The final area for hidden maintenance problems that I want to cover is the boat’s electrical system. Most modern boats rely heavily on their electrical systems, and some don’t carry adequate backup systems. What constitutes an “adequate backup system” could be a whole other article so I am not going to get into that debate. Suffice it to say, for most boats the electrical system is a key to running the boat, so we need to know its main hidden vulnerabilities.

BATTERY CHARGING

The alternator fitted to the engine is not designed to charge a flat battery and will do a very poor job if you make it try. This applies to any battery type—lithium chemistry or lead acid, whether open, sealed, AGM etc. All of these different batteries require a specific charge profile with current and voltage-controlled phases to effectively recharge them. Alternators produce a fixed voltage, usually between 13.4 V and 13.8 V.

If you feed this into a heavily discharged large battery bank the battery can easily draw more current than the alternator is designed to produce. This leads to overheated alternators and overstressed belts. If either fails, you have no charging. If you don’t burn up the alternator getting the battery back up to 80-percent capacity, 13.8 volts may not ever bring the bank up to 100-percent charge and certainly not do it in a reasonable engine run time.

This is why your shore charger has different profiles that you can select depending on what batteries are fitted. Generally, this will be between 14.2 and 14.8 V, depending on the battery type. To get to this voltage using an alternator you must have an external three-step regulator that allows you to select a profile for your battery type. Most major marine electronics companies produce one, but you need to fit it! An effective DC charging system is needed on any boat that is likely to spend more than 48 hours away from shore power, which includes motorboats. Motorboats often have higher current demands because when they are underway with the engine running they normally have plenty of electrical power so don’t need to be stingy. That also means they may have smaller battery banks and can easily be down to 50- or 60-percent discharge in a night at anchor. Even with the engine running for six or seven hours the next day, the battery will not be fully charged because the voltage is too low.

Unless you are on a cat with a large solar array across the aft deck, you are also unlikely to have enough alternative energy sources to regularly get the batteries to full charge. This is a common reason for the premature demise of all types of lead-acid batteries, which need to be fully recharged at least once a month, ideally once a week for best battery life. I don’t have much experience with lithium—out of my price range and looks much too complex. (Read our recent piece on a full lithium refit here.) —but even if the advertising is true and it does not mind deep discharges and will not be damaged by not being fully recharged, you are still going to have a lot less battery capacity than you think based on the bank size.

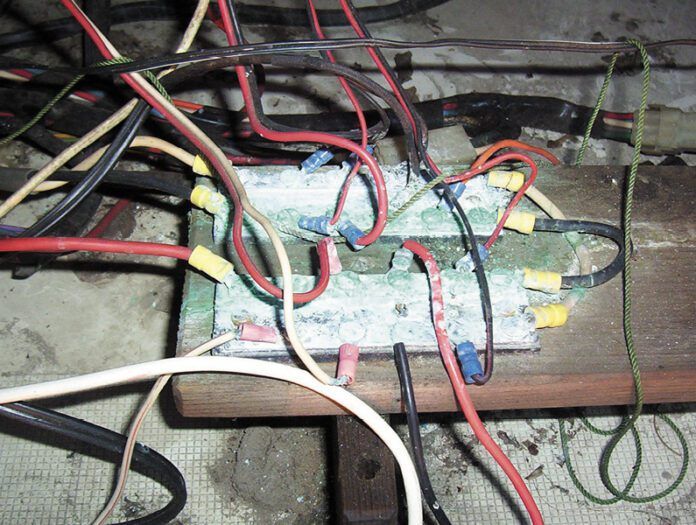

INADEQUATE CABLES

Once you have an external regulator it will charge the bank faster and more effectively but that means it is putting out more current. Often, the original cables are not specified for this and are not heavy enough, so you get a lot of voltage drop between the alternator and the battery, which again leads to inadequately charged batteries. Unless you are either an electrician or are prepared to do a lot of study, this is not a job for the amateur, you need to get it properly designed by an expert who can calculate the right cable sizes.

Also on the battery management side, two pieces of equipment commonly cause problems:

BATTERY SELECTORS

Apart from the obvious issue of forgetting to switch from “both” back to the house battery when the motor is off, which leads to a dead start battery that won’t get the engine turning, battery selectors are also prone to failure. When used with large banks, you inevitably get some sparking across the contacts each time you switch over. There is a lot of power in a battery bank and if you connect two together that are at different states of charge, that power immediately rushes from one to the other to try and balance their states of charge.

That is why it says to only do it with the engine off but it still does not eliminate the problem on anything but a small bank. This sparking leads to a build-up of carbon on the contacts and dirty contacts cause heat. Eventually, the heat is enough to soften the plastics and either the switch fails or catches fire. Each battery bank needs a dedicated fire switch that cannot connect the start and house banks together. Batteries are then charged by a multi-output shore charger and voltage-controlled relays for alternator charging.

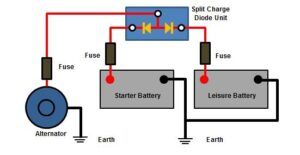

DIODE SPLITTER

The second piece of gear that causes problems is the diode splitter, which distributes the charging current between two banks. They do work and are reliable, but they inevitably have a noticeable voltage drop across them. This effectively causes the same issues as undersized cables.

