Six years ago (“Marine Sealant Adhesion Tests,” published November 2016) Practical Sailor began exposing samples of marine sealants to weather and sunlight to compare how they retained adhesion and flexibility, and how well they resisted mildew. Periodically and at the end of five years, we examined the samples and awarded final grades. Near the end, we tested removing mildew with a deck cleaner and dilute bleach. Eventually, we took the sample panels down, but we didn’t throw them away. We put them in a storage area, in case we needed to refer back to them.

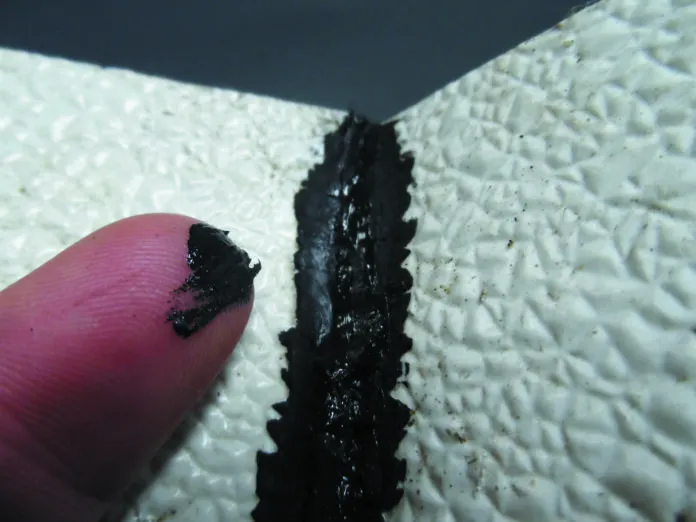

Recently, we’ve received several reader reports that 3M 4000 UV used to bed hardware had become sticky and begun to leak. We went back to our sample rack, and sure enough, the 4000 UV had lost all strength, the surface had become slightly sticky, and the center had become liquid, with the same gooey feel it had the fresh out of the tube. It was a complete failure and a mess. It was a shocking change from less than a year before. It was as though the polymer had suddenly unzipped and returned to its uncured state.

The rest of the samples on the rack were performing exactly as we left them a year ago, just one year stiffer, as expected. The other polyether, Loctite Marine, was unchanged.

The response from 3M was as follows:

“Thank you for your inquiry regarding 3M™ Marine Adhesive Sealant 4000 UV, Black. We are sorry that the product did not meet your expectations. At 3M, we aim to continuously improve our products. Your feedback indicates that you have product that is prior to our reformulation in late 2018. We appreciate your interest in the product and are happy to send you a sample of the reformulated product.”

We’ve asked for a sample and will be re-testing it alongside competing products. But we won’t know anything definitive for five years. Meanwhile, we’re not going to be using 3M 4000 UV. Inspect projects where you used it, specifically anything pre- 2018. Until we know more, we’re recommending Sika 291 as the Best Choice for all-around sealing of fiberglass and deck hardware, and Loctite PLS40 Door and Window as our Budget Buy. We’ve been using these for decades and they’ve never let us down. Our 2016 Marine Sealant Adhesion Test” highlights other standouts for specific jobs.

We are currently following up with 3M to get more details regarding the failure of its product. Some posters on online forum threads report similar failures. We’d like to hear from anyone else who has had a similar experience with 3M 4000UV or any adhesive sealant. You can email us at practicalsailor@belvoir.com

Interesting finding on the 3M 4000. I, too, have a failure story with this stuff. I used white 3M 4000 to seal my hatch coamings where they meet the deck and after a year or two the caulking had chalked up and completely deteriorated, streaming across my deck in chalky white rivulets whenever it rained or I washed my boat. I was shocked, given 3M’s reputation for quality. It was so bad I figured I’d been sent a batch of counterfeit product from the online retailer I bought it from.

We had issues with Sika 291 on a 2007 built boat, 3 years after taking delivery in 2008, any caulk exposed to sun showed “checking” & chalking deterioration.

Silpruf 2000 replaced 291 in a 2015/16 major rebedding of all windows, portholes & most hatches.

