Self-adhesive hardware-store hooks don’t stick well to bare fiberglass. Just last week we had one wash into the bilge-pump strainer on our test boat. Velcro tape is handy for window screens, and stick-on clips make it easy to route electrical cables, but over time, the bond between the glue and the gelcoat fails.

Our recent experience replacing fixed windows taught us a few things about using 3M VHB Tape, sparking an interest in its other possibilities. Specifically, we were curious about the potential other uses for the required primer, Tape Primer 94, which greatly improved the tape’s adhesion. Hours of scraping away the old 3M tape with a heat gun convinced us that peel-and-stick adhesion products had the potential to develop surface bonds comparable to high-strength adhesives. Although UV attacked the bond between the glazing and the tape, the bond between the tape and the fiberglass frame was still amazingly strong because this area was protected from UV.

3M describes Tape Primer 94 as an “adhesion promoter” for use in conjunction with 3M VHB Tape. According to 3M, the primer supports adhesion of VHB tape to polyethylene, polypropylene, acrylonitrile butadiene styrene (ABS plastic), polyethylene terephthalate /polybutylene terephthalate blends (PET/PBT), rubber, concrete, wood, glass, bare metal, and painted metal surfaces.

We aren’t surprised that the 3M primer is so effective with gelcoat. Although not a PET (polyethylene terephthalate, the most common polyester), gelcoat has a similar composition to PET. It makes sense that the primer helps develop such a strong bond with gelcoat.

Could this primer be used to improve bonds with other substrates we encounter on our boats? We were most curious about the 3M’s claim that primer was effective with PE (polyethylene) blends. Tape adhesion to PE is notoriously bad, and even the best glues and adhesive sealants will not bond with PE unless the plastic has been heat-treated.

We wondered if the tape primer might improve the performance of other tapes and stick-on accessories, or improve the adhesive strength of glues, caulks, and sealants. Could it help caulk stick better to polyethylene (notoriously difficult to bond with), metal, bare fiberglass, and other types of plastic (Starboard, Azek, Coosa board, etc.)? Could we get Velcro tape to stick to our polyethylene companionway slider? Could the primer help sail repair tape stick better to sails or Sunbrella? It sure would make life easier if we could depend on high-strength Velcro tapes (3M Dual Lock), adhesive snaps (SNADs) or 3M VHB tape to fasten panels, trim, accessories, etc.

USING 3M TAPE PRIMER 94

3M Tape Primer 94 is completely clear and very thin, smells something like contact cement, and when it’s dry, feels something like spray contact adhesives like 3M Super 77 and Gorilla Spray Adhesive.

The two bonding surfaces must be clean and dry before the tape primer is used. Contaminated surfaces should be cleaned with a 50/50 mix of isopropyl alcohol and water, and a clean lint free cloth should be used for wiping the surface. You can also clean the surface with denatured alcohol. Allow the surface to dry before applying the primer.

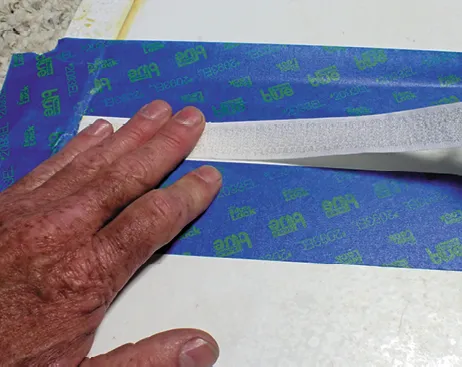

Apply the primer as thinly as practical. It will dry in 5-10 minutes. Apply two coats to more porous surfaces. When bonding to extremely porous surfaces, such as wood or very rough fiberglass, use a fairing compound to level the surface. Install the self-adhesive product within one hour of priming.

WHAT WE TESTED

We tested the adhesion of VHB Tape, several sealants, and self-adhesive hook-and-loop tapes on both untreated surfaces and after coating the same surfaces with 3M Tape Primer 94. The results are tabulated in the adjacent table. We also tested the adhesion of these same products on polyethylene after flame treating the polyethylene, which has been proven to improve the adhesion of some glues, caulks, and sealants. We also tested adhesion of tape and self-adhesive snaps (SNADs) on both polyethylene and gelcoat.

Before we get into the results of our tests, we need to clarify the holding ability of VHB tape under normal application. The foam core of VHB Tape slowly creeps (slips) and you can expect it to fail under shear loads greater than 15 psi. However, under momentary loads of less than a few seconds, ultimate tensile strength can be as high as 50-150 psi. VHB Tape should only be used when the sustained loads are very low, but we’ve found that it can resist shearing from modest impacts—say someone bumping hard into the fastened object.

