Photos by Ralph Naranjo

New, single-braid, high modulus polyethylene (HMPE) lines, such as Amsteel Blue from Samson Ropes, WR2 (wire rope replacement) from New England Ropes, and Vectrus from Yale Cordage, have revolutionized the way sailors think about standing and running rigging. Bit by bit, these low-stretch ropes are replacing wire rope on board. But the changeover is not without controversy.

In several reports, Practical Sailor has examined the pros and cons of high-modulus fiber in standing and running rigging. We have evaluated fiber halyards as a cost-effective replacement for wire halyards (see PS August 2007 online), and we have discussed the challenges in finding terminals for fiber standing rigging (see PS September 2007 online). We also recently looked into replacing wire lifelines with fiber (see PS September 2012 online).

We still encourage using uncoated wire lifelines (without any sheathing) for cruising sailors, but we are well aware of the allure of fiber lifelines. In this report, well explore the pros and cons of fiber lifelines in more detail and compare results of our most recent tests.

Its easy to understand why fiber lifelines have become all the rage. They enable racers and multihull enthusiasts to save critical pounds. Do-it-yourself sailors find them easy to splice. They look cool, save weight, and are gentle on the hands. A key advantage is that they don’t corrode like wire does.

Practical Sailor has long advocated uncoated, 1 x 19 strand 316 grade stainless-steel wire lifelines (7 x 7 strand may be used for installations with more bends). Although uncoated lifelines lack the aesthetic appeal of vinyl-sheathed wires, corrosion and frayed wires offer warning when replacement is due. In our September 2012 report, we found that corroded, vinyl-coated lifelines failed at less than 20 percent of their stated breaking strength.

Fiber lifelines also have inherent problems. Ultraviolet light weakens the fibers, although recent studies show that this weakening occurs at a fairly predictable rate-a loss of 30 to 50 percent in strength over five years. You can compensate for this by using a larger-diameter fiber lifeline with a tensile strength that far exceeds the wire lifeline specifications, or by replacing the fiber lifeline at more frequent intervals.

Manufacturer testing and anecdotal reports suggest that one-quarter-inch, single-braid HMPE lifelines can retain the required strength for eight years in average usage in northern climates, but durability can be highly variable, depending on conditions or use. Some recommend using covered line, but we have no proof that a cover reduces UV exposure any more than simply using larger line. Our investigation into sewn splices (see PS October 2014 online) revealed that in most cases, cover and core both lose strength at the same rate. The ultraviolet rays easily penetrate the cover.

Fiber lifelines second weakness is chafe. As a result of some fiber lifeline failures caused by chafe, the racing rules allowing for fiber lifelines have changed. The fundamental standard is the International Sailing Federation (ISAF) Offshore Rule. Section 3.14.6 of the rule defines acceptable materials and diameters for lifelines. (Most interpreted the new rule to exclude the cover from the minimum required diameter, since the cover does not add any strength to the splice.)

In 2012, ISAF accepted Dyneema. However, in January 2105, the international governing body of sailboat racing (ISAF) banned the use of Dyneema in all offshore races (Categories 0-3).

The U.S. national body, U.S. Sailing, allowed Dyneema for the 2015 race season, but a Dyneema ban is expected for 2016. Dyneema is still permitted for inshore racing (Category 4 and 5). Individual race rules may vary. (Dyneema is permitted in the Chicago-Mac, but not the Newport-Bermuda race.) All known failures have occurred on racing boats, which see far more chafe on their lifelines than cruising boats.

Chafe usually occurs when lifelines are used as handholds (a bad habit) or where sails and sheets bear on them. Chafe also occurs where the lifeline passes through stanchion holes. In more than one reported incident, race crew members were lost overboard (unharmed) as a result of this hidden chafe. Clearly, if youre considering switching to a fiber lifeline, youll want to closely inspect any possible chafe points, and deburr and polish (with 600-grit sandpaper) any places where the line makes contact with stanchions.

