Your boat and fittings may be made of corrosion-resistant materials, but not your electronics, spare electrical components, and many engine parts and bearings. They don’t have to get wet; the mere presence of high humidity is enough to turn them into rubbish by the time you need them.

Fortunately, sailors aren’t the only people facing this challenge. Most manufacturers produce spare parts years in advance of need, and they can’t afford for them to become rusty and ruined before they are even shipped.

Firearm enthusiasts and the military face complex storage problems, and in fact, the US military has moved away from protective grease for person weapons, converting to special disposable (but reusable) storage bags.

Cleaner than coil and grease coatings, these bags protect areas that are hard to reach. Additionally, the protective coating does not need to be removed, since it is very thin and will slowly evaporate once the part is removed from the bag.

We did not test vapor-phase anticorrosion emitters made by the same makers. These small cups or tabs emit the same anti-corrosion chemistry, reminiscent of air fresheners. They can be used in any small, sealed space, so they offer less control as the bags. If the bags proved worthwhile, we reasoned, wed move on to test the emitters.

What We Tested

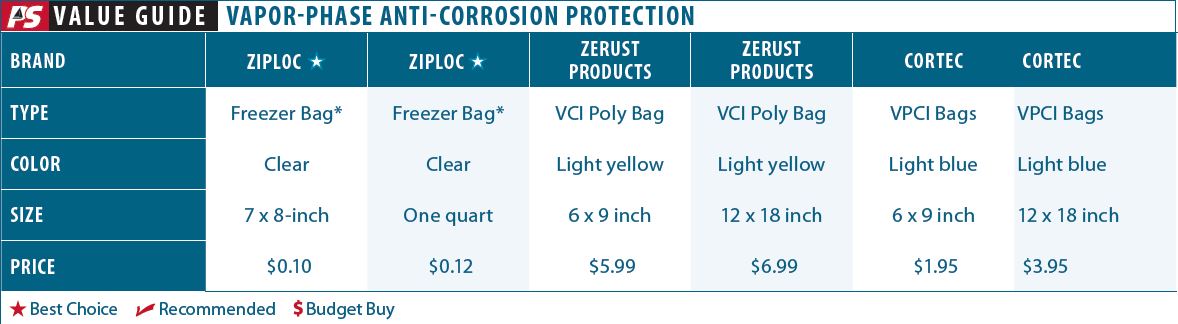

Zerust and Coretec are Ziploc-style bags that control humidity and oxygen flow, and are impregnated with vapor phase anticorrosion chemicals. These are available in sizes ranging from a snack-bag size to one large enough for a lap top or even outboard engine. We tested 6- by 9-inch bags. We also left one plain freezer bag cracked as a control, and sealed one freezer bag with a Dry Top silica gel capsule. This was our low-humidity control.

How We Tested

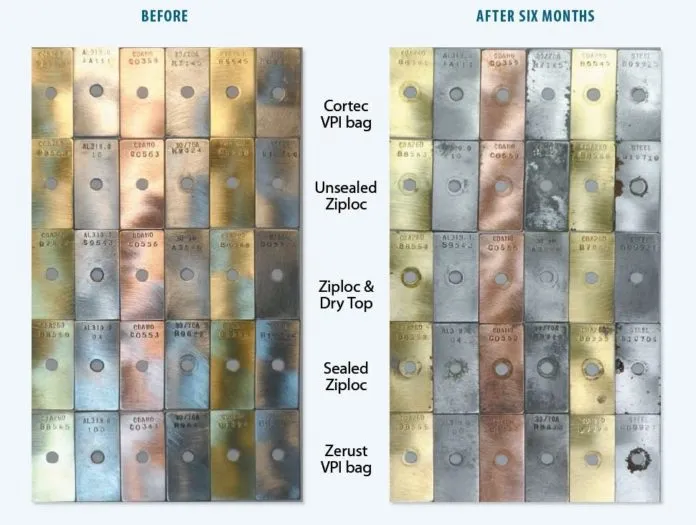

We prepared polished 1- by 2-inch sample coupons (tabs) of representative metals, assembled into galvanic parings: brass to aluminum, solder to copper, and steel to brass. We placed these samples inside the VCI (vapor-phase corrosion inhibitor) storage bags, a common Ziploc bag (with Dry Top silica), and with no protection at all, and left them in a footlocker-sized humid chamber for one year.

The chamber contained a layer of compost and was placed outdoors in a shed to allow moderate temperature swings to produce some condensation. We also included a flash drive and a CD in each bag.

Observations

At one month, the open-bag control was showing heavy condensation and the flash drive had failed, and within two months the aluminum sample was showing visible corrosion.

At six months, all of the bags had slight internal condensation, except for the Dry Top bag; the Dry Top canister had almost entirely changed color, so we regenerated it in the microwave and reinserted into the bag. The flash drives had failed in all but the Dry Top bag.

At the end of one year, all but the Dry Top bag had considerable internal condensation. The flash drive in the Dry Top bag was still functional. All of the CDs remained mildew free and readable.

The exposure was extremely severe, even for a boat, and probably representative of 3-5 years of damp conditions. Considering this, we believe the vapor phase corrosion bags would ordinarily meet the manufactures five-year projection. However, we believe a simple sealed bag would be enough in most cases.

ZeRust VIC Storage Bags

The makers of these bags, Northern Technologies International Corporation puts semi-volatile organic inhibitors into the polyethylene material during manufacturing.

These inhibitor condense on metal surfaces, coating them with a few-molecule thick layer that is supposed to inhibit corrosion.

The layer is so thin, however, it seems to have no effect on corrosion. They are effective for up to five years, according to maker. Light yellow in color, they are available from 3- by 5-inch to 24- by 36-inch, with prices ranging from 25 cents to $2.50 each.

Bottom line: Pass. Keeping moisture out by using double sandwich bags and (optional) silica gel capsules can be equally effective in most environments.

Coretec VpCi Bags

Light blue in color, these bags from Vycom Plastics are available from sandwich bag size to 4- by 5-feet at prices ranging from $1.50 to $20.

Bottom line: Again, wed not bother with these. Keeping moisture out by using double sandwich bags and (optional) silica gel capsules can be equally effective in most environment.

Daubert Cromwell Metal Guard

Lacking a tight closure, these must be heat-sealed to close. Any vacuum food sealer will work, as will tape or a zip-tie.

Bottom Line: These were not tested. Except for the closure these bags differ little from others we tested in this category.

ZipLoc Freezer Bag

When tightly sealed these provide considerable protection from condensation. In most cases, they are probably enough to keep parts rust free.

Bottom line: These bags offer enough protection for most parts. For critical parts, double bag and throw in a silica gel capsule.

Conclusions

The VCI bags outperformed plain freezer bags, but the difference was small. We recommend using Ziploc bags for delicate parts, and double-bagging critical items with silica gel capsules of one sort or another. The anti-corrosion bags strike us as overpriced for something with marginal benefit for sailors. If you want something for your toolbox, wed opt for re-usable silica gel boxes over emitters.

Hi Folks. The same things that destroy metal also destroy food. Could food preservation systems be used on metal? I use oxygen obsorbers, Mylar bags, etc. Works great for food and doesn’t cost much. Try Packfresh USA as a source and see what you think. They sell on eBay. Thanks for the article. I’m going to experiment with the food storage method on some metals and see what happens. Mylar bags don’t allow much moisture in/out. A normal plastic baggie sure does. A good test might be copper and zinc in the same bag. Who knows, it might not even go galvanic.