LAB TESTS

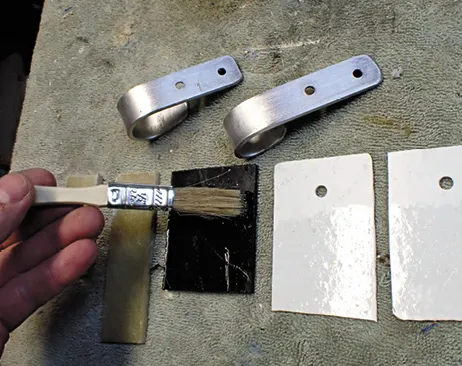

We primed samples of polyethylene, fiberglass, acrylic, Sunbrella, and polyester sailcloth with 3M 94 Tape Primer, and then mated them to aluminum hooks and fiberglass panels. We primed one end of a polyethylene sheet and then tested the peel strength of our hook-and-loop tape with and without primer. Because Tape Primer 94 behaves and handles like contact cement, we also tested Gorilla Spray Adhesive as a primer for applying self-adhesive Velcro to polyester fleece and Sunbrella.

Polyethylene. We tested both VHB Tape and Sikaflex 291 polyurethane sealant on untreated PE panels, panels treated with Tape Primer 94, and panels that had been sanded and flame treated (see sidebar on page 15). The tape primer did not improve Sikaflex’s adhesion. The tape primer did significantly improve VHB Tape’s bond with PE, but flame treating nearly doubled the holding ability; the foam core of the tape sheared before the bond.

Bottom line: When gluing poly-ethylene, make sure to flame-treat it first. After flame treatment, Sika 291, Loctite PL S40, and Sudbury Elastomeric Sealant are good choices for sealing or bonding polyethylene. Primer does not help here.

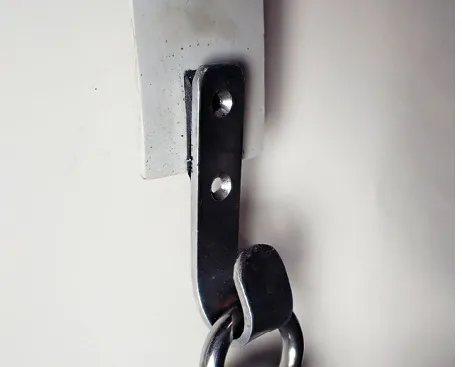

Aluminum. We used 150 grit sandpaper to remove the oxide film and immediately primed the metal with 3M Tape Primer 94. The other bonding surface was gelcoat. Without primer, the tape easily peeled away from the aluminum. With primer, the bond held, but the tape’s foam core sheared.

Bottom line: 3M Tape Primer 94 is recommended for any stick-on products applied to aluminum.

Bare Fiberglass. Obviously, effectiveness will depend on the surface profile. If it’s too lumpy, there could be adhesion problems. We tested on 1708 biaxial cloth that had been neatly hand rolled, but not vacuum bagged or given a seal coat. Tape Primer 94 did the trick, as the foam sheared before the bond let go.

Bottom line: Stick-on products will adhere better to bare fiberglass after it has been primed. If the fiberglass surface is very rough or uneven, you will likely need to level it with filler, sand, wipe clean, and then apply Tape Primer 94.

Gelcoat. We tested adhesion of VHB Tape on new, clean and unwaxed gelcoat with and without the 3M 94 Tape Primer. Without the primer, the VHB Tape peeled at about 50 psi, leaving no residue. With primer, the foam failed at 70 psi. Under normal working loads (about 10 psi) neither failed.

Bottom line: Primer is recommended for applying stick-on products to gelcoat, but it won’t improve bonding of polyurethane sealants, which adhere well to gelcoat without any priming.

Sail Repair Tape. We tested 3M Tape Primer 94 on repairs of used Sunbrella and used polyester sailcloth (tradename “Dacron”) with Bainbridge Sail Repair Tape. Without a primer, tape does not stick to Sunbrella, but after applying the primer, the tape bond was strong enough to tear the Sunbrella during the shear strength test. On polyester sailcloth, the primer improved peel resistance significantly and increased shear strength 40 percent. We did not test the primer on fleece.

Bottom line: Tape Primer 94 strengthens sail repairs made with sail repair tape. We’ll be using it with sail repair tape in the future.

ON-BOARD TESTING

We mounted cockpit line hangers in the cockpit of our test boat using 3M VHB Tape without any primer one year ago. They are showing zero signs of lifting. The sustained load is less than 1 psi and the impact loads they encounter are estimated at less than 10 psi.

We have also used VHB tape without primer to mount numerous polyester and PVC hatch covers to acrylic lenses, and we’ve had no failures. We have mounted anti-pollution and fire extinguisher placards using VHB tape on numerous boats over 30 years with no failures.

