Most offshore sailors are familiar with jacklines, those long lines-typically made of high-strength, low-stretch webbing-that run along the deck, offering a convenient way for sailors to clip in with their safety tethers and still move about. They provide peace of mind when going forward, and security in the event of a misstep. In previous articles, we reviewed the use of tethers and jacklines . In this report, we take a closer look at the ideal jackline material, with particular focus on elasticity and how the best material is not the same for big boats as it is for smaller boats.

In our recent article on do-it-yourself webbing projects , readers asked about making their own safety equipment using the webbing that rock climbers rely on. Although racers at the highest level often fabricate their own safety gear, we hesitate to recommend DIY safety gear for everyone because it requires intimate knowledge of the material specifications as well as the load requirements for the application.

A DIY jackline is possible, however. Manufacturer specifications for webbing and cordage tend to be fairly accurate. And, for tether and jackline applications, it doesn’t require rocket science to calculate the loads. The amount of stretch and impact imparted by a fall has been exhaustively tested and modeled in rock-climbing applications.

The questions that matter for jackline applications are: Will the line stretch so much that a sailor can slip over the side, and will the impact be so great that it will over-strain the system or injure the sailor? Both are possible without proper design, and as well see, one material doesn’t work for all boat sizes. While the International Sailing Federation (ISAF, the world governing body for the sport of sailing) has a minimal, one-size-fits-all standard for jacklines (see accompanying story), we can do better by choosing materials and sizing appropriate to the specific boat.

What We Tested

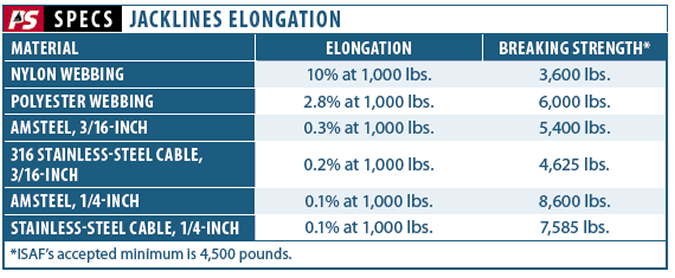

In order to come up with some basic guidance for choosing jackline material according to boat size, we built a model for performing a series of tests that allows for common materials and variables. The products tested included: 1-inch nylon rock-climbing webbing, 1-inch polyester jackline webbing, 3/16-inch and -inch Dyneema, and 3/16-inch and -inch 7-by-17 stainless-steel cable (Grade 316). Although Dyneema jacklines are often encased in 1-inch webbing to reduce the potential for rolling underfoot, we didnt do this because the webbing doesn’t affect the Dyneemas strength or stretch.

