If you’ve ever been humbled by a single impossibly stuck fastener, or plan on adding hardware to your spar, running gear, or deck, this report on anti-seize protectants is right up your alley.

If you own a boat, you need a corrosion-fighting regimen. We’ve tested a boatload of products to protect your boat, but each case is a little different, sometimes calling for a different treatment. Perhaps you just smear some waterproof grease or lanolin and hope for the best? Or perhaps you’ve bought into the advertising puffery that anti-seize products fight corrosion by isolating dissimilar metals? (Oddly, some of these same products also advertise their conductivity in electrical connections).

In fact, these heavy-duty protectants all rely in some part on their grease-like consistency to get the job done. Some are primarily lubricants focused on preventing wear, while anti-seize products focus on keeping air and water out and adhering well, even when forcefully doused with water or immersed in it. Actual results with each type of product vary with the product and the metals involved.

Photos by Drew Frye

Chemistry Matters

Most corrosion in a marine environment is the result of dissimilar metals in the presence of an electrolyte. A stainless-steel bolt in a lower unit and a carbon steel bolt on the engine present completely different chemistry. At ambient temperatures, the corrosion inhibitors function both by scavenging oxygen and by coating the metal surfaces with an organometallic film.

However, at high temperatures (above 400 F) organics burn off and grease slowly turns to carbon. Temperature cycling and differential expansion create extreme pressures, and prevention of seizing and galling comes down to the effectiveness of solid films and the magic of inorganic chemistry.

Some of the products we tested for this report are loaded with metal or inorganic particles; Kopr-Shield contains a fine dispersion of copper, and Bostic Never-Seez contains nickel powder.

This approach may work at high temperatures, but prior testing ( see “Conductive Grease vs. Corrosion”), only increases dissimilar metals corrosion in a wet environment. Thus, there are metal-free marine formulations that rely on dispersions of inorganic solid lubricants. Since our testing is at ambient temperature, our results may not apply to the engine room.

What We Tested

Excluding water and preventing corrosion are important in ambient temperature applications, so we included products we have used successfully for years: Lanocote, Green Grease, Corrosion Block Grease, Rector Seal Teflon Pipe Dope, No-Ox-Id, and Tef-Gel. For higher temperature use we also included some conductive greases.

We also tested a few anti-seize products that were recommended by folks who have turned a lot of wrenches; Kopr-Shield, Loctite Marine Grade Anti-seize, and Bostik Never-Seez.

We did not test Duralac, which is more of a coating than a conventional anti-seize. A barium chromate primer that functions like a gasket, Duralac physically prevents electrical contact, in doing so fights corrosion. This product is popular among some riggers, but it is restricted for sale in some areas since barium chromate is a suspected carcinogen.

How We Tested

The true test of anti-seize product is whether you can remove the fasteners later. We tapped holes in an aluminum mast section for #8 stainless machine screws. A carbon steel plate was drilled for 1/4-in. bolts to simulate engine and trailer fittings.

We applied the test product as directed, tightened down and recorded the torque, and then left the samples hanging under a dock for 18 months, just above the high tide line so that they would be immersed during spring high tides, dry during neaps, and enjoy high humidity all the time. We installed extra control samples so that we could monitor the progress of corrosion and seizing.

After 18 months of tough exposure, the aluminum mast section was lightly corroded around the fastener holes and the edge where we cut it to expose the raw alloy. Fasteners coated with Green Grease, Lanocote, Tef-Gel, and Loctite LB 8023 required about the same torque to remove as when they were installed, as though they had been installed the day before. Other products were more difficult, but none were a real battle.

One reason for this is that we used Allen head screws, which provide a tight fit for the hex key; if we had used Phillips head fasteners, the less effective products (rated Fair or Poor in the table below) and the control would have been a struggle. Lesson: Use hex-head or Allen fasteners whenever possible.

Observations

Not surprisingly, the fasteners bedded in plain steel were more difficult to break free. The steel plate and bolt heads showed significant rust.

In fact, had we waited just a few more months, we would not have been able to remove any fasteners that weren’t coated with the most effective anti-seize products.

Before removing each bolt we lightly chipped the rust away. A six-point wrench was then firmly tapped onto the head, and firm vertical pressure was applied to keep it there. Even with carefully applied pressure, five of the six control fasteners and several product-coated fasteners snapped when we tried to remove them.

We did not use heat, impact wrench methods, or penetrating oils, although we’ve tested plenty of these-see adjacent article. Green Grease was the only ordinary lubricant that made any measurable difference, but we suspect that protection would only have lasted another month or so.

Omni Lubricants Green Grease

A top performer in our waterproof grease testing (See “Budget Priced Winch Grease“), we’ve used this countless times on all sorts of fasteners, when it was the first thing at hand.

We’ve been a little disappointed when we used it on outboard lower units, outboard clamps and spars (aluminum), and in testing it did not shine as an anti-seize.

Bottom line: Not a great anti-seize, but still one of our favorite greases.

