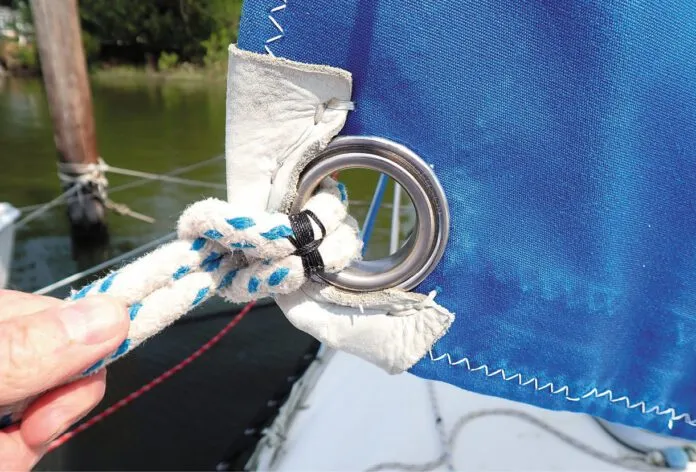

LOVE HITCH AT THE CLEW

Regarding your recent report “In Search of a Snag-free Clew,” (see PS February 2024), even luggage tags can catch on wire shrouds. The smoothest knot at the jib clew, in my view, is a clove hitch. With this knot, the starboard and port sheets come out at the correct orientation, and material around the eye cushions the angle between the sheets.

There are some disadvantages, it is hard to untie after loading, so the sheets usually stay on the sail. And as with any sheet made from a single line, you can’t have different colors for port and starboard.

Talbot Bielefeldt

Starlight, Precision 21

Kilisut Harbor, WA

The clove hitch is similar to a cow hitch, also called a luggage tag knot (see www.animatedknots.com). The clove hitch has a low profile and tacks smoothly, but as you mention, it can be hard to untie. For offshore cruises, we like being able to untie sheets and reuse them when changing headsails.

PAINT-ON UV SAIL PROTECTION

As a subscriber since the 1980s I’ve learned to take your advice to heart, and was impressed with Drew Frye’s 2019 article on painted UV sail protection (see “The Case of the Painted Jib,” PS January 2022). I tried it myself, painting a 15-year-old sail with MDR dinghy paint. It has held up remarkably well.

When I ordered a new genoa late last year, I told the sailmaker not to add a Sunbrella cover—saving me a fair bit of money. I decided to again paint the leech and foot myself. But I was concerned that spinning oils, or other coatings on the new polyester might prevent adhesion. When I received my new genoa from Far East Sails I washed the leech and foot area with a diluted solution with 1:10 ratio of Simple Green to water. This seemed to work.

I’ve now furled and unfurled the sail a few times and the paint is clearly well adhered. The sail is lighter and has much better shape than if I’d specified a fabric UV cover. The last sail I painted had some leakage under the 3M blue masking tape, so this time I used a green tape from Amazon advertised for rough surfaces, with a stronger adhesive. That gave a much sharper edge.

Based on my last experience and the way this new sail looks, I’d recommend the painting process using MDR, especially for a light air sail that would benefit from minimized weight.

For the future, what cleaner would be preferable for removing any soluble coatings or oils on a new sail that would prevent adhesion? Obviously, we don’t want to use any chemicals that would damage a new sail.

Roger Neiley

SolunaMare, Saga 43

Newport Beach, CA

A hard surface cleaner such as Spic-N-Span, or a dilute mix of washing soda and tri-sodium phosphate (TSP) would make sure any oils or coatings that would inhibit good adhesion are removed prior to painting a new sail. Simple Green should do just as well.

