoint, sailing is about speed, comfort, and stability.

From an aesthetic standpoint, comparisons of a 35-foot catamaran to a cruising monohull are usually akin to comparing a coupe to a delivery van. Though both may be designed to accomplish the same purposes, the execution varies greatly. Many cruising multihulls present a slab-sided appearance, and boxlike profiles with cabins extending high above deck level.

The 105Mc does not. When viewed from the quarter, the Mc has a relatively sporty appearance, even with the addition of a cockpit canopy that raises the boat’s profile. Viewed on the centerline, there’s no question she’s a cat, though the unsightly strakes of the 3400 version have been eliminated.

Smith says Gemini catamarans are designed for “serious ocean cruising,” adding that “a 23-day passage with son Neil across the North Atlantic opened my eyes to her capabilities.”

During the passage, he says, the pair encountered 45-knot winds and 35-foot waves, but never felt they were in harm’s way, and were comfortably ensconced in the cockpit wearing layers of fleece.

As most readers know, voyaging in multihulls offshore demands some different sailing techniques and priorities than sailing ballasted monohulls. The high initial stability of a multihull works both ways: the boat will mightily resist capsizing, but if it does go over and invert, it will be virtually impossible to right again without the assistance of a large ship with a cargo crane. Assuming the essential integrity of the hulls, the platform will be stable, and the crew will live in an inverted world pending rescue. However, very few owners of cruising multihulls have the occasion to take their boats into conditions that seriously challenge their initial stability, and (North Atlantic deliveries by designers notwithstanding) this Mc will usually be sailed in coastal or near-coastal waters.

The Mc has the same basic dimensions as the 3400. Note that the weights published in the company’s sales literature and on its website are at odds with each other. Dimensions in this article are accurate, Smith says: “The 105M and the Mc are the same weight—9,600 pounds. We realized after our trans-Atlantic trip that the weights we had given for the 105M were too low. We finally bought a pair of scales!

“The mast on the Mc is a foot taller than the 105M, and has a 1′ crane.” The mainsail now carries a large roach and full battens, increasing mainsail area from 260 to 340 square feet, a hefty jump. The 150% genoa carries 350 square feet.

A new option is a flat-cut overlapping genoa known in the multihull world as a “screecher.” This 490-square-foot sail produces spinnaker performance without adding a pole and guys.

The furling drum for the screecher tack can move athwartships on a curved track that is mounted at the prows of both hulls and across the bowsprit/anchor platform, forward of where the anchor is dropped through. This movable tack allows more flexibility with sheeting angles, especially when attempting to work to weather.

The cut of the sail allows it to be sailed to within 50 degrees of the apparent wind, and the tack arrangement doesn’t get in the way of the ground tackle.

Smith describes the hull shapes, introduced in 1995 on the 105M model, as “revolutionary in the multihull industry.” They have a 9:1 length to width ratio.

“They closely resemble a racing monohull,” Smith says. “They are shallow and fat, with a teardrop shape to produce more speed and increase load-carrying capacity. Compared to the 3400, narrower shapes allow hulls to be moved outward to produce stability without increasing beam.”

The foredeck has 39″ of clearance at the bow. (Note that the builders refer to the deck area forward of the cabin as the “bridge deck,” but we’ll use “foredeck” as we don’t want to confuse it with the bit of decking often found between the cockpit and the companionway.)

Asymmetric centerboards were designed to reduce turbulent drag and increase lift. Constructed of a combination of fiberglass mat and Kevlar surrounding closed cell foam, they pivot upward to allow shallow-water anchoring. Located in cavities on the hulls, they are raised from inside the main saloon, a convenient arrangement that does not interfere with galley or navigational chores. Smith says the combination of hull and centerboard redesigns produced a boat requiring “25% less energy to push it the same speed.”

The cockpit sole has been lowered slightly to increase headroom to 6′ 7″. However, the modification does not impair the helmsman’s view forward through a large Lexan window that spans the deck. The wheel was moved outboard, allowing the helmsman to steer from the rail. Mainsail controls are now located on a thicker transom that provides more comfortable seating for crew, and the stern has been modified to allow access from swim ladders.

Smith’s personality is that of a consummate tinkerer. However, unlike industry giants, he enjoys the luxury of being able to continually focus his attention on one product with an eye toward evolutionary improvements.

Deck

One early impression while sailing this boat is that the cockpit doesn’t resemble a spaghetti factory, though the boat is as well-equipped with name-brand equipment as a similar-sized monohull.

