Why is it that folks who tuck their dogs into fancy hand-knit sweaters seem to be the same ones who leave their boats unprotected through northern winters? Snow, ice, air pollution, and sunlight, combined with alternating periods of freezing and thawing, can age a boat much faster in the winter months than in the more moderate climate of summer.

Perhaps the reason why many fiberglass boats are left uncovered is that their owners remember the problems of building a wooden frame over their wooden boats from years gone by. A complicated framework of 2×4 trusses and furring strips is as expensive and time-consuming to build as it is difficult to store for the summer.

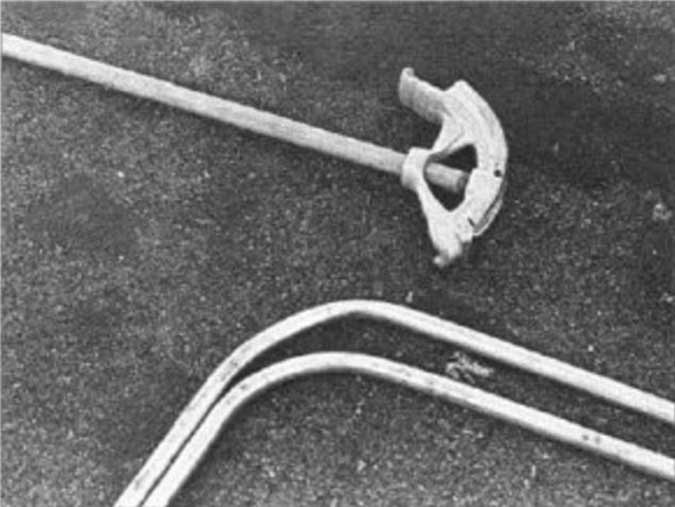

There is an alternative to the wooden frame, however, and to the poor practice of using the mast for a ridgepole. A durable, lightweight and inexpensive framework of thin-walled steel electrical conduit can be easily assembled in less than a day. Best of all, it is reusable, easy to store, and can be built with only a hacksaw (or tubing cutter), a screwdriver, a tubing bender, and a wrench.

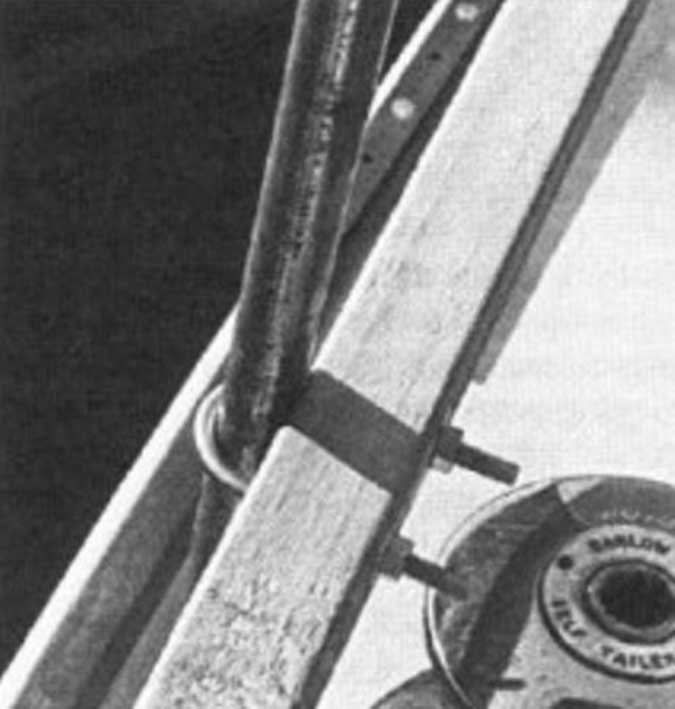

Conduit, also known as EMT (electrical-mechanical tubing), is readily available from building and home centers as well as electrical supply outlets. The frame for a 30- to 35-foot boat will take about twenty 10-foot lengths of 3/4-inch l conduit (about 7/8 inch OD),1 a 20- to 25-footer might require ten or twelve lengths of 1/2-inch conduit. In addition, you will need a few conduit connectors, a couple dozen hose clamps or gizmos called Kover Klamps, and a roll of duct tape. The total cost for the frame materials for a 30-footer runs about $100.