Corrosion Block Grease

This is another synthetic grease like Green Grease. It is widely available and popular with boaters for protecting everything from trailers to outboards.

Bottom Line: While it may serve its purpose in other realms, it did not shine as an anti-seize.

Forespar Lanocote

Lanocote was a top performer in our grease wash-off testing. It has been our go-to product for most rigging and seacock issues for decades. Proof of lanolin’s durability and dry-out resistance at moderate temperatures is a tub of 1920s lanolin grease we still use.

In our testing, Lanocote provided mediocre protection for steel, and fared better when used with aluminum and stainless. We’ve used it on rigging screws for years with good results.

Bottom line: Recommended for stainless and aluminum, Lanocote is not our first choice for steel.

No-Ox-ID Grease

We first tested this product eight years ago for protecting electrical connections. Although it was not very effective in the challenging steel/steel pair in this test, it was a top performer on the aluminum/stainless pair.

Bottom line: Recommended for stainless fittings in aluminum, an excellent choice for protecting electrical contacts-circuit panels, bus bars, or butt splices.

Ultra Safety Systems Tef-Gel

A specialized product that riggers often tout, Tef-Gel is loaded with Teflon, which provides considerable lubrication under extreme pressure. It did an impressive job in eliminating seizing in both the aluminum/stainless pair and the steel/steel pair.

The only apparent downside to this product is that fasteners lubed with Tef-Gel often need just a little extra torque before they will stay put. For this reason, locknuts are a good idea in any high vibration settings, such as motors.

Bottom line: It is expensive, but it is also the Best Choice for aluminum, stainless, and carbon steel.

RectorSeal Teflon Pipe Dope

Primarily used as a pipe sealant, this is a top quality PTFE (Teflon) pipe dope. Any pipe fitter knows that Teflon pipe sealants are a boon to disassembly. While it works on piping, it didn’t impress us during our testing.

Bottom line: Save it for plumbing.

Loctite LB 8023 Anti-Seize

This metals-free concoction came highly recommended and met all our expectations for protecting fasteners in steel and aluminum. With a temperature rating that makes it practical for engine room applications, this is what we classify as essential goop, something that belongs on every auxiliary sailboat.

Bottom line: Best Choice and Best Buy for your tool bag.

Bostik Never-Seeze

Loaded with nickel powder, the local outboard shop swears this is the remedy to frozen bolts on lower units. It failed to protect both test samples.

Bottom line: Here’s a case where reputation exceeded performance.

Conclusions

We found a new must-have for our tool box; Loctite LB 8023 Marine Grade Anti-Seize. It was impressive in wet conditions and the temperature rating suggests it should be pretty good in hot places as well. Tef-Gel is also a top performer on the stainless aluminum pair and remains our first choice for rigging based on long experience.

Five out of the six bolts broke in the steel-to-steel control group. The test screws were #8 machine screws, and 1/4-in. bolts.

After 18 months of exposure to brackish water, the aluminum mast was lightly corroded, especially the threads, where shiny alloy had been exposed. The steel plate, on the other hand, was heavily rusted. Even with careful pressure, five of the six control fasteners and several treated fasteners snapped as we tried to loosen them.

Although we took no special measures to loosen the bolts (impact wrenches or sprays), no screw heads stripped.

This was probably because we used a six-pointed wrench which is less likely to strip a bolt-head. For the aluminum screws, we used hex-head screws. Regular Phillips-head screws can easily strip.

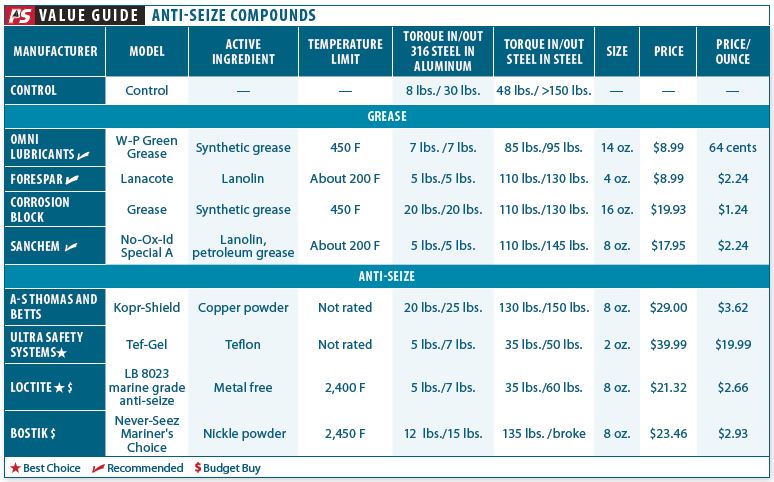

1. The samples were immersed in brackish water during spring tides.

2. We used a six-sided wrench to ensure a good grip for breaking the bond.

3. Five of the six untreated fasteners snapped as we tried to remove them.

4. The lanyard was attached to a load cell that recorded torque. The stainless-steel/aluminum bonds were all relatively easy to break.

