As with all things in life, everything goes well until it doesn’t. It is an inevitable truth that something will go wrong eventually and will need some TLC! Taking precautions with regular and preventative maintenance will certainly help prolong the time interval between any issues. When it comes to our beloved engines, however, all the preventative maintenance can’t prevent the invisible wear and tear on various components. This wear can result in a broken water pump impeller or, as in the case of this true-story, a worn-out fuel lift pump.

Because these components are hidden, it is difficult to know their condition at any given time. In the case a water pump impeller, we can keep an eye on the temperature gauge, as well as audibly see and hear the sound of water coming out the exhaust port. For the fuel system, most diesel boats have a see-through bowl below the fuel/water separator filter. If there is any water in the fuel, it can be purged out before any problems occur.

But after that, any fuel related issues must be diagnosed step by step, to determine the cause. This may sound daunting for a novice or DIY boater, but it is in fact quite simple, and can be done with basic tools fairly inexpensively.

FUEL SYSTEM DIAGNOSTICS

As we were leaving our harbor, getting ready for a great day on the water, everything was going well until, without warning, the engine lost power. I immediately checked the temp and fuel gauges and saw all was well. I could only keep the engine in idle and we crawled back to the yacht club, reaching the dock seconds before the engine quit.

As most diesel engine owners know, 90 percent of problems with diesel engines are fuel related! So, a systematic diagnostic of the fuel delivery system was the logical first step. I was able to immediately eliminate a few possibilities.

- I knew my fuel tank was full.

- I knew my fuel was super clean thanks to the fuel additives I always use. (Biobor JF biocide, K100 water eliminator and SeaFoam).

- There was no water in the fuel/water separator.

- I rebuilt my three fuel injectors two years before.

I have a confession to make. Because of the fuel additives I use, I haven’t changed or needed to change my fuel filters in over seven years!

Check fuel/water separator and secondary fuel filter. So, clearly, I thought that had to be the first thing to do. Luckily, I keep two spares of everything on board. So, I closed the fuel valve at the fuel tank and changed the fuel/water separator and the secondary fuel filter located on the engine next to the fuel lift pump.

In doing so, I did notice that the old filters were not dirty and there was very little sediment at the bottom of the transparent bowl (under the water separator). So, even though installing new filters was a good first thing to do, the fact that the old ones were not dirty told me these were not the cause of the power loss.

Part of the process of changing the filters requires priming each one to purge the air out of the fuel line. First is the fuel/water separator, which has its own manual primer pump and bleeder screw on top. Basically, you pump until fuel starts to come out of the vent screw, then you tighten down the vent screw.

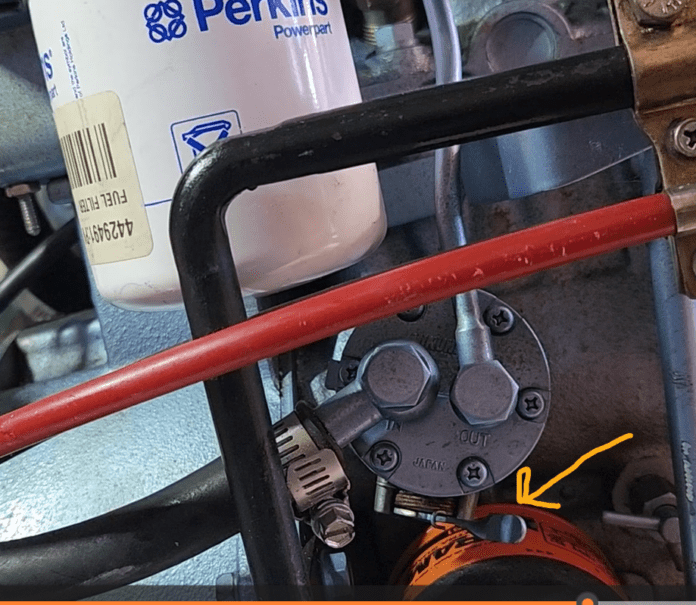

Then, there is the manual primer pump located on the fuel lift pump, which fills the secondary fuel filter. It too has its own bleeder screw to release any air in the fuel line feeding the injectors.

Once the filters changed and fuel lines purged, I tried to start the engine and it would simply not start. And yes, I did make sure the kill switch was not on, which is a common mistake that many of us make.

Check fuel injector lines. The next step was to loosen each injector fuel line, one by one, and turn over the engine (with the kill switch on this time). We spotted that there was very little fuel coming out the fuel line at the injectors. Normally, there should be lots of fuel at high pressure.

So, now we knew it was the fuel-lift pump for sure. Another telltale was the primer lever on the lift pump. It seemed very sluggish, and when pumping to prime, it had very little resistance and took forever to fill the secondary fuel filter.

