To the lubber, tying-up to a bulkhead seems like the simplest of all docking situations. Perhaps with floating docks this is true. You just throw in a few fenders and tie a few lines. Simple. But in the world of tidal bulkheads with pilings or rough concrete facings, it is often a hammer and anvil situation, with the wind and waves hammer incessantly as the anvil moves up and down with the tide, causing fenders to slip out of position.

Like most savvy cruisers, we actively avoid exposed bulkheads, but since one of our test boats, a 32-foot PDQ catamaran, can’t squeeze into some fore-and-aft slips, it has spent weeks pinned alongside during powerful squalls, in narrow canals with nasty wakes, and in harbors prone to surge. We’ve kept our rub rails intact where others have fled, and here we pass along what we’ve learned.

The distilled experience of seaman is invaluable, but at Practical Sailor, we like to quantify. While there are rules of thumb for sizing lines, fenders, and fender boards, we wanted to see what our test boat actually requires. Like our slip mooring study (see Springlines for Storm Preparedness, PS July 2016), the data presented here applies only to this specific boat, and it is scattered. However, if you apply a scale factor appropriate to your boat, review the fender and fender boards load rating data, and consider line materials and geometry observations, you should be able to engineer a system that will give you peace of mind. In rough conditions, an unprotected bulkhead can become unsafe, so it is best to consider other options before a serious storm or front sets in.

How We Tested

We exposed a 32-foot catamaran to winds from 10-45 knots (recorded at masthead) against both concrete and piling tidal bulkheads and measured the dockline tension with a calibrated load cell and fender load with a calibrated deflection beam.

This test beam was a thin, 1 x 4-inch plank much lighter than a working fender-board. By measuring the amount of bend under known loads, we were able to develop a calibration chart for use during testing. By measuring the amount of bend during testing, we could estimate the fender load.

The bulkheads were in protected locations with only recreational boat traffic and limited fetch of less than 200 yards. We based all of our testing and calculations on a single fender bearing point to keep things simple. Multiple fenders and fender boards will reduce the load by half or more. Our tie-up included spring lines, breast lines, and bow and stern lines.

What We Tested

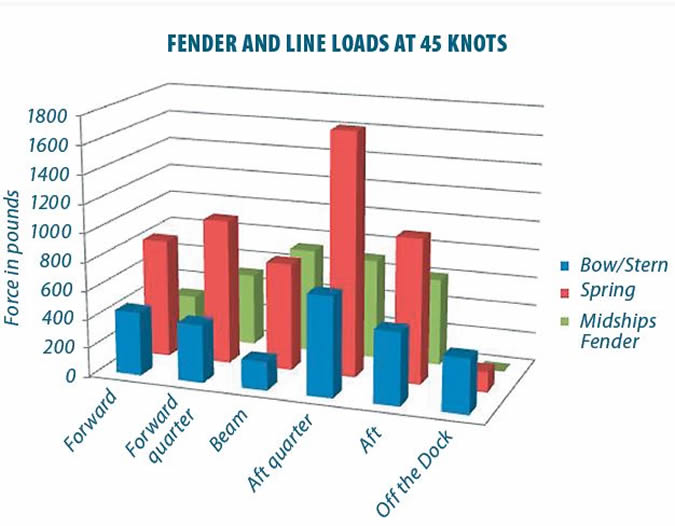

On the boat we measured line tension and fender loads in a variety of wind speeds and directions. Our measurements were generally limited to 35 knots with limited data points in higher winds. Adjusting lines in a high wind is difficult and moving fenders is dangerous or impossible. We then extrapolated into higher ranges based on previous data wed collected.

The effect of waves across significant fetch was not considered in our basic calculations. Experience and limited measurements during this project tells us that forces in a harbor that is poorly protected will be two to four times greater and can become unsafe in just 15-20 knots, depending on the degree of protection. All data and recommendations assume that wave effects will be very limited.

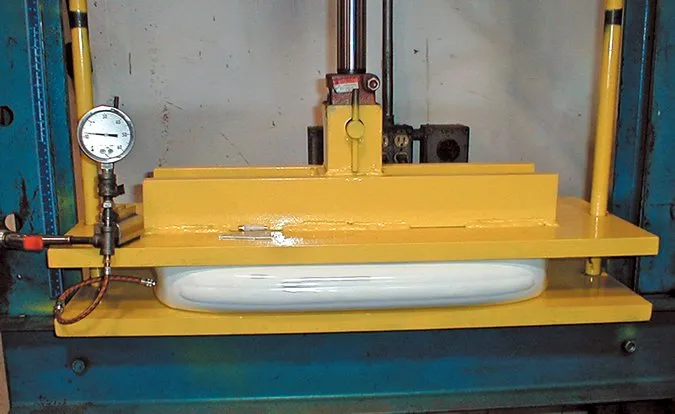

How much pressure can a fender take? Vendors gave us some guidance, but we decided to drive our car across some old fenders just for fun, to simulate the squeeze between boat and fender boards.