FIGHTING MILDEW

Regarding your recent Inside Practical Sailor blog post on fighting mildew, “Preventing Mildew in Marine Fabric,” for several years I treated both sides of my sprayhood with 303 High Tech Fabric Guard. I had a big problem with mildew on the underneath side of the Sunbrella. When I switched to only treating the outside, the mildew problem was greatly reduced. The attached photo shows Wassail, our Najad 440 sailing in the U.S. Virgin Islands. My wife and I took delivery at the factory in Henån, Sweden in May 2006, sailed in Scandinavia for a couple of summers, then from Europe to St. Lucia. Finally, in 2011 we sailed from Fajardo, PR back to Newport, RI. We live in Newbury, MA and keep Wassail at Merri-Mar Yacht Basin, Newburyport, MA when it is out of the water. During summers since 2011 we don’t have a particular home port, but sail between the Long Island Sound and Nova Scotia. The photo is of Wassail in the U.S. Virgin Islands.

Nick Horem

Najad 440, Wassail

Newbury, MA

It is likely that the hydrophobic properties in the 303 High Tech Fabric Guard on the bottom of your sprayhood prevented the spray hood from drying quickly. Exposed to direct sunlight, the 303 applied to the top would eventually become more permeable, while the 303 applied to the bottom formed a membrane to delay drainage. Under these conditions, even a light rain could result in a fully saturated sprayhood—at least its horizontal surfaces. Moisture, as we know, is ambrosia for mold and mildew. Leaving the bottom uncoated makes perfect sense.

On an unrelated note: We’re always intrigued by the names of boats that appear in Mailport, and your boat’s name, Wassail, struck a chord, so to speak. For those, like us, who were wondering what the western holiday tradition of wassailing has to do with sailing (beside the opportunity for a pun), a quick dive into the etymology of the word offers clues. According to the Oxford English Dictionary, the word derives from the Middle English salutation wæs hæil ‘be in (good) health!’ Like the Hawaiian phrase ‘aloha,’ the salutation “Wassail!” was used in both greetings and farewells—events that form an essential part of a cruising sailor’s life. The pun—“was sailing” and “wassailing” (spreading good cheer)—is subtle and slanty enough that we can let it pass.

THUMBS UP FOR LEISURE FURL

Regarding your report on mainsail handling (see “Taming the Main, Sail-handling Systems for Bigger Mainsails,” PS January 2008), my wife and I, now in our mid-to-late 50’s have sailed our 42-foot sloop for more than 20 years. In the beginning it had a Dutchman system that significantly simplified mainsail handling. About five years ago, when we our rig was damaged in a collision with another boat (not our fault), we replaced the mast and installed a Forespar Leisure Furl in-boom furling system. We love it. It’s dramatically safer for our type of cruising and will undoubtably extend our ability to manage the 370-square-foot main. We reef sooner and more often, and when it comes time to stow the sail, neither of us have to be on the high part of the deck (or steps on the base of the mast) to secure it. It was well worth the cost.

Sean Davern

New Horizons, Hunter Passage 42

Seattle, WA

ANTIFOULING FOR CHESAPEAKE BAY

I just read your most recent update on bottom paint. You covered a lot of ground with great detail. I recently hauled and repainted my boat with Micron CSC. I’ve used it on my Bavaria 44 for five years on the York River in the Southern Chesapeake Bay. I’ve been pretty happy with it, but I dive on the boat several times each season, especially first thing in the spring, to keep the bottom clean. Like you, I’ve noticed that after the first 12-18 months the paint is not as effective at staving off soft growth or barnacles. After hauling out last month, it had been 2½ years since my last paint job. Barnacles were starting to get a grip in several places where the paint had worn thin or was completely gone. I clearly waited too long, but was enjoying the summer sailing, so I put off the haul out. Based on your results, I will most likely switch to Total Boat Krypton next time. I’ll probably only go 18 months on this bottom job.

Jake Brodersen

WineDown, Bavaria 44,

Hayes, VA

PAINT STRIPPING WITH DRY ICE

I am seriously considering hiring a service that will do dry ice blasting for $3,000 to clear layers of bottom paint off an O’Day 25 that I bought for $1,500. What do you think?

Albert Pierce

O’Day 25

Malletts Bay, Vermont

Before you plunk down a big chunk of change on blasting off the old paint on your O’Day, you should try scraping the paint (see “A Scraper-only Approach to Bottom Paint Removal,” PS April 2024).