What We Tested

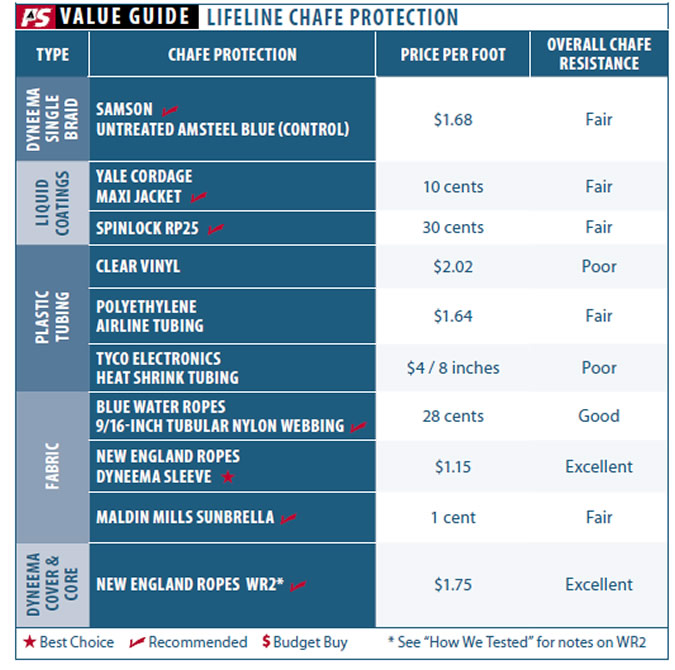

Although you can buy covered HMPE lines, we focused on bare single braids and double braids, which are more commonly used for lifelines. We looked at some familiar chafe guard materials: nylon tubular webbing and Dyneema chafe sleeves, as well as some non-traditional materials, such as heat-shrink and plastic tubing. We also tried the liquid coatings that proved effective for polyester rope protection (see PS March 2015 online). We then tested line with an integral Dyneema cover (NER WR2) versus oversized Amsteel to see which was stronger after equal torture.

Observations

Our rope abrasion machine was slightly modified to include a sawing (side-to-side) movement, in addition to the back-and-forth (lengthwise) abrasion; see How We Tested for more details. Although the test data proved revealing, some of the most useful observations regarding the performance of the various chafe protection materials couldnt be quantified; real-world results will be highly dependent on the type of installation.

Floating: Some chafe materials molded to the stanchion and stayed in place without being secured; others slipped/floated through the stanchion hole no matter what we did. Generally, those that stayed put worked best. We recommend testing fit to see which material/style works best on your stanchions.

Heat shrink: Commonly used to seal electrical connections, heat-shrink tubing shrinks when heat is applied, allowing it to snuggly conform to whatever it is sheathing. One problem with using heat shrink tubes on fiber lifelines is that applying heat to polyethylene line, which melts at a lower temperature than polyester, is risky. But even more damning, heat-shrink tubing simply didnt hold up in our test. Any burr will cut through it in a few cycles at heavy load.

Plastic tubing: Clear vinyl tubing doesn’t like to stay in place and is difficult to secure. Compressed-air hose held up better, but it was hard to secure and wore on the line when it deflected at a sharp angle.

Fiber guards: Fiber guards were relatively effective, but getting a good fit and finish required different techniques. We got the best results by sliding a round mandrel inside the tubing (small artists paint brushes worked for us), cutting the fiber guard to fit with a razor, and then melting the ends while slowly turning the mandrel. This procedure was essential for using Spectra tubing, which doesn’t melt and fuse as easily as other materials. Coating fiber chafe sleeves with Yale Maxijacket also increased durability and reduced fraying.

Some covers, like the APX, contain a high proportion of Aramid fibers and can’t be fused by heating. In these cases, we resorted to whipping them onto the fiber lifeline or splicing them in place. Since the best guards are rather thick-much heavier than typical line covers-splicing in the tails will weaken the lifeline by about 20 percent. Although you could taper the ends of the cover to create a smooth transition, it was easier and effective to simply whip the covers in place.

Coatings: While the paint-on (or dip) coatings provide some protection for light abrasion and oscillating wear, they were ineffective against the sawing motion inside stanchion holes. We would use Spinlock RP25 to combat superficial wear in places where sheets and sails might chafe the lifelines, but you will need a physical cover to prevent stanchion chafe. Coatings are convenient since you can apply (and re-apply as needed) in places where line chafe appears. You can coat chafe sleeves as well as the line itself. They will increase the sleeves life four to eight times, and keep the chafe guards looking neat, but the sleeves don’t need extra protection.