Halyards are led to winches on the mast rather than sheetstoppers on the cabintop because, Smith says, “you’re operating on a stable platform, even in a blow,” so moving forward is not as treacherous.

The mast carries straight double spreaders and is stepped on deck atop the main bulkhead. The headstay is opposed by a split backstay with tensioner. Halyards are internal. Shrouds are dead-ended on chainplates at the main bulkhead. The chainplates are bolted through steel strapping bonded into the foredeck area.

The mast is rigged with permanent checkstays angled 20 degrees aft. These are supported through the deck by a stainless steel rod married to a steel plate mounted horizontally in the hull. The powerful sailplan is well supported.

As is true on most catamarans, movement forward is relatively effortless. The combination of 14″ wide steps, a handhold on the canopy, a stainless steel handrail recessed in the cabintop, and 10″ wide decks, allowed us to move forward safely in blustery conditions we encountered on a test sail.

The large sundeck and plastic seats attached to the forward rail provide passengers comfortable lounging spaces forward of the mast when underway. Unlike a lightweight monohull, the cat’s performance is relatively unaffected by weight on the foredeck. Storage compartments are located in each hull.

The helmsman steers seated on a 27″ wide x 16″ deep seat that affords unrestricted views forward. We sailed with three passengers under the canopy without interfering with the skipper. Though the saloon may be enclosed in stinky weather, clear windows on the top half of the cockpit bulkhead slide open to allow the driver to commiserate with passengers.

The mainsheet is attached to the end of the boom and a section of track mounted on the stern rail that affords excellent sail control. However, the task becomes difficult when the cockpit is enclosed by a clear vinyl cover.

Lockers for storage of propane tanks and an optional generator are also located in the cockpit.

Belowdecks

Step over an 11″ doorframe into the saloon and there’s no comparing the open spaces of the Mc’s 14-foot beam to the view along the saloon of a typical 34-foot monohull. That impression is augmented by a portlight array that provides 360-degree visibility, and four Bowmar hatches that allow light and air to flow in from overhead.

Fiberglass surfaces are light and shiny, and veneers nicely finished. The fit of most cabinetry is above average.

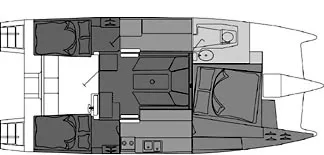

The centerpiece of the saloon is a C -shaped dining area surrounded by cushions that, with the table removed, serves as a conversation pit. When lowered, the table converts to a double berth.

The space to port, amidships along the hull, is dedicated to the navigator. The master stateroom is forward amidships and to starboard, with the bunk set at a slight angle. The head is forward to port. There’s an elongated galley on the starboard side, matched by a navigator’s station along the port side, and twin staterooms aft.

The boat has enough bunks for 6-8 adults, but Smith rightly calls it “a couple’s boat.” This is a refreshing contrast to builders who overstate the livability of their products.

In addition to its spaciousness, the minimum headroom, even in the head, is more than 6′, so most passengers will be able to stand upright.

Though the interior is not dramatically different than typical production boats, several touches contribute to a favorable impression. The dining table is solid teak. Leaves increase the surface of the table to feed 6-8 adults, and it rotates 90 degrees to fit the crowd.

Part of the navigator’s 89″ long work surface is elevated and shaped so a chart kit fits securely.

Aft staterooms have a 28″ x 28″ area in which to change clothes without banging the hull. Both have double berths and opening ports. Propane sensors and fume detectors are standard equipment in the staterooms, as are audible alarms.

The size of the galley on the Mc was increased by locating countertops on the inboard and outboard sides of the passageway, and the addition of drawers and cabinets. Similarly, room for a built-in microwave was added. The space is filled with a Voyager 2000 two-burner stove with oven and broiler, and two-section stainless steel sink. A solar vent is located overhead. The four-cubic-foot refrigerator is a Dometic American.

Skipper’s quarters are filled with light by a port spanning the hulls that presents views through black Lexan. The queen-sized berth sits on an island with nothing below it but water. Storage is forward in the hull, and in bins to starboard. The aft bulkhead of the compartment is enclosed by smoked glass that slides out of the way to provide a view corridor for the helmsman.

The head compartment on the Mc is big, bright, and well-ventilated. A good touch is a siphon arrangement that allows fresh water to be pumped through the toilet after every use, helping to eliminate odors.

Throughout the catamaran, spaces are well-organized and proportioned, so crews will rest, eat, and sleep in comfort. The skipper’s quarters are large enough to help compensate for the monthly mortgage payment and slip fees.

