Rules of thumb are rather useless when it comes to equipment that is stored in a locker and then used roughly. We’ve broken lots of new and old equipment during testing and learned a lot about what to look for, but even so we are often surprised when good looking equipment fails and scratched up stuff works fine. Inspect closely and often, regardless of age.

UV Damage. A requirement for a flag that faded in a predictable manner would be nice. About one year of full-time exposure to the sun is known to weaken webbing about 25%, a fair basis for retirement.

Abrasion. With machine stitching, any appreciable general abrasion, wear around carabiners, or broken stitches at the ends of the splice are cause for retirement. Scratched carabiners, on the other hand, are usually fine, although any cracks or other signs of crevice corrosion in the hardware is cause for concern.

Corrosion. Any stiffness in the gate can prevent proper closing. A brief soak (1-3 hours) in vinegar or diluted CLR (better) may free up stiffness due to superficial corrosion or lime deposits. Lubricate with waterproof grease or spray corrosion inhibitor and place them back in service. If longer soaking is required, retire it. Corrosion in key structural areas of the carabiner are also important; any corrosion or separation of the anodized coating in the nose area or around any of the gate pins is grounds for retirement.

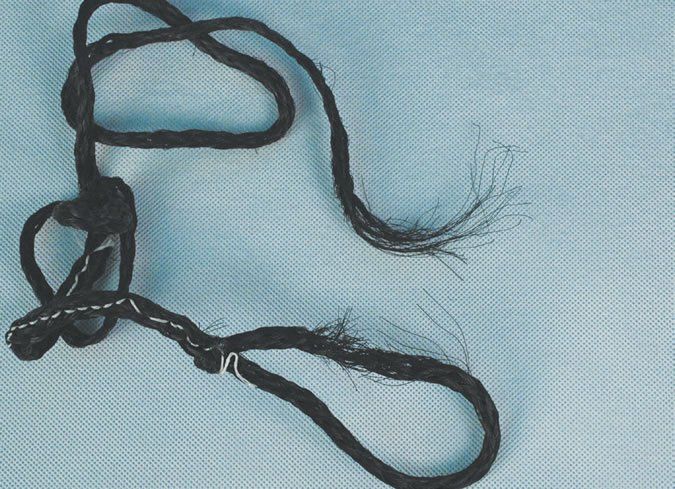

Overload flag. Obviously, a tether should be retired when its overload flag has been exposed, even partially. But you don’t throw have to throw them away. The old tethers are still good for a variety of uses. Cut the slings off and put them to use in less critical areas like securing fishing rods while trolling, or as deluxe dinghy or kayak painters. The webbing can turn into reefing and sails ties, or sewn into any number of interesting projects. Waste not.