More than a decade ago, we first reported on a problem with popular boat shoes. It didn’t matter which style they were—traditional topsiders or athletic-style sailing shoes. With very few exceptions, no matter what brand we tried, the shoes would be grippy at first, able to stick to decks like glue. Two years later, though, the soles would harden, and we would slide across a deck with even the slightest heel, like a loose cannon in a campy pirate film. It was dangerous. General purpose sneakers don’t harden like this, but few provide the same amount of grip as a new sailing shoe. Since shoes are your primary point of contact with your boat, they are essential equipment on a blustery day.

Why do the soles go slick? Manufacturers suggested that UV exposure is a cause, but that doesn’t make sense for shoe soles which don’t see a lot of sun exposure. And we’ve noticed that some older stock shoes have soles that are hard and slick right out of the box, even though they had never seen the sun. Collecting samples for this report, we found stores selling nearly identical shoes that varied dramatically in their ability to grip.

The only difference, as far as we could tell, was how long they had been sitting on the shelf. We’ve never seen a shoebox with a “best purchase by” label, but this might be a good idea, since the manufacturers we spoke with acknowledged that their sailing shoes can turn hard in a few years due to their composition.

In fact, durability depends on the rubber formulation. Unfortunately, the formulations are so tightly guarded that we found it impossible to determine the polymer blends manufacturers used in their shoe soles. Every shoe sole is a blend, and minor ingredients matter. But what is it with sailing shoes? It’s not like every shoe sole inevitably gets hard. The soles of our running shoes don’t get hard. We have a pair of New Balance trail runners that we use for painting, and they have about the same grip as they did when we bought them 10 years ago, grip that is comparable to our two-year-old Sperrys.

FIELD REPORTS

New shoe designs are introduced once or twice a year, so it’s hard to make definitive recommendations regarding which specific shoes will last the longest, and which shoe soles will lose traction. When assessing durability of the current offerings from major manufacturers, the best that we can do is look at our ongoing long-term tests, gather input from contributors, and comments from PS readers. This report primarily is an update on our ongoing research into ways to preserve or restore grip on our sailing shoes. Below is a brief summary of our research on specific shoes. There are, we assume, many other brands and models that have soles that lose their traction with age. The following are the ones we’ve been able to confirm.

HELLY HANSEN

We’ve had several reports of the Hydropower shoe soles hardening and losing their grip within 1-2 years. A test pair of women’s Ahiga V4 Hydropower shoes lasted 3 years before hardening.

MUSTO

We had multiple reports of Musto shoes going hard within 1-2 years. The Musto boots seemed to last a little longer (3-5 years), but they were used in cooler climates and not all year. The soles on a pair of PS test boots became hard after two years, and we got this explanation from the factory: “We would expect the rubber to harden through normal age degradation (rubber unfortunately does degrade; it is inherent in its compound makeup) … On average, we would expect about 5 years worth of use from this product . . .”

Musto suggested a freshwater rinse would delay deterioration, but since no plastic hose material is affected by seawater, and all known elastomers are rated “excellent” for salt exposure, we doubt that regular rinsing would significantly extend the life of our rubber soles or uppers. Most pointedly, none of the sneakers we’ve worn on the boat, around the water, or kayaking, go hard. Nor did any of our kayak boots.

Musto also mentioned exposure to heat as a cause. Excessive heat or cold could cause the shoe soles’ grip to change, but none of the shoes monitored in our long-term field test were exposed to anything approaching extreme temperatures, so this couldn’t be the cause in our samples.

GILL

We have no reports about Gill shoes going hard early in their life (within two years), but we got this feedback from the factory: “. . . Typically, outsoles that [become slippery with age] contain a high proportion of natural rubber. Natural rubber offers a good blend of grip and durability, and is non-marking, but it does have the potential to harden over time . . . You can renew the surface by using 60 grit sandpaper. Many deck surfaces aren’t especially abrasive, so another suggestion is to wear footwear on and off the boat—walking on sidewalks and concrete surfaces will naturally renew the surface.” Gill also suggested minimizing exposure to sunlight and heat.

OTHER BRANDS

We had many reports of Sperry and Sebago shoes (both brands are owned by Wolverine Worldwide) going hard in 1-3 years. PS staff has worn dozens of pairs of Sperrys that have gone hard. Like many people, it seems, we can’t resist an end-of-season sale. The makers cite exposure to heat, sunlight and the natural effects of aging as the causes of hardening. The moccasin style shoes with leather uppers popularized by Sperry, Sebago, and others is one of the most common type of sailing shoe that get resoled. Sanding the soles of Sperrys that are less than five years old can improve the grip.

