We think of all stick-and-rip, hook-and-loop fasteners as Velcro-just as we ask for Kleenex after a sneeze-and most tend to have uniformly low performance expectations of these velcro products, assuming that they will have limited holding power from the beginning. These assumptions are not totally unwarranted.

Velcro will inevitably be the first component of a canvas project to fail, with ultraviolet rays degrading the fine threads and holding strength dropping to zero within two to four years. When used to mount even the lightest equipment, the velcro fasteners vibrate loose without warning. The Velcros adhesive can slowly ooze off in heat, buckle in humidity, or simply turn to dust. So do any of them actually work? PS testers decided to find out.

What We Tested

Velcro is the original and most visible brand of hook-and-loop fasteners on the market. More recently, 3M/Scotch and other manufacturers have entered the fray, adding totally new product categories. Instead of just original woven hook-and-loop fasteners, ubiquitous on clothing and sail covers, some now have molded hooks, offering increased strength, reduced creep, and suggesting a whole new range of applications.

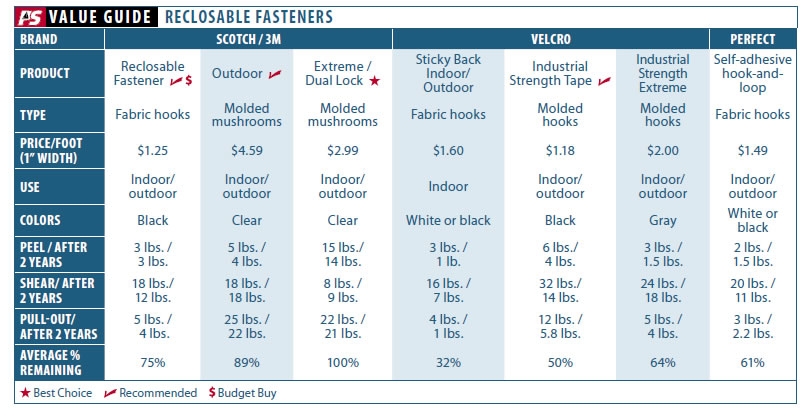

For this report, we tested seven self-adhesive, velcro tape products-including products with textile hooks and loops, molded hooks with textile loops, and plastic molded hooks on both sides-from three makers, 3M, Velcro, and Perfect. We did not test sew-on tapes; however, there were no adhesive failures during our strength testing, so wed expect similar performance from these products sew-on counterparts. In our experience, by the time the stitching begins to fail, the fastener has also lost grip and is due for replacement.

How we tested

The test samples were adhered to pre-cleaned, fiberglass panels; testers applied pressure (10 pounds per square inch) for 10 seconds and then left the samples alone for 48 hours to enable them to fully bond to the fiberglass.

To evaluate the shear strength of the fasteners, testers pulled a 2-inch length of each sample end-wise until it failed. Testers then peeled the two strips of each sample apart, with one adhered to the panel; this we called peel strength. Separation strength was measured by pulling 1-inch samples directly apart, as you might pull on a snap. Testers then aged the samples for the equivalent of two years in an accelerated aging chamber (UV and heat). After the aging, we repeated the same tests wet and dry.

We also tested several products aboard a test boat in various applications (to secure mosquito netting, exterior hatch covers, and lightweight panels), observing any tendency to buckle or creep with humidity and temperature changes.

Observations

We surveyed a handful of sailmakers about the velcro they use in sail covers, etc., and they all said they favor polyester hook-and-loop fasteners and sewn-on installations, rather than glued-on. They work only with fasteners that feature the textile hook-and-loops, and not the plastic, molded hook-and-loops since the molded types are not sew-on. The consensus was that the textile hook-and-loop fasteners generally last only two to four years, depending on sun exposure, and that they prefer to install mechanical fasteners wherever practical.

This mirrors our lab-test findings: Nylon products do not hold up outdoors, and even polyester products lost much of their strength in just two years. However, we aged the tapes open, with the hooks and loops exposed. Typically, the fasteners will be closed, thus protected from to the sun. In addition to losing grip due to UV damage, the velcro fasteners tested on the boat suffered several other types of failure.

