The first second-hand sailboat my husband and I considered as a potential “project boat” was listed for sale on an online classified website in France for a few thousand euros. With just a handful of sailing lessons under our belts, we were naïve, ambitious and inspired by countless hours of boat refit videos we had binged during the pandemic lockdowns on YouTube. We were captivated by young couples who had picked up someone else’s old fiberglass boat trash for as little as a dollar and transformed it into something beautiful. Or, so we thought.

As seller Jac’s dinghy approached the 15m ketch sitting at anchor in a bay filled with boats in southwestern France, my excitement began to wane. Up close, the rot, rust and filth I’d spied from a distance became overwhelming. Climbing down below revealed the worst: it was like an abandoned work site with pools of water in places where water should definitely not be.

Smiling politely after Jac’s tour of his dilapidated boat, where every step was a safety concern, we told him we had a lot to discuss and would let him know if we were interested soon. Perhaps to spike our empathy, he invited us to sail on his other boat that afternoon. Eager for any chance to sail, we hopped aboard his 9m monohull. As he raised the mainsail and navigated us out to sea without once turning on the engine, we hummed along at 6-7 knots in the late afternoon breeze.

However, frustration grew as Jac only allowed Remy to hold the tiller or tend to the sails, despite us both having the same minimal experience. Confined to the tiny cockpit, my exposed legs soon began to itch below the hemline of my skirt. On the drive home, we were both furiously scratching at our skin; exposed glass-reinforced plastic (GRP), better known as fiberglass, had found its way all over our bodies.

I was reminded of visits to my uncle’s surfboard factory as a young teen to pick up a new board, itching my feet on the way home if I’d worn open shoes. Indeed, I come from three generations of surfboard shapers, beginning with my grandfather and his brothers, who were experts in working with fiberglass to build boats, swimming pools, surfboards, kayaks and more. They often worked without protection, and my grandfather died young from a lung-related illness (as did some of the other brothers, and at the time of writing I just learned another uncle—who worked extensively with fiberglass—has died from numerous cancers found throughout his body including the lungs at the ripe age of 69).

Despite a presumption that fiberglass is a hazardous material (it’s not officially classified as one, yet…), the thought of a huge boat refit, which would require us to spend months or even years dealing with fiberglass, was daunting, and we declined Jac’s offer without hesitation. It was only recently that research revealed the shocking impacts of GRP on marine environments and its potential entry into our food chain.

WHAT’S THE PROBLEM WITH GRP DISPOSAL?

The use of Glass Reinforced Plastic (GRP) in sea-faring craft was adopted in the early 20th century but truly boomed from the 1960s. By 2020, nearly 80 percent of ship hulls (less than 20m long) were made of GRP. In the UK alone, the number of recreational boats owned by households was estimated at 1.2 million in 2019, but the Royal Yachting Association (RYA) suggests the number is closer to 5 million when including kayaks and paddleboards. The revenue from building sporting and pleasure boats in the UK is predicted to be around $4.8 billion.

While GRP’s popularity has surged due to its durability and versatility, the issue of managing composite waste remains largely unaddressed worldwide. Landfill remains the most cost-effective method of disposing of waste composites, and efforts to use bio-derived products or recycle materials are hampered by high costs and a lack of standards.

A 2019 report by the International Maritime Organization (IMO) estimated there were around six million fiberglass boats in the European Union alone. Each year, more than 100,000 GRP boats in the EU reach the end of their useful life. Of these, only about 2,000 are recycled, and 6,000 to 9,000 are abandoned but accounted for. This leaves approximately 90,000 to 100,000 boats per year unaccounted for, likely abandoned and leaking harmful chemicals into the surrounding environment.