The fuel lift pump is a critical component to the entire system. Mounted on the engine block, normally just before the secondary fuel filter, the lift pump operates via the engine cam shaft providing the right amount of fuel and fuel pressure to the injector pump.

Luckily, this is an easy and straightforward part to remove and replace. There are two fuel lines and two mounting screws involved. Remember to shut off the fuel valve at the fuel tanks and add an absorbent pad under there to catch any diesel fuel that will inevitably spill and drip.

For most marine diesel engines, the fuel lift pump is an easy part to find and is not expensive. I found one the very next day, both locally and online for less that $60.

A FRIEND IN NEED

Once the new fuel lift pump was installed and we double checked to ensure all nuts, bolts and injectors were tight, I proceeded to start the engine. It started right away and sounded great, but after about 10 minutes, it died again!

Luckily, during this whole process, many fellow club members came to see me and checked how I was doing on with this repair. One of them, Dujro, was the one that detected the lift pump lever seems sluggish.

The other one, Laurent, troubleshooted the final step. He reminded me that I had left the fuel valve at the tank switched off! I felt a bit embarrassed and turned on the valve—the engine came to life again, sounding and performing like new.

DIY does not mean doing things alone. In large part, the boating world is made up of amazing people that have this unspoken bond and a willingness to share and learn from each other. One should never feel alone or hesitate to ask for help and advice. During this particular repair alone, no fewer that seven people came to offer help, shared some thoughts and came to see and learn. I even crossed the street to a fellow member’s house to ask his advice. He jumped on his bike, came over to the boat and he spotted the problem with the lift pump, saving me hours of troubleshooting.

Anyone know the techincal rationale for the loop trap on the return line?

Hi Ben, not sure what you are referring to by the term “Loop Trap”. But in basic terms, the fuel return line, which picks up “excess” fuel after the injectors, to makes it’s way back to the fuel tank. Nor sure, but I hope this answers your question. Have a great day and thanks for your comment.

Information on the lift pump is extremely valuable.

I’ve had two electric lift pumps fail in my sailing career. They’re more easily diagnosed because there’s no “click” or pumping sound when I turn the key. I was able to get a replacement from the engine manufacturer (Westerbeke) in a few days the first time. I also bought a spare which saved the day the second. I wish they were cheap like these mechanical units. Over $200 OEM! Westerbeke W46 and now 55D.

Thanks for this and all the other articles. I’ve been a subscriber from the beginning, and credit PS more than any other source for information making my sailing safe, fun and economical.

Bob

The above diagnostic procedure has a couple of faults: 1) “loosen each injector fuel line, one by one, and turn over the engine (with the kill switch on this time).” No! The kill switch cuts off fuel to the HP pump, stopping the engine when engaged. 2) “Normally, there should be lots of fuel at high pressure. So, now we knew it was the fuel-lift pump for sure.” No, again! Given that the kill switch was engaged, there will be no or v. little fuel from the injectors, so, no, the test does not condemn the lift pump; what about the HP pump? It could indicate the same symptoms.

Having a vacuum gauge is very helpful. It indicates the amount of negative pressure (suction) it takes to get the fuel from the tank to the lift pump. I have found this to be a useful diagnostic tool, especially when the primary filter is clogging up.

To diagnose the problem, start from the fuel tank and end at the injectors. That said, in some cases, it may be easier to go for the “usual suspects,” as you did by changing the filters. If you lack or are unsure of your diagnostic skills, you can use the R&R (remove & replace) method until it’s fixed or you run out of money!

Is it possible for a fuel lift pump to fail partially time? I recently ran out of fuel with six gallons of diesel left in the 36 gallon capacity tank. Both of the fuel filters are clean. I am wondering whether the fuel lift pump was no longer able to pull fuel from the tank due to the decreased volume.

Hi Clarke, good question and yes, it is possible. As a matter of fact, in retrospective, mine was showing signs for a while. But it was only by diagnosis and process of elimination. If your filters are for sure clean, the lift pump, by what you describe, would definitely be the next and likely, culprit.

The best thing I ever did for my diesel was to fit an in-line electric pump (cheap at your local auto parts store) between the fuel tank and the first filter, with a switch in the engine compartment. Bleeding the system after changing filters was simply a matter of switching on the pump and waiting until the bubbles stopped at the lift pump, rather than pumping away interminably at the primer lever. When the lift pump quit I simply switched on the electric pump. When it was working again it sucked fuel through the (switched off) electric pump with no problem. Highly recommended both as a backup and as a labour saver.

Hi and thanks James. That is an excellent idea and back up. Would you have a picture or the make and model of your electric pumo?