380

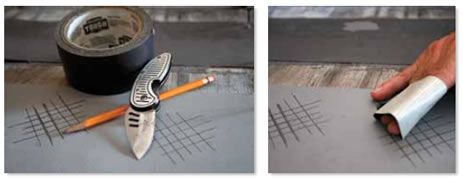

When we last looked at inflatable-boat paints in the June 2010 issue, our test panels had been exposed to the environment for less than 30 days, so the overall ratings were provisional at best. One key question that the first evaluation did answer was that regarding adhesion. Finding a coating that sticks well to either of the two chief inflatable tube materials, PVC and Hypalon, is not easy. Because the coated surfaces are flexible, expanding and contracting significantly as the tubes are inflated and deflated, the coating itself must also have some inherent elasticity. Dinghies take some serious knocks and scrapes, so abrasion resistance is also key.

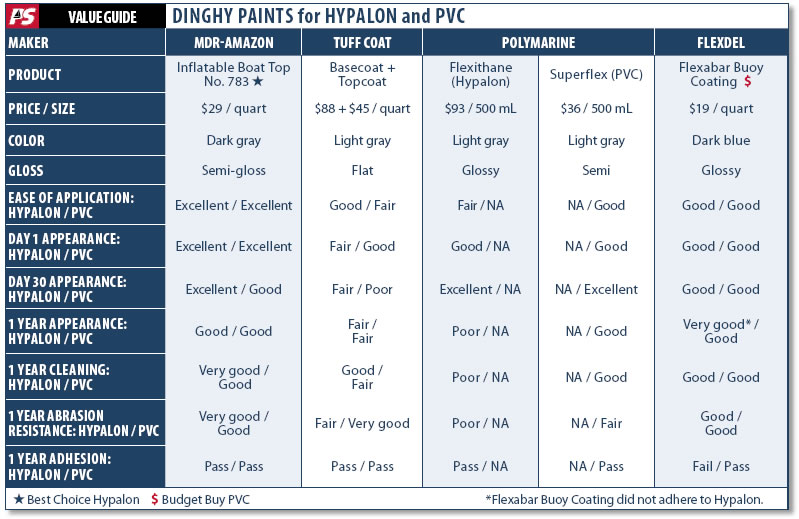

In our first round of testing, four products stood out. The Budget Buy was a one-part paint (No. 783) from Marine Design Research (MDR)-Amazon, which at $29 per quart was the cheapest product in our test. A paint marketed for painting buoys, Flexdel’s Flexabar Buoy Coating also earned a Budget Buy rating, but for PVC only. For Hypalon boats, we recommended Polymarine’s Flexithane as the Best Choice, and Polymarine’s Superflex earned a Best Choice for PVC boats. The the only true two-step system tested, Tuff Coat from Synergy Research Corp., was a “middle of the pack” performer. Two coatings from Inland Marine, Inland Topside Paint and Liquid Rubber, were pulled from the test due to application issues. These products will be re-tested.

After one year exposed to the elements, all of those ratings have held true, except for the Polymarine Flexithane, which has faded drastically since our initial rating period. Polymarine’s other coating, Superflex PVC, held on as a Recommended product, but it dropped a notch overall behind the less expensive MDR-Amazon.

The rapid deterioration of Polymarine’s products, among the more expensive in this comparison, was surprising. Most paints were designated for use on both PVC and Hypalon, so we applied the test paints to samples of each and left them in the Florida weather for a year. For more details on how we tested, see “Inflatable Dinghy Paint Torture Test” on page 29.

MDR-AMAZON

MDR-Amazon, a New Jersey-based maker of marine maintenance products, offers several different colors of paint for inflatable boats. We tested the dark gray No. 783 Inflatable Boat Top Coating, which turned out to be too dark (and hot!) for warm climates, but it held up well. The coating is a water-based vinyl paint designed to be a flexible coating for Hypalon, PVC, and vinyl. The MDR product is non-toxic and odor-free. Because it’s water-based, cleanup and application are very easy.

MDR recommends using its Inflatable Dinghy Cleaner prior to painting, and this did a good job of cleaning up the old Hypalon. No strong solvents were required.

After one year, the MDR paint was smooth and relatively easy to clean. It had lost most of its gloss to oxidation, but the finish was otherwise smooth, intact, and looking good. Adhesion was Excellent on both panels. The abrasion resistance was slightly better on the PVC.