How We Tested

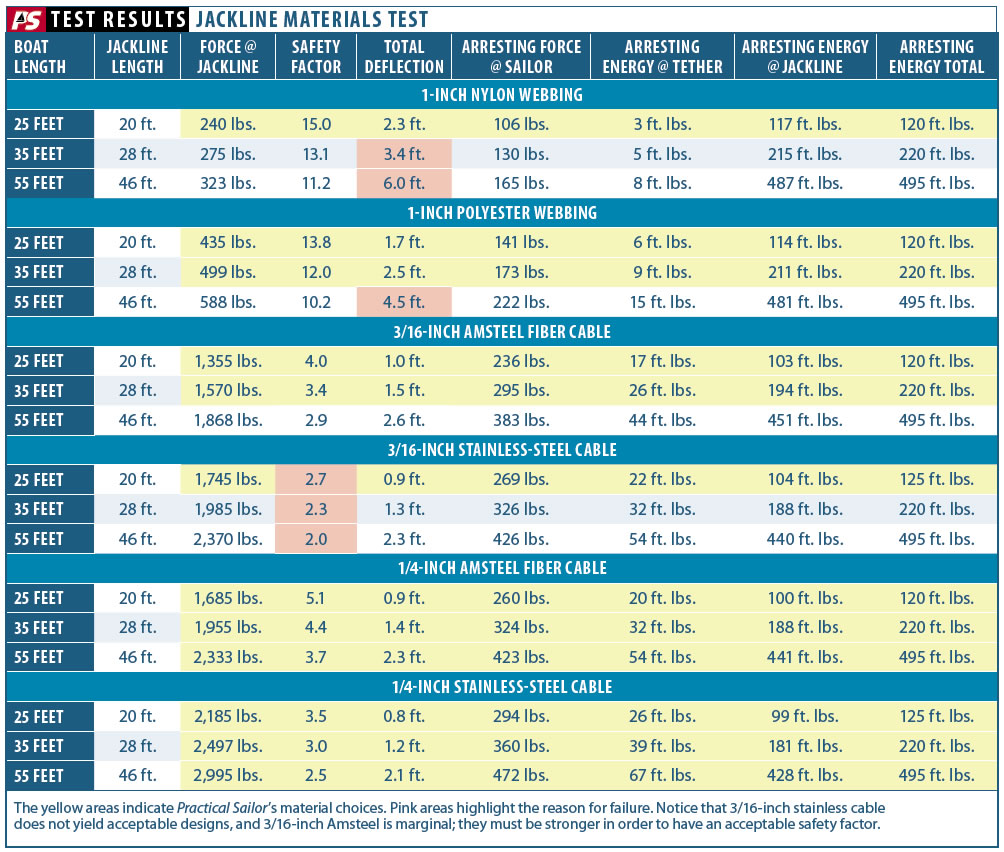

All of the results posted in the accompanying table were based on a combination of lab testing and load modeling. Any assumptions regarding installation and application in the real world were confirmed on one of our test boats in the Chesapeake Bay. To estimate loads, we needed a test dummy to fall, and for this, we used the standard mass (225 pounds) as described in ISO 12401, an established international test for safety harnesses and tethers.

We assumed that a crewmember on a bigger boat, because he had more distance to fall, would attain a higher velocity than one on a smaller boat. We made the jackline slightly shorter than the boat, and we assumed that only one sailor would fall on the jackline at a time. (None of the products we looked at recommended that more than two people be attached to a single jackline simultaneously.)

We set a limit for impact force at 700 pounds. The U.S. military uses 1,200 pounds for a safe parachute opening force, but that is with a full body harness. To determine final impact force on the body of our victim, we factored in tether stretch, but not the shifting of the harness on the body, and any chest compression; each of these would reduce the peak impact load. Once stretch was accounted for, the real-world forces on the body were reduced to less than 500 pounds in all cases.

Observations Model

The data is presented in the accompanying table, Jackline Materials Test. The yellow areas indicate acceptable design combinations, while pink areas indicate specific failures. As the jackline becomes longer, stress goes up, so more stable, stronger materials are required.

Stretch: The tightrope effect gives very different results on a long jackline versus a short one. Due to the increased fall speed on larger boats, stretchy materials like nylon webbing will be ineffective on boats longer than 25 feet. On boats over 35 feet, even commercial polyester webbing jacklines will stretch farther than the 2.5-foot allowance we used as our baseline, making high-modulus materials very desirable.

Impact: Without some stretch, the sudden stop at the end of a fall could be dangerous, particularly on a smaller boat with a high-modulus jackline. There is no need to use a material lower in stretch than required.

Stress: High-modulus jacklines deliver very high loads to deck fittings, which may be an issue on both small and large boats. On the smallest boats, decks are thinner and even mooring cleats may not be strong enough; on larger boats, weak hardware fittings may reduce the safety factor.

Small boats (shorter than 30 feet): For the smallest boats, nylon webbing-even though it doesn’t quite meet ISAFs strength requirements-provides a safe, dependable alternative. Because the shorter distances involved, the dynamic loads of a fall on a small boat are relatively low, and a nylon jackline functions at a higher safety factor than any other material.

