Material selection is just one of many details regarding jacklines that deserve careful thought. If you are re-installing your jacklines, be sure to read our 2007 report and review some of the following tips that emerged from this test.

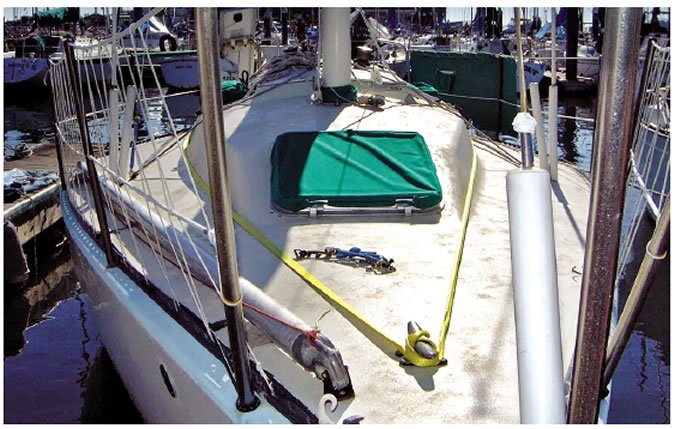

Although you can use existing hardware for anchoring jacklines to your deck, finding adequate anchor points on light boats can be difficult, since the deck and fittings might not be very strong. Whatever hardware you use must be strongly reinforced and capable of supporting the anticipated loads.

Confirm that the entire system is of known minimum strength. The International Sailing Federation (ISAF) standards recommend 4,500 pounds minimum breaking strength for webbing, although we recommend more for boats longer than 40 feet in order to provide an adequate safety factor. The minimum safety factor is 2.4:1, based on dynamic loads. This means that the gear you use should be capable of supporting 2.4 times the amount of force generated by a falling body (or bodies), or by a person who is dragging in the water at maximum boat speed.

Nylon webbing stretches a great deal when it is wet, so nylon jacklines should be tensioned when wet.

Webbing jacklines should be twisted-not laid flat. This makes them easier to clip into when wet, and they wont flap in the wind.

Outboard-powered boats should never have jacklines or tethers so long that a sailor who has fallen overboard would be towed behind the boat near the prop.

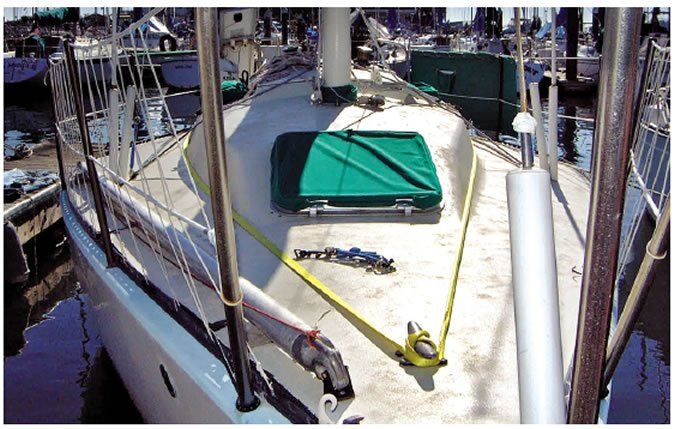

Jacklines should stop well short of the bow. Fast boats, multihulls in particular, can hurl a person forward when the bow stuffs into a wave.

The cockpit should have at least one dedicated fixed point for clipping into. Consider installing dedicated clip-in points (padeyes) at other work stations-i.e. at the mast or at the bow.

Rope jacklines can be acceptable on boats with higher coachroofs that allow the lines to be routed off the deck where they wont fall underfoot. Rope is more durable than most other choices; it is also easier to clip on and off with carabiners.

When Dyneema or stainless cable are used on the deck, sheathing them in tubular webbing can reduce their rolling under foot. However, some of our testers preferred exposed Dyneema because the clipped-on carabineers slid along the jackline more easily.

Jacklines must be clearly distinguishable from running rigging, so that there is no chance of clipping into the wrong line. Color is not enough, as the typical sidedeck is littered with control lines, and colors are indistinguishable in the dark.

Jacklines should be permanently rigged during a passage. It takes time to become accustomed to their use, and sailors have often gone overboard in benign conditions.

Jacklines should be rigged under sheets and over deck-routed control lines so that a sudden tack or jibe does not grab the tether.

If you rely on stainless-steel hardware, use only the highest quality. (Wichard is one company whose hardware has consistently done well in our tests.) During our field research, we came across a 46-foot boat with very tight, 3/16-inch stainless jacklines attached with 3/16-inch stainless shackles. Our tester grabbed the jackline at the centerpoint with gloved hands, gave it a maximum effort jerk, and one of the shackles exploded, the cable whipping about. Stainless-steel jacklines must be very conservatively sized to account for hidden corrosion.