Clear vinyl windows are a miracle when they are new, allowing sailors to have an outdoor experience while keeping rain and spray at a distance. As they age, however, yellowing, stiffening, and cracking set in as the plasticizer that keeps them supple begins to deplete. The right fix is new vinyl, but in the meantime we need a quick fix, something fast, easy, and good enough to get us to the end of the cruise or season.

What We Tested

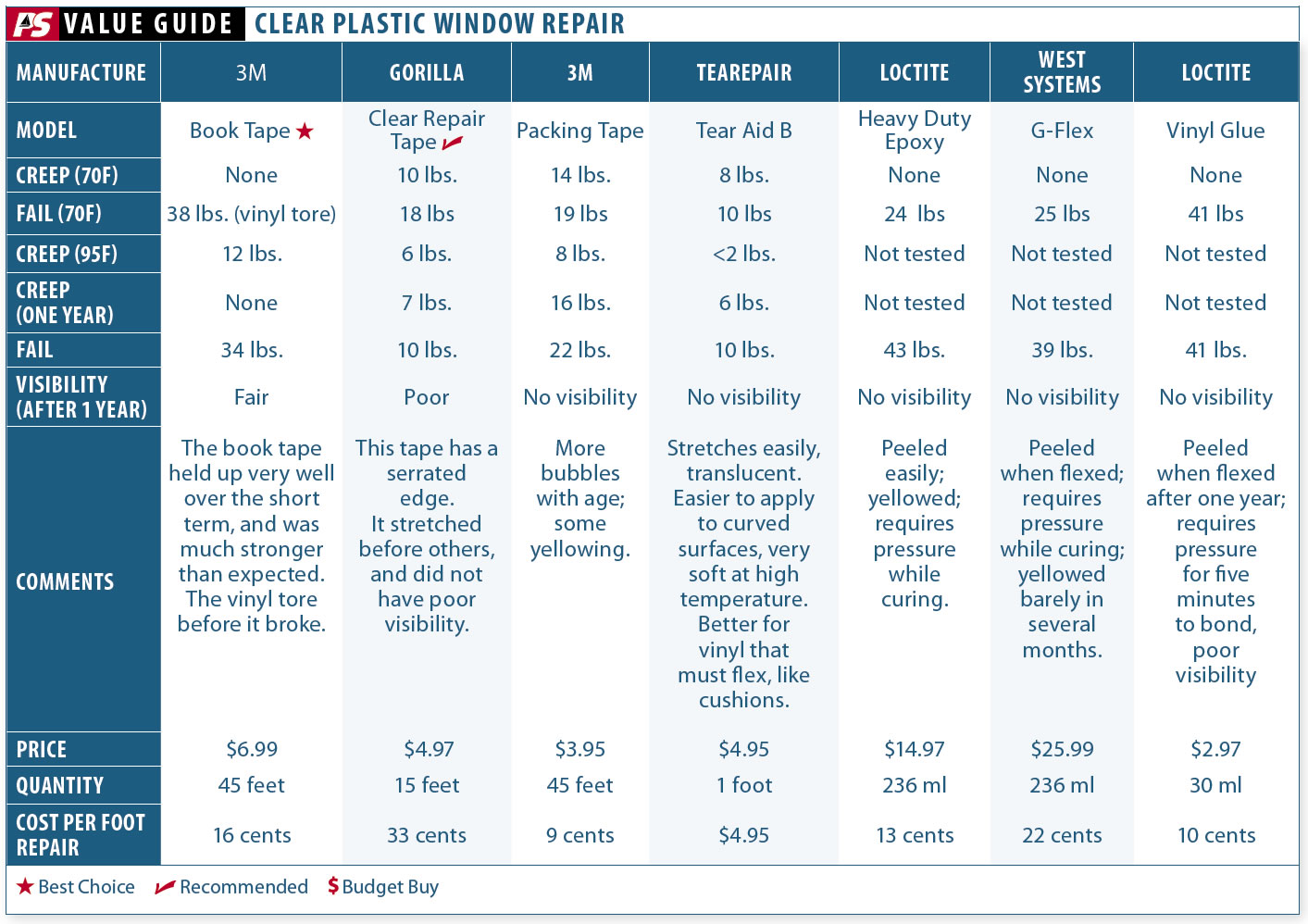

We tested eight different products, five tapes and three glues. Tapes included 3M packing tape, 3M Book Repair Tape, and Gorilla Clear. We then added a few methods that might just last a little longer: Tear-Aid Type B, a specialized repair tape for soft vinyl, and patches glued on with West Systems G/flex Epoxy and Loctite Vinyl Repair Glue.

How We Tested

All testing was performed using aged vinyl sections the we used in our vinyl protectant testing series (see Protecting Clear Vinyl Windows, January 2014). Although these samples were never treated by us with protectant, they may have been in a former life, so the bonding areas were cleaned with TSP to remove all traces of wax and surface plasticizers, without damaging the vinyl.