Large boats (40 feet and longer): Based on our findings regarding stress, we are hoping that ISAF will consider upgrading its working load limits for anchors and jackline materials on boats over 40 feet. ISAFs minimum safe working load (SWL) for a webbing jackline is currently 4,500 pounds (before factoring in stretch). Although this seems like a cautious number, in a maximum impact scenario, the jacklines on a large boat that adheres to these minimum guidelines will have a safety factor that is as low as 2:1.

Safety factors: All cordage loses its strength as sunlight and weathering take their toll. Thus, the minimum acceptable 2.4:1 safety factor will diminish over time (the 2.4 safety factor is used by OSHA for climbing and safety gear in like-new condition subjected to a one-time worst case fall-not to be confused with a safe working load). We recommend owners of boats 40 feet or greater aim for jackline materials and deck fittings that can withstand 8,500-pound loads when using high modulus (Dyneema or stainless steel cable) jacklines. This might be considered overkill, but it allows for a conservative safety factor of 2.4:1, a margin that is still less than the 3:1 safety factor that is the norm in other hazardous occupations that require safety tethers.

Product Reviews

The prices in the following product summaries are for a set of two, 35-foot long jacklines. This would be adequate for a 30-foot boat, allowing for an extra 3 feet to tie off or lash as applicable. The exception is the 1-inch nylon webbing, which was a shorter length, since this product is only recommended for smaller boats.

Blue Water Webbing

While not quite up to the ISAF strength standard, Blue Waters 1-inch webbing product is available at outdoor stores like REI (www.rei.com). Commonly used by rock climbers, it has an adequate safety margin and is cheap enough that you can replace it frequently so that it maintains close to its design strength.

This is an acceptable choice for the coastal cruiser in a small boat with a tight budget. It is a little stretchy (which can be reduced by pre-wetting and tensioning), but this is manageable as long as the length does not exceed 20 feet. Provided that you can fabricate strong end connections or use deck cleats, we see no problem using this webbing. It can also serve as an inexpensive cover material for high-modulus jacklines (Dyneema or stainless steel). We found a set of two, 20-foot jacklines for about $19, or 36-cents per foot.

Bottom line: This is the Budget Buy pick for boats shorter than 25 feet. We do not recommend it for jacklines over 20 feet long.

