In addition to all of that lovely salt, seawater is very hard, nearly saturated with calcium. All it needs is something to react with (uric acid in the head) or localized overheating (engine) to create concrete-like incrustations. Sometimes mechanical removal is possible; a favorite cruiser ritual involves hauling out the sanitation hoses and beating them on concrete to remove internal scale build-up. Heat exchangers can be reamed out with a rod, but most engine and plumbing systems are inaccessible without considerable disassembly.

A less labor-intensive alternative is to dissolve it with an acid descaling chemical, which hopefully will attack the calcium salts selectively, leaving the expensive metal bits undamaged. Flushing a cup of white vinegar each week is a popular scale preventative treatment for the head. Its allowed to soak in the plumbing for 30 minutes or so before flushing through, in hope that build-up will be prevented. Or so we hope.

What We Tested

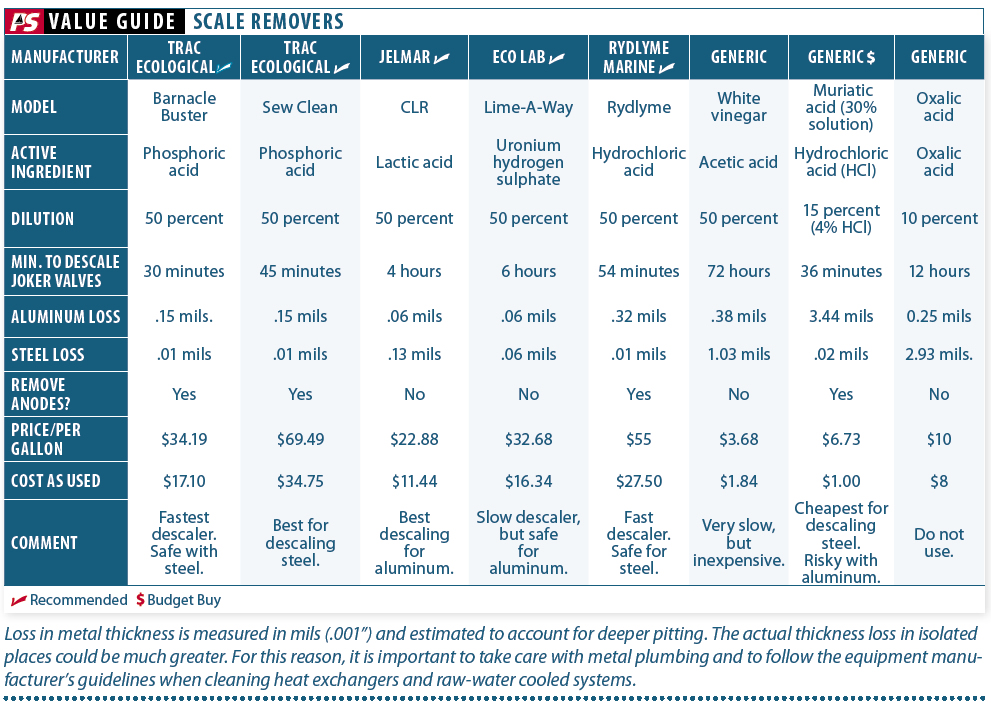

Descaling chemicals range from weak acids to strong acids, and are available both as generics and as pre-formulated solutions. Among generics, we tested white vinegar, oxalic acid, and muriatic acid (AKA hydrochloric acid or HCl). Among pre-formulated solutions we tested CLR, Lime-A-Way, Rydlyme, Barnacle Buster, and Sew Clean.

Photos by Drew Frye

How We Tested

First we measured the time required to eat the scale deposits off a collection of used joker valves. Testers diluted each solution to manufacturer recommended ratios and immersed a section of joker valve in the solution and observed. The valve sections were moderately agitated every 30 minutes, and the valve was considered clean when all of the deposits came off with agitation or a very light brushing with no detectable resistance. Muriatic acid was used as a control on one section from each joker valve.

We then placed standard ASTM corrosion coupons in a separate container of each solution to measure corrosion over time. The samples were weighed to the nearest milligram before testing began, and then at two hour intervals over the next 8-72 hours. Each intermediate test required wiping the coupons clean, rinsing with distilled water, and drying. Although metals corrosion is a minor issue when cleaning sanitary plumbing-there should be no vulnerable metals in the system-mariners often use these products to clean piping, inboards, and outboards, and in those applications, the potential for harm calls for caution.

Although the manufacturers sometimes suggest use without dilution, we diluted most products 50 percent (see Value Guide) based on the realistic assumption that there would be residual water in the plumbing.

