Beneteau is the largest sailboat manufacturer in the world. The company builds monohulls and multihulls ranging in size from 23 to 57 feet, and in recent years introduced a power trawler to the US market.

In general, the Beneteau brand appeals to the mainstream, offering boats designed by Groupe Finot, for use by casual cruisers. Beneteau’s First line, targeted to the performance sailor, includes boats drawn by the likes of Farr and Associates. Though performance is the primary criterion in the First line, those models also provide a full galley, dining area, and enclosed sleeping quarters.

The Beneteau 323, introduced in the 2010s, was designed to fit into the US niche, which has always been a moving target. Composed of several elements, it includes people new to the sport, those moving up from smaller boats, those moving down from bigger boats, and empty nesters who may not want to bring crew aboard to handle the chores, and who are content to sail alone or shorthanded. These groups are all looking for mid-sized boats with big-boat amenities.

The 323 replaced the aging 311, which was only moderately successful in the US market. The new 323 couples good overall performance with a spacious cockpit and living accommodations suitable for four. During our test sail we learned she’s pretty quick, albeit somewhat tender.

Design

When Beneteau boats first appeared on the US scene more than three decades ago, they were distinguished by rounder, more radiused shapes than traditional American boats, and hulls and decks were accented by black portlights, some molded into the topsides—a bold step in those days. The next generation had more traditional profiles, though plumb bows and reverse transoms became the norm. The boarding and swim platforms that initially took hold in Europe are now de rigeur here.

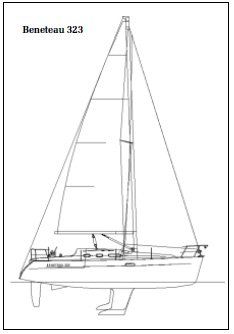

Though the 323’s appearance follows a more modern aesthetic, her appearance depends upon your point of view-literally. The view in the photo above, from leeward when she’s under sail, shows her slightly heeled. From this angle, she looks ready to challenge all comers, with a nearly plumb bow, reverse transom, and a hint of swoop to her sheer. The coachroof looks low, and a Plexiglas portlight that spans the coachroof adds a rakish touch.

However, stand her back up and take a look at her at rest, and she takes on the appearance of the cruiser she’s intended to be. Viewed from abeam, the topsides show themselves at their true height, and the cabintop’s elevation reflects a goal of having sufficient headroom for crew to stand upright without fear of banging a noggin on the headliner. The cabintop slopes downward gradually enough to provide standing headroom in the forward cabin, albeit at the expense of a lounging surface on the bow.

The mast sits above the leading edge of the keel, perhaps a bit farther forward than it would be on similar boats. This opens up some space belowdecks. The designers also carried the beam well aft, increasing interior volume enough to allow space for an aft stateroom and full-sized head.

Deck Layout

The newest Beneteau models have two unique and positive characteristics—a patented helmseat bracket that eases access when stepping aboard, and a pivoting wheel that opens the space between the binnacle and starboard cockpit seat. Boats manufactured in the US are equipped with a split backstay, eliminating that boarding obstacle, as well.

The helmseat bracket is attached in a manner that allows the seat to be tilted entirely out of the way of boarding passengers; it is the best method of securing a seat that we’ve seen.

Of the wheel arrangement, Beneteau says, “It’s held in a locked position by a stainless steel pin. Pivoting the wheel out of the way is as simple as pulling the pin and rotating the wheel forward to the second locked position.”

The pin has a positive lock, and only stops in two places, so appears fail-safe. We’d equate it to the lever on the steering wheel of an automobile that allows adjustment of the height of the wheel. When pivoted forward, the wheel still doesn’t interfere with the addition of an optional cockpit table on the binnacle.

With 6′ 4″ of space between the binnacle and the companionway, the cockpit is long enough to seat six comfortably on teak slatted seats. However, there are no cutouts or cubbies, and a single winch handle pouch is the only storage area in the cockpit. Owners might want to add line pouches, fabric gear holders, and cup holders to avoid operating in a cluttered space. A cockpit locker to starboard provides stowage for sailbags, docklines and fenders, cleaning materials, and so on.