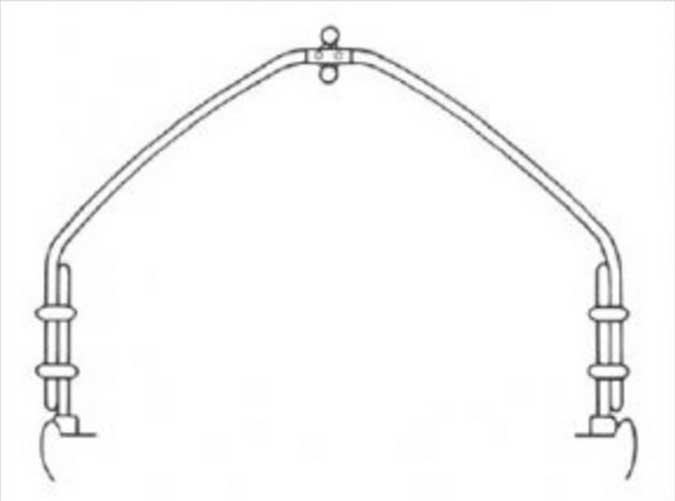

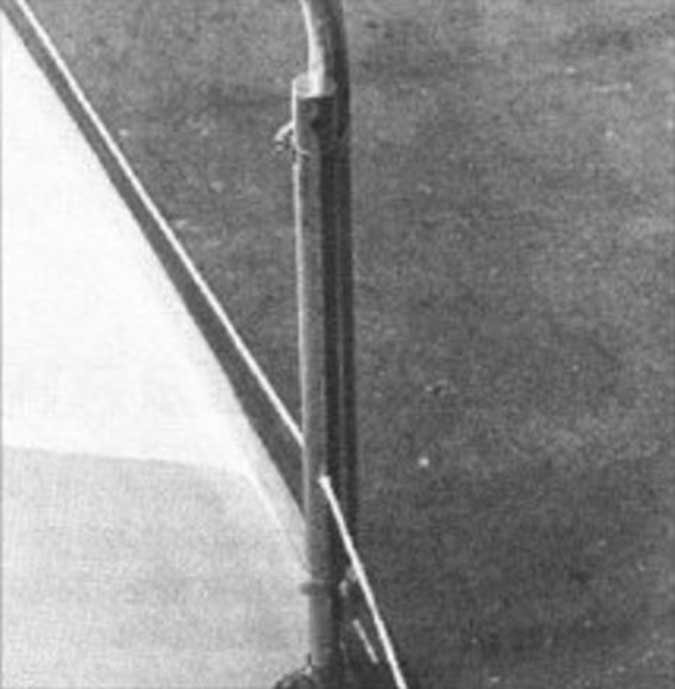

Two curved risers, attached to the bow pulpit and stern rail, support a fore-and-aft ridgepole made of straight lengths of tubing. The ridgepole is supported along its length by a series of arches, made from two lengths of tubing connected at the top. The arches attach to the lifeline stanchions, giving the frame a great deal rigidity. When laying out the arches, try to allow enough headroom to permit passage fore and aft on deck with the frame and cover in place. If the mast is left stepped (not recommended), run the ridgepole off-center to one side of the mast.

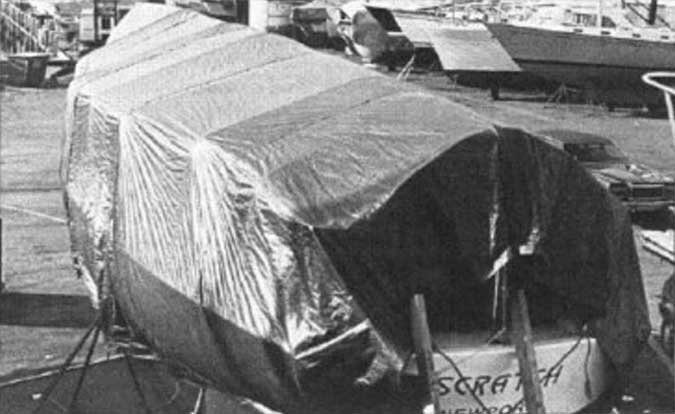

The photo above should help you to determine the proper dimensions and proportions for your boat. If you boat is larger than about 35 feet, or if anticipate a great deal of snow, you may want to add additional uprights between the deck and the ridgepole.

Plastic Tarpaulins

At one time, a custom-fitted canvas boat cover was a hallmark of the well found yacht. With the widespread growth of yachting came cheaper alternatives such as covers made from short ends of awning material or old sails. Next it was clear polyethylene-fragile, degradable in sunlight, and rarely tough enough to last through an entire winter.

Today, the best answer is one of the readily available covers of polyethylene reinforced with polypropylene. There are dozens of these covers on the market, some good and some not so good. Typically such covers run from about 6 or 7 cents up to 15 or 20 cents per square foot. In a somewhat higher price range, Griffolyn makes some rugged and well-finished tarps ranging in price from 10 to 40 cents per square foot, depending on the size and type. Price is not always a reliable guide to quality, but tarps marketed specifically as boat covers are generally better than the typical department-store and main order variety. The cheapest tarps will probably last a full season if well protected; the better ones should last for several years. If you are purchasing one of the better tarps through the mail, it would be wise to ask for a sample swatch before ordering.

The secret to a long life for a plastic cover is to stretch it tightly over the frame and around the hull. Polyethylene tarps can’t stand much flapping and flogging and will quickly succumb to fatigue and abrasion. This may mean an occasional trip to a boatyard to routinely check the lashings. Also make sure that the cover is protected from sharp points and rough surfaces. Scrap carpeting or old towels taped to protrusions will help. Conduit is smooth enough not to need padding; it is the connectors, bolt heads and other sharp corners that do the damage.

When a cover begins showing signs of wear (thin spots where light shines through, for instance) it can be preserved with strips of good quality duct tape. Duct tape will stick well to a plastic cover-at least for one season-if it is rubbed on well.

Some companies have begun to market ventilators to be installed in their covers. In our experience, we find that a polyethylene cover gives plenty of ventilation without the work and cost of installing vents. Most plastic has pinhole-sized “vents” (or it will have after a few months use). And, of course, there is no need to ventilate the cover if you leave the boat underneath buttoned up tight as a drum.

The covered boat shown does not have enough pitch.The snow and ice would collapse this set-up in my humble opinion.

This looks like a very practical approach to building a frame. I bought a 28′ wooden boat this spring. It came with a canvas cover, but no frame, not surprisingly.

Unfortunately, it does not have lifelines, or the stations that go with them. Are there other good ways to hold the frame in place?