There comes a time in the life of every fiberglass boat when the molded nonskid pattern on the deck wears thin. Foot traffic as well as the sun’s ultraviolet rays attack slowly but inexorably, degrading the gelcoat. Over-enthusiastic scrubbing and harsh cleaners don’t help. When the bumps aren’t bumps any more, and the surface loses its grip, deck restoration becomes more than a matter of aesthetics, but safety, too. It’s also a consideration if you’re thinking of selling the boat—a major facelift without a tremendous commitment of time or money. But how to fix the problem?

Because the original nonskid pattern was molded in at the time the boat was built, it cannot easily be re-created. Instead, new material must be applied on top of the old. And while gelcoat can be sprayed on decks and hulls, it’s seldom done. It’s very expensive, and the bonding of the gelcoat to the substrate will not be as strong as the original. There are more realistic and less costly alternatives, The first is two-part polyurethane paint. Like gelcoats, this type of paint is abrasion-resistant, and the gloss in topside paints can be reduced with flattening agents.

Painting the deck, therefore, is solution No. 1. But paint alone does not provide sufficient traction, so some sort of powder or granule must be added to the paint or sprinkled on top of the wet paint. In days of yore, sand was a readily available nonskid compound, but would tear up one’s knees like, well, sandpaper. Some people used finely crushed walnut shells, too, but not, from what we ever saw, with very good results.

Today, the most popular nonskid compounds include polypropylene, silicon oxide, pumice, and polymers, all in basically a powder form.

Popular solution No. 2 is to glue a nonskid patterned mat to the deck. These rubberized products are available in different colors and are permanent; some companies recommend using their special adhesive to apply them.

Background

We’ve tackled the issue of refurbishing old decks several times.

In the November 1, 1995 issue a variety of nonskid mats were tested, not just for decks, but cockpit soles, engine rooms and locker floors. These included interlocking squares such as Deck Mate and Dri-Dek. But in the end Treadmaster won.

In the October 15 issue that year, Bill Seifert had some cleaning tips for non-skid. He preferred Mr. Clean, only using Soft Scrub for problem spots. Scotchbrite pads, the next level of aggression, should be used very sparingly, he said. He told the story of a friend who used Comet relentlessly and kept his non-skid spotless. But by the end of his first season he was getting pink sports on deck that seemed to get worse the more he scrubbed. Seifert pointed out that he’d gone right through the gelcoat and was now scrubbing away at the underlying fiberglass laminate.

In the August 1, 1998 issue, we described several gelcoat repair services, beginning with the familiar Match ‘n Patch kit by FibreGlass-Evercoat (www.evercoat.com), sold in many chandleries. Two other companies, Spectrum (www.spectrumcolor.com) and Mini-Craft (www.minicraft.com), premix gelcoats to manufacturers’ specified colors. Spectrum sells a Tint Adjust Kit to cope with fading, and Mini-Craft will custom match a color if you send them a chip. Lastly, we noted that Gibco Flex-Mold (817/236-5021) has a kit that allows you to make a mold of good nonskid pattern, and then transfer it to the damaged area, a sort of copy and paste operation.

In the February 1, 2000 issue we ran a Chandlery piece on Sure Step, a polish and protectant formulated for non-skid. We were impressed by it. It’s made by Aurora Marine (905/564-4995, www.auroramarine.com).

In a PS Advisor of April 1, 2001, in response to a question about deck-painting and what to do about stress cracks near stanchion bases, we went through the various options, pointing out that stress cracks must be routed out and refilled with resin and filler. We also suggested that the reader consult Allen Vaitses’ Fiberglass Boat Repair Manual (International Marine, www.internationalmarine.com).

Most recently, we recommended Bondo in our August 2001 article on gelcoat repair kits.

Whew. That brings us up to date.

The Evaluation

For this evaluation, the products examined were restricted to those that the average boatowner could apply.

We did our usual walking through the marine discount catalogs and, as is the way of research now, also delved into the Web.

The final list shown in the table includes four paints; eight paint additives and two mats. We chose not to include the numerous smaller nonskid pads and tapes because they’re not intended for covering large areas.

The paint companies represented are major players in the marine business: Interlux, Z Spar, Pettit, US Paint, Sterling, and Epifanes. Each sells a nonskid powder that can be added to paint. It doesn’t necessarily have to be matched with the same company’s paint, but that’s what we did to be on the safe side. In many instances, it’s important to stick with one company’s system all the way through, like using only the Awlgrip reducer with Awlgrip paint. But with nonskid powders we don’t think it matters. Indeed, one company spokesman said we could use his compound with any paint we liked. The companies do have recommendations. Interlux, for example, suggests 4-6 ounces by weight to 1 quart of paint.