THE CHALLENGES OF FIBERGLASS BOAT DISPOSAL

The problem of disposing of old fiberglass boats has reached global proportions, particularly for island nations with limited landfill space. Fiberglass, or Glass Reinforced Plastic (GRP), is non-biodegradable, meaning it remains in the environment for centuries. Disposing of fiberglass waste often involves harmful practices such as illegal dumping and burning, which release toxic emissions and microplastics. These actions degrade local ecosystems and contribute to long-term environmental pollution, affecting both human health and marine biodiversity.

Efforts are underway to find viable solutions, including recycling methods like pyrolysis, chemical breakdown and mechanical disintegration. Pyrolysis can convert waste into products like syngas and oils, but it requires significant investment and emits greenhouse gases during the process. Chemical recycling techniques, such as solvolysis, show promise in recovering valuable materials but are still in developmental stages, facing barriers like high operational costs and complex process controls. Mechanical recycling, which involves grinding fiberglass into fillers, is limited by energy costs and the degradation of material properties, reducing its economic viability.

Despite these efforts to address fiberglass waste disposal needs, such methods are not yet widely implemented on a large scale, and therefore traditional practices, like landfill disposal, persist.

Dumped and wrecked vessels pose significant threats to sensitive habitats, such as reefs, seagrasses, and estuarine intertidal zones. Additionally, these old fiberglass boats create hazards to human health and safety and, in some cases, become temporary shelters for homeless individuals. Beyond deliberate dumping, many boat owners leave derelict vessels moored at marinas and sheltered anchorages due to unrealized refit dreams. Long waiting lists at marinas, where securing a spot is both costly and time-consuming, discourage owners from giving up their paid annual place while they await the purchase of a new vessel. For instance, Jac was selling his failed project boat after nine years of it sitting on anchor because he needed the mooring back for his newly acquired smaller boat.

The lack of awareness about proper disposal options and the high costs associated with transporting and disposing of old fiberglass boats further compound the problem. Consequently, these vessels are abandoned, left to deteriorate and pollute the environment, as their owners grapple with financial constraints and the complexities of responsible boat disposal.

GRP’S IMPACT ON MARINE LIFE

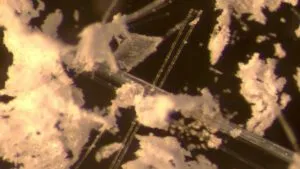

When GRP boats are repaired, abandoned or dismantled, tiny fiberglass particles are released into the environment. These particles persist in the water and accumulate over time, posing threats to marine life, especially filter feeders like oysters and mussels. A groundbreaking study by scientists from the University of Brighton and other institutions led by Dr. Corina Ciocan found alarming levels of fiberglass particles in marine bivalves collected near active boatyards on the south coast of England.

The study revealed up to 11,220 particles per kilogram of wet tissue in oysters and 2,740 particles per kilogram in mussels. These creatures, being filter feeders, are constantly ingesting water and inadvertently accumulating these particles in their tissues.

The study also indicated that contamination peaks during the winter months, coinciding with increased boat maintenance activities. The accumulation of fiberglass particles in the digestive glands of oysters and mussels can impair their health, affecting feeding, growth and reproduction, potentially leading to population declines and broader ecological impacts. This aligns with previous findings that highlight the potential risks of microplastics and synthetic fibers on marine life, emphasizing the need for immediate action to mitigate these impacts.

RECYCLING AND DISPOSAL OPTIONS

Given the environmental impact and the growing number of old fiberglass boats, addressing disposal and recycling options is essential. So what are the current options? I’ve mentioned some above, but let’s break down the methods in more detail and the challenges each method presents:

LANDFILL DISPOSAL

Landfill disposal remains the most common method for dealing with old fiberglass boats, primarily due to its low immediate cost and ease of access. However, this approach is highly unsustainable. Fiberglass is non-biodegradable, meaning it remains in the landfill for centuries, contributing to long-term environmental pollution. The decomposition of fiberglass can also leach harmful chemicals into the soil and groundwater, potentially affecting local ecosystems and human health. Additionally, many landfills are already near capacity, especially in densely populated regions and island nations.