Observations

In minutes, it was obvious which chemicals were fast acting and which chemicals were aluminum-safe. The Barnacle Buster, Sew Clean, muriatic acid, and Rydlyme samples immediately began bubbling wherever lime was present and on the aluminum coupons. The other chemicals-CLR, Lime-A-Way, oxalic acid, and vinegar-also caused bubbling on the lime deposits, though less vigorous, and very few bubbles appeared on the aluminum coupons.

Within one to three hours, depending on the product, the lime deposits were either rapidly disappearing, or becoming loose. What constitutes clean will depend to some extent on the application; the deposits will probably be loosened sufficiently to flush out before they are completely dissolved, which can take considerably longer.

Although few bubbles appeared, the steel coupons also corroded. However, the pattern was reversed; after correcting the exposure time for equal cleaning effect, the chemicals that worked the fastest and did the most damage to the aluminum coupons were the least damaging to steel, and the slower chemicals, which were safe for aluminum, were more damaging to steel, although the damage was less than that done to the aluminum coupons by the fast acting chemicals. Additionally, the steel corrosion was uniform and left a smooth surface, different from the pitting attack observed on the aluminum coupons.

The remaining metal coupons-brass and copper-were not materially affected by any solution during the normal cleaning period. A few milligrams were lost from the copper coupons, which plated loosely onto the steel coupon. This was more of a curiosity than a reflection of noteworthy damage.

All of the solutions are acidic and hazardous as used, but after neutralization or dilution, they contain only relatively harmless or biodegradable components. Obviously, the amount used should be limited to what is needed and disposal should be according to local requirements. Head cleaning acid can stay in the holding tank until the next pump-out (assuming the tank is not aluminum, which is a terrible mistake for holding tanks anyway).

Although we did not test stainless steel, it is known that most common stainless steel alloys, including 316, are vulnerable to stress cracking by hydrochloric acid, even when diluted. While minor exposure of low-stress fasteners to diluted hydrochloric acid for limited time periods poses a minimal risk, do not soak critical stainless steel parts in hydrochloric acid or hydrochloric acid-containing cleaners.

Copper and brass are also susceptible to chloride stress cracking. Stainless steel and brass bellows-type hoses are particularly vulnerable to cracking and should be removed during cleaning with hydrochloric acid-containing chemicals.

Limited tests confirmed that the products that are aggressive towards aluminum are also aggressive toward aluminum, zinc, and magnesium anodes. If you intend to descale a system that includes anodes, temporarily replace these with plain plugs.

We divided the field into two groups: fast acting acids with shorter soak times of one to four hours ( muriatic acid, Sew Clean, Barnacle Buster, and Rydlyme); and slower acting acids requiring soak times of two to eight hours (CLR, Lime-away, Vinegar, Oxalic acid).

Muriatic Acid

This solution of 30-percent hydrochloric acid is by far the least expensive option, but it is also nasty stuff to work with. Chemical burns are quite possible, particularly to the eyes, and the fumes are hazardous to both the eyes and pulmonary system. These are not long term health risks, such as exposure to carcinogens or toxic metals-stomach acid is largely muriatic acid-but rather momentary acute hazards.

Familiarize yourself with safe working practices before you begin. When diluting to pour acid into water, not water into acid, which can create splattering, fumes. We suggest that all solutions be made up outdoors into labeled gallon jugs so that the 30-percent acid is not handled inside the boat or in confined spaces. Keep your head upwind while pouring 30 percent acid and wear goggles while mixing.

Many retailers are now stocking only green hydrochloric acid, which is the same acid packaged at 20 percent to reduce user exposure to fumes. Because the fume concentration is reduced 90 percent at this lower concentration, this is a safer choice, although 50 percent more is required to get the right mix.

We diluted the 30 percent muriatic acid to 4 percent (about one pint per gallon of water). The resulting solution is still acidic and smelly, but much safer to handle. At this concentration it reacted very rapidly with the scale, though not as fast as several commercial products. Cleaning was very effective, but aluminum loss rates were nearly ten times higher than even the other fast acting products.

Bottom line: This is the Budget Buy choice when there is no aluminum around.

Sew Clean

Based on phosphoric acid, Trac Ecologicals Sew Clean was the fastest and most effective descaler of the group. There is no objectionable odor, it is somewhat less acidic than muriatic acid, making it a bit safer around metals and skin. Although not as damaging to aluminum as muriatic acid, its still not something wed want to leave inside an outboard engine for longer than required.

Bottom Line: Recommended. This is the best choice to remove heavy scale deposits from sanitary systems.

Barnacle Buster

Similar to Sew Clean, this product, also from Trac Ecological, worked slightly faster, and with slightly greater corrosion rates on the metal samples.