Construction

The Gemini plant is a model of efficiency, with no wasted space, as we learned during an afternoon tour. Boats typically require 5-7 days to proceed past six stations to a forklift waiting to launch them into a creek behind the facility.

Hulls, decks, and interior liners that provide reinforcement of the structure and a base for furniture are solid fiberglass. Liners are glassed and tabbed into the hull prior to installation of the deck.

The lamination schedule calls for vinylester resins bonding a barrier coat of 1.5-oz mat followed by two layers of 18 x 15 Cofab mat. The only coring is 1/2″ end-grain balsa across the foredeck and cabintop, and in cockpit areas in which there are no deck fittings.

The hull-deck joint is a shoebox design bonded with something Smith calls “black poly putty,” produced by Cook’s. Most builders prefer 3M5200 but Smith has used the putty for 20 years because “it has an 8- hour setup time that allows workers to be more precise in the placement of the two sections. It makes a phenomenal bond that is not brittle because it is chemically cured, a better alternative than air-cured products.”

Once installed, the deck is secured with stainless steel fasteners on 5″ centers and the joint is covered by a gunwale guard.

Following his trans-Atlantic trip, Smith decided that the boat needed to undergo a weight loss program. When constructed, most boats are heavier than designed, and the Mc was no exception. Smith estimates the boat was 1,000 pounds too heavy.

“It was not a matter of speed, but of comfort,” he said. “I felt that by reducing the boat’s weight I could increase its buoyancy and produce a more comfortable ride.”

To that end, he replaced drawers in the forward stateroom with bins, substituted 1/2″ plywood for 3/4″ in some areas, and lightened the lamination in some nonload-bearing areas.

The boat’s Achilles heel could be the solving of wiring or plumbing problems, should they occur. Wiring looms are attached to the liner prior to the installation of the liner to the hull, and are virtually inaccessible. Of the arrangement, Smith says “our looms are foolproof. Remember, we’ve been doing this for 20 years and the process is evolutionary, not revolutionary.” Spare hoses are installed during construction to ease retrofitting appliances, and 12-volt wires are run through PVC to avoid heat and chafe. Wires exit the mast into the forward stateroom, and can be accessed in a panel between the deck and liner. Still, we wouldn’t want to perform subcutaneous surgery on this boat.

Performance

We sailed the 105Mc on the day after the Annapolis Boat Show ended, when multihull manufacturers congregate to offer rides to interested sailors. A northeaster arrived that morning, bringing winds that built to 25-35 knots and produced a 3-4 foot chop. We were the only multi hull on the water.

With the wind abeam when we slipped dock lines, once we were underway she motored well despite her windage. On the bay, the boat sailed with little heel, and fast, under a reefed mainsail and a flat, 90% jib. Nearby, the three-person crew aboard a 30-foot monohull struggled to keep their boat on her feet.

Sailing closed-hauled, speed fluctuated between 6.5 and 7 knots. The short chop produced a bumpy ride and water over the bow, but we stayed on course with very little leeway. When we cracked off, speed fluctuated between 7 and 12 knots in wind speeds ranging from 17 to 25 knots. She was easy to steer, and responsive when we made sudden maneuvers to avoid crab pots.

The canopy protects crew from the elements, but may provide a false sense of security, as we learned when we moved forward from its protection and stepped into a chilly breeze and seaspray. Handrails are well located, and the nonskid was effective on the wet deck.

The boat is propelled under power by a single Westerbeke diesel, using an outdrive leg than can be lifted clear of the water. The current standard engine is 27-hp, up from the 20-hp engine previously installed.

Conclusions

This third generation of Gemini cat is an improvement over her predecessors. She sails as well to windward as can be expected of a cruising catamaran (better than many) and shows good speed and stability off the wind. She’s easy to operate, and well-built. Spaces belowdecks are comfortable and larger than those on similar-sized monohulls, though the lack of a second head will be an inconvenience for skippers overnighting with large crews. With the 27-hp engine, a 150% genoa and furler, and electronics, the tab for the 105Mc is $129,500. Add a screecher for another $5,400.

Contact – Performance Cruising, Inc., 410/626-2720, www.geminicatamarans.com

Where is the production site, and can a tour of the facility be arranged?

The boat is no longer in production. Tony retired and sold the company. I think during the 2005 market crash everything fell apart. The outdrive and engine aren’t made anymore. The new owners redesigned the boat and ruined the original idea. They tried to design a boat for the single handed rental market in the Caribbean with a deeper draft and fixed keels. It didn’t sell well.