PYROLYSIS

Pyrolysis is a process that involves the thermal decomposition of fiberglass in an oxygen-free environment at high temperatures, typically between 400°C and 800°C (752°F to 1472°F). This process breaks down the complex polymer matrix into simpler chemical compounds, such as syngas (a mixture of hydrogen and carbon monoxide), oils and char. The resulting products can be used as feedstocks for the chemical industry or as alternative fuels, offering a potential revenue stream to offset the process’s costs.

Despite its promise, pyrolysis requires significant investment in specialized equipment and infrastructure, as well as strict environmental controls to manage emissions. The study “Fraud of Plastic Recycling” highlights that pyrolysis often results in more pollution than traditional waste management methods due to the energy-intensive nature of the process and the potential release of greenhouse gases and toxic byproducts. Furthermore, many facilities marketed as “advanced recycling” are actually functioning as waste-to-energy plants, burning plastic waste for fuel rather than creating new plastic products, which undermines the circular economy concept. As a result, pyrolysis is still not widely implemented on a large scale due to these barriers and its environmental implications.

MECHANICAL RECYCLING

Mechanical recycling involves grinding fiberglass waste into a powder or small particles that can be used as fillers in various applications, such as concrete, asphalt, or new composite materials. The process typically includes shredding, milling, and sieving the fiberglass to achieve the desired particle size. While this method can reduce the volume of waste sent to landfills, it faces significant challenges due to the high energy costs involved, which increase operational expenses and diminish the environmental benefits. Additionally, the mechanical breakdown of fiberglass can lead to degradation of the material properties, resulting in a reduction in quality and strength that limits the applications and market value of the recycled product. These filler materials are often used in low-value applications where performance is not critical, further reducing their appeal.

Furthermore, mechanical recycling does not completely eliminate environmental concerns, as it can produce fine particles that contribute to microplastic pollution if not properly managed. Given these challenges, further research is needed to enhance the efficiency and quality of recycled materials, potentially unlocking new applications and making mechanical recycling a more sustainable and economically viable option.

CHEMICAL RECYCLING

Chemical recycling involves breaking down the resin matrix in fiberglass composites to recover the glass fibers and other valuable components. This process often uses solvents, catalysts or chemical reactions to dissolve the resin and separate the fibers. One promising approach is solvolysis, which employs solvents under high temperature and pressure to depolymerize the resin. The recovered glass fibers can be reused in new composite products, retaining much of their original strength and quality.

However, despite its potential, chemical recycling presents several challenges and risks. The high operational costs and the complexity of process control make it difficult to scale up this method for widespread commercial use. The need for specialized facilities also poses a significant barrier to implementation. Additionally, there are environmental concerns, as the reuse of materials could still pose risks if the new products are not managed responsibly, potentially releasing similar pollutants into the marine environment. This concern is particularly important as the fibers and resins may still degrade into microplastics if not properly handled.

Although chemical recycling offers a more complete recovery of materials than mechanical recycling, it remains in the developmental stages. Efforts to optimize these methods focus on enhancing efficiency and ensuring that the reintroduced materials do not contribute to further environmental degradation. Continued research and innovation are crucial to making chemical recycling a viable solution for the growing problem of fiberglass waste.

PRACTICAL STEPS FOR DISPOSING OF OLD FIBERGLASS SAILBOATS

Given the significant environmental challenges and limitations of current disposal and recycling methods for fiberglass boats, it is crucial for boat owners to explore responsible alternatives. Here are some practical steps that can be taken in different regions, utilizing available resources and initiatives to minimize environmental impact:

UNITED STATES

Local Authorities: State-specific regulations regarding boat disposal can vary, so it’s important to consult local environmental agencies or the Department of Natural Resources (DNR). In Florida, for example, the Florida Fish and Wildlife Conservation Commission provides resources for removing end-of-life boats.

