Sometimes we go to great lengths to look at the boats we evaluate. It might involve a flight across the country to a boatbuilder, or it might be as close as the local boatyard and marina. Evaluating a serious cruising boat, however, often takes a little more effort.

In the case of the Holmann-designed FD-12, we first traveled by air to Belize in Central America, and then by outboard-powered dugout canoe over 20 miles of open ocean to a jungle river in Guatemala. We finally found FD-12 sisterships Winterhawk and Moonshadow peacefully anchored off the banks of Lake Izabal, 30 miles up the Rio Dulce. We spent a week cruising the FD-12 on this tropical fresh water lake.

Here’s what we found out.

The Boat And The Builder

The FD-12 resulted from the collaborative efforts of German designer Eva Holmann and Dutchman Willem Eickholt. In the mid-1970s Eickholt, part owner at the time of Flying Dutchman Yachts, decided to build his dreamboat. A lifelong sailor, he knew he wanted an aft-cockpit, flush-decked cutter of moderate displacement and minimum wetted surface with a fin keel, skeg rudder, canoe stern, and clipper bow. “I also wanted her to be fast. Long passages bore me,” says Eickholt. “Last but not least, I wanted her to be pretty in a timeless way.”

He chose Holmann, known for her fast, unsinkable cruising designs, to help design the boat.

“Generally speaking, Eva and I got along well,” Eickholt told us. “The stormy part of our relationship was Eva’s refusal to draw an ‘ancient, speed-robbing silly canoe stern,’ and my equal determination to have the boat the way I wanted her.” But when the German-Dutch war ended, their ‘war baby’ proved an impressive performer despite, as Eva said, its ‘repulsive’ stern.

Since the late 1970s, 25 FD-12s have been built at Ta Yang Yacht Building Co. and other yards in Taiwan. In 1980, Eickholt broke away from Flying Dutchman Yachts to form Willem Eickholt and Associates, Inc., and continued to build the FD-12. Each boat is built “on order,” and interiors are totally customized.

Construction

The FD-12 hull is a fiberglass sandwich cored with Viny foam, a Japanese product similar chemically to Airex. Viny foam, which is lightweight, and provides both strength and resiliency, also insulates against heat and sound, and helps to eliminate condensation within the cabin. A pair of full-length longitudinal stringers and fiberglass and foam floor timbers athwartships provide further stiffening.

Teak plywood bulkheads extend to the base of the hull. A Viny foam wedge insert at the foot of the bulkhead creates a broader bonding angle and distributes transversal stress to prevent bulkhead fractures. The entire bulkhead assembly is fiber-glassed to the hull.

The hull-to-deck joint is an inward-turning hull flange, overlapped by the bulwark flange. The joint is through-bolted, filled with Thiokol, coated with fiberglass, and then topped with a teak caprail. This is a strong joint. The owners of the two FD-12s we sailed in Guatemala reported no hull-to-deck joint leaks.

The deck is cored with Philippine fir rather than traditional balsa. Fir is strong, but it’s heavy, and puts unnecessary weight high in the boat where you don’t want it.

A massive teak rubrail with rectangular-shaped portholes recessed into it offers some protection to the midsections of the hull. However, installing portholes in topsides is always difficult, and both boats in Guatemala had experienced porthole leaks. Leaks in deckhouse ports are simply an annoyance. In a hull they can be dangerous and in extreme cases can lead to loss of the vessel.

The chainplates are stainless steel straps that extend through the deck. Four chainplates (two port and two starboard) bolt to bulkheads, but two chainplates (one port, one starboard) bolt to fiberglass knees. The knees are hefty, but several owners of FD-12s report their decks have lifted due to a kneeto-hull bond failure. (On the first dozen or so hulls, Ta Yang Yacht Building Co. gelcoated the hull interior before glassing in the knees. In later hulls, knees were properly bonded to the bare hull.)

To form the mast step, an aluminum H-beam through-bolts to a floor timber, and the mast sits in an oval-shaped aluminum weldment that bolts to the mast step. This arrangement provides a strong platform and eliminates corrosion problems that occur if a mast is stepped in the bilge.

