When Leon Slikkers founded S2 Yachts in 1973, much of the attention to detail that had previously characterized Slickcraft powerboats—Slikkers’ earlier boatbuilding venture— traveled with him to the new boatbuilding company. In the 13 years S2 sailboats were in production (S2 still makes powerboats), the company produced a variety of modern cruising designs from the board of Arthur Edmunds, all characterized by longish fin keels, freestanding spade rudders, straight sheerlines, and a staggering variety of draft options and cockpit locations.

In the early ’80s, S2 reached more for the performance market with the Grand Slam series of small boats, and the 10.3 “offshore racer-cruiser.” These higher performance boats were designed by Scott Graham and Eric Schlageter, well known for their MORC and smaller IOR designs.

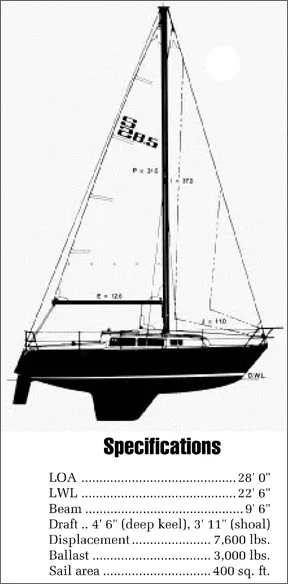

The S2 8.5 is a 28-footer cast in the company’s traditional mold. Her hull dimensions, sail area, displacement, and general design characteristics put her square in the middle of the modern 28-footers such as the Tanzer 8.5, Newport 28, O’Day 28, and the Pearson 28.

The boat’s styling is conventionally modern. She has a fairly straight sheer, fairly high freeboard, and low, raked cabin trunk with dark tinted flush ports. Production of the 8.5 ran from 1981 to 1983. The boat was replaced by the similar S2 8.6, which continued until S2 stopped making sailboats in 1986.

Construction

The hull of the S2 8.5 is a solid hand layup. Glasswork is excellent, and is noted by owners as one of the main considerations in buying the boat. Gelcoat quality is excellent.

Slight roving printthrough is evident, but it is not objectionable. Minor hard spots are visible in the topsides, probably caused by the attachment of interior furniture and bulkheads.

The deck molding is cored with end grain balsa, giving a solid feel underfoot as well as providing reasonable insulating properties.

S2’s hull-to-deck joint is the basic type that we would like to see adopted throughout the industry. The hull molding has an inward-turning flange, onto which the deck molding is dropped. The joint is bedded in flexible sealant, and through bolted on six inch intervals by bolts passing through the full length slotted aluminum toerail. The joint is also through bolted across the stem.

All deck hardware is properly through bolted, although pulpits, cleats, and winches merely use nuts and washers on the underside of the deck, rather than the aluminum or stainless steel backing plates we prefer.

Another feature of the hull-to-deck joint is a heavy, semi-rigid vinyl rubrail at the sheerline, quite aptly termed a “crash rubrail” by S2. This will go a long way toward absorbing the shock of the inevitable encounters with docks and the other hard objects that seem to be attracted to the topsides of the typical sailboat. Although this rail is black when the boat is new, it had dulled to a chalky gray on older S2’s we examined.

The builder advertises “bronze seacocks on all through hull fittings.” These are not traditional tapered plug seacocks, but are ball valves mounted directly to through hull fittings. A proper seacock—whether it uses a ball valve or a tapered plug—has a heavy flange to allow through bolting to the hull. This is an important safety feature. Should a valve seize, it may become necessary to apply a great deal of leverage to the handle in order to open or close the valve. The deeply threaded through hull stem can easily break under these conditions, and more than one boat has been lost in this manner.

We also suggest that seacocks be installed on the cockpit drain scuppers and the bilge pump outlet, both of which may be under water while the boat is sailing. Light air performance would benefit by the fairing in of the through hull fittings, particularly the head intake and discharge, both of which are far enough forward to have a significant effect on water flow past the hull.

Ballast is a 3,000 pound lead casting, epoxied inside a hollow keel shell. We prefer an external lead casting bolted to the hull for its shock-absorbing qualities and ease of repair. This preference was reinforced recently when we examined an old Bristol 27 just sold by a friend. The surveyor noticed dampness near the bottom of the leading edge of the keel, which showed slight external damage. Probing the loose putty revealed some abrasion of the glass keel molding. In order to sell the boat, it was necessary to grind away a large portion of the glass at the front of the keel, dry out the ballast, and reglass the lead—a job that took several days of work and cost our friend a fair chunk of money.