West Marine Webbing

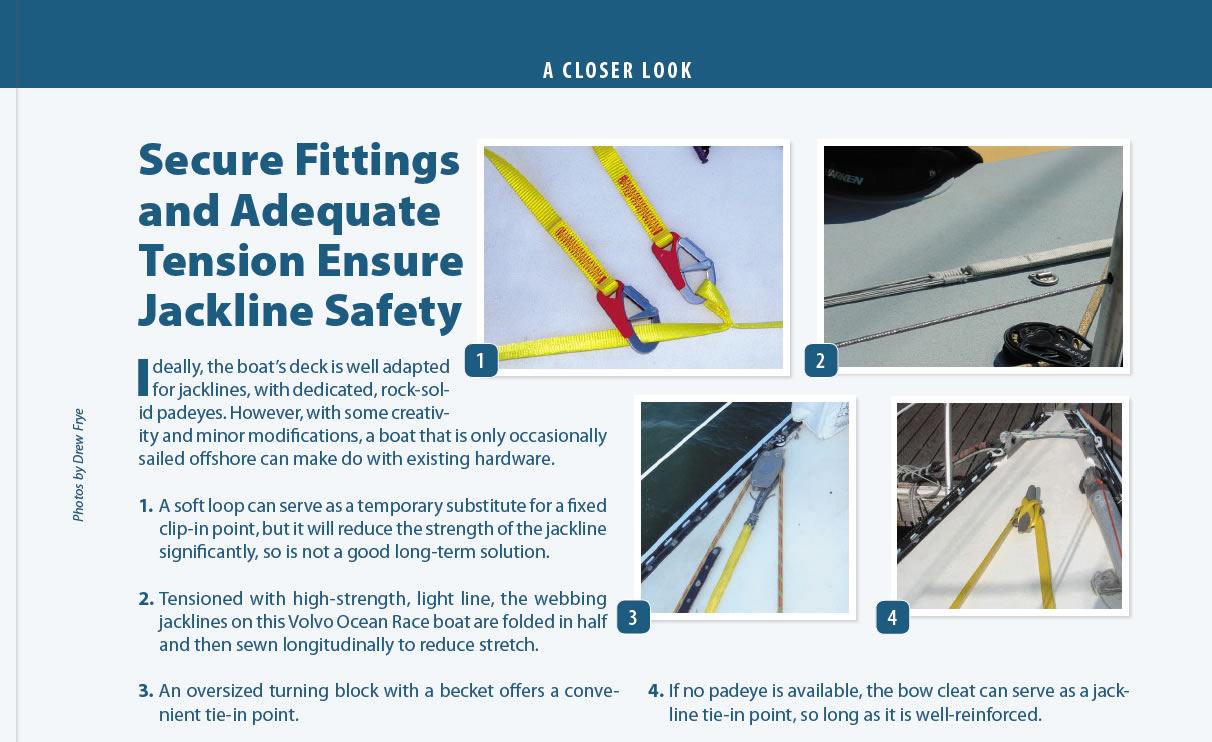

With a 6,000-pound strength, this 1-inch, bright-yellow polyester webbing easily exceeds ISAF standards and is a good design compromise for most boats. Pre-stitched with an eye at one end, the West Marine jacklines are easy to set up on most boats. They easily attach to a bow cleat with a cow hitch, and the tail can be cleated to a stern cleat (allow 3 feet for cleating and adjustment). While this setup is acceptable and inexpensive, a boat ideally will have dedicated attachment points 4 to 5 feet short of the bow and stern.

A set of two 30-foot West Marine jacklines sells for $150.

Bottom line: This jackline is Recommended for all boats up to 40 feet long.

Wichard Lyfsafe Jacklines

The Wichard Lyfsafe jacklines are very similar to the West Marine jacklines but have a full-length, reflective strip. While this can be useful when wearing a headlamp, we rarely do this at night because we want to preserve our night vision. The adjustable buckle was more trouble than it was worth; every time you adjust the length there is a cover to be removed. A lashing or cleat hitch worked better for us-but this is also a matter of preference.

A set of two 27-foot jacklines retails for between $142 and $175 online.

Bottom line: Weve been using both the Lyfsafe and the West Marine jacklines for several years now and cannot detect any real difference between them, except for the Lyfsafes reflective thread. Both are excellent options for boats up to 40 feet.

Mantra Mark IV webbing

Balance Communitys Mantra Mark IV polyester webbing is designed for the sport of slack-lining, a recreational form of tightrope walking; it has been showing up on race boats in the 35- to 45-foot range. This webbing product is stronger than common polyester webbing, lower in stretch, less expensive, and plenty durable. It is available in green or purple.

Prices online run about $75 for a 35-foot set of two. You can add a sewn end loop at each end for $7.

Bottom line: As is often the case with equipment that does not have the marine designation, this product is much more affordable than others in this category. This is our Budget Buy for boats under 40 feet.

Polyester or Nylon rope

Although we did not model any specific half-inch polyester or nylon rope, our test boat (a 34-foot catamaran) has used half-inch, nylon double-braid for many years, and it has served fine on that boat, where the jacklines are rigged along the top edge of the cabin trunk.

Polyester and nylon rope offer considerable stretch, which is beneficial on a catamaran because it moves quickly and there is a potential for a crewmembers body to pick up a fair amount of velocity during a fall. The test boats center-cockpit design makes for very short jacklines (20 feet long on a 34-foot boat) relative to the boats beam (16 feet). Because of high UV resistance and high safety factor, the rope can remain rigged at all times for at least five years. That said, this material is absolutely the wrong choice for most monohulls.

High-quality double-braid from major cordage houses sells for about $1.25 per foot.

Bottom line: Rope is not a recommended jackline material for monohulls; multihulls are a different story, however.