The FD-12’s underbody has a cruising fin with a long run and a full skeg. The keel is ballasted with cast lead and molded in one piece with the hull. For careening purposes the hull sits squarely on the fin and skeg to avoid damaging the rudder.

The rudder rides on two bearings, the upper one supporting the steering system. To protect the rudder and the steering mechanism, the skeg is designed to break away in case of a collision. This is also a handy feature for those planning to cruise shallow waters where sooner or later even the best sailors usually run hard aground.

There’s approximately 200 cubic feet of polyurethane foam wedged into the bow, stern, keel and other nooks and crannies on the FD-12 to provide positive flotation. Positive flotation is rarely built into a cruising boat because it consumes so much space, but we would definitely consider it if we were building the ultimate cruiser.

Holmann comments: “Most composite boats only need a bit of help to give them positive flotation, but the amount of flotation must be carefully calculated. If you miss it by one cubic foot, you’ll have a very expensive sinker, but it will sink.”

Size of water and fuel tanks varies depending on interior layout, but all FD-12s carry ample water and fuel for long-distance cruising. One FD-12 we sailed carried 250 gallons of water, the other 150. Fuel is stored in two 125- to 150-gallon black iron fuel tanks. Black iron tanks tend to corrode. Aluminum tanks are a better choice for storing diesel. Water tanks are stainless steel, but the metal is an inferior grade, and the tanks we inspected were rusty.

Performance Under Power

The engine is installed underneath the floorboards at the bottom of the companionway in its own separate bilge. This type of installation keeps the engine weight low where you want it. Spilled engine oil is confined to a small area. The separate bilge also protects the engine from water that might enter the other two bilges.

On the downside, the engine is difficult to access. The front of the engine, located under floorboards inside a galley locker, makes it particularly difficult to change or tighten belts, etc. The rear of the engine is more accessible, but overall it’s a poor set-up for a big 50-footer.

The FD-12 is so customized that you’re liable to find three different engines on three different boats. In Guatemala, one FD-12 was fitted with an 80-hp Ford Lehman diesel with a two-bladed prop, the other a Lehman-Peugeot 4D61 with a three-bladed prop.

The 64-hp Lehman/Peugeot was noisy, vibrated excessively, and overheated if driven over 2,000 rpm. We’d recommend a larger, more reliable engine. The 80-hp Ford Lehman propelled the FD-12 along nicely, but a similar-sized Perkins might be a better choice for marine use. Still, the FD-12 hull is easily driven and both engines gave us a speed of 6 to 6 1/2 knots through the water in flat seas. Like most sailboats, the FD-12 tends to have a mind of its own in reverse, although one PS reader reported that it steered well in reverse with a Max Prop. With a 250- to 300-gallon fuel capacity, you can easily expect a 1,000-mile cruising range under power.

Performance Under Sail

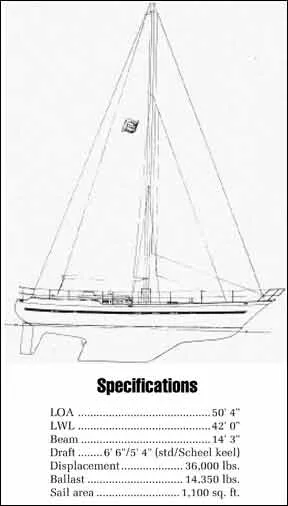

With its relatively fine entry, 42′ waterline, and efficient underbody, the FD-12 is a high-performance, blue-water cruiser. It’s also a hefty boat (36,000 lbs. displacement), and a comfortable passage-maker under most points of sail. However, like many heavy-displacement double-enders, this boat rolls in heavy air downwind.

The FD-12 is powerful on a reach or broad reach in winds over 15 knots, and performs respectably to weather. It loses speed in light air, but in 15- to 20-knot winds, you can count on averaging at least six knots under sail.