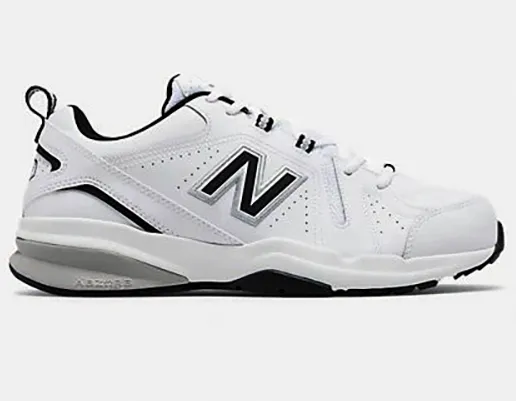

NEW BALANCE

As a form of control in this study, we included one pair of new athletic shoes (not sailing shoes), and 5- to 8-year-old shoes of the exact same shoe that we had saved for painting. Both shoes had been used for sailing during their life. We could measure very little difference in grip between the two pairs. Loss of grip seems to be primarily a deck shoe problem.

TESTING

Back in 2007 we tested a wide range of shoes on two simulated deck surfaces (teak and non-skid paint) that could be inclined from 25 to 50 degrees. For this comparison we’ve repeated the test with some new and used shoes, before and after sanding and on several surfaces.

OBSERVATIONS

Tread style. On smooth surfaces, Sperry’s herring-bone pattern and similar tread patterns flatten out and grip as you walk. On a gritty surface, no tread (yes, no tread) or minimal tread is better. Like slick tires on a drag racing car, these flat soles present a maximum area of contact. The tread on a trail-running shoe has just the opposite effect; less surface area in contact with the deck means less grip. Athletic shoes, particularly shoes with treads for gripping tennis courts or basketball courts, can provide reasonable traction, but avoid thick heavily cushioned soles which can make your feet less sensitive to objects underfoot like sheets and halyards.

Material. Gum rubber and rubber/polyurethane blends grip gelcoat, while carbon/thermodynamic rubber blends (climbing shoes) grip pavement and rock.

Deck surface. Paint or tape with embedded abrasive grip can improve the grip of deck shoes, but the improvement is only noticeable if the shoes have already lost their grip. Surprisingly, we found that a new shoe with a grippy sole will stick just as well to a textured deck as it will to non-textured deck. Neither the stick-on surfaces like Seadek or textured vinyl grip tape are very helpful in improving grip.

Shoe fit. Snug fit matters. During testing at steep deck angles, our feet slid around in the shoes that lacked tight lacing or good heel support. We could walk right out of some of the low-cut versions, especially those with only 2 or 3 pairs of lacing eyelets.

RESTORING GRIP

One of the most interesting findings in this round of testing was that a shoe sole’s grip can be restored. Combining what we have learned from testing, manufacturer-input, and experience in the field, these are some of the tips we have for restoring shoe grip:

Do not save your deck shoes only for use on the boat, believing that this will make them last. Several makers explained that routine use on abrasive, rough surfaces like concrete wears away the old, hardened rubber. We’re not saying they should be your everyday shoes, but taking a short walk on concrete now and then will keep the soles fresh. You might want to clean the soles before bringing them back on board.

SANDING

A more controlled way to abrade the hardened surface of your shoe soles is to use sandpaper. If your shoes have lost a little grip, sand them with a finish sander using 60-80 grit paper. An ordinary palm sander is fine. You can use wet or dry paper. You can apply less pressure on the most worn areas, like heels and toes, but give special attention to the instep, edges of the sole, and around the rand (toe cup), areas that aren’t abraded while you are walking.

Don’t be hesitant with the finish sander. The abrasive paper takes off less material than you might expect, and you aren’t harming the high-wear areas. It should take less than a minute.

In our testing, we found traction was dramatically improved with sanding, allowing us to get 1-2 additional seasons out of our 3-year-old shoes. Taking this simple step has the potential to save you hundreds of dollars over a sailing career. Remember that the rubber is hardening from both outer surfaces toward the center. The first sanding will expose some fresh rubber, but within three to five years, like an opened tube of caulk, the rubber will be hard clear through.

SOLVENTS

Readers asked about solvents, treatments, or sprays that would restore the grip. We tried many solvents, ranging from alcohols and ketones to aromatics and blends. In each case, we saw no effect. We tried a few grip sprays marketed to basketball and tennis players. As far as we can tell they are just cleaners. Unless you stepped in something slippery, no solvent or cleaner will help.