Bottom Line: Recommended for barnacles and heavy duty descaling.

Rydlyme Marine

This formula is based on muriatic acid but with effective corrosion inhibitors, it attacked the scale nearly as fast as Sew Clean, but with less corrosive attack on aluminum than generic muriatic acid.

Bottom Line: Recommended for heavy duty descaling of systems not containing aluminum.

White Vinegar

The slowest of the slow, the best we can say is that its inexpensive, easy to use, and aluminum-safe. Unfortunately, there are downsides. It was the most aggressive towards steel on a mil/cleaning time basis, the scale removal was glacially slow, accomplishing little even with an overnight soaking, and a number of cruisers reported giving up on vinegar as a preventative method after becoming unconvinced it didnt do much.

Bottom Line: Save the white vinegar for your salad.

CLR

Being dubbed the fastest acting of the slow group sounds like a dubious distinction, but this familiar product from Jelmar wasnt that slow, and it did the least damage to aluminum parts for a given amount of calcium removal. On the other hand, it was the safest effective product for descaling an outboard motor.

Like all of the slow-acting products, there is no objectionable odor, and though you should keep all descaling chemicals off your skin, it is relatively safe, no more dangerous than many strong cleaners. Internal sacrificial anodes do not seem to interfere significantly, although removing them may is a good idea for longer soaks.

Bottom Line: This is our Best Choice for cleaning aluminum-containing systems.

Lime-A-Way

Similar to CLR, although based on different chemistry, this product from Ecolabe is gentle to metals and just a little bit slower.

Bottom Line: Recommended for aluminum containing systems.

Oxalic Acid

Also known as wood bleach, it is an effective teak cleaner (Spiffy Teak Tips for the Penny Pincher, PS March 2016) and rust remover. However, it was not effective on head scale and was the most aggressive to steel per cleaning cycle.

Bottom line: There are better choices.

Conclusions

The products tested fell into two categories: those that work slowly but were aluminum-safe (a relative term-exposure time should still be controlled), and those that worked more quickly and were steel-safe. Among the slow but aluminum-safe chemicals, we like CLR and Lime-A-Way.

Among the fast and steel-safe chemicals, you have a choice between many effective and relatively user-friendly descalers, and muriatic acid, which is dirt cheap but stinks to high heaven and requires user caution.

Dont put too much stock in the exact rankings; we know from experience that both the rate and most effective formula can depend upon the chemistry of the scale. The amount and type of scale buildup can vary between applications (heads, barnacles, and engine scale), as well as from boat to boat.

The only really serious mistakes are using muriatic acid on aluminum, leaving any solution in the plumbing or cooling passages longer than recommended, or using a higher concentration than is recommended.

If we were forced to pick an overall winner, we would give the nod to Sew Clean for its combination of speed, reasonable corrosion rates, and relative safety. For descaling engine cooling passages, CLR is a safe bet, following the engine manufacturers guidelines.

Loss in metal thickness is measured in mils (.001) and estimated to account for deeper pitting. The actual thickness loss in isolated places could be much greater. For this reason, it is important to take care with metal plumbing and to follow the equipment manufacturers guidelines when cleaning heat exchangers and raw-water cooled systems.

getting rid of calcium deposits- so what’s the bottom line on vinegar for the head and hose plumbing?

I’m certainly not going to use HCl.

No not HCL. I use sulfuric which is commercially sometimes known as muriatic acid.

Muriatic acid is dilute hydrochloric acid-not sulfuric acid.

The secret to vinegar is twofold:

1) It only works well in fresh water.

2) It must be quite warm, but not hot.

So start by flushing the head through a few times with sweet water, letting it sit a bit between flushes, then flush it as dry as you can.

Then pour in 2 litres of warm water, max 50c that is 25% white vinegar and let that sit overnight if possible.

Then flush with fresh water and do it again if necessary.

A little brush work while it’s working helps the process.

The same mixture does wonders on your water speed wheel in the depth sounder to clear the life that forms there.

All cheap, effective and eco friendly.

Fair winds, Olisboa

There is an old adage when diluting powerful acids. Do as you oughtta add acid to watta. With the correct accent of course. adding water to a powerful acid can cause splatter as the acid leaps towards the water.

Muriatic acid is dilute hydrochloric acid-not sulfuric acid.

Congrats interesting article, when you descale an outboard cooling system run for years in salt water assume the mentioned products must recirculate through the entire powerhead’s water passages with removed thermostat. Will any of these products dissolve efficiently a large salt crust that has taken over the internal sacrificial anode that’s blocking the entire exhaust chamber water passage while no product recirculates through that precise area ? If you can send me an email will send pictures showing that scenario for a better understanding.