The FD-12 is cutter-rigged with the mast stepped fairly well aft. There’s a quick release on the inner forestay to accommodate large headsails, but we doubt you’ll use it often. Working sails consist of a Yankee, main and staysail, but in winds under 15 knots a roller furling genoa comes in handy. The boat we sailed also carried a cruising spinnaker which the owners reported using on long passages even when shorthanded.

Double spreaders, hefty 7/16″ wire rigging, swage fittings, and Ronstan turnbuckles provide a strong rig. The two forward babystays have a quick release lever so they can be led aft when using a spinnaker pole.

Instead of using running backstays to take the load of the inner forestay, the FD-12 rig incorporates intermediates which lead just behind the aft lower shrouds. The intermediate angle is so acute that the intermediate must be large in diameter and strongly tensioned to provide support. This adds a lot of compressive load to the mast. Intermediates can also cause unnecessary chafe on the mainsail downwind.

Running backstays would be more effective. The FD-12 is a big 50-footer, but it’s well-balanced and easy to handle. Winches on the boats we sailed were self-tailing Barients and Meissners. The Barients were up to par, but the owners complained that the Meissners failed often, and parts were difficult to find and replace.

On Deck

The FD-12’s roomy, flush teak deck provides a stable sailing platform. The cockpit is efficient for sailing and safe for passagemaking. It’s not too big, has decent cockpit drains, and high coamings that impart a snug, secure feeling, especially offshore.

The steering wheel is hand-laminated teak and spruce. A mainsheet traveler spans the cockpit well just forward of the wheel, and there’s an alternative mainsheet arrangement on top of the cabin house. Genoa sheet winches are mounted outboard of the main coamings just forward of the traveler. These winches are well located, but one of the stanchions gets in the way if you are beating to weather and need to ease the sheets to fall off downwind.

Otherwise, the stanchions are strong. They are installed with backing plates and have side braces that bolt to the caprail. To provide a safe way to climb aboard a boat with extremely high freeboard, there are two stainless steel boarding ladders (one port, one starboard) that fold in half over the lifelines.

There were three Bomar hatches forward on one FD-12 we sailed, and one custom teak hatch and Dorade vents on the other. The teak hatch is pretty, but Bomars are easier to maintain, and provide more ventilation.

The aluminum mast is made by Yachtspar of New Zealand and painted with polyurethane. Two stainless steel mast pulpits act as supports when working at the mast, and provide a place to secure gear and lines.

There’s a stainless stemhead fitting with double anchor rollers forward. On early hulls this fitting was too flimsy; on later hulls, they strengthened the anchor roller fitting, and also added an extra support strut to the bow pulpit.

The entire forepeak (6′ long and 3′ to 5′ wide) of the FD-12 is designed for storage. You can enter the forepeak cargo hold by opening two huge hatches cut into the deck aft of the anchor chain windlass. These hatches are extremely heavy—so heavy they must be tied to the lifelines so you won’t lose a finger (or worse) if they slam shut accidentally. They are well-gasketed, but it’s disconcerting to see such big holes cut in the foredeck.

The forepeak locker is great for storing sails but it’s cavernous and it’s sometimes difficult to find things. Also, the anchor chain drops onto a shelf inside this locker, and excess chain can easily get snagged amongst all the rubble.

There are three bronze hawseholes—port and starboard—cut into the bulwarks forward, aft and amidships. They are well-placed but a little undersized.

Scuppers on the FD-12 do not drain overboard. Instead, hoses are attached to scupper drains and led to through-hull fittings located just above the waterline. This arrangement prevents water from staining the topsides, but we don’t like unnecessary throughhull fittings at the waterline.

Owners report that chainplate covers must be rebedded periodically to prevent deck leaks. Stainless weldments on the FD-12 tend to weep rust, and we question the quality of the stainless used throughout the boat. (Taiwan boatbuilders have a reputation for building with inferior stainless. For some reason, the importance of using superior metals is not a concept they readily understand.)

The two FD-12s in Guatemala both had Fleming Major vane gears which were not sensitive enough in light air. A Monitor would be more effective.