If you have been regularly applying protective treatments to the windows and are considering a glued patch, also wipe the area with mineral spirits (brief exposure should do not harm-do NOT use xylene or other aromatic solvents, since damage will be immediate).

For the glued patches, we masked the patch area, sanded lightly, and applied with overnight clamping pressure. Tape patches were applied to both sides, glued patches to one side only.

Each repair material was tested in three ways. First, they were made up in long 2-inch wide strips, so that we could compare visibility, flexibility, and relative strength. Then each material was made into test coupons, which were slowly pulled in a test rig to determine both creep stress (slippage) and ultimate strength. Finally, 8- by 10-inch samples were left in the sun for a year, after which they were observed and re-tested.

3M Packing Tape

Clear, easy to apply, and possibly already sitting in a drawer at home, packing tape makes a decent repair if you carefully apply to both sides. However, it is only about half the thickness and strength of book tape, it bubbles over time, and is more prone to yellowing. Beware of cheaper tapes. Most packing tapes are designed for a 10-day life span and do not hold up in the sun.

Bottom line: Limited UV resistance and less strength leaves it a tier below 3M Book Repair Tape.

3M Book Repair Tape

This tape is strong, cheap, clear, and relatively easy to apply. We had difficulty chasing all of the bubbles out on test samples. Once we did, however, they didnt come back and the repair remained clear for one year. It is less flexible than other products, so it really helps to apply with the vinyl flat. In every strength test the vinyl failed before the tape.

Bottom line: This is our Best Choice. It would be a good addition to your sail repair kit.

Gorilla Clear Repair Tape

This tape is like the 3M Book Repair Tape but even thicker, so we had high hopes even though we didnt like the serrated edges. It is more flexible than Book Repair Tape, which makes it easier to apply to warped vinyl. On the other hand, flexibility limits strength; Gorilla Tape stretched under relatively low loads.

On the good side, it showed no tendency to creep or peel under sustained loads that cause some stretch. We believe stretching will only occur at loads far beyond typical applications, since it is close to the stress level that begins seriously stretching new vinyl.

Bottom line: Superior durability in sunlight and good moisture resistance earn a this tape a Recommended rating.

TEARepair Tear-Aid Tape B

A specialized tape for soft vinyl repair, Tear-Aid is specially formulated to bond to vinyl, despite the presence of plasticizers that accumulate on the surface. None of the other tapes had trouble bonding, but it could be due to the age of our sample, or because the sample had been scrubbed clean of surface plasticizer contamination before we taped.

Tear-aid is far more flexible than the other tapes and much more flexible than vinyl, so it did not create a hard spot, suggesting it might be particularly effective for repairs in corners and in areas that are rolled repeatedly. The downside is that it stretches under very low stress; only 1 to 2 pounds of pull in hot weather. Visibility was not as clear as other tapes.

Bottom Line: Not recommended for windows, but it might work with upholstery or rain gear.

Glued Patches

Glued patches held the promise of durability, but they were hard to apply and results were disappointing. Their stiffness when cured inhibited bonding as the vinyl flexed.

Loctite Heavy Duty 5-Minute Epoxy

All glued patches involved application challenges since they required clamping, but 5-Minute Epoxy reduced the clamping time. We masked outside the patch area, dewaxed and sanded, and then used masking tape to hold patches in place. We ended up with air bubbles every time. But worse, the patches were easily peeled by flexing or a fingernail.

Bottom Line: Given the installation difficulty, poor bonding, known UV vulnerability of epoxy, and poor appearance, we did not advance this method to long-term testing. Not recommended.

West Systems G/Flex Epoxy

Considerably more flexible than standard epoxies, we expected G/flex to bond better and be less prone to cracking loose when flexed. But the slow cure is troublesome.

The glue runs on vertical surfaces, and cures more yellow than clear (even more apparent after a few months in the sun). And after all that, it still peels when flexed sharply, and can be pulled off in one piece with a tug.

Bottom Line: G/flex is good for so many other projects that it was worth trying. But its clearly not a great choice for clear vinyl.

Loctite Vinyl Repair Glue

The required clamping time is much less than epoxy, only a few minutes until there was a good grab. It peeled relatively easily when we flexed the test panel.

In addition, the patch was visually ugly, since like all PVC cements, the glue partially dissolves the vinyl, destroying clarity. It also shrinks upon drying, distorting the vinyl. Its resistance to UV rays was very good.

Bottom Line: While this may be the strongest repair and useful on seat cushions, it was not very translucent compared to the tapes.

Conclusions

We expected to find glued repairs better than tape, but instead we found the glued repairs to be a lot more difficult to carry out, even in the workshop, and the results were stiff, highly visible, and much harder to fix if we didnt like the first results. The right tape, on the other hand, was cheap, quick, and lasted a year or more. Best of all, the tape patch can be nearly invisible.