Neither the battery selectors nor the diode splitter are likely to be seen on new production boats unless they are small and designed as day sailors. They date from an era when a cruising boat with a 45-amp alternator and 150-amp house bank was seen as perfectly adequate! Today, they should not be on anything other than a trailer sailor. If you maintain the battery selectors and the diode splitter, you should get 10 to 15 years of service from a decent set of flooded lead-acid batteries.

BANK SIZES

The final point about charging systems will focus on bank sizes. There is a lot of misinformation circulating about this one, but the main thing that constitutes a hidden danger is the idea that flooded lead-acid batteries can only be discharged to 50 percent of their capacity, but other types can safely go down to 20 percent or even flat. This is a dangerous myth and neither is true! It is recommended that you don’t discharge any type of lead-acid battery below 50 percent regularly but doing it occasionally is not a problem. The ideal size bank will mean that on a “heavy” day you will be down to 50 percent, but most days will only cycle down to 70 to 80 percent. That will maximize the life of the bank. However, that is not the reason it is recommended to limit discharge to 50 percent.

Think about this scenario. It has been a long, dark night.Navigation was difficult and visibility low, so you have had everything, including the radar, on all night. At dawn, it is still heavily overcast so you are going to get little help from solar—time to fire up the engine and get the batteries up to charge. You do that and find that there was a leak that soaked the charge controller or some other vital component so the alternator is putting out nothing. You are two days from a marina with shore power. With 50 percent capacity left and because you’re economical, you have enough power left to run nav and essential electronics for those two days. If your bank was down to 20 percent, you are looking at a long night with no nav gear or radar. The 50 percent rule was not to protect the batteries, it was to give you an emergency power reserve in case of a charging failure! It applies to all types of banks unless you have a separate below-deck generator.

PLANNING FOR FAILURES

The final point I want to make is a principle to apply to all maintenance. Look at the system you are working on and imagine the ways it could fail. For example, could your furling gear jam, your engine fail to start etc. Then ask yourself, “If this happens, would it be safe or dangerous?” The classic example is roller head sails. If the gear failed, is that 120-percent overlapper going to unfurl in 30 knots? Can I get it down if it does? Will the boat sail in heavy weather with just the main up?

By contrast, if a hanked-on sail fails, usually because the halyard breaks, it just drops on the deck. This is the fail-safe/fail-dangerous principle. Any system that you think can fail dangerously should be a high priority for maintenance and you need to think through an effective emergency strategy to employ if it does fail. If you can’t work out a strategy, or you consider that it would create a critical incident, maybe you need to change the system! Systems that are fail-safe can go further down the to-do list.

If you are a Harry Potter fan, remember Mad-Eye Moody’s saying, “Constant vigilance.” Happy sailing and stay safe.

Good stuff!

Regarding propane, even the portable cylinders have a reputation for leaking, sufficient that the home code only permits two 16 oz. cylinders and no larger cylinders in your garage or basement. In the past 15 years of part time cruising, I’ve had two leak when not attached to the appliance. They were good sized leaks, sufficient to blow up a boat. One we threw overboard (we were off shore) and the other we carried way out in a field until it was done hissing, about 36 hours later. Either could have been a disaster.

You can buy brass storage caps for a few bucks on Amazon–we reported on this a few years ago. I now use them religiously, on the boat and at home.

Portable cylinders should have a safe storage place on board. The propane locker is a possibility, if there is room to do so safely and they can be secured. Along the rail in a secure holder is another.

Very good points and I agree, the best place to store any propane is on deck regardless of there size. The same goes for gas/petrol for the outboard.

why is it that when I try to download an article as a pdf, the right hand side is cut off by about an inch. ?

how to fix?

Bruce, I don’t have an answer but FYI I don’t have that issue when I save as a pdf on my iPhone.

A technique used aboard Contessa is to purchase brass cylinder caps to seal the portable propane bottles. An extra layer of protection for the boat and the cylinders is to vacuum seal them in plastic bags. This protects the cylinders from corrosion and will let you know if there are slow leaks.

Thanks very much for this article, which adds enormously to my somewhat meagre understanding of electrics, which are way more complicated than people acknowledge.

Indeed, there seems to be two classes of people: those that understand electrics, and the rest. And what’s worse, neither can understand each other and those that do understand electrics simply can’t get it into their heads that others don’t and they simply treat them as idiots, which absolutely does not help. Or they also use nonsensical metaphors like electrics are just like water flowing in pipes – NO IT’S NOT! Water doesn’t spontaneously burst into flames or give you shocks, FFS!

The sense and rationale for an external voltage regulator in this article makes more sense than everything else I’ve ever read about boat electrics.

Good article. I do have 3-step temp compensated charging regulators on both solar and alternator. I did want to mention my battery bank is only 460 amphr FireFly and my solar is 400 Watts. I am solar independent on a 38 foot boat cruising the world solo, currently in Tonga.

I attribute my ability not to have to run the engine o a couple factors.

* I rebuilt my fridge box with a min. Of 6 inches except the top ( it’s only 3”). It has staggered insulation joints, a radiant barrier, and convective barrier.

* my lighting is completely LED

* My nav system and boat wifi access point is completely based on 1 Raspberrt Pi computer running Opencpn with Radar and AIS chart overlays. Runs on (.4 mps)I share the screen to an iPad over WiFi in the cockpit.

* My watermaker is one of the original Spectra Catalina 200c’s

Generally I’m charged by 10:30am and can go about a week with no sun. I’m not bragging, but hope others can follow some of my examples, and add some more 😎