Much of the boat’s interior structure is plywood, glassed to the hull. Fillet bonding is neat and workmanlike with no rough edges to be found.

Chainplates are conventional stainless steel flat bar, bolted to bulkheads and plywood gussets in the main cabin. These are properly backed with stainless steel pads. Due to the fact that the hull is lined throughout with a carpet-like synthetic material, it is not possible to examine the bonding of the chainplate knees to the hull. The stemhead fitting is a stainless steel weldment, through bolted to the deck and hull and reinforced inside the hull with a stainless steel gusset to prevent deflection of the deck from the pull aft of the headstay. We’d like to see a metal backup pad behind this fitting rather than the washers which are used.

General construction is thoughtful and well executed, with excellent glasswork, a strong and simple hull-to-deck joint, and reasonably installed hardware and fittings.

Handling Under Power

Although some early models of the 8.5 used a seven horsepower BMW diesel, the 1982 version employs an eight horsepower Yanmar. These small Yanmars are quite impressive, light in weight and far smoother than the company’s older rockcrushers.

Because of the high freeboard and considerable windage of the 8.5, the standard engine is the absolute minimum power plant for the boat. Recognizing this fact, the company offered a 15 horsepower, two-cylinder Yanmar as an option. For another 75 pounds and $1,150, we would want this option on the boat if the ability to get places under power is a real consideration.

The extra fuel consumption of the larger engine will scarcely be noticed. The 18 gallon aluminum fuel tank will probably give a range under power of over 250 miles—more than adequate for a 28 foot cruising boat.

The fuel tank is located under the cockpit and is securely mounted and properly grounded. There is an easily reached fuel shut off between the engine and tank. Unfortunately, the fuel fill is located in the cockpit sole. Spilled diesel oil turns even the best fiberglass nonskid into an ice skating rink. Fuel fills should be located on deck, where spills can be efficiently washed away.

Engine access is via a large removable panel on the inboard face of the quarterberth. This panel lacks any kind of handhold to make it easily removable, which will discourage regular checking of the engine oil. The top companionway step also removes for access, but it’s a long reach to the dipstick.

There is no oil pan under the engine. It will be necessary to be very careful when changing oil to keep the bilge clean. We have yet to see anyone change oil and filters on a boat engine without spilling something.

With the quarterberth panel removed, access for routine service is excellent. The quarterberth has remarkable headroom over, so that the mechanic will not feel like a trapped spelunker after a half hour of work. Engine removal will require some joinerwork disassembly.

Handling Under Sail

The S2 8.5 is no slug under sail. Her PHRF rating of 174 to 180 compares very favorably to other boats of her size and type. The Sabre 28, for example, has a rating of 198. The Pearson 28 about 195, and the O’Day 28 about 198.

Part of this is no doubt due to the fact that the standard sails on the boat come from the North loft. While North’s OEM sails may not be the vertical cut Mylar-Kevlar wonders that adorn custom boats, they’re a lot better than most.

S2 now uses Hall spars. The simple masthead rig is extremely clean, with airfoil spreaders and internal tangs. The boom features an internal outhaul and provision for two internally-led reefing lines, with cam cleats at the forward end of the boom.

The deck-stepped mast is mounted in a stainless steel deck plate incorporating plenty of holes for the attachment of blocks. Halyards and Cunningham lead aft along the cabin house top to a pair of Lewmar #8 winches. Lewmar #16s are optional, but hardly necessary.

The main is controlled by a six-part Harken rig mounted on the end of the boom, and a Kenyon traveler mounted on the aft cockpit coaming. This will work fine with the tiller-steered version of the boat. With wheel steering, the mainsheet is likely to be a nuisance to the helmsman.

Because of the end-of-boom sheeting, a boom vang will be essential for full mainsail control. Ironically, the boat’s drawings show almost mid-boom sheeting, with the traveler mounted on the bridgedeck at the forward end of the cockpit. This is probably a better arrangement, although it heavily loads the center of the boom and requires more sheeting force.