If you want to use tape, look for 3M Book Tape or Gorilla Clear Repair Tape; cheap packing tapes will only let you down. And remember, the vinyl is still aging. We can cheat time a little-not stop it.

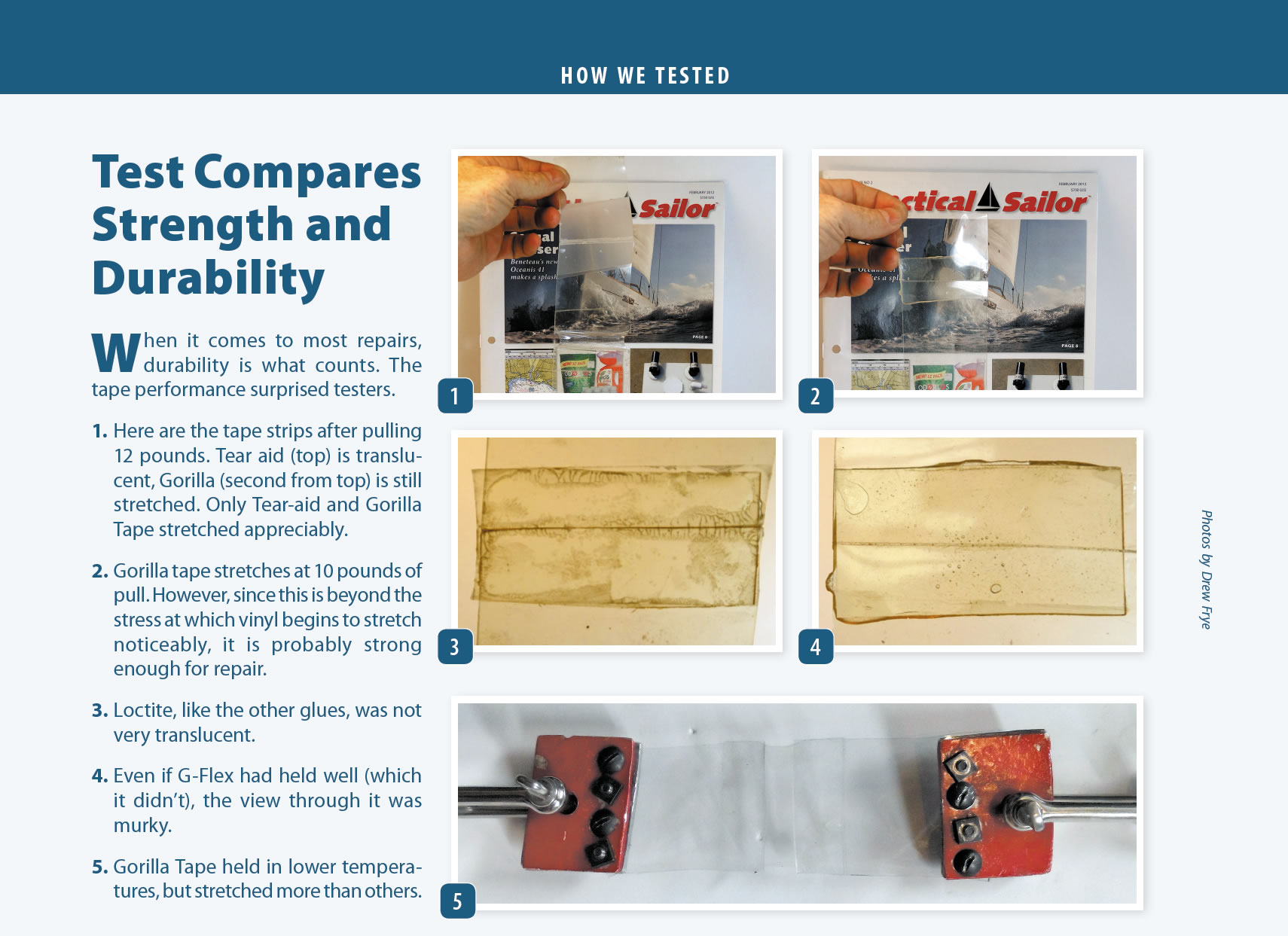

When it comes to most repairs, durability is what counts. The tape performance surprised testers.

- Here are the tape strips after pulling 12 pounds. Tear aid (top) is translucent, Gorilla (second from top) is still stretched. Only Tear-aid and Gorilla Tape stretched appreciably.

- Gorilla tape stretches at 10 pounds of pull. However, since this is beyond the stress at which vinyl begins to stretch noticeably, it is probably strong enough for repair.

- Loctite, like the other glues, was not very translucent.

- Even if G-Flex had held well (which it didn’t), the view through it was murky.

- Gorilla Tape held in lower temperatures, but stretched more than others.