Interesting tests. However, well known brands your dilution is at 50%. That is NOT The manufacturers recomended dilution ratio’s For safe effective descaling.. 4 to 1 dilutions are recomended. 4 litres of water to 1 litre descaling solution.

Generic Acids Muratic & Oxalic you have used straight high concentrations with NO Other propriatery CORROSION INHIBITORS.

I would not use muratic acid to flush an out board motor.

6% Oxalic acid with added proprietary corrosion inhibitors, wetting agents, cleaning surfactants etc.. is safe to use for a quick maintenance flush your raw water cooling system. inboard & outboard.

Very informative post, thank you for taking the time to write this all out! Most folks have to learn this the hard way.

What a wonderful detailed and well thought out article !

If you ever publish an update, I would have some comments/suggestions :

1. Vinegar is actually a diluted form of acetic acid, with acetic acid making up 4 percent to 6 percent in “white” vinegar, depending on the brand and type of vinegar.

2. add the pH value of of all products to the table.

3. add Sulphamic (Sulfamic) acid to the table – Sulphamic acid is inexpensive – it retails in powder form and is often used to clean the excess grout off tiles. A 1% solution has a pH of 1.2 (compared to white vinegar’s 2.5 pH).

4. You should mention that, in many applications, neutralization with soda and flushing with water is advised.

RydLyme is often used for flushing marine engines – having a nice balance of speed, safety, biodegradability and effectiveness. It is very expensive, compared to most of the descalers listed in the table.

RydLyme is made in the USA. I live in Canada and have searched on the internet many times, but can’t find a place where to buy it. It is listed on Amazon but “currently not available”

Ths SDS data sheet says that RydLyme is 5-9% Hydrochloric acid !

https://www.apexengineeringproducts.com/wp-content/uploads/2019/12/RYDLYME-SDS-112020.pdf

only Rydlyme, Nu-Calgon and hydrochloric acid based descalers will remove Calcium or Sodium carbonates found in Tropical waters

hi

could you please me

i have a suzuki df140 hp 4 stroke 2004

this motor has done 650 hours

i have a serious corrosion problem

last week the top of the engine block cracked and leaked water

i repaired the crack gut engine is running rough and won,t rev past 2000rpm

this model has a bad history of serious corrosion

the engine builders installed a steel plug in the aluminum exhaust passage

the mechanic replaced the high pressure petrol pump and ran the engine and it reved very well

3 months later i started it before going on a fishing trip and noticed it was running rough

so i called him and he came back to look

when i started it he noticed the crack leaking water

he told me the engine was finished and full of corrosion which caused the block to crake

i was shocked and decided to try and remove corrosion

i thought as a start i will try 25 litres of water to 2.5 litres of hydrochloric in a tub and run till very warm then run water through it and repeat this a few times and see what happens

after this will try rydlyme as i seen on you tube with same motor but smaller

if you have any suggestions i would appreciate

cheers mick

I have used Concentrated Barnacle Buster twice in my engine using the Sea Flush Funnel system. I dilute the Concentrated Barnacle Buster according to instructions (4:1) in a six-gallon bucket, start the engine and run it until the bucket is empty. Then I wait the six hours to let it work. Afterwards, I remove the Sea Flush and once again start the engine and flush the system well.

NOTE: In a conversation with the manufacturer, I was specifically told NOT to let it sit overnight and that six hours was a reasonably safe time to let it do its job of descaling the raw water system.

My only question on the product is that there is no way to really know what kind of a job it is doing because the entire raw water system stays intact, i.e. there is no dismantling of the engine but, then again, that is what I am paying for and a good thing.

The PS tests had a scientific tone to it using metal coupons rather than a practical test on a real engine. I would have preferred to see before and after photos of a reasonably scaled-up engine done but that would be a lot more work, something they and we are all trying to minimize.

About 30 years ago, I read an article in a sailing magazine that suggested using vinegar instead of holding tank deodorant in the head to prevent calcium buildup and reduce odors. I tried it, it worked great, the boat maintained a fresh smell, and it was very inexpensive. However, after about 8 to 10 months the rubber joker valve and gaskets started leaking from the continuous exposure to the vinegar. After replacing all of the rubber fittings in the base of the head, I went back to using standard holding tank deodorant.

This PS test does not say much about the reaction to any of rubber components exposed to these products. I would assume that the integrity of any rubber fittings in the system is not an issue as long as the descaling solutions are properly flushed out.

What would be your recommendation for seawater side of “chiller” air conditioning systems?

And what types of metals are typically in that side of the system that should be considered in picking the solution?