In Part 1 of our special report on multihulls we scrutinized the implications of stability and the benefits derived form a wide stance, buoyancy and hull shape of multihulls. This time well look at structural issues and the energy transfer that takes place due to a multihulls impressive initial resistance to heel. We will also delve into what all this means for the rig, rigging, hull structure and hardware interfaces. For a more recent look at capsize risk, see our report Multihull Capsize Risk Check.

Photos by Ralph Naranjo

The big engineering challenge for multihull designers, engineers and builders revolves around minimizing weight, while at the same time, maximizing strength and stiffness of a large surface area structure. Extra pounds rob performance, and many early multihulls were built with less attention to weight control and where stress and strain radiated through the structure. Consequently, some parts of the hull were far heavier than necessary and other areas were underbuilt.

When naval architects, designers, and engineers began using finite element analysis (FEA) software in their structural evaluations, they could better define hotspots, the precise locations for the highest loads when the amas (hulls) and akas (cross members) when a boat is under sail in a seaway. This gave the design team a means to add specifically-aligned fiber reinforcement in specific areas while lessening FRP layers in regions of the boat where sailing loads were less. In a well-engineered multihull, the load paths and laminate alignment coincided.

The energy transfer between a rig and hull is like a wrestling match between air-pressure on sail surfaces and the righting moment of the multihulls wide-stance footprint. Rig loads rush through the rigging to chainplates and the mast step and finally make their way into the hulls and cross members.

A monohulls elongated egg-shaped hull simplifies the transfer of energy between the rig and hull. Chainplates anchor the standing rigging and act in conjunction with the nearby mast step to create a perpetual tug of war between tension and compression. Aboard a catamaran, the athwartships distance between the mast step and chainplate significantly increases, creating a more complicated load path.

In some ways, the wide footprint of a cat or tri provides a more optimum platform for standing rigging. The ultra-wide rail-to-rail beam reduces shroud load and allows for backstayless standing rigging, which in turn opens space for a huge roach mainsail-the backbone of a multihulls performance and power under sail.

The challenge is how to make the table-like bridge deck that fastens the cats two hulls together, or the akas (cross members) connecting amas to the trimarans central hull, stiff enough to handle the bending moment created by tensioned rigging and the compression loads delivered to the mast step. The monohull remedy to just beef it up is a bitter pill in multihull world.

As in the aerospace community, better engineering makes more sense than does simply adding more resin and units of laminate. Like aircraft, the components in a multihull have large surface areas and extra weight is the enemy. But high-tech aerospace solutions like the use of prepreg epoxy/carbon laminates, titanium, and other esoteric materials are too expensive for most conventional yacht projects.

Trimarans are usually higher-performance, lower-volume vessels that attain a little bit of heel. The two amas or outriggers that create righting moment via buoyancy must be kept light so the central hull is the center for accommodations and gear storage. Weight reduction is a pivotal factor during the design and build phase, and payload is part of the equation.

The hulls of a trimaran are usually connected with hollow molded cross members and the rig is stepped on the deck of the central hull with rigging attached to both chainplates on the main hull and on the outboard amas. Twist and flex will cause dimension changes and load spikes in various parts of the standing rigging that must be anticipated in design calculations.

Both monohulls and multihulls react to changes in wind and sea conditions. However, there are differences in how much energy is transmitted from the rig to the hull(s). Aboard a mono hull, theres much less form stability-inherent righting moment due to the shape of the hull. And without ballast (lead, crew weight, sand bags, etc.) heel happens quickly, so sail-carrying capacity is limited. By adding ballast, a secondary righting characteristic is created, and heel is diminished.

One advantage to heeling is that the load spike on the standing rigging is reduced. Heel is like a shock absorber, reducing peak loads and signaling to a crew that its time to reduce sail area. Even deep-draft, modern, beamy race boats will heel in the puffs, lessening the strain on the rig and its component parts.

Multihulls, by comparison, stand up to the puffs and turn a gust into acceleration. Theres little heel involved causing higher rigging than those aboard a monohull with similar sail area. Consequently, the rig and rigging scan’tlings must be able to handle higher loads, and the structure that spreads the energy into the hulls must be able to cope with greater tension, compression, and shear loads.