Belowdecks

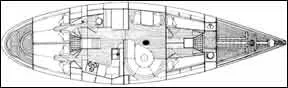

There is no standard arrangement belowdecks. Every FD-12 has been individually customized to meet the buyer’s needs. With such a wide possibility of interiors available, we restrict our comments to Winterhawk (hull #19), the boat we sailed in Guatemala.

Belowdecks, Winterhawk is incredibly spacious—so spacious that with five crewmembers aboard we never felt cramped or hemmed in. Furniture is built of plywood with a grooved teak veneer. The cabin sole is teak and holly. Bulkheads in staterooms and heads are white Formica, and a number of large round mirrors bolted to bulkheads impart a sense of light and space.

Ten bronze opening deckhouse ports, in addition to hatches, provide adequate ventilation, but you might want to install fans or an extra hatch in the aft cabin.

Indeed, Winterhawk has all the creature comforts of home. There are two heads, one forward and one across from the galley, each with hot and cold pressure water and manual fresh and saltwater foot pumps. Both heads have showers with teak grates, and sumps which pump overboard. On our cruise, hot showers flowed freely thanks to a Balmar ASC Aqua Master watermaker. (Driven by a Northern Lights 5kw generator, this AC model desalinates about 19 gallons per hour, and completely eliminates the need to take on water from shore, which is especially helpful in countries where the quality of water is questionable.)

A large L-shaped galley on the starboard side of the doghouse has two deep double sinks, plenty of storage, and enough counter space for two people to cook at the same time. The lockers behind the stove are difficult to reach, but there are plenty of additional galley drawers, as well as cubbyholes for pots and pans.

A huge icebox and freezer with AC and DC refrigeration keeps perishables cold, but insulation could be increased all around to make the box smaller and more efficient. We had difficulty adjusting the knobs on the Hillerange propane stove, and given our druthers we’d opt for a Force 10. Two 20-lb propane tanks are appropriately stored under the helmsman’s seat in a vented locker.

The nav station, across from the galley, is comfortable with good working space for chartwork, ample stowage for charts and tools, a red flourescent light for night work, and ample room for installing electronics. FD-12s come standard with four 200-amphour batteries.

Winterhawk has four Prevailer 8Ds, which the owner praises highly. The electrical system includes 110-volt and 12-volt service. Wiring is supposedly to U.S.C.G. regulations, but the electrical connections for the masthead wiring on Winterhawk are in the bilge where they are vulnerable to water damage. Two electric bilge pumps backed up by a manual bilge pump are adequate for emergency bilge pumping.

The saloon has a large U-shaped dinette to starboard and a single settee to port. A Dickinson diesel stove sits amidships for heating the cabin in colder climes. Storage for books throughout the saloon is plentiful, and there are big lockers for canned goods underneath the settees.

Forward, port and starboard, are two almost identical cabins. Each has a single berth with teak leeboards, plenty of drawers and two louvered hanging lockers.

The aft cabin is a large owner’s stateroom with a double and single berth and a small night table withmirror. Again, there are plenty of drawers and several hanging lockers. Some might object that there is no head in the aft cabin, but for offshore passagemaking a head in the doghouse by the companionway ladder makes more sense.

Some FD-12s, like Moonshadow (hull #2) have layouts similar to Winterhawk but with a few more berths. Others have completely different interiors. (For example, hull #7, has the saloon in the doghouse, and the galley in the saloon.) However, all are designed to cruise long distances in comfort, and you’d be hard-pressed to find a 50-footer with more room to accommodate your whims and fancies.

Conclusion

The FD-12 is a moderately fast, well-appointed, comfortable world cruiser. In our minds, positive flotation in a cruising boat is a big plus. We’d like to see more boats built with it.

On the negative side, corroding weldments on deck hardware and rusty fuel and water tanks are a source of potential problems. High freeboard and a canoe stern make for a safe, dry boat, but it would be interesting to see drawings of the FD-12 with an Eva Holmann-designed reverse transom.