Recycling Programs: While a nationwide program is lacking, several states and organizations offer recycling solutions. The BoatUS Foundation offers information on local recycling programs and is currently accepting grant proposals for the removal of “bad boats” from U.S. coastal waterways and the Great Lakes, and Sailors for the Sea provides resources for environmentally responsible boat disposal.

Donate or Sell: If the boat is still seaworthy, consider donating it to organizations like the Sea Scouts or local sailing clubs, which often accept donations for educational purposes. Selling the boat to a buyer with the resources, capacity and knowledge to conduct a proper restoration is another option.

Creative Reuse: Repurposing old boats into floating homes, garden structures, or art installations is gaining popularity. This approach not only reduces waste but also gives the boat a unique second life, supporting sustainable creativity.

Support Research and Development: Organizations invested in developing better methods for managing end-of-life boats are worth supporting, such as the American Boat and Yacht Council (ABYC), working towards innovative and more efficient solutions.

CANADA

Local Authorities: In Canada, Transport Canada oversees abandoned vessel regulations. The Abandoned Boats Program, currently closed for submissions, has provided funding for assessing, removing and disposing of abandoned boats.

Recycling Programs: The Clean Marine Program in Ontario offers solutions for boat disposal. Some marinas partner with recycling companies to dismantle and recycle boats responsibly.

Donate or Sell: Organizations like Sail Canada or community sailing programs often accept boat donations for training, benefiting the community while extending the vessel’s life.

Creative Reuse: Varous initiatives include like transforming old vessels into unique living spaces or office units, again extending the vessel’s life and addressing other social challenges such as housing shortages.

Research and Development: Reach out to local universities, environmental groups and research institutions who may be innovating waste disposal and recylcing methods. Become a citizen scientist by encouraging community involvement in pilot programs or studies.

UNITED KINGDOM

Local Authorities: While there is no single nationwide authority, local harbor authorities and organizations like the Royal Yachting Association (RYA) provide guidance on boat disposal. Projects like the Langstone Harbour initiative and the Abandoned Boats Project in the Dee Estuary focus on removing derelict vessels and restoring natural habitats.

Recycling Programs: The Boatbreakers program specializes in dismantling and recycling old fiberglass boats, offering comprehensive services for environmentally responsible disposal. Responsible Boat Disposal provides re-homing and recycling services to boat and dinghy owners, who face the necessity to dispose of their beloved vessels either because of their age or condition. Marine GRP Recycling removes end-of-life and decommissioned sailing yachts, motorboats and dinghies from private properties for recycling and “nature-friendly” disposal of parts and bits.

Donate or Sell: Donating boats to sailing schools or charities like the Royal National Lifeboat Institution (RNLI) can give vessels a second life, while some organizations refurbish boats for community use.

Creative Reuse: The UK has embraced innovative uses of old boats, converting them into playhouses, garden sheds or even cafes, reducing waste and showcasing creativity.

SPAIN

Local Authorities: The Dirección General de la Marina Mercante oversees vessel disposal regulations. Boat owners should contact regional offices for authorized disposal methods.

Recycling Programs: Spain has several recycling centers for dismantling and recycling boats. Organizations like Ecoembes collaborate with local authorities to manage waste, including fiberglass boats.

FRANCE

Contact Local Authorities: The French government has established the APER (Association pour la Plaisance Eco-Responsable) program, providing guidelines and support for disposing of fiberglass boats.

Recycling Programs: The aforementioned APER is a global leader in boat recycling, offering a network of collection points for dismantling and recycling. This initiative aims to recover and recycle as much material as possible, reducing landfill waste, and is subsidized by a levy on new boat sales to support the cost of transporting end-of-life boats to APER’s disposal facilities.

Donate or Sell: Donating boats to sailing clubs or associations like Les Glénans, France’s renowned premiere sailing school, supports sailing education whilst extending a vessel’s usability.