REPAIRS

In many cases, the upper fails before the sole. We found that a Sunbrella patch glued with white polyurethane works well for repairing holes in the uppers. The steps are simple: cut a matching Sunbrella patch from scrap (most canvas workers have plenty of offcuts). Glue the patch down with Sika 291 or Loctite PL S30. The result is a comfortable patch that is barely noticeable, and the repair will outlast the sole.

Shoe Goo is useful for patching small wear spots on the sole, covering them before they go through if possible (see “Shoe Goo’s Gift to Sailors,” PS April 2023). But we don’t recommend it for patching large areas of the sole, because it is more slippery than the original sole. It is also good for repairs to the upper, although not as good as the Sunbrella/polyurethane repair method.

RESOLING

We fully support keeping old shoes and clothes out of the landfill, but that dedication to reducing consumption comes with a price. There are a few companies that will resole boat shoes, but the cost is nearly that of a new shoe. In many cases, not just the sole needs fixing; the midsole, lining, and uppers could be worn out, so you might be wasting your money on shoes that have reached the end of their useful life.

We’ve tried a half-dozen resoling companies over the years and found it is best to work with a company that specializes in resoling your specific brand and type of shoe. For example, Rancourt will resole its own boat shoes (www.rancourtandcompany.com), while NuShoe resoles a variety of brands, including Sebago boat shoes (www.nushoe.com/sebago-shoe-repair.html). It’s always best to call the resoling company to make sure you are getting what you want. Several years ago, we sent a pair of Rockport boat shoes to Resole America (www.resole.com), a company that advertised itself as an authorized resoler for Rockports, but all they could offer was the Vibram sole for a hiking shoe. If any PS readers have had experience with online resolers, we’d like to hear of your experience (email practicalsailor@belvoir.com).

DECK SHOES

When looking for a pair of comfortable, grippy deck shoes, it helps to review what we know doesn’t work. Heavily padded walking shoes, and running shoes are not deck shoes. You want a low center of effort so that your ankles won’t roll on a sloping surface; you want a thin sole so you can feel the rope you just stepped on; and you want that sole to conform to the curve of the deck. Designed to absorb the impact of running and shield you from stone bruises, most multi-surface sneakers are too padded and too stiff to serve as deck shoes.

Court shoes (tennis, pickleball, etc.) can work if they’re not too heavily padded. They have the right tread and are more comfortable during a walk around town better than pure deck shoes. Grip varies, and although you can test grip on the smooth tile at the shoe store, the out-of-the-box grip does not always correlate to good traction after some wear.

Most moccasin-style boat shoes are not good deck shoes compared to contemporary designs. Their lack of support, lack of padding, and mediocre durability are among several reasons we don’t recommend them for active sailors. Low-cut moccasin style shoes with just two or three pairs of lacing eyelets like the original Sperry Topsider may be fashionable, but they don’t support your foot like a higher cut shoe with five or more pairs of lacing eyelets. During the steep-slope phase of our testing, we often felt like were going to slip out of our Sperrys. And anyone over 40 who has trudged across town to the immigration office in a pair of sailing moccasins knows how unsuitable they are for walking.

Allowing your feet to breathe in the tropics prevents athlete’s foot, but open-toed sandals are not deck shoes. Rope will get between the sole and the toes, tripping you.

The most popular “performance” deck shoes, in comparison to all the previous examples, offer vital support, sensitivity, and grip, but sacrifice some comfort as a walking shoe.

GILL RACE TRAINER

One of Gill’s most popular sailing shoes, the Race Trainer looks like a low-profile sneaker and is similar in appearance to our 2019 Sperry Harbormasters. These shoes have improved drainage (holes in the insole go right through outsole—they hold zero water) and a very sticky sole. Grip is excellent and the shoe is comfortable, but there isn’t much room for an orthotic sole if you choose to use one; our heel lifted out even with the thin stock insole. The shoe has a speed-lace system that snugs up in seconds, but we replaced it with conventional laces so we could get a better fit.

Bottom line. These comfortable shoes did well in the non-skid testing, but some users may want more room for an orthotic sole. We’ll report back on hardening.

SPERRY HARBORMASTER

One of Sperry’s most popular models, the Harbormaster has gradually evolved over the years. We’ve had several pairs during the past 30 years. The original model was comfortable for sailing, cruising, and even walking around town. However, the soles have consistently turned hard after three years. The 2019 design currently in testing is more lightly built than the original, making them not quite as comfortable for walking, but more sensitive to changes in footing. This is a fair trade-off for the sport boat sailor.