The mainsheet is located mid-boom and the traveler is located on the coachroof. Halyards and sail controls are led aft through Spinlock turning blocks to three-wide Spinlock XAS rope clutches. Standard hardware includes Lewmar #30 self-tailing winches as primaries, and smaller twins on the cabintop. The standard gear list also includes a rigid vang—a real plus—and continuous reefing lines inside the boom.

Headsail sheets can be led through inboard or outboard sail track. There are four mooring cleats for the docklines, and a 10″ aluminum stemhead fitting equipped with a bowroller for the anchor rode. The roller is oriented off-center for those occasions when two hooks are deployed, and to avoid dinging the gelcoat during retrieval. The anchor well is self-bailing.

305-526-4179 – https://www.yachtworld.com/yacht/2005-beneteau-oceanis-clipper-323-9240623/

The mast and boom are anodized aluminum sections constructed by US Spars. Stainless steel standing rigging runs through a single set of spreaders. The mast is deck-stepped. Since this boat is designed to meet CE Category 2 requirements for coastal cruising, it’s not a great concern that the mast is not keel stepped. The boat is not designed to be sailed extensively in big seas and heavy winds. The mast is supported by a compression post located at the forward edge of the dining table.

Boats are sold with an “almost” fully battened mainsail and 116% genoa built by Neil Pryde. Fully battened mainsails ease trimming, but Thoney says that “the battens do not extend to the luff of the sail, making it less likely a sail will bind while being hoisted or lowered.”

The standard suit of sails presents 540 square feet of sail area to the breeze. A genoa furler is not standard equipment, as it is aboard most of this boat’s competitors. An optional Profurl B29-S is the most common choice of 323 buyers.

The company also offered a Z-Spar in-mast mainsail furler option, which reduces sail area about 15%.

Belowdecks

Given the constraints of operating within the space available in a 32-footer, Groupe Finot managed to locate things in a way that allows four adults to have adequate elbow room in the living quarters. The saloon is fitted with an L-shaped galley to port at the foot of the companionway, settees port and starboard that will seat six comfortably, a functional nav station, and generous-sized head that could even serve as a wet locker. Forward and aft cabins will each sleep two adults comfortably.

With 10′ 7″ of beam, there’s little room for a pas de deux, as the dining table prohibits much movement when leafs are up. The primary casualty, though, appears to be the size of storage areas belowdecks and the absence of a second cockpit locker. Granted, the boat wasn’t designed for extended offshore cruising, but it’s nice, if you’re going on a week-long cruise, to be able to stow your personal gear in a drawer or locker and not have to live out of your duffel bag. Though there are several storage compartments, many are shallow or narrow.

We would quickly point out that the Beneteau323 is far from alone in this shortcoming; in fact most modern production boats of this size suffer from the same problem: Given a choice between bigger places to lounge around and bigger places to stow gear and clothing, people seem to think the former choice is better, and designers respond. It’s a shame, because a boat of this size looks very different with gear for four aboard than it does at a boatshow with a vase of flowers and a copy of one of those glossy sailing magazines on the table.

A neat touch is the sliding companionway slat that eliminates the hassle of dealing with multiple sections of Plexiglas and their storage. The designers managed to add this feature without compromising access to the engine compartment.

Varnished handrails provide a firm handhold when moving belowdecks, and footing is secure on curved fiberglass companionway steps coated with a heavy-duty nonskid. The saloon measures 9’8″ on the centerline and 7’7″ wide at a point behind the settees where storage compartments are located, with a bit over 6′ 3″ of headroom at its highest point. Spaces are well lit with overhead light fixtures, three ports on each side of the cabin, and the flush deck portlights. Light also is reflected by a shiny fiberglass liner fitted with Douka wood strips, the same material used throughout the interior.

This model also reflects improvements in the fit and finish of Beneteau yachts that have been noticeable since the woodshop was fitted with computerized cutting tools and varnishing machines.

Standard equipment in the galley includes a two-burner stove/oven combination connected to a 10-pound LPG tank that may provide a summer’s supply of fuel. An Adler-Barbour 12-volt reefer also is standard. Working space is on a generous laminated countertop measuring 3’11” wide and 20″ deep. The stainless steel sink is fitted with a single faucet mixer tap that disperses both hot and cold pressure water.

