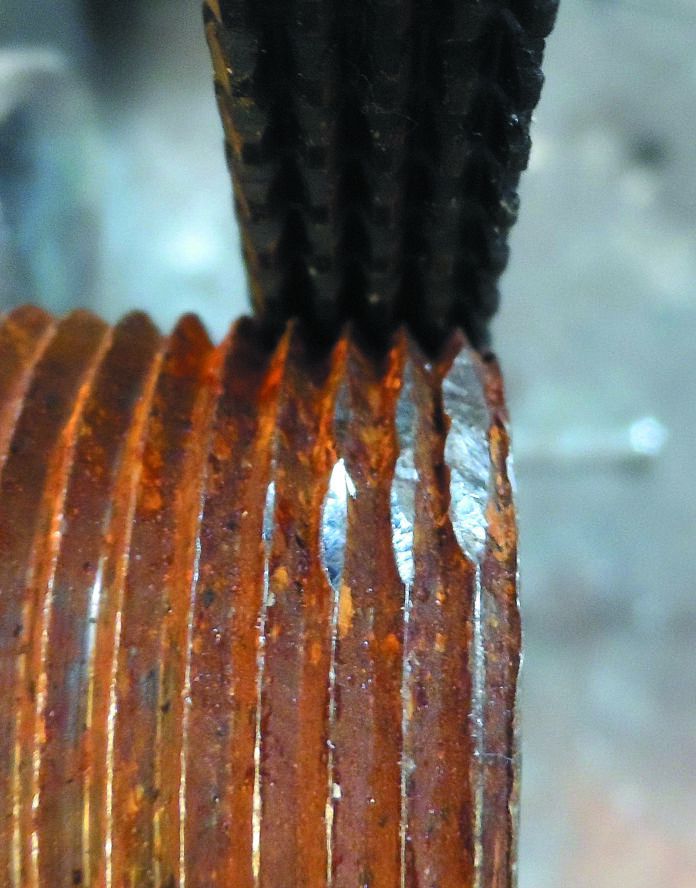

Thread restoring files cannot restore stripped or severely corroded threads, but they can work wonders on threads that have been distorted by impact, clogged with corrosion products or adhesives and paint, or where the first few threads have been torn off or mangled. Common Unified National Fine (UNF), Unified National Coarse (UNC), National Pipe Tapered (NPT), and metric threads all use the same 60 degree angle, so if the thread restoring file matches the pitch (threads per inch or TPI), it will work. Technically, pipes from 1-2 inches require an 11.5 TPI file, but 11 TPI works very well.

Rotary files need only match the angle (60 degrees), but except for very large threads, I find they can be hard to control and hard to work with in tight spaces. Unlike thread restoring files they are not stabilized among multiple threads so the repaired thread may wander, especially when cross threading is involved. Finally, they only remove material rather than straightening bent threads. They are best on very large threads and only for cleaning up a starting thread (not for load bearing threads).

The primary advantage of a rotary file is that it can be used for internal threads, but I have not had much success with this. Internal threads can be dirty, but unless you cross threaded a part, they are seldom damaged. If seriously cross threaded, chasing with a tap is generally the only road back.

A fine triangular mill file has a 60 degree angle and a small one can restore threads in a pinch, but like the rotary file, it is not stabilized by multiple threads. It can work in a pinch, but the results are often disappointing. I would not use this method on an expensive or critical part.

Our recommendation is a double ended, 8-thread restoring file, covering 11-24 TPI. This will repair pipes up to 2 inches, NF bolts from 5/16-inch to 1.5- inch, UNC bolts from #10 to 5/8-inch, pipe from 1/8- to 2-inch, and some metric bolts in the same ranges (a separate file for metric is better). The sort of tool you won’t use often, but if it works once, it’s paid for.

When using a thread file wear gloves and remember to align the file with good threads as you repair damaged ones.

Id like to get information on electric propulsion systems for my sailboat.