Some spray petroleum products are good for loosening bolts, some seal electrical connections, some protect against corrosion, some even claim to improve conductivity.

Over the years we’ve put these products through a variety of tests, with some surprising results. In one study, we found an anti-corrosion coating that actually seemed to promote corrosion.

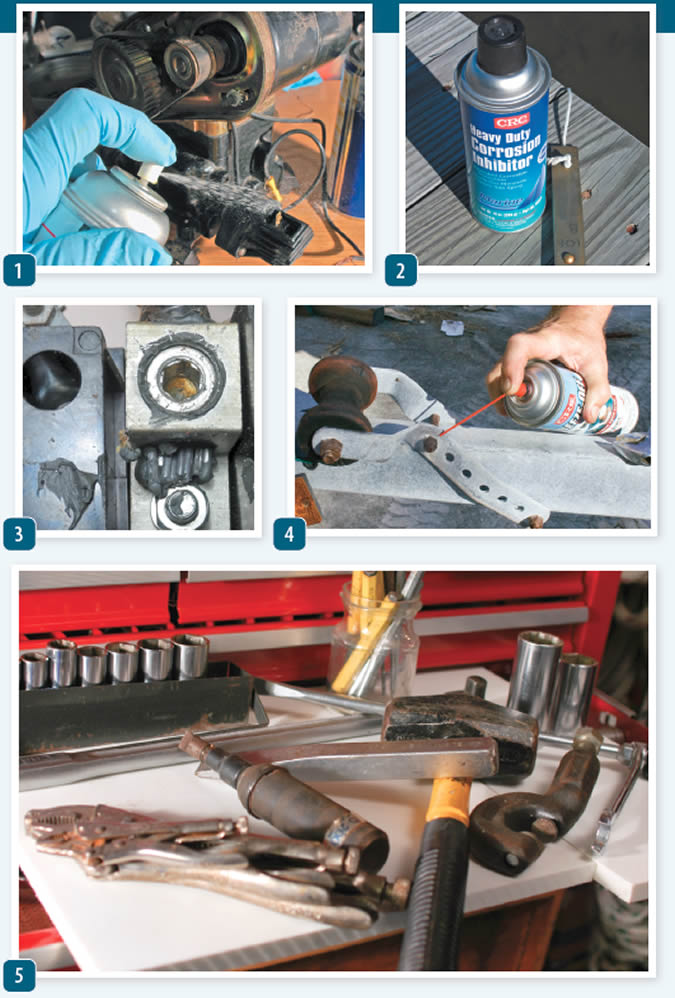

1. To test products that claim to protect electrical connections, we immersed store-bought electrical toys into a fish tank.

2. CRC Heavy Duty Corrosion Inhibitor came out a winner in our test of anti-corrosion spray coatings.

3. Some products that claimed to improve connections and fight corrosion fell flat in our test.

4. Seized bolts on an old trailer bore the brunt of our anti-corrosion spray test.

5. The bond-breaker’s tool kit: vice grip, impact driver, cold chisel, lump hammer, and nut cracker.

This article was originally published on 12 June 2018 and has been updated.

I remember someone telling me a long time ago you can dump brake fluid into the engine oil and it will wipe out the bearings within about 500 miles don’t know if it’s true or not

Aluminum and stainless set up a galvanic pair that causes corrosion over time. My experience is that almost any heavy grease will provide enough separation between the two metals to allow years later disassembly under reasonable conditions. It’s important that the grease be present where the fastener meets the opposing metal at the head, not just the threads. My boat go to is 3M 4200 sealant, but for home projects on non-galvanized steel I have had decent results with vaseline.

If memory serves, No-Ox-ID was invented when aluminum was used in house wiring to prevent corrosion between aluminum-copper pairs. It contains zinc particles that oxidize before either AL or CU.

I use dielectric (bulb) grease when I work on electrical connections, including filling crimp fittings. None have failed. It’s cheap insurance. I put a tiny bit on mini-toggle light switches that consistently failed due to corrosion. Problem solved.

I have not used the Loctite product, but I have used what I think is a similar automotive product for spark plugs. The packaging is identical except for the text. It’s downside is that it is messy, getting over everything and hard to clean up. Careful, sparing application is required, but you still need to wear gloves.

what did you think of Kopr Shield.? i have been using it for years and like it.

I’ve been using Tefgel more and more as the years go by. Eliminating galling of SS is tefgels primary use but I find new applications all the time. I recently fully coated two rudder shafts just before install into the rudder bases. The packing material for those rudders was a product from Sealing Equipment Products Company M2254, a full synthetic and Teflon packing so zero graphite to create a galvanic reaction. Rudders act more like a valve stem than a propeller shaft too so it’s a bit different between the two. Not all products on boats have to be marketed to the marine industry or say marine on the label, I believe most products are appropriated from industry and tweaked slightly to be sold into the marine world.