Retrofitting: If youve already installed new fiber lifelines, you can still fit sleeves without taking everything apart. The best option is to split two-inch nylon tubular webbing, wrap it around the lifeline, and then whip in place as a chafe sleeve. One PS reader said his nylon sleeves have held up for over five years in the Caribbean. Another option is to wrap Sunbrella around the lifeline. Although the Sunbrella doesn’t resist chafe that well, it wore better than plastic tubing in our tests and is easily replaced.

Lifeline Chafe Results

This report focused on chafe guards, not the lifeline materials themselves, so we only evaluated a few samples. In addition to our ongoing field test of lifeline materials, we are planning a more exhaustive review of lines in the near future. Here we briefly introduce a few common lifeline products.

Samson Amsteel Blue

Perhaps the best-known HMPE line, Amsteel Blue finds widespread use on towing, logging, and commercial trawling vessels. Light, strong, low stretch, abrasion-resistant, and relatively inexpensive, its the benchmark against which other lines are compared. Wearing 20 times slower than common polyester rope, this line is stronger than steel. For better handling and durability, most boaters buy a larger diameter than they need, giving it a large safety factor. Based on manufacturer tests, even after five to eight years in the sun, a quarter-inch Amsteel line will retain the strength specified under ISAF standards. Splicing is a snap; a bury splice (Brommell splice) is no more complicated than a knot. If you prefer not to splice, you can use Dyneema whipping twine to lockstitch eyes in place (see PS October 2014 online).

Bottom line: With proper stanchion hole preparation, chafe guards, and conservative sizing, Amsteel Blue should provide years of service. Recommended.

New England Ropes STS

New Englands STS is another 12-plait, hollow-braid line, very much like Amsteel. It performed the same as Amsteel in our tests, but it has a lower price tag. Practical Sailor has this line installed on a test boat in the Chesapeake, and it is holding up fine.

Bottom line: Slightly less expensive than Amsteel, and indistinguishable in terms of performance thus far, New England STS is our Budget Buy.

New England Ropes WR-2

New England Ropes (NER) introduced this covered line to avoid the need to install chafe protection. Although the Dyneema cover is tough, it isn’t as resistant as a true chafe sleeve and is susceptible to burrs. NER suggests that the cover protects the core from UV rays, but our own testing indicates that a cover provides insignificant protection for small lines. Typically, the eye-splices are core-only-a cover-and-core splice is tricky on this line-so the eyes will likely be exposed to UV anyway. The small diameter (4-millimeter core) limits this product to boats of less than 28 feet, according to U.S. Sailing guidelines.

Bottom line: We Recommend the 5-millimeter size; the 3 millimeter diameter does not meet U.S. Sailing specifications. Be sure to smooth the stanchion holes anyway.

Chafe Protection

The range of materials available for chafe protection is nearly infinite; this comparison is fairly narrow in scope, but we tried to evaluate products that were representative of each category. If you have found success with a particular product not reviewed here, let us know at practicalsailor@belvoir.com.

Liquid Coatings

Liquid coatings provide one of the easiest solutions. We looked at two different liquid coatings, Yale Cordages Maxijacket and Spinlocks RP25.

Spinlock RP25

Though it goes on thick, the solvent-based Spinlock RP25 is nearly invisible once it soaks in and dries. Yale Cordages Maxijacket offered better overall performance in our previous testing with polyester, but the two were evenly matched when it came to protecting Amsteel. Unlike Maxijacket, RP25 does not stiffen the line, making it perfect for coating high-wear areas. Spinlock recommends this product to protect against chafe in rope clutches as well.

Bottom line: Recommended. This product is our preferred choice among liquid coatings for chafe protection on high-wear lifeline sections and Dyneema splices.

Yale Cordage Maxijacket

Yales Maxijacket is simple to brush on and dries sufficiently for installation in a matter of hours, although we let it dry two weeks before testing. Expect the line to be stiffer after coating. It matched RP25s chafe protection on Amsteel Blue, and provided greater protection for both Dyneema and nylon chafe guards.

Bottom line: Recommended. If you have a variety of rope materials that you want to protect, and don’t mind the added stiffness, this is a good choice.

Plastic Tubing

The advantage of clear plastic hose is that you can see what is going on underneath. The disadvantage is that it wears easily. Our generic brand, bought at a local hardware store, sold for about $2 per foot.

Bottom line: Better than nothing, but don’t expect much.