The amount of nonskid compound was measured before mixing so that the same amount was applied to each panel. If you were redoing your decks, you’d want to experiment with amounts first because you can control the density or spacing of the granules on a surface.

Interlux, West Marine, Evercoat, and Epifanes sell paint with the compound already mixed in. About the only advantage we see to premixed paints is that the ratio of additive to paint is correct. You’ll save a little money, too, but the premixed paints are generally offered in just a few basic colors.

For testing, a 4′ x 8′ x 3/4″ sheet of plywood was cut into sixteen 1′ x 2′ panels, and a paint or mat applied to each one. The mats were secured with WEST System epoxy.

Once dry, each panel was propped at an angle for a tester to stand on. The angle was increased until the tester’s shoes began to creep or slip. From experience testing both nonskid paints and deck shoes, we know that most shoe/deck interfaces start to slip at around 40°. Therefore, we tested each panel at 40°, and then moved up to 45° and 50°. No shoe/panel held at 50°, and only three held at 45°.

Next, we laid the panels flat on the ground, secured them, and stepped onto them with a quick sideways motion, such as one would make moving fast and then having to suddenly stop. A subjective traction rating was given. The same test was repeated with the panel wet. These rough judgments more or less corroborated the more scientific slip test.

Last, we made observations regarding the uniformity of the nonskid compound, because in some cases it easily piles up and doesn’t look good. Besides aesthetics, notes were made on how easily the surface abrades skin.

Application

There are two suggested methods of applying nonskid compounds. One is to mix it thoroughly into the paint before application. The other is to sprinkle it onto a fresh coat of paint, let it dry, brush off loose granules, and then cover it with another coat.

We tried both methods and found that premixing the compounds produced a much more even distribution than shaking. Our efforts at the latter were poor, no doubt in part due to inexperience. Still, we gave it a valiant effort, employing several sizes of shakers and sifters. Inevitably, however, distribution was uneven, often in waves, with areas of dense concentration and others nearly void of nonskid.

Another choice presents itself when deciding whether to use a brush or roller. The latter, we found, does a better job of distributing the compound evenly, though overworking the surface with either can cause the granules to load up in bunches.

PAINT ADDITIVES

Interlux Polymeric Noskid. Interlux Polymeric Noskid Compound was mixed with one-part white Brightside Polyurethane rather than the more abrasion-resistant two-part Interthane Plus. Since their introduction about 10 years ago, we’ve learned to love the one-part polyurethanes for their easy application and high gloss. (See our upcoming February 15 issue for a report on topside paints.) Though the Interlux compound is shown in catalogs as one size only, two are offered: regular #2398 and coarse #2399. Uniformity of distribution was above average, and the panel looked good. Performance was in line with other fine and coarse compounds. The fine compound slipped at 40°; the coarse held at 40° but crept (a slow slip) at 45°.

Z Spar Nonskid Compound. Only one grit is available from Z Spar—fine. It slipped at 40°. Z Spar recommends using a 4-ounce (by weight) can to 1 quart of paint. One-pound cans of #M-612 Non Skid Compound, for use with 1-gallon paint containers, also are available. Priced at $10.99/4 ounces, the Z Spar product is expensive compared to the Interlux product at $19.95/quart.

Pettit Skidless Compound. Like Z Spar, Pettit offers just one grit size. But unlike Z Spar, Pettit’s is very coarse. As we would expect, coarse compounds give better traction. The #990 Skidless Compound held at 40° and 45°. And it was rated 4 in the flat skid test, wet and dry.

US Paint Griptext. US Paint offers three grits, the most of any manufacturer. They range from fine to coarse to very coarse. As was found with the other products, it’s harder to achieve uniform distribution with coarse compounds than with fine. One must stir longer and regularly, and be very careful to avoid overworking the surface—one or two rolls or brush strokes at the maximum. Only the very coarse Griptext held at 40°, and all earned just a 3 in the flat skid test.

Sterling Antiskid. The fine and coarse Sterling compounds both slipped at 40°. The performance of the fine compound was expected (none of the other fine powders held at 40°), but Sterling’s coarse was the only one that just plain slipped at 40°. The can is rather industrial looking and contains no instructions for application, stating, “See application guide for further information.”

PAINTS

Epifanes Nonskid Deck Coating. Epifanes is known more perhaps for its line of varnishes. However, the company’s premixed paint performed well. Its uniformity rating was a 5, the flat angle skid tests earned 4s, and it held at 40° in the angle test. The polypropylene beads used in this paint can be purchased separately if one wants to use a different brand of paint, or to increase the density of granules. Four colors are available: gray, French gray, white and cream.