Innovative Reuse: The Batho Shipyard in Nantes rescued old fiberglass boats with a playful approach, renovating unseaworthy vessels for on-land use such as campground accommodation and playground features. Unfortunately they recently announced the closure of business, citing: “despite the environmental emergency and the need to emerge a sustainable economy, it is difficult to engage customers to invest in socially and environmentally sound products that are better, but financially more expensive.” A reminder that we likely cannot solely recycle and upcycle our way out of the GRP end-of-life boat crisis, and must reduce our dependence on this material overall.

POLICY IMPLICATIONS OF FIBERGLASS WASTE

The classification of fiberglass as a hazardous material would be a significant policy shift that could dramatically affect how old fiberglass sailboats are disposed of and recycled. The growing evidence of the environmental impact of fiberglass particles, such as their persistence in marine environments and potential entry into the food chain, should prompt regulators to reconsider its status.

One major initiative in addressing this issue is the OSPAR Convention, a collaborative effort between European countries to protect the marine environment of the North-East Atlantic. Article 6 of the OSPAR Convention outlines the obligations of the contracting parties to adopt programs and measures to prevent and eliminate pollution from land-based sources. This includes ensuring that activities under their jurisdiction do not cause pollution to the marine environment of the North-East Atlantic. The article emphasizes the need for coordinated efforts and cooperation among the parties to effectively implement these measures. It also stipulates that parties must apply the best available techniques and best environmental practices to achieve the objectives of pollution prevention and elimination.

OPPORTUNITY FOR INCLUDING FIBERGLASS IN THE LIST OF CONTAMINANTS OF POSSIBLE CONCERN UNDER OSPAR

The OSPAR Convention, through its Quality Status Reports (QSR), continuously evaluates and identifies contaminants of emerging concern to protect the marine environment of the North-East Atlantic. The 2023 QSR highlights several operational objectives, including the identification and prioritization of new contaminants for action under the CONnECT project. This initiative analyzes samples across the OSPAR area to identify substances that are widespread and occur in concentrations that may adversely affect marine organisms.

Given the growing awareness of microplastics and their environmental impact, there may be an opportunity for fiberglass to be considered for inclusion in this list. If fiberglass is widely recognized as hazardous waste, it will be subject to stricter regulations that govern its disposal and recycling. This would necessitate new guidelines and enforcement measures, potentially incentivize innovation in sustainable disposal technologies and encourage investment in research and infrastructure to manage fiberglass waste more effectively.

Additionally, this classification could drive the creation of extended producer responsibility (EPR) schemes, where manufacturers are held accountable for the end-of-life management of their products, thus fostering a more circular economy within the boating industry. By holding manufacturers responsible for their products throughout their lifecycle, EPR schemes can promote the design of more sustainable and regenerative materials*.

*(We are currently exploring the potential use of bio composite materials in our upcoming Wharram wooden catamaran build).

Should GRP be classed as hazardous, the implementation of new regulations and the development of necessary infrastructure will require substantial investment. Therefore, governmental support and incentives are crucial to ensure a smooth transition towards environmentally responsible practices. As more countries consider the hazardous classification of fiberglass, international cooperation and alignment of policies will be essential to effectively tackle this environmental issue.

TAKE ACTION: ENTER INFO INTO THE BAD BOATS DATABASE

The “Bad Boats” database is an open-source community resource collecting important information on end-of-life and problematic fiberglass (GRP) boats. Data will be made publicly accessible and will be shared with researchers and stakeholders committed to mitigating end-of-life vessel littering and pollution around the world. Data collected will be integrated into a publicly-accessible interactive, visual mapping program in the near future.

Your contributions play a crucial role in mitigating the harmful effects of GRP and hazardous materials pollution on marine ecosystems and human health, whilst also contributing to the advocacy for sustainable solutions.

This project invites volunteers from around the world to help track and document the end-of-life status of boats in their local areas or whilst in visiting locations. By collecting data on the location and condition of these vessels and environmental habitat they situate in, we aim to build a comprehensive resource that supports scientific research, informs policy and fosters community engagement.