Opposite the galley you’ll find a chart table is large enough to spread chart kits, and the electronics panel large enough for the installation of VHF radio, GPS, and stereo system. The panel also has a 110-volt outlet. Space in the forward cabin is filled primarily by a double berth. Removing the bunk insert produces a space with 6′ of headroom and enough space for an average-sized crewmember to dress while standing. With the insert in place, the berth measures 6’10”, though it is only 5′ wide at the head. Storage is in a hanging locker to port.

+44 (0)2382 120 000 – https://www.yachtworld.com/yacht/2006-beneteau-oceanis-clipper-323-9280720/

At the other end of the hull, the aft cabin is furnished with a double berth measuring 6’10” x 6’3″ in a space lit and ventilated by a portlight in the transom, two opening ports, a halogen light overhead, and two reading lights.

A hanging locker is located to port, and a storage shelf spans the stern.

Beneteau obviously considers a full- sized head to be a desirable feature in this market. The 323 designers produced a space that’s larger than that found aboard most 32-footers. With 6’2″ of headroom and measuring 4’9″ fore and aft, the space is wide enough to bend over the sink without banging the interior bulkhead, and allows a bather to shower while seated on a bench. Light and fresh air come through two Lewmar portlights. Aft of the vanity is a tall, shallow, fiberglass storage area in which wet gear and towels can hang to drop and dry.

Except for the lack of storage space (perhaps unavoidable, given the demands of the market) the designers deserve high marks for producing well-conceived and well-equipped living spaces, while not increasing interior volume to the point where the boat’s sailing qualities begin to suffer.

Construction

Though traditionalists and custom builders often disdain the use of hull and deck liners, the major manufacturers have developed construction methods and are using adhesives that negate many of the historical criticisms of this method of building boats. Properly constructed and installed, hull and deck liners provide structural support for the hull and sturdy areas onto which bulkheads and furniture may be installed. Space-age adhesives also produce secure bonds that allow liners to flex without breaking the bond. Once buried in fiberglass, plumbing and wiring runs also are now accessible through PVC conduits. From the consumer’s standpoint, these processes also allow builders to maintain lower prices.

Given 30-plus developmental years, Beneteau’s system appears to have reached maturity. Hulls are solid fiberglass with vinylester resins in the outer skin to prevent osmotic blistering. Behind the skin coat are computer-cut sections of fabric wetted with polyester laminating resin.

The company is now using zone-specific stitchmat in the layup, varying the weight of the fabric to meet calculated stress loads in specific areas. In theory, this method avoids overbuilding in certain areas, and we suspect it may also reduce the cost of the lamination, while slightly reducing the weight of the final product.

The hull liner consists of a pre-formed grid system of fiberglass stringers, beams, engine and tank supports, and cutouts into which tanks are installed. Chainplates are attached to stainless steel rod bedded in solid fiberglass. The lamination schedule employs non-woven stitchmat fiberglass, and unidirectional rovings. Hull and deck liners are bonded with a polyester adhesive compound.

Bulkheads are bonded to both hull and deck to produce a monocoque structure; they are bedded in a two-part polyurethane adhesive, an alternative to the traditional method of tabbing with fiberglass strips.

The deck is a sandwich cored with Trivera, a polyester cloth that provides some structural support while preventing print-through during the lamination process. (Larger boats are cored with end-grain balsa.)

Areas where deck gear and stanchions are installed are solid fiberglass. Deck gear is secured with nuts, bolts, and backing plates. This can almost be considered a “traditional” method of construction these days, since some builders are now bedding aluminum plates into the fiberglass and tapping them to receive mounting bolts for deck hardware. The advantages of that method include the elimination of protruding washers and nuts belowdecks, and of the leaks that often come through these mounts. The big disadvantage would be in stripping the threads in any of the tapped holes.

In the hull-deck joint, the deck rests on an inward-turning hull flange, and the two are married by a combination of stainless steel fasteners, polyurethane glue, and a toerail secured with through-bolts and nuts.