We attached our companionway cover to the polyethylene sliding hatch with self-adhesive hook-and-loop tape, but it peeled off within three months after only a few uses. We then reapplied the tape after lightly sanding and heat-treating the polyethylene. The tape is firmly bonded, and we expect it to stay.

We used self-adhesive snaps (SNADS) to secure the sides of the companionway cover. On the gelcoat we cleaned but did not prime the surface. Several months later, the SNADs show no signs of failure.

CONCLUSION

3M Tape Primer 94 significantly improves bonding of self-adhesive products to some surfaces, including gelcoat, molded non-skid, unfinished fiberglass, and aluminum. It helps sail repair tape bond to sail cloth. It does not appreciably improve bonding to polyethylene, but sanding plus flame treatment can improve adhesion on polyethylene. Porous or irregular surfaces must be sealed and leveled first. Very porous material, such as fleece, may be better primed with 3M Super 77 or Gorilla Spray Adhesive. In all cases, mask the surrounding area to prevent a mess.

Unfortunately, 3M Tape Primer 94 does not help with polyurethane sealants, epoxy, or Plexus. For these products follow the standard surface preparation practices, except when gluing polyethylene, which should be sanded and flame treated first.

VALUE GUIDE: ADHESIVE SEALANT ADHESION TEST: POLYURETHANES AND BLENDS

1. Sudbury elastomeric sealant was the only sealant in our past tests that bonded so well to polyethylene that the sealant failed before the bond. The top panel is polyethylene.

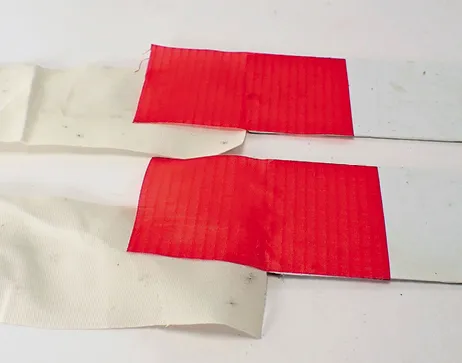

2. We applied 3M VHB tape to polyethylene that was flame treated and the tape held until its foam core failed.

The primer is applied thinly and doesn’t take long to dry, so you want to have everything you need ready to go as soon as you apply it.

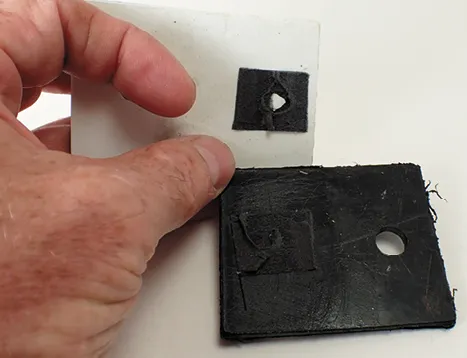

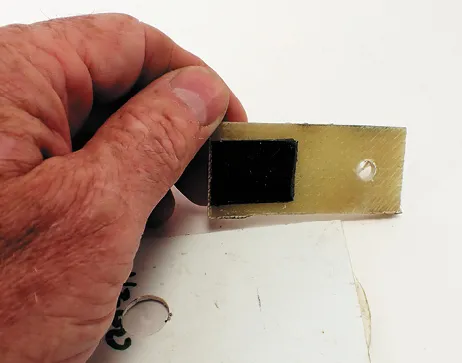

We used homemade hooks to test the primer’s ability to improve the

adhesion of VHB tape to various materials.

Priming porous fleece with 3M Super 77 helped keep peel-and-stick Velcro tape stuck to this fleece blanket for five years.

3M Tape Primer 94 did not markedly improve bonding on porous surfaces. This fleece hem has no stitching; it is glued with 3M Super 77.

3M Tape Primer 94 is transparent, so masking off surrounding area will help with cleanup and prevent wasting any primer.

As the load approaches 20 pounds, the foam backing on the VHB tape begins to creep. The bond eventually failed at around 75 pounds.

When we used the primer with VHB on bare fiberglass, the tape sheered before the adhesive bond failed—an adhesive success story.

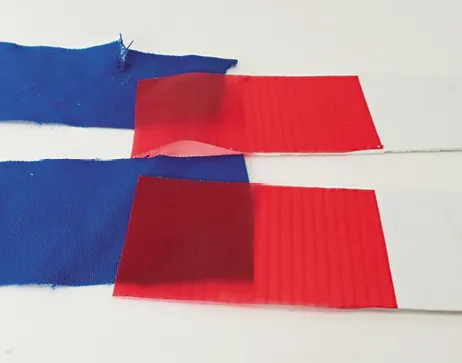

Priming with 3M Tape Primer 94 increased the sheer strength of sail repair tape on polyester sailcloth by about 50 percent.

Sail repair tape combined with 3M Tape Primer 94 held on used Sunbrella until the Sunbrella tore. Bonding to new Sunbrella is difficult.