Despite the fact that the shrouds are set well in from the rail, the boat lacks inboard headsail tracks. Rather, you are limited to snatch blocks shackled to the toerail track. A six-foot piece of track set inboard of the rail would be a useful addition.

Standard headsail sheet winches are two-speed Lewmar #30s. Options include both larger winches and self-tailers, both of which are worth considering for either racing or cruising. The cockpit coamings are wide enough for mounting larger primaries and secondaries.

The high-quality rig and sails add to the price of the S2, but they are additions well worth the cost.

Deck Layout

The deck layout of the 8.5 is clean and functional, with no toe stubbers to catch you unawares. There are two foredeck mooring cleats, but no bow chocks. The necessity to lead an anchor line well off the boat’s centerline, coupled with high freeboard forward, is likely to result in a boat which sails around on her anchor or mooring. The 8.5 has a pair of wide stainless steel chafing strips at the bow which will greatly protect the deck from the chafe of the anchor line.

The 8.5’s foredeck anchor well is one of the best we’ve seen. It is shallow—just deep enough to hold an anchor and adequate rode. There are double scuppers, which offer less likelihood of clogging. The lid is held on by a full-length piano hinge, and there is a positive latch.

The shallow locker well above the waterline means that water is less likely to enter through the scuppers, which can be a real problem with a deep anchor well. When the bow pitches into waves, a deep anchor well can fill with water, and if the scuppers clog with debris, you can find yourself sailing around with several hundred pounds of extra weight in the worst possible position. There is no provision for securing the bitter end of the anchor rode, but a big galvanized eyebolt installed in the well by the owner will solve that one.

The running lights leave something to be desired. Their location at deck level just aft of the stem makes them vulnerable to damage when handling ground tackle. We much prefer an international style bicolor mounted on the pulpit, another two feet off the water: easier to see, and out of the way. Wiring for the running lights is exposed in the anchor well, and should be secured out of the way.

A recessed teak handrail runs the full length of the cabin trunk, serving the dual function of heavy weather handhold and cabin trim piece. Its shape makes it far easier to oil or varnish than the conventional round handrail, although the wide, flat section seems somewhat awkward after years of grabbing round rails.

The 8.5’s cockpit is the maximum size we’d want to see on a boat of this size. The T-shape is designed to accommodate the optional wheel steerer, yielding a somewhat odd layout for the tiller-steered version. A bench seat spans the aft end of the cockpit. Although this makes good seating in port, we doubt that you’d want anyone sitting there under sail: too much weight in the end of the boat. It does make a natural helmsman’s seat for wheel steering.

The engine controls and instrument panel are also located at the aft end of the cockpit, and are basically inaccessible to the helmsman of a tiller-steered version.

There are two lifting lids in the aft cockpit bench, giving access to a cavernous space under the cockpit. To be useful, dacron bags should be fitted to the inside of these lockers. Then, they’ll be handy stowage for spare sheets and blocks.

There are comfortable contoured seats along each side of the cockpit, with a huge locker under the port seat. Although plywood pen boards somewhat separate this locker from the engine space under the cockpit, it would be far too easy for deeply piled junk to get knocked over the board and into the engine. This locker should be partitioned into smaller spaces unless it is to be used exclusively as a sail locker.

The battery boxes, fitted at the forward end of the locker, could benefit from plywood or fiberglass lids to keep battery acid off gear which might find its way onto the batteries. The box is designed to take two batteries—one battery is standard—stored in plastic containers. A single lid covering the whole box would be more efficient.

The huge cockpit will accommodate up to six for sailing, and eight for in-port partying. The cockpit seat bottoms are contoured, and the cockpit coamings slope outboard for more comfortable seating. However, the seats are both too narrow and too short for sleeping.

The forward end of the cockpit is protected by a narrow bridgedeck. However, the cockpit coatings extend a full foot above the level of the bridgedeck, To block the companionway to the level of the top of the coamings will require leaving two of the three drop boards in place when sailing.

Although there is moderate taper to the sides of the companionway, making it easier to remove the drop boards, it is still necessary to lift each board about five inches before it can be removed. This is far safer than many tapered companionways, where boards practically fall out if you look at them wrong. The companionway slide is one of the best we’ve seen. It’s a contoured piece of acrylic fitted with a convenient grabrail. It slides easily in extruded aluminum channels, and is fitted with a fiberglass storm hood. As on many boats, the aft cabin bulkhead slopes forward, rendering it impossible to leave the drop boards out for ventilation when it rains.