Using an indoor product, commonly rated to only 120 degrees, in an outdoor setting will almost surely lead to adhesive failure, as we experienced. In order to stick to glass and other surfaces, the adhesives are typically rubber based. However, this type of glue is not durable at high temperature and is prone to oxidation and stiffening.

Outdoor adhesive fasteners are more likely to carry a higher temperature rating (200 degrees is common) and generally use acrylic adhesives. While outdoor velcro fasteners are less suitable for applying to slippery plastics, they are good on gelcoat, aluminum, and polycarbonate. They offer superior UV resistance and work better on rough surfaces.

Buckling due to humidity cycling can be a problem anywhere on a boat, specifically where lengths over six inches are used. Our mosquito netting installation, with fastener runs as long as 10 feet, has been troublesome this way. Gaps began to appear within days of application. The problem was worse with the nylon products than with polyester, but the final solution was to use a non-self-adhesive product and secure it with epoxy. No more buckling, though removal and replacement every five years is time consuming.

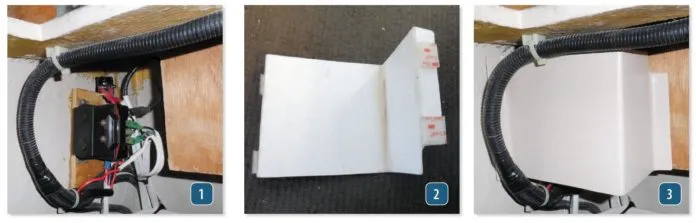

Molded hook products (such as Scotch Extreme / 3M Dual Lock) do not suffer from buckling because only 1- to 2-inch lengths are used; any longer, and the attached object is likely to be damaged during separation-they grab very hard.

Do not use Scotch Extreme or Velcro Industrial Extreme around insect screens. They grab the fabric with such tenacity that both the fabric and the fastener can be damaged. Do not use these to mount pictures on carpet-lined cabins; it will pull the carpet loops out. The hook portion of these products should not be used where contact with clothing or fuzzy fabrics is likely. Scotch Extreme is also generally incompatible with other loop products.

There is a tried-and-true method to getting hook-and-loop fasteners to stick to window screens. If you place either gaffers tape or similar tape (or even another strip of hook-and-loop tape) on the opposite side of where you are bonding the hook-and-loop fastener, the adhesives will bond to each other through the holes in the netting. We have some screens made this way and the bond has lasted eight years.

The effects of aging on the test samples were fairly obvious. In general, the textile hook-and-loop products degraded more quickly due to UV, while molded products were more stable. We also noticed that textile hook-and-loop products will gradually creep if subjected to variable loads over about 10 percent of the failure load. The exceptions are Scotch Extreme and Scotch Outdoor; they will stick until the failure load is reached. These two characteristics combine to make Scotch Extreme suitable for securing toll passes to windshields and hatch covers on boats (see PS, March 2016). Scotch Extreme is also suitable for mounting removable panels and lightweight rigid objects.

Self-adhesive products should be applied between 70 and 100 degrees for a good bond; most makers recommend installation temperatures between 68 and 85 degrees. To apply them, press firmly in place for at least a few seconds, and wait 24 to 48 hours for maximum holding power to develop. After application, they will function well outside that range, according to adhesive specifications.

Lab Test Results

The fabric-loop products lose about 20 percent of their strength when wet. The molded products lose 10 percent of their strength when wet.

Polyester is best for hook-and-loop types; nylon is not as durable. Polyethylene is preferred for the molded types.

The products quickly sorted themselves into two groups: those with fabric loops and Scotch Extreme. The fabric-loop products show considerable strength in shear, and much less when peeled or pulled directly apart. These are fine for jacket cuffs, canvas flaps, and clew straps, all of which rely on shear strength and easy removal by peeling.

The Scotch Extreme, in contrast, has mediocre shear and peel strength, but massive resistance to pulling straight apart. We understand why automobile and equipment manufacturers are using it to secure rigid panels; it does not creep, it snaps securely into place, and if the bonding is at least 2 square inches, you need a screw driver to pop it open.