Dyneema

With relatively low cost, light weight, low-water absorption, and ease of splicing, 12-strand, single-braid, quarter-inch Dyneema can seem like a wonder rope, but it does have its caveats. Although we can’t recommend it for small boats due to the high-impact forces and the loads that it could impart to deck fittings, Dyneema offers reduced stretch for boats less than 30 feet, and is the right answer for boats greater than 40 feet. For boats over 35 feet long, we do recommend upsizing from ISAF requirements (4,500 pounds SWL) to 8,600 pounds. This will give it increased durability, a more acceptable safety factor, and allow for two sailors at the same time. Jackline anchors must match the 8,600-pound rating.

Some sailors demand that the lines be encased in 1-inch webbing to reduce rolling underfoot, and others like them bare to allow the clip to slide smoothly. If we were planning to leave them rigged continuously, we would upsize to 5/16-inch diameter to provide an allowance for UV and wear (even if covered, the ends are bare). You must follow the manufacturers guidance on any splices or lashing used to form loops.

Our pair of 35-foot Dyneema jacklines totaled $160, including the webbing sheath.

Bottom line: This is our Budget Buy for boats 25 to 55 feet long.

Annapolis Performance Sailing

The custom-made jacklines from Annapolis Sailing Performance (APS) are fabricated from quarter-inch Amsteel and 1-inch tubular webbing-similar to our do-it-yourself Dyneema jackline. The APS jacklines include a splice in each end; one end is cow-hitched to a fitting, the other lashed with 1/8-inch Spectra cord, which allows for size adjustment.

Weve sailed with these on race boats and found them to be ideal. Priced at $1.62 per foot, plus $34 labor, means that a pair of 35-foot APS jacklines will run about $215.

Bottom line: These are the Best Choice for boats 25 to 55 feet long.

Stainless Steel

Although quarter-inch stainless steel jacklines are more expensive than webbing and rope options and can impart potentially harmful loads on hardware and falling sailors, stainless-steel cable can be the right answer for boats longer than 50 feet. Stainless steels long service life and imperviousness to sunlight (giving the jacklines the ability to be permanently rigged) are important advantages. We recommend upsizing from the ISAF requirements (4,500 pounds SWL) to 7,500 pounds SWL to increase durability and to allow for up to two sailors on the line at once. Anchor points must also be suitable for the increased load, and the line should be encased in 1-inch webbing to reduce rolling underfoot.

Riggers can assemble stainless-steel jacklines for about $350 per set.

Bottom line: Durability makes these our Best Choice for boats over 50 feet.

Spider Silk Mark II webbing

Made from Vectran, Balance Communitys Spider Silk Mark II 1-inch webbing has stretch comparable to stainless steel cable of the same breaking strength, yet its light weight allows for a monstrous 15,000-pound rating in 1-inch webbing.

Though we have not yet tested Spider Silk in the real world, the specifications are certainly impressive, and it used for slack lining. Vectran typically has excellent flex durability, and although its somewhat vulnerable to UV, the damage levels off after about 500 hours, and there after, its comparable to polyester webbing.

Because of its ultra low stretch, Spider Silk should only be used in lengths over 60 feet. Available in white only, it runs about $242 for a 35-foot set; sewn ends are available for $10.

Bottom line: The specs are impressive, and we are waiting for real-world reports from big boats. Any early-adopters out there?

Conclusions

A harness, tether, and jackline are no guarantee youll stay onboard. The most common failure is that the sailor slips out of his harness, which is loosely fitted over wet foul-weather gear. For maximum security, wear a harness fitted with crotch or leg straps. No matter how fit and broad-shouldered the sailor is, it is always possible to slither out of any harness when your hands are overhead (such as when reaching up toward rescuers).

All of the jackline products we investigated are suitable for certain boats or certain circumstances, but some are simply a bad choice in the wrong application. High-modulus materials can be a bad match for small boats, and larger boats should go beyond ISAF standards to 8,500 pounds when installing high-modulus jacklines. The readily available, commercial polyester jacklines rated for 6,000 pounds safe working load are a good, all-around choice for 30- to 40-foot sailboats.