And here is where lies the crux of the multihull dilemma: How do you build a lighter boat that can withstand higher loads, and still meet a fairly reasonable price point?

Building the Boats

Production catamaran builders have settled on a streamlined, cost-effective approach to boat building, one that fine tunes molded FRP monohull boat building techniques. Most builders have shown increased attention to detail and better resin control. They recognize that excess resin adds weight and little strength.

The big challenge is the huge surface area of the bridge deck and the need to lessen the layers of FRP used in the hull and deck structure. Balsa wood is the most popular core material and polyester resin continues to be the laminating resin of choice even though the resin and the E-glass stitched, woven, and mat fabric represent the lowest grade and lowest cost laminating material. S-glass, carbon fiber and epoxy resin are much stronger, provide better adhesion and are materials of choice in high-end performance multihulls-but in marketing studies, the cost benefit analysis have minimized their use in most mainstream production multihulls.

Theres a significant engineering challenge in building lighter weight, large surface area sailboats that can withstand the torment of a long, lever-like rig and the righting moment associated with 2-to-1 beam-to-length ratio.

One way to meet the strength requirements dictated by the FEA analysis without adding weight is to remove layers of laminate from parts of the boat that experience less stress. This may result in some parts of the hull having 1/8-inch of FRP laminate over 11/4-inch of end-grain balsa. This might be enough to handle the sailing loads, but what happens when a barely floating log or 7/8-inch submerged 55-gallon barrel lays in the crosshairs of a cat or tri traveling at double-digit speeds? Point loads and impact resistance may be needed in areas outside the finite element analysis hot spots for sailing-induced loads.

This is why a naval architect adds a safety factor to the scan’tlings and often recommends additional laminates and watertight bulkheads forward. The higher safety margin can also be attained using more expensive higher modulus and stronger materials.

Currently, when it comes to cruising multihulls, there are two industry trends at play. The most common is to beef up the boats and motorsail in lighter air. The booming catamaran charter business offers a strong incentive to adhere to this game plan.

Most charter cats are Caribbean bound, where abundant tradewinds, modestly skilled sailors, and an emphasis in casual sailing has yielded smaller rig sizes. The net result is big-volume cats, plenty of amenities, less tendency for capsize and a need for more patience under sail in light air. Mid-sized cats are too small for a generator, so some motorsailing and upsized alternators will pack in the amp-hours while motorsailing-a logical compromise that shouldnt be overdone.

High Performance Philosophy

Some years back, my wife and I sailed a 34-foot production monohull out of Tampa Bay headed south on a little cruise to the island of Cayo Costa, near Naples. From the start they found themselves alongside a 38-foot catamaran headed out the bay on the same beam reach. In the light air conditions (5 to 10 knots) they werent too surprised to be staying even with the larger multihull. Their working sail combination was a 135 masthead genoa and a 2 + 2 battened batten mainsail. As the breeze filled in both boats picked up speed, but the anticipated separation didnt happen. By early afternoon it was blowing 15 to 18 and the monohull was still beam reaching nip-and-tuck with the cat.

Ralph was probably paying a little more attention to trim and sail shape, but a closer look at the cat revealed the its handicap. The boat had a fair-sized rig, but the boom of the full-batten, fat head mainsail was about 12 feet above the water, greatly reducing sail area. They had a decently trimmed genoa, with telltales flying properly.

By the time we reached Boca Grande Pass, the breeze began to lighten and the monohull pulled ahead enough to notice that the cat had no boot top showing on both the leeward and the windward hull-a sure sign that the payload she carried was creating unnecessary drag. It was neither skills on the helm nor superior sail trim that put our boat in the lead-it was purely a lesson about multihull carrying capacity and the downside of dead weight.

The industry hasn’t abandoned the multihull sailor who wants to go fast, drag along the least amount of payload, and still enjoy cruising under sail. Many of the fast cats, tris, and an occasional proa utilize carbon-epoxy reinforcements in key load-carrying hot spots. They also use carbon spars, fiber rigging, and laminate sails that would draw the envy of any monohull race crew digging a trench in the ocean.