Performance

With a sail area-displacement ratio of almost 21 and a displacement-length number of 152, you would expect this boat to be quite sprightly for a cruising boat—and you would be right. We took a sail on the Chesapeake, and found the 323 to be a very good light-air performer albeit a bit tender in stiffer breezes. Initially sailing in 5 knots of wind, we saw 4-4.5 knots of speed on the GPS. This was, of course, speed over the ground, but there was little current.

When true windspeed increased to 10 knots, we close-reached at 5.8-6.2 knots (SOG). The boat was well-mannered and dry, but was slightly overpowered in the gusts at that point with the full mainsail and 116% genoa. We’d guess that a single reef in the main and/or a working jib would provide a more comfortable combination when windspeed reaches 15 knots—but we’d like to hear from any 323 owners on this topic. Please go to the comments.

Beneteau 323

LOA: 32′ 10″

LWL: 29′ 2″

Beam: 10′ 8″

Draft, std: 4′ 9″

Draft, deep: 5′ 11″

Displacement: 8,448 lbs.

Ballast: 2,414 lbs.

Sail area: 540 sq. ft.

D/L: 152

SA/D: 20.8

Water: 42 gallons

Fuel: 17 gallons

Auxiliary: Yanmar 18-hp.

The wheel is large enough to allow a helmsman to steer from windward using the leeward seat as a footbrace, a typical position for cruisers. Though we’re generally in favor of tillers on boats of this size and type (like the Europeans), the wheel was quite responsive, giving good feedback. There’s a slight weather helm, which makes for easier steering than a balanced helm, for most people.

She easily tacked through 90 degrees and accelerated to 5.5 knots as quickly as we could properly trim the sheets. The test boat was fitted with a shoal-draft keel drawing 4’9″, which is good for the Chesapeake. Owners in heavy-air venues and deeper water should consider the optional 5’11” fin keel for more stiffness and better windward performance.

Easing sheets and sailing on a beam reach, our GPS registered 7.5 knots over the ground.

It was nice, on returning to the dock, to find the boom low enough that flaking the mainsail is a simple matter, even without lazy jacks.

Pricing

In the early 2000s when the 323 was introduced, base price was $76,700. Yacht World listings now show a low of $49,900 for an ’05 version to a high of $73,000 for a 2006. All prices are subject to the rules of “willing sellers/willing buyers,” but given the boat’s price history and current offerings, the Beneteau 323 appears to hold its value. The “preliminary” equipment list back then appeared to include an optional “cruising package” of standard equipment and included Raytheon ST 40 Bi-data instruments, ICOM VHF, AM/FM/cassette player and speakers, cockpit shower, and 110-volt shore power cord.

Among the competition in the same rough price range would be the Catalina 320, Hunter 333, and Jeanneau 32, but option packages and boat-show deals scramble the price picture. Brokerage sites usually show a mix of prices reflective of model year, condition—and the eagerness of the seller. Always, boats will show differently according to the fastidiousness of the owner, so a survey including sea trial will help you find a good one. And there are plenty of 323s out there.

Conclusion

Sailors scouring the marketplace for a boat in this size and price range should check out the 323. She provides good creature comforts, but is designed to be sailed, and is nicely performance oriented. The company builds solid structures. The quality of deck gear, spars, and standing rigging is good. She performs well in light to moderate winds, and shortening sail when the wind pipes up will be relatively straightforward. And, though she comes from a French- owned company, she’s built in the US at Beneteau’s 200,000- sq. ft. factory in Marion, South Carolina. Customer service is facilitated by dealers working directly with the plant there.

What make of anchor do you recommend for a Beneteau 323. I sail in waters of B.C. Canada. What weight do you recommend for cruising in BC Strait of Georgia.

Look at the YouTube video tests by SV Panope and then talk to Ground Tackle Marine.

Hasn’t Groupe Finot closed the Marion facility?

Thanks for a great review. It confirms the boats reputation to me. I wish the SC sailboat plant was still opened.

An idea for a future story would be traditional sailboat builders that have merged or gone out of business the past 15 years.

I would like to see, for every boat reviewed, the particulars on keel build, material/ballast, and attachment method to hull.

Good review. My wife and I bought a new 323 in early 2008. After a couple of build quality issues were repaired and replacement of some accessories Beneteau cut cost on, boat has been a dependable and relatively trouble free. I still own and enjoy the boat.