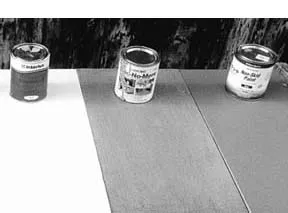

Evercoat Skid-No-More. This acrylic latex paint, with very coarse rubberized grit, has been around for a long time. It is reasonably priced at just $12.49/quart. Unfortunately, its performance in the flat skid test was a 1, easily the poorest of the paint products. It also slipped at 40°. Skid-No-More is available in just one color—gray, though it can be tinted using gelcoat coloring agents.

West Marine Non-Skid Paint. Available in three colors—clear, white, and gray—this paint was a surprise performer. It rated 4s in the flat skid test and held at both 40° and 45°, only one of three to do so. Priced at $19.99/qt., it’s a Best Buy… if you can handle the limited colors.

Interlux Interdeck. This premixed paint uses very fine granules. It has a low gloss, which is good for use on decks, and it looks very good. Unfortunately, the very fine granules also mean slip resistance is not among the highest. Though it did rate 4s in the flat test, it slipped at 40° in the angle test.

LARGE MATS

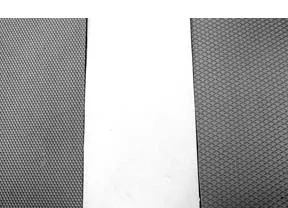

Treadmaster. Treadmaster has been around a long time. Like a molded nonskid pattern, mats are usually cut into shapes and applied leaving smooth channels between them. This can help drainage of dirt particles.

Treadmaster is a very good nonskid treatment, rating 4s in the flat skid test and holding up to 45° in the angle test. Its drawback has been its abrasiveness on skin. So a smoother version now is available for sitting areas—Treadmaster SP. This product is indeed less abrasive, but with an expected loss in slip resistance. In the flat skid test, it fell from a 4 rating dry to a poor 1 rating wet. And it slipped at 40°.

Treadmaster is available in four colors—white sand, light blue, blue, and teak. A “Marine Adhesive” is available for application, though we know people who’ve used epoxy resin with satisfactory results.

Vetus Deck Covering. This Dutch product, very similar to Treadmaster, is available in two colors—gray, called Happy Elephant; and tan, called Safari. The pattern is round rather than diamond. It weighs slightly less than Treadmaster (7 oz./sq. ft. vs. 8 and 11 oz./sq. ft.). It had only average ratings in the flat skid test but held at 40° in the angle test.

Conclusions

Your first decision should be to choose either a paint or a mat. Painting will cost you less money, can be easily redone, but probably won’t look as nice. For certain, you will lose the old nonskid pattern—unless of course there’s a lot of it left, which may show through the paint. This raises the question of whether you should sand off any remaining molded pattern before painting. (No one ever said this was going to be easy. And you will remove all hardware in the way, like cleats and stanchions, right?)

Mat is more expensive and heavier than paint, and the look, while attractive and uniform, is bold. It’s not difficult to work with, but once it’s on, you may as well consider it permanent. Hopefully it will last for the life of the boat.

Now, let’s sort through the various products in each category. It’s difficult to choose among the additives, as they all seem to perform essentially the same. That is, those of the same grit. The coarse grits give better traction, but are much more difficult to apply uniformly. Therefore, we’d choose a medium or fine grit. In terms of performance only, the Pettit Skidless Compound was the only one to hold at 45°, but is very coarse. Next would be Interlux Polymeric Noskid Coarse and Griptex Nonskid Extra Coarse. Of the fine compounds, the Griptext has a slight edge.

Of the paints, the West Marine is a Best Buy. It is one of just three products to hold at 45° in the angle test. But color choice is limited, and we’re not very confident about tinting. Epifanes is more expensive but a top-quality paint, and its performance with fine granules was the best.

Treadmaster DP outperformed its rival, Vetus. And at almost half the price, it’s a no-brainer. (Special order through a discounter might get you 20% off the Vetus.) Treadmaster SP for sitting, however, seemed quite slick when wet.

Also With This Article

Click here to view “Value Guide: Nonskid Paints & Mats.”

Contacts

Vetus, 410/712-0712, www.vetus.com

Treadmaster, 866/383-1888; www.plastimousa.com/treadmaster.htm

Paints and Additives: www.westmarine.com; 800/BOATING or www.boatus.com; 800/937-2628

Great article. Personally, I’ve found that Heskins Safety Grip tape does a great job and is well worth a look…..https://www.heskins.us/safety-grip