These more performance-oriented cats and tris are easy to spot. They avoid the layer-cake look and the high windage and even higher boom height they signify. Their low volume hulls, lofty rigs, less windage and high bridge deck clearance set the stage for performance under sail. Many of these boats are built to exacting standards and each molded part is vacuum bagged and painstakingly assembled with careful attention to optimize resin to reinforcement ratios. Core density is varied and point load reinforcements and core infills are strategically placed. This yields a light, stiff and strong boat thats quick to accelerate.

But cruisers need to recognize the implications of big rigs and high sail area/displacement ratios. Like a 600-horsepower Ferrari, they offer an experienced crew a chance to excel, but with a novice at the helm, big power can spell big trouble. Most of the You Tube clips that capture wild sprints punctuated with an upside-down conclusion stem from operator error rather than a sailboat flaw. When overdriven, these multihulls easily exceed their maximum righting moment-which occurs with very little heel. After that, the righting moment drops rapidly, and if not quickly depowered, the cat or tri will continue to rotate toward its limit of positive stability (LPS) and topple into an inverted position.

Monohull sailor Bill Lee favored the phase fast is fun, and multihull advocates know that faster is even more fun. With this alacrity comes the twitchiness of lots of sail area and no lead to slow you down and keep you upright. The challenge lies in instantly depowering a boat that will not tolerate a knockdown. Outcomes like last months rescue in the Mediterranean of the five-member crew of a capsized 74-foot Privilege cat drive home whats at stake.

Quick Release Technology

The Kiwis call sailors with more than one multihull capsize under their belts a Flipper, a dubious honor that has gained enough attention and concern that many multihull sailors are looking to technology for answers. The idea of a quick-release mechanism that will act like a fuse in an electrical circuit sounds simple, but in reality, little things like a hockle in the mainsheet or traveler thats not ready to run can defeat a rapid release.

Early auto-ease devices were based upon angle of heel that was tracked via a mechanical pendulum-like sensor. Unfortunately, when ocean sailing, wave-face geometry could induce heel in only moderate wind conditions. Under these circumstances, false alarms, in which the sheet or traveler line released prematurely was likely.

Today, Ocean Data Systems UpSideUp equipment is aboard all the Ultimate tris, including the MOD 70s along with many other ocean racing and cruising multihulls. Their basic sheet release system is comprised of digital heel and trim sensors linked to load cells and pressure sensors that automatically signal line release actuators when its time to let go.

The combination of angle change and tension sensing greatly reduce the false alarms that hindered pendulum-only sensing. UpSideUp continuously monitors both athwartships and fore-and-aft angles, and is set to signal excess heel and bow down inclination-accelerations that can lead to big trouble.

For more details about these auto-sheet release systems, you can contact Ocean Data Systems at info@oceandatasystems.com.

Conclusion

Peter Hogg is long time multihull racer/adventure sailor whose cruising has been in the fast lane. He places modern multihull sailors, or for that matter, single hull sailors as well, into one of two camps-those who go sailing and those who go anchoring. For both, the attributes of the boat chosen should dovetail with its use. And if boat show trends tell us anything, its clear that the quest for more accommodations is winning out over the lust for more speed. The design extremes are fine as long as they comport with the crews preference and skill set.

The concern that we have at Practical Sailor is what happens when the right boat ends up in the wrong hands. It isn’t hard to imagine a situations in which a crew looking for fast passagemaking, ends up with an overweight, under-rigged multihull that needs 20-plus knots to get things going. A sailboat with too much windage and too little underwater foil surface has a hard time making progress up wind.

Perhaps more worrisome is the flip side of the coin (see The Cost of Miscalculating Hatteras, PS March 2015), in which crews with more boat than they can handle, are outgunned, over-powered and occasionally dismasted or capsized.

