Estimating size has always been tricky, because it depends on the insulation value of the boat, climate, and how quick you want the boat to cool down. It also depends on window covers and awnings and how much window space you have. Houses, on the other hand, tend to have similar insulation values, and the rate at which they cool is not important because people leave the AC on all summer.

For example, the simplest rule of thumb for sizing is about 100 BTU/square foot, which would calculate out to a whopping 33,000 BTU for our test boat (a PDQ catamaran). Another rule of thumb is to multiply the actual accommodation volume by 14 (height x width x length in feet x 14 = BTU). This yields about 17,000 BTU for the test boat, which is close to our needs if we did not use window covers and awnings to reduce the solar load during the day.

In actuality, a 12,000 BTU AC would have suited our boat, but our home marina has dock power limitations, so we skimped and settled for 10,000 BTUs, demonstrating that rules of thumb are often oversimplifications.

How can we get by with so much less? Most of the cabin is cored with 1.25-inch of foam, plus a foam ceiling liner, and we cover all of the windows to reduce solar gain. We are also willing to let the AC take an hour to fully cool the cabin. What is the problem with oversizing? In addition to weight, noise, lost storage space, increased power demand, and expense, dehumidification is less efficient when an AC unit is oversized.

Although this is counter intuitive, unless the AC unit has a relatively long cycle time (on for at least 70-percent of the time), the compressor does not run long enough for the coils to accumulate condensation and have it drip off and drain away. The air is cooled, but not dried, which is actually more important than cooling in most boating areas. Because our unit is smaller, the cabin is dehumidified and thus comfortable without cooling to an excessively low temperature. It still runs no more than 25 percent of the time on a hot night, once the cabin is cooled.

An AC installer has to be conservative. If he downsizes the unit and the cooling does not meet customer expectations, he is in a pickle. It is safer for him to oversize a little. The problems with oversizing is increased power draw at the dock, possible modifications to the power system (you may need a new electrical panel), less efficient dehumidification, more noise, more space, and more expense. A 16,000 BTU AC will cool your boat quickly, and 10,000 BTU will probably do a fine job so long as windows are covered and you can wait a little while.

In the case of our PDQ catamaran, we wanted to be able to run the boat on 15 amps (including charging and lighting)-so we underestimated BTU requirements. Duct size is critical, and specified by the manufacture. Too small and you lose efficiency, too big and the air does not mix well.

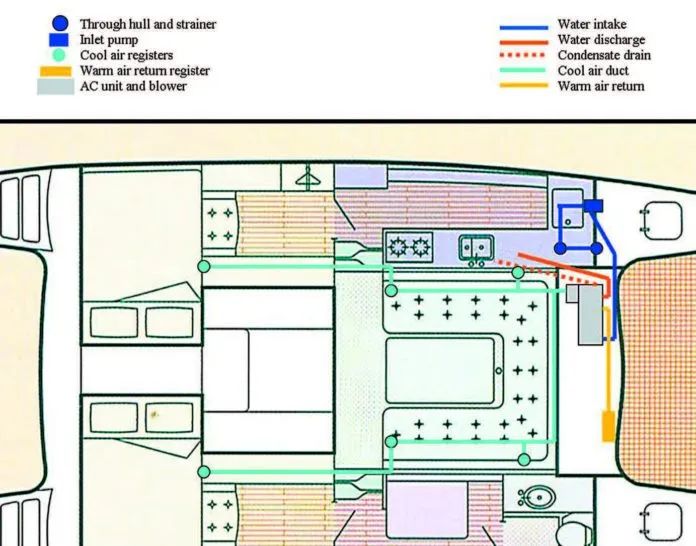

You want to blow the cold air in high so that it can sink, and to locate the return intake low in the boat. The duct area is typically proportional to BTU. Typically a 10,000-16,000 BTU unit will have three or four 4-inch outlets and an equal size return.We used four outlets on our catamaran, however two ducts can work on a monohull. One outlet is generally not be enough.

The principles for estimating size on a boat and home are similar, with a few twists to allow for solar heating. First estimate the worst-case interior vs. exterior temperature range. In our case, we used (100F-75F)= a 25F-degree temperature differential.

To calculate BTU requirements-in effect, a measure of the heat lost or gained through our hull-for the 25F inside-outside temperature differential in our boat’s home waters we used the same method we used for estimating heater sizing (see A Customized Way to Calculate Heating Needs, PS January 2019). This requires repeated tests on several cool nights, using a typical 1500-watt space heater set on high (1,500 watts=5,150 BTUs/hr).

In the case of our test boat, we determined we needed 1.5 x 1,500-watt heaters (6,394 BTU/hour) to maintain a cabin temp of 75F on a 20F night. As you’ll note, in winter, the difference between outside and desired inside temperature was 50F. In summer, the difference was only 25F degrees. So our cooling BTU requirements were only about half of those for heating, or about 3,800 BTUs.

However, because solar gain-radiant energy from the sun entering through windows-is a factor during summer, we have to compensate for that.

Estimating Solar Gain

To estimate solar gain, measure the hatches (square feet) and multiply by 1,500 BTU/ft2, and divide by three, assuming they are not all in the sun. This can be considerably reduced through the use of covers, but do not take credit for that here. In the case of our test boat, there were 35 square feet of windows, so counting only 1/3 (the sun only hits 1/3 squarely at one time) gives a solar gain of 11,700 BTU.

The Final Calculation

So . . . with no window covers, our test boat would require 11,700 BTU (solar gain) + 3,800 BTU = 15,500 BTU total. Some owners of sister ships have units that large and are sure they are needed. They also have occasional problems with the compressor icing due to the excessive size.

However, we have canvas window covers for all of the windows, which reduce the solar gain by 1/2 to about 5,850 BTU, or 9,650 BTU. As mentioned, we have a 10,000 BTU unit and might be a little happier with 12,000 BTUs on the hottest days. When it gets really hot we close unused cabins during the heat of the day. At night the system is adequate.

Conclusion

Air conditioner sizing depends a great deal on window covers. We recommend window covers, but size according to how you will use the boat. There is a considerable range. While you can make your own canvas covers, we opted to make our own hard covers, described in this step-by-step article on building fiberglass hatch covers. If you don’t have the time to build your own cover, Outland makes some handy snap-on hard covers, and if you prefer canvas covers Sail-rite has everything you need, beginning with this how-to instructional video.

There are lots of on-line calculators. However, when we used any of these calculators, we got 2-3 times greater requirement than we did using our own numbers. A lot depends upon how fast you want to cool the boat. We were satisfied with taking an hour to cool down.

For reference we found two online guides.

– Marineair.com: www.marinaire.com/category-s/28.htm