We tested using -inch lines, including both double braid and three-strand nylon breast lines. We tested both -inch three-strand nylon and 1/2-inch polyester double-braid spring lines, noting differences in forces and fender stability. We tested breast lines that were nearly plumb to the dock (80 degrees) and at more acute angles (45 degrees), noting differences in line force, fender force, and movement. Springlines were about one-half to two-thirds the boat length.

Observations

Polyester vs. nylon. Nylon is traditional for all mooring lines, valued for its ability to absorb impact. However, we wondered if this is always a good thing for spring lines. The boat will move fore and aft with the tide as the angles change, depending on the range and the length of the springs. Due to the stretch of nylon three strand (5 to 10 percent, depending on load), we commonly observed fenders moving as much as 2 to 4 feet, enough to dislodge the fender and require frequent line adjustments.

When we retested using polyester double-braid spring lines, the boat stayed in position much better, even in high winds, when surge waves were present. However, the dynamic loads on the spring lines, breast lines, and fenders were all many times greater than the loads using nylon.

When we switched to three-strand nylon in areas with large tides and strong quartering winds, the lateral movement was too great, making it difficult to keep even long, five-foot fender boards in place. Our solution was to use nylon springs, with about 18 inches of slack, and a second set of polyester double-braid lines to back them up. This graduated stiffness worked better. More conservatively sized spring lines or perhaps double- braid nylon, which has less stretch, might also be better options than three-strand.

Nylon breast lines were always preferred-either three-strand or double braid. We tested polyester briefly, but it had no advantages and resulted in much higher forces, bouncing against the fenders, and causing considerable discomfort.

Breast line angle. We tested breast-line angles nearly perpendicular to the seawall and at right angles (45 degrees). We quickly realized that in most wind directions, the optimum angle is perpendicular to a line drawn between the breast line deck cleat and the most distant loaded fender (see illustration). This can be close to perpendicular if there are several fenders, or as acute as 45 degrees on a wide catamaran pivoting on a single fender board. Forces on all lines and fenders is minimized by using the correct angle. This detail is most relevant for catamarans.

Slack. As with our July 2016 study, less slack is required for tide than you think, and if you want to keep fenders in place, the minimum is best. Unlike mooring between pilings, where a little motion is harmless, a boat tied alongside should be kept tight if there are waves running.

Piling condition. Closely examine the pilings before dropping in your fenders. Are there any nails, bolt heads, or protruding timbers? In addition to puncturing fenders and cutting lines, these can snag the boards when the tidedrops.

Tidal range. Note the predicted range of tide. Can fenders become trapped either on top of the dock at high tide or under the dock at low tide? Breast lines must be at least four times the expected range, and spring lines 8-10 times the range. Confirm that slack springs cannot become trapped between fenders and pilings, where they will rapidly chafe.

Fender tie points. Do not attach fenders or fender boards to the lifelines. Not only does this invite leaks by repeatedly stressing the bases, if a fender hangs up, the forces can be enormous. Better, attach them to an aluminum toe rail, stanchion base, or padeye. Use a clove hitch, perhaps backed up with an overhand knot if you will be gone for long. A clove hitch is nice to adjust, but it can loosen with repeated load cycling. A series of half hitches works but is more troublesome to adjust later.

Stabilizing lines for fender boards. If the tidal range is great, or end-to-end movement is significant, secure lines to the ends of the board to help prevent lateral movement. However, if the boat moves too far and the board snags on a piling, don’t expect miracles. Fenders secured to the toe rail or stanchion bases stay in place better than those tied to lifelines.

Fender placement. The load on a fender can be significant, easily reaching 1,000 pounds in a severe thunderstorm. Avoid placing them near portlights. Add a third fender in the center of the fender boards for backup and to distribute the load. A smaller fender often fits best, accommodating the curve of the hull. Fenders placed at multiple locations are beneficial, depending on the curve of the hull, but without fender boards, they are very likely to pop out of position in rough weather.

Minimize loads. Share the load by using two fender boards locations. However, in many cases boarding requires pivoting the boat so that just one fender location bears the entire load. This is a problem with the test boat, since it is easiest for passengers to board very near the transom.