After two years in the field, the shoe’s grip was no better than our around-town sneakers, and after three years, the sneakers were clearly gripping better. We’ve vigorously sanded the soles on the Sperrys and restored much of the original grip. Next year, their fifth in use, will likely be their last season.

Bottom line. The Harbormaster had the best fit, support, and heel cup design of those tested. Plan on replacing them every 3-5 years.

ZHIK FUSE

The Zhik Fuse performance shoes are a lot like the Sperry Harbormasters in terms of comfort and fit. Grip is excellent, although the heel lifted slightly when walking up steep inclines. We have not found any widespread complaints of sole hardening.

Bottom line. The heel didn’t fit well on our testers. Grip is good, but the shoe is priced 20-30 percent above competitors with comparable grip. More testing is needed.

NON-SAILING SHOES

You don’t have to look far to find sailors who are quite happy with shoes designated for other sports that require grip. Australian Jessica Watson, who famously sailed non-stop singlehanded around the world at the age of 16, preferred a pair of Chuck Taylor Converse sneakers.

VANS

First introduced to these in the 70s, these were the shoe of choice for adolescent skateboarders raiding backyard swimming pools. Recommended by fellow sailors, they have many features that would suggest they would make a good boat shoe. The soft rubber sole provides excellent grip and the uppers are low to the ground, as one would expect in a sport that aims to defy gravity. They are widely available in practically every color scheme. Models with synthetic fabric dry well.

Downsides are narrow fit and only modest support around the ankle on some designs. Some models with more padding tend to absorb water. Do the soles harden? We’ve had a pair in the field for five years now, and although the sole is worn smooth in some places and the uppers have completely faded, the grip on the soft rubber sole is still acceptable.

Bottom line: Vans offer excellent grip, but they aren’t much cheaper than good sailing shoes. Although some materials dry fast, Vans generally lack drains and other water-friendly features of true sailing shoes. Wide-footed folks might have to look elsewhere.

VOLLEYBALL SHOES

Like most court shoes, volleyball shoes offer solid traction, good support, and walking comfort, but the extra padding can diminish tactile contact with the deck. You can’t always feel the line you stepped on until it’s too late. For years, our Tech Editor Drew Frye sailed with a pair of Dunlop Volleys, but these are no longer available. Some PS readers have recommended Asics indoor sport shoes.

Bottom line: Court shoes show potential to make good sailing shoes if quick drying isn’t a priority. We’d be interested in hearing from the tennis or pickleball crowd if they’ve found a good crossover shoe.

TRAINERS

We’ve often sailed wearing our regular New Balance 608 Trainers. Nothing special, these multi-surface shoes have mostly leather uppers and a thick sole, moving them out of the deck shoe category. But they have excellent support in all directions, a solid heel counter, comfortable padding, and a sole that is relatively grippy. We wear them on the boat often, and the only downsides are their slow drying and the excessive padding that dampens sensitivity under the sole (you can’t have both). Usually costing less than $60, these grippy training shoes are a bargain.

Bottom line: These are not what we’d call deck shoes, but they are comfortable and offer acceptable performance. New Balance is representative of just one of many mainstream multi-purpose shoes that could serve cruising sailors well. Look for a flat tread profile and a sole without side protrusions that can snag a rope or a pad eye.

SANDELS

We’ll sometimes wear snug-fitting strap sandals when it is hot, or we are in the dinghy. The lack of protection and the trip hazard makes them a poor choice for deck shoes.

Bottom line: Avoid open-toe sandals. Closed toe models, like the Keen Newport, are better for boats, but still don’t offer the support you’ll need for active sailing.

CONCLUSION

Durability is elusive in shoes, even in boat shoes that don’t see a lot of miles. It seems that no matter how much you pay or what type of sole you have, grip is only going to last 2-5 years, even with sanding. On most boat shoes, the plastic gets hard and you lose grip. If you choose a softer blend polymer sole that doesn’t go hard, then it will likely wear out faster. Either way, five years is the expected lifespan. A key take- away here is that expensive shoes may offer better fit, features, or comfort, but don’t expect longer durability or better grip.

Perhaps our most interesting finding from our research is that wearing your boat shoes on concrete helps renew the grip. You just need to brush off the grit off before boarding. If your shoes seem to be getting slick after a year or two (compare them to your sneakers) scrub them thoroughly with an orbital sander and medium grit paper for several minutes, concentrating on the edges and instep. You should get an extra year or two. Forget magic sprays and solvents.