Zero leaks or deterioration since, fingerpointing between builder/Sika – owner pays…

First, a big thanks to PS for publishing this article. What especially bothers me is that it seems that 3M so quietly changed the formulation in 2018 – apparently aware of the problem – but said nothing to the untold thousands of boaters at risk, leaving them to twist in the wind…

We had a major UV4000 failure in 2015. We caulked the deck/toerail joint on our Cal 2-46. A few months later it all turned to dust. 3M said it was probably out of date, which is plausible.

https://svbrightwater.wordpress.com/2015/11/02/status-from-loreto/

I am curious as well as I used 3M 4000 (White) to re-bed all of the side windows on my Catalina 30 last year. The 3M 4000 is used to bond the metal window frame to the fiberglass cabin.

I noted that the fillets of 3M 4000 started looking crappy very quickly (dull, cracked). However, since I am more concerned with water LEAKS, I cannot complain as there are zero leaks to-date (knock on wood)…

Kind of disturbing when you realize the 3M product was also labeled safe for underwater use.

That’s interesting. I have used the white 4000UV for years and have been pleased with the results. Some bad batches perhaps?

I used 3M UV4000 to re-seal the deck joints on my 2019 Fountaine Pajot catamaran. Within 18 months, the caulked joints have literally have desolved/cracked or failed in over 30% of the sealed caulk lines (mostly where they received the most exposure to sun).

Does the white caulk fail as well as the black 3M UV4000? What solvent is best to use to clean up the failed caulk? If 3M wants to maintain their reputation, they should provide replacement caulk at no charge.

Mineral spirits (regular–not the odor-free type) or VM&P naptha are the go-to solvents for polyurethane clean-up, as well as for this.

This was quite disturbing news for us. Our boat went through a $235,000+ refit after a nearly direct hit from Hurricane Harvey (Port Aransas, TX). All cosmetic. Our neighbor’s rig broke, and went through ours. Our mast survived, but not much else on the deck did. As well, we had cracked chainplates, and they were replaced.

In going through the invoices for the work, I see “3M 4000” listed quite often. This work was done in 2018 and 2019. Also in 2019 we replaced our windlass, and I rebedded deck prisms. The deck prisms have a large exposure of the 4000, both above and below. It is absolutely failing. It’s “checkerboarding”, and the pieces are gummy when you rub them between your fingers. Same thing with the windlass.

Why do I think we will be spending the next 5 years finding more and more areas where this is failing? This is really a nightmare for us. I’d guess it might take 500-1000 hours to rebed everything on our boat that’s been bedded with 4000 in 2018 and 2019. I think we might need an attorney…

I too did a major re-caulk of major seams on the for deck of my Seawind 1000 cat. The UV 4000 failed in less than two years. Basically it turned to dust. Had to redo the whole job. Not happy about that. UV 4000 was recommended by my rigger. When I told and showed him pictures of the seams he could not believe it as he says he uses it all the time.

I used black 3M UV4000 to seal between the deck & toe-rail on my San Juan 24 sailboat. After a few years, the 3M product disintegrated. Not sure if this was a UV issue or from deck cleaning agents, but regardless, am very disappointed with this product.

Control samples that were stored in the dark have remained like new. To our understanding, reversion is triggered by UV exposure and we have not heard of failures below the waterline.

Does this report re. 3M 4000 also have any bearing on their 5200 (fast cure) adhesive? I have been using that. Should i be concerned?

THIS REALLY SUCKS, LEAVING IN 2 days for hurricane season, having the boat waxed and detailed…guess what they found ? Yup, over 100’ of gummy window edge caulking!

3M 4000UV STRIKES AGAIN! It’s going to cost me $1000 to have it replaced while I’m gone, I don’t like having work done without being present.

Anyone gotten anything from 3M ?

Next best replacement in white?

We’re a Catalina Dealer for the last 35 years…yikes! This was our go to stuff.

Replaced winches with pair of Lewmar EVO ST50 Chrome self tailing winches in April 2021 and used 3M 4000UV. No visible negatives yet. ~ ~ _/) ~ ~ MJH

Supplement: That was the white caulk. ~ ~ _/) ~ ~ MJH

SV Poppycock had a bunch of failures of work we did in late 2018. All failures happened where it was exposed to sun and sea.