Line Deflectors. A dinghy on davits or wind vane may block the run. In this case, you can rig a deflector (see adjacent photo). A fender placed under a line crossing the dock or deck can save gelcoat and chafe, and adds additional shock absorption to the line. Use chafe gear for sharp spots, although avoiding or eliminating them is better.

Test Results

All of the numerical data was collected with less than a 200-yard fetch. Limited data collection with longer fetch (>600 yards) or surge produced loads at least twice as great and the conclusion that exposed bulkheads are generally unsafe and those exposed to surge require great respect. We observed equivalent forces and movement during both 40- to 50-knot squalls in good harbors and 20-knot winds in harbor exposed only partially attenuated to wave surge. Think hammer and anvil.

Line loads. Polyester spring lines resulted in considerably higher forces than nylon, but we still like the more positive positioning, since having a fender pop out is a critical failure.

Spring theory. Occasionally the spring rate of the fender and polyester spring line would match, setting up a violent bouncing rhythm in strong quartering winds. Adding another line or fender would usually break this bouncing cycle. Nylon did not seem to generate this same problem.

Fender testing. We were not able to burst any vinyl fenders, even some frighteningly old ones; they simply got flat and stretched. For maximum load bearing capacity, inflate the fenders according to the pressure recommended by the maker, generally 2-3 psi (softer than a kick ball, much softer than a soccer ball).

However, the maximum load bearing capacity is determined by the plastics elasticity and the width of the fender board. In general, thicker fenders will carry greater loads. We did not evaluate fabric fenders, these are expected to have a different load relationship.

Fender boards testing. We only investigated pressure treated lumber. We’ve seen painted and varnished boards, and even fine hardwood boards.

In our experience, fender boards are disposable and should be expected to take a licking. Rough use can wear a board to the safe limit in less than a season. Some sailors add metal wear strips for this reason.

We based our testing on a stack of pressure-treated lumber that was representative of a board that has been in use for a while. The tables assume that a fender will be mounted near each end, with the center line of the fender 10 inches from the end. In severe conditions, place another fender in the center to limit the bend of the fender board.

Remember that, at times, the fender board will shift with the tide, causing the entire load to come onto one fender; having a second fender in the center helps by absorbing some of this asymmetric load.

Bulkheads are a terrible place to be caught in a blow. If you have time, move to a safer spot. In severe conditions they can be downright dangerous. However, so long as the wave action isn’t great, these tactics should see you through a squall unscathed.

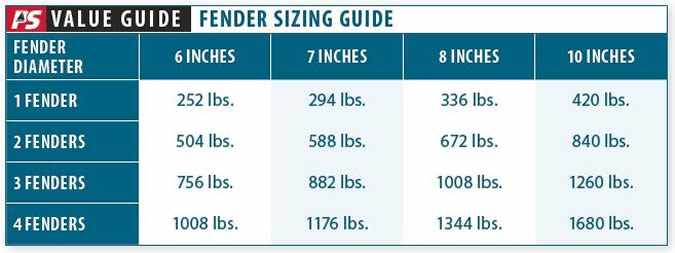

Two 8-inch diameter fenders or greater (in black) are the minimum size to absorb the loads on our hypothetical 32-foot catamaran in a squall.

Polyester spring lines resulted in higher forces than nylon, but better kept the boat in place, which reduced fender loads and the tendency to push them out of place.

Yet another PS article compromised by a lack of basic information about the subject. In this case it was the arrangement of fenderboards – length, fender arrangement, etc. I’ve seen many lengths, number & arrangement of fenders – which one was used? A simple picture would really help.

Please give the raw data. Thank you.

We kept our 42ft catamaran side-tied to a concrete seawall for two years with no problems, in all weather up to and including an unexpected cat 1 hurricane. This was in Port Canaveral, Florida.

We used polyform A-series round fenders.

A pair of extremely large A-5 fenders as the primaries, and a pair of very large A-4 fenders as a backup. As additional backup, we had three Taylor Made “Big B” HTM fenders (12×34). All were tied to the boat wth 1/2″ doublebraid, and no fender boards were used.

We were very happy with this setup and had no problems whatsoever. The backups were never needed, other than for peace of mind.

Tidal range was generally about 4ft, but up to 6ft. We were at the end of a fairway and fetch was up to 1200 ft, but mitigated by docks and boats on both sides. Dock lines were 3/4″ nylon 3-strand.

I loved the round fenders. We carry four more reasonably-sized A-3 rounds and four 12″ Big B for general docking.

Subscribers can download the July 2018 issue of Practical Sailor, http://www.practical-sailor.com/subscriber-only/july-2018-full-issue-pdf, for additional data, tables, illustrations, and images associated with this study.