Bottom line: The MDR-Amazon showed Good performance, especially for Hypalon applications. At $29 a quart, it clearly stands out as a bargain.

SYNERGY RESEARCH CORP.

Tuff Coat, manufactured by Synergy Research Corp., is sold as a two-part system comprising a quart of basecoat and a quart of topcoat.

The basecoat is a synthetic rubber compound designed to bond directly to Hypalon, but it can be used on PVC with a little extra sanding and cleaning with acetone. The topcoat is a water-based acrylic vinyl.

We tested a flat grey (no-gloss) topcoat, which SRC recommended for older, distressed boats, but the company offers the product in a range of glosses and colors.

After 30 days, the flat paint we applied showed some brush marks. After one year, the Hypalon sample was adhering well with a smooth, relatively abrasion-resistant finish. Appearance was rated as Fair. Over the PVC fabric, the paint had a dirty, rough appearance that did not resist abrasion as well as the Hypalon sample. It’s appearance was also rated Fair.

Bottom line: The Tuff Coat provided durable protection to both materials. It did not hold up as well to the weather as the MDR-Amazon, but it was the only other paint that didn’t have significant wear or adhesion problems over Hypalon. We would be interested to see how the Tuff Coat’s gloss products compared.

POLYMARINE

Polymarine, a British company with an extensive line of accessories, components, and products for inflatable boats, is distributed through Inflatable Boats USA in Bradenton, Fla. The company offers two different paints for inflatable boat restoration. Its Flexithane is specifically designed for Hypalon, and Superflex is for PVC fabrics.

Both paints call for special prep using Polymarine cleaners and solvents, and, in the case of Superflex, a PVC primer. After one month, both paints showed a smooth satin finish, rated Excellent for abrasion resistance.

463

After one year however, Flexithane, our favorite Hypalon paint at one-month, had deteriorated significantly. It had a mottled, faded appearance and was wearing through in some places. The PVC coating, Superflex, was doing much better. It had a uniform grey color that compared well with the finish of the MDR-Amazon or the Flexabar Buoy Coating.

Bottom line: Flexithane’s durability, considering its good start, was a disappointment. The Superflex held up well, but its price is higher than other PVC products that faired better over the long haul.

FLEXDEL

The maker of Flexabar Buoy Coating, Flexdel also manufactures a range of water-based antifouling bottom paints that Practical Sailor has tested. Its Buoy Coating is sold as a restorative paint for flexible and pump-up PVC and vinyl buoys and fenders. It also works well for inflatable boats, but it is not marketed for such applications.

The Buoy Coating currently comes in a wide range of colors; we tested the blue (No. 40103). Flexdel touts the paint’s durable, UV-resistant finish. It bonds to PVC, but the company makes no claim that it will adhere to Hypalon.

The company makes a Buoy Coating thinner used to prep surfaces. The paint has an extremely strong odor but dries very quickly, leaving a bright, glossy finish. After 30 days, the Hypalon coating was lumpy, while the PVC sample was as good as new. The Hypalon sample failed our adhesion test, but the adhesion to PVC was excellent.

After one year, this was one of the glossiest samples in our test, matching the MDR-Amazon product’s Good ratings in every category. Both Flexdel samples were smooth and easy to clean; however, the Hypalon sample did fail the adhesion test.

Bottom line: The least expensive of the lot at $20 per quart, the Flexabar Buoy Coating is the PS Budget Buy for PVC application.

Conclusion

Before considering painting a Hypalon or PVC dinghy, try some of our best rated cleaners and protectants from our 2008 dinghy cleaner test. We were able to revive some severely weathered dinghies using these products.

The mixed bag of results in this test demonstrates the importance of protecting your dinghy from UV damage. Fortunately, the material that gave the paints the most trouble, Hypalon, also lasts longer.

If your Hypalon dinghy has reached the point of no return, then MDR-Amazon’s formula makes the most sense. The only other contender, Tuff Coat, is harder to apply and more expensive.

For owners who want to revive or protect their worn PVC dinghy, either the MDR-Amazon or Flexdel paints are recommended. Flexdel is less expensive and had a bit more gloss.

Keep in mind that the finish quality is what we would call “industrial,” not beautiful. Also, be sure to follow the prep instructions carefully, otherwise you may run into adhesion problems.