Belowdecks

Owners consistently praise the interior design and finishing of S2 sailboats. From looking at the 8.5, it’s pretty easy to see why.

There are no exposed interior fiberglass surfaces except the head floor pan molding. The hull and cabin overhead are lined with a carpet-like synthetic fabric. While this will undoubtedly cut down on condensation, we at first wondered how this fabric would hold up over time. Inevitably, the hull liner and even the overhead will get wet. In freshwater areas, this is no problem. The water will eventually evaporate. In salt water, however, wet fabric never seems to dry. Salt draws moisture like a magnet draws steel. Since first seeing this boat, however, we’ve had good experiences with the fabric. Be sure, however, to get a good wet-or-dry vacuum to keep it clean.

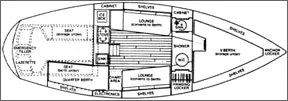

Interior layout is fairly conventional, with Vberths forward, and immediately aft, a full width head. The head can be closed off from both the forward cabin and the main cabin with solid doors—a real luxury in a boat this size. There is a large hanging locker in the head, and reasonable storage space for toilet articles.

The word for the main cabin is “wide,” with the settees pushed as far outboard as they can go. Décor is a little heavy on the teak for our taste, but it is one of the better coordinated interiors we have seen. S2 had a good interior decorator.

A fold-down dining table seats four. When folded against the bulkhead, it is held in place by a single latch, which makes us nervous.

Neither settee is full length. The foot of the port settee runs under the galley counter, making it long enough for sleeping, although your feet may feel a little claustrophobic in the tiny footwell.

The starboard settee is an unusual configuration. The aftermost 12″ of the settee folds up to form an arm rest, leaving a gap between the end of the settee and the head of the quarterberth.

Inexplicably, this gap is referred to on the accommodation plan as a “charting area,” although there is neither a standard nor an optional chart table. It’s sort of like the designer ran out of energy before completing the interior design.

Over the non-existent “charting area” is the best electrical panel we’ve seen on a 28 foot boat. The panel has a locking battery switch, battery test meter, and a panel with room for 14 circuit breakers, although only half are installed on the standard boat.

The space is welcome, since with the proliferation of marine electronics most electrical panels are woefully inadequate.

Most quarterberths tend to induce claustrophobia. That of the 8.5 is more likely to exacerbate any tendencies you might have to agoraphobia. At last, a quarterberth which will not give you a concussion when you sit bolt upright in the middle of the night after your neighbor drags down on you in a wind shift.

The standard main cabin sole is carpet-covered fiberglass. For an additional $325, teak and holly was available for the traditionalist. We’d want it. Unfortunately there is no access to the bilge in the main cabin. None. This is inexcusable, and could be dangerous. A few hours with a saber saw should solve this rather basic problem.

The galley is workable and accessible, with no awkward posturing required to do the dishes. The sink gets an A+. It is a full nine inches deep, is large enough to take a frying pan, and mounted close to the centerline.

In contrast, the icebox gets a C-. It is larger than normal on a boat of this size, but it drains to the bilge, has a poorly insulated top, and a tiny, uninsulated hatch without a trace of a gasket. Boo.

Because of limited counter space, the two burner Kenyon alcohol stove is mounted athwartships, rather than fore and aft. This means that the stove cannot be gimballed, and that it is necessary to reach across the inboard burner to reach the outboard one. Given the fact that countertop gimballed stoves are usually dangerous, the lack of gimballing doesn’t bother us much. What does bother us is that if you want to upgrade the stove to something more functional, the limited space allocated will stretch your ingenuity.

A fold down table at the end of the galley counter gives additional counter space, but it must be left up in order to use the port settee for sleeping.

Roominess, excellent execution, and good color coordination are trademarks of the interiors of all S2s, and the 8.5 fits well into this enviable tradition.

Conclusions

The S2 8.5 is a good boat for cruising the Great Lakes or any coast in comfort and a certain amount of style. Her appearance may be a little modern for traditionalists, with her straight sheer and European-style cabin windows.

Pricey? Yes, but when you look at the things that go into the boat—the rig, good sails, and a comfortable, well finished interior—the price may seem a bit less painful. You still pay for what you get.