When your favorite boat shoes become slippery, buy new shoes. Sure, they might have cost a bundle, but what is the cost of a bad fall?

TEST REPORT: SHOE GRIP BEFORE AND AFTER SANDING

1. Some veteran sailors swear by their Chucky Taylors. We prefer more cushion and support.

2. The thick sole of the New Balance 608 drops them out of the deck shoe category. The shoe did well in our grip testing, however.

3. Any shoe that leaves your toes exposed is undesirable as a deck shoe—no matter how grippy.

SOCKS

ORTHOTICS

TESTING FOR FIT

We’ve generally been satisfied with the non-skid on boats. Our pet peeve is when it doesn’t cover all the right places, ending short of the edges of steps and cabin tops. That’s often where you need it most, but for whatever reason—non-skid wears fast on step edges, it doesn’t look right, etc.—builders opt to leave key parts of the deck, or cabintop smooth.

Thanks for the “soleful” article. As a sailor of many years, I recall Sperry canvas topsiders and seaboots purchased about 50 years ago as never suffering the hardening described in your article. I particularly recall a pair of rubber seaboots which I owned from about 1970 until I retired them in the mid ’80’s; neither the uppers nor the soles ever got hard. When retired they had over 35,000 sea miles. I don’t know what materials were used then, but I don’t think I’m viewing the past with rosy glasses – the boots and shoes were better. More recently every pair I’ve bought hardens quickly. In order to avoid this problem I recently bought a pair of Duberry “Ultima” boots (~$400!) for a sailing trip to Mexico and return. I (incorrectly) assumed they would fare better than others. They were marginal when they arrived, and were hopeless within a year. It’s now been about four years, and the soles are rock hard. Sanding offers essentially no improvement. However…

I did research online, however, and found a lot of articles about using a mixture of methyl salicylate (Oil of Wintergreen) and isopropyl alcohol to soften rubber. I just soaked the soles of my Duberry boots in the concoction, for about 15 hours, and the rubber softened dramatically. The degree of friction increased substantially (Unscientific assessment – coefficient of friction up ~500%). An interesting bonus (?) is that the boots smell like a candy store. It’s only been a day since I completed this experiment, so it’s certainly possible that they’ll return to their previous state shortly. We’re working on my wife’s topsiders now, but I think they’re hopeless, as the brittle sole has been chipping away in small chunks recently. I must say, I’m pretty disgusted with investing large amounts on this junk.

I agree with Stephen’s comment about “old” Sperry Topsiders. (I’m old enough to remember that Sperry would re-sole leather topsides.) For a few years, I used LL Bean top-end boat shoes. Even after the soles wore too nearly bald and started to crack at the thin spots, they still had great traction- wet or dry. I still use them in the Spring when working on my boat (34′ Sea Sprite) while it’s on the hard and I’m 10 feet in the air. I wear Sperrys on the water, but have to release almost every year- “planned obsolescence” comes to boat shoes.

An additional comment on PS’ evaluation of boat shoes- I think you overlooked another very important property- at least important to some of us. Shoes with “deep” treads pick up and retain sand and mud, while siped soles clean off quickly and completely. My first boat was a wooden Lightning with a lot of varnish in the boat. I learned to clean shoe soles quickly and completely- I continue to avoid shoes with deep tread patterns for boating.

Excellent point about deep treads, and the issue came up in the review of Xtratuf shoes and sandals, but it was unfortunately cut for space. They demonstrated monstrously good grip on grit nonskid and the slimiest boat ramps, testimony to their commercial fishing roots. If you have a trailer boat and frequent ramps you need these, nothing else comes close. But if you walk on fine gravel or sticky sand they load up and require a pounding on the dock and a rinse with water before then come on board. Often, when we transitioned from a gravel yard to a sidewalk we could hear stones in the tread clicking on the concrete.

Most deck shoes seem to be moving towards the same wave tread common on modern indoor basketball shoes, a case of convergent evolution; both are optimized for traction on smooth, potentially wet (sweat in the case of indoor basket ball courts) surfaces. Coincidentally for sailors, this tread style is also good at shedding sand.

When we find shoes that don’t go hard, we’ll report back. Right now I’m wearing 2-season old Gill Race Trainers, and they still stick like glue, far better than common sneakers. But we’ll see. I’ll have to test them on the test ramp next summer to see if there is any change.