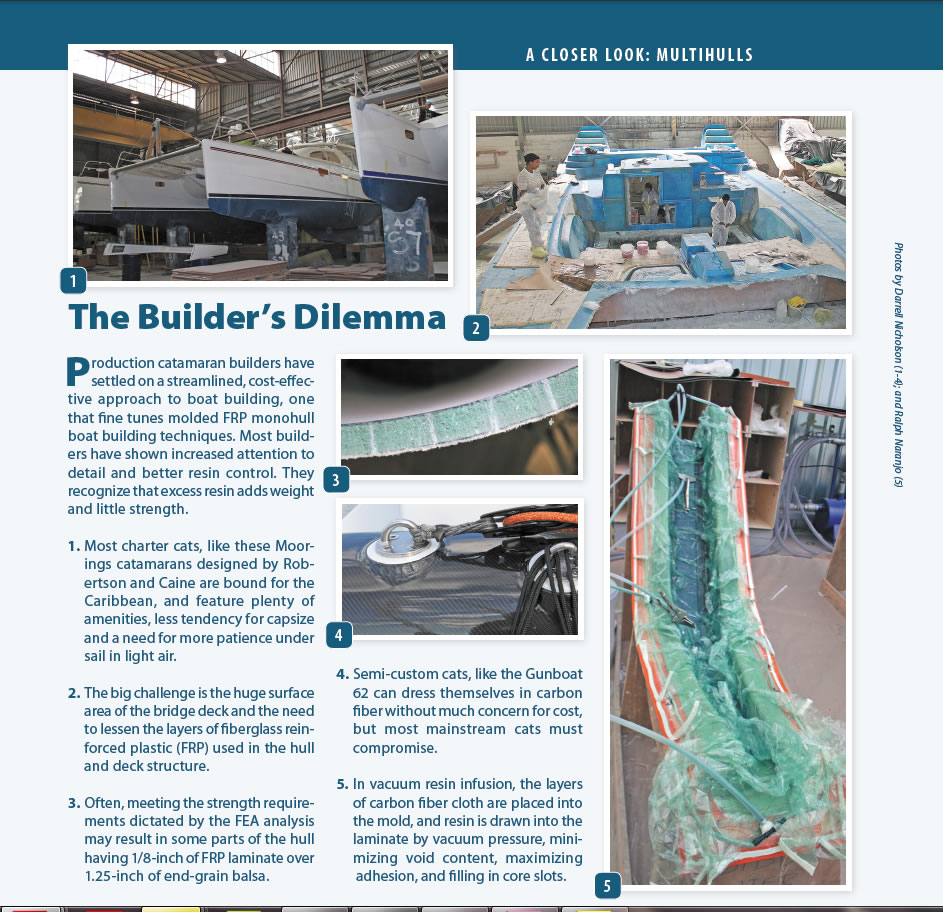

Production catamaran builders have settled on a streamlined, cost-effective approach to boat building, one that fine tunes molded FRP monohull boat building techniques. Most builders have shown increased attention to detail and better resin control. They recognize that excess resin adds weight and little strength.

- Most charter cats, like these Moorings catamarans designed by Robertson and Caine are bound for the Caribbean, and feature plenty of amenities, less tendency for capsize and a need for more patience under sail in light air.

- The big challenge is the huge surface area of the bridge deck and the need to lessen the layers of fiberglass reinforced plastic (FRP) used in the hull and deck structure.

- Often, meeting the strength requirements dictated by the FEA analysis may result in some parts of the hull having 1/8-inch of FRP laminate over 1.25-inch of end-grain balsa.

- Semi-custom cats, like the Gunboat 62 can dress themselves in carbon fiber without much concern for cost, but most mainstream cats must compromise.

- In vacuum resin infusion, the layers of carbon fiber cloth are placed into the mold, and resin is drawn into the laminate by vacuum pressure, minimizing void content, maximizing

adhesion, and filling in core slots.

In the first sentence is that the correct link?

I’m pretty sure it is not. If @PracticalSailor could update with the correct link, it would be appreciated!

I also looked at the PDF of the print copy which references the January issue (also incorrect I think) which is the linked article about safety and incidents on paying passengers on trans-oceanic races. Please let me know how to find the first half of this article!

Thanks!!