Compressed air hose

Used to deliver air from compressors to various tools, this polyethylene compressed-air hose was the stiffest sample we tested. We found that it gave great protection when it was wedged into the stanchion hole; otherwise, it slipped out of place and gave no protection. The stiffness was a problem when the lifeline angled down to a deck fitting.

Bottom line: Fine for straight runs, but not for lifelines that enter or exit stanchion holes at relatively sharp angles.

Tyco Heat Shrink Tubing

Heat-shrink tubing offered practically no protection to the lifeline in our tests. It must be installed at temperatures that might damage the HMPE line, and costs about $12 per foot.

Bottom line: Heat shrink for chafe protection of HMPE is a mistake.

Fabric Guards

Bluewater Climb-Spec

This nylon tubular webbing fits neatly over lines up to a quarter-inch. Testers were pleased with the way the surface fuzz on the webbing gripped the stanchion hole, keeping the webbing in place. During bench testing (which simulated nearly 10 years normal use), testers saw virtually no wear.

When we seized the webbing to the line so that it moved with it, the chafe resistance was less, but still impressive. UV rays will tatter this material over time, but it is thick and densely knit, so it isn’t unrealistic to expect 10 years of life. Coat it in Maxijacket, and it will surely last that long.

To use, simply cut three-inch lengths, melt the ends on a mandrel (described above), and thread the webbing through the stanchion holes, followed by the lifeline itself. This product stayed in position without any additional measures, and we know cruisers who have left tubular webbing chafe guards unsecured for years. If you feel the need to secure them to the lifeline, a simple lockstitch will do, or a whip-lock will be very secure. For lifelines, you have a choice of sizes from 5 to 12 millimeters. It is available from outdoor stores and climbing outfitters.

Bottom line: This cheap and very effective chafe protection is our Budget Buy among fabric guards. You can find it at online outdoor sports retailers like REI (www.rei.com).

NER Dyneema Chafe Sleeve

This Dyneema chafe sleeve is similar to nylon webbing in appearance. After bench testing, we saw no visible signs of wear on the webbing or lifeline. Although it was more difficult to fuse the ends than with nylon, it is simple to whip in place. Because it is thinner than the nylon, it is prone to slipping out of place in larger (10 millimeter) holes, but will fit better in the 8-millimeter holes. A little Maxijacket or RP25 over the whipping will make it very durable.

Bottom line: Tough as nails and economical for the small amount required, this product is our Best Choice.

Sunbrella Wrap

While we preferred tubing products for neatness and staying in place, we knew there would be sailors who want to add chafe protection after installation. We cut 2 x 2-inch squares, formed them as a snug double wrap, and it performed nearly as well as nylon and Spectra tubing. We think a simple lock stitch will be needed to keep it from slipping out of place. Although this will add more friction to the cover, it should still prove fairly durable.

Bottom line: Recommended. If you did not install chafe guards when you threaded your new fiber lifelines through the stanchions, this is a quick and easy retrofit.

Conclusion

Fiber lifelines will never have the lifespan of stainless cable, but proper deburring of stanchions holes, chafe guards, and regular inspection should ensure a respectably long life. If you use oversized, quarter-inch Dyneema line with Dyneema sleeves at wear points, you will undoubtedly extend the life of the lifelines. Although double-braid line offers simplicity, single braid with chafe guards offers greater reserve strength, durability, and economy. Like many things, it comes down to personal preference.

New England Ropes WR2 is very impressive. The cover is nearly impervious to damage. The shortcoming is that in the largest size (5 millimeters), the core is only 4 millimeters, so it only meets ISAF requirements for boats 28 feet long or less. For small cruising boats, a WR2 upper and an Amsteel lower would be a durable, light, and affordable option.

For retrofitting, we preferred the fabric guards to plastic tubing; they seemed less prone to damage from bending, wore better, and were easier to fit. The Dyneema sleeves provided the ultimate in protection, but less exotic materials will do well if the guards stay put in the stanchion hole.

Among the paint-on products, Maxijacket excels at providing heavy-duty protection for nylon and polyester, extending wear by four to eight times, but at the cost of considerable increase in line stiffness. RP25, on the other hand, protects HMPE line fairly well without noticeable stiffening, making it more useful on lifelines. Given the small amount required to treat a line, we recommend you purchase the product that best fits your needs; RP25 for HMPE or Maxijacket for polyester and nylon.