288

Paint companies, boatyards, and boat owners will no doubt be closely checking the impact of an antifouling report issued last month by the San Diego Unified Port District and funded by the Environmental Protection Agency.

San Diego port officials forwarded its “Final Report on Safer Alternatives to Copper Alternatives to Antifouling Paints for Marine Vessels,” to the EPA in February. Presenting data on a wide range of alternative antifouling paints that contain limited or no harmful biocides, the 152-page report is based on both controlled panel tests and field tests on several different powerboats and sailboats that berth in the port district. The report highlights several findings regarding the cost and effectiveness of paints that contain no harmful biocides. It also includes guidelines on how to choose a paint that is both effective and minimizes impact on the environment.

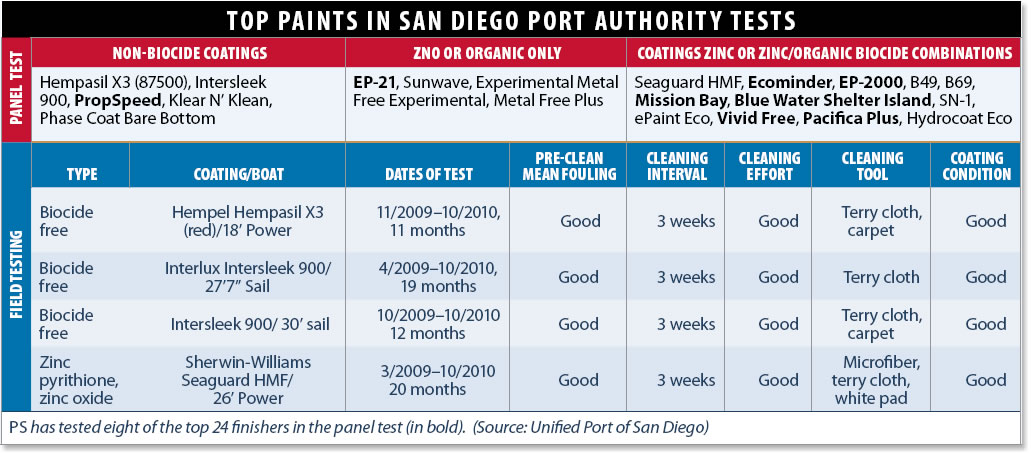

In the preliminary panel test, several mainstream paints that used a zinc biocide were effective, but because the goal of the test was to find alternatives to biocides, very few zinc paints went on to the second round (see table right).

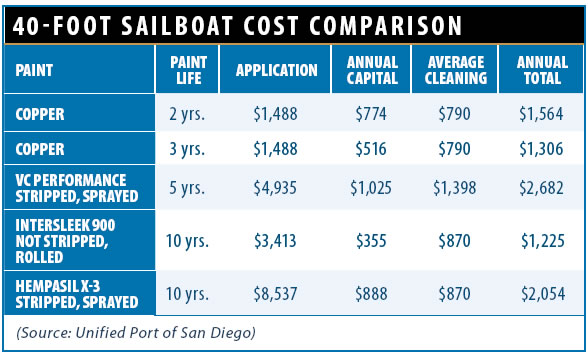

One aspect of the report that will interest Practical Sailor readers is an economic analysis of the annualized cost of using a paint that has no biocides. According to the study, once the application and cleaning costs are amortized over the life of the paint, the costs of using a hard, slick non-biocide paint are comparable to the annual expenses for using copper-based paints. (Panels were cleaned every three weeks for the test.)

However, the most optimistic cost estimates for non-biocide paints rely on a five- to 10-year projected life span for hard, slick non-biocide paints (see table page 13). Since the San Diego in-the-water hull tests lasted less than two years, the longer projections were based on manufacturer-supplied data from large commercial ships, the primary users of these types of paints. Nevertheless, the study’s authors suggest that such lifespan projections are not unreasonable, so long as boatowners adhere to the recommended maintenance regimen. The report concludes that the successful transition to a non-biocide paint will require close cooperation of regulators, boat owners, paint manufacturers, boatyards, and hull cleaners.

According to the study, to prolong the life of a paint—including those that have biocides such as copper or zinc—hull cleaners must start with the least aggressive cleaning tool possible, such as terry cloth. The Port of San Diego is currently gathering input on a draft rule requiring that hull cleaners obtain permits in order to work in the district waters.

Read the report at http://www.portofsandiego.org/environment/alternative-hull-paints.html.