Field Testing Results

To our dismay, both the nylon and polyester products showed a tendency to creep and buckle due to changes in humidity. Long lengths are particularly vulnerable. We recommend using polyester, even in the cabin. (Most indoor-rated products are nylon; most outdoor products are either polyester or polyolefin.) For sew-on projects, nylon goes well with nylon fabrics, matching the humidity elongation and stretch characteristics. We found that as long as we simply followed the manufacturers indoor/outdoor recommendations, the products performed well.

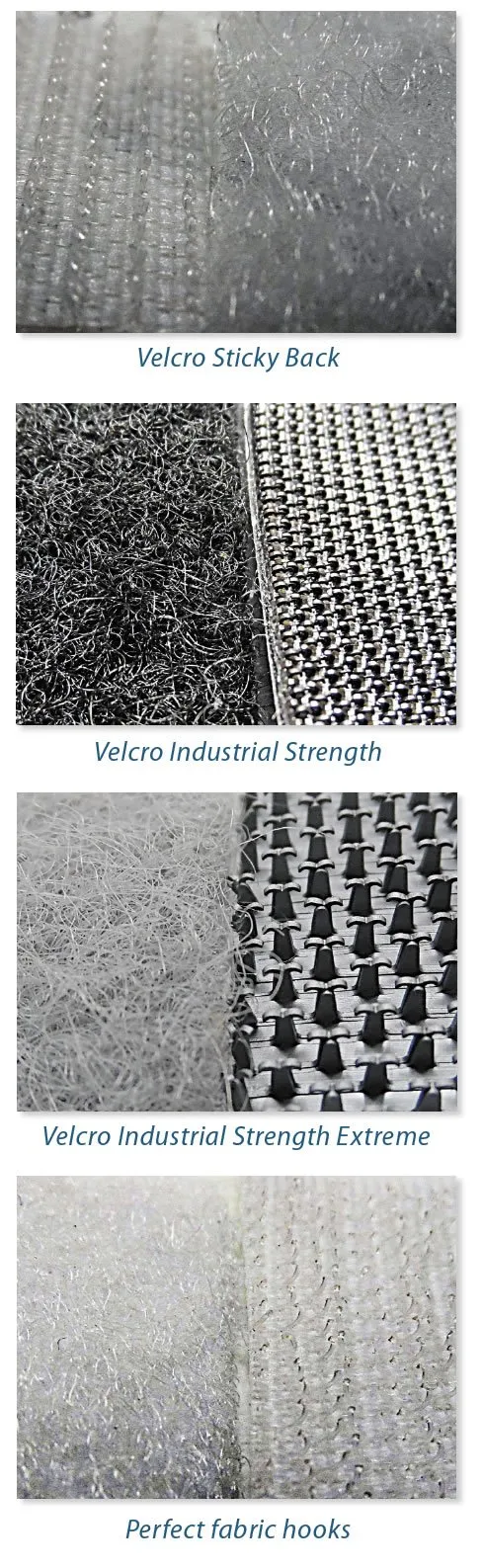

Textile Hook-and-Loops

Fabric hook-and-loop fasteners are best suited for clothing, fabric flaps, and positioning upholstery. These are not suited for mounting heavy objects; they tend to creep, and eventually let go. No specific cycle life was given, but about 1,000 pulls seems a reasonable expectation, based upon our experience with clothing tests.

Velcro Indoor/Outdoor

Velcros light-duty Sticky-Back Indoor/Outdoor failed rather badly in our first bug-screen installation. While it is probably fine for use around the house, it suffers in humid environments. The nylon material grows and shrinks with daily fluctuations in humidity, and then buckles up. Additionally, the rubber-based adhesive failed in two years on board (in a fully shaded location), turning hard. After two years, this product had very little strength left, only about 32 percent of its original.

Bottom line: The Velcro-brand Indoor/Outdoor is fine for indoor use, there are better options for on board.

Perfect Self-adhesive Hook-and-Loop

With polyester fabric and an acrylic adhesive, the Perfect Self-adhesive Hook and Loop fared much better after aging than its nylon cousin. However, it was still relatively weak and just as susceptible to buckling in humidity. The hook tape and loop tape are sold separately. It comes in a variety of colors, and sailmakers like the sew-on version of the product.

Bottom line: The Perfect tape is good for very light-duty use in short lengths only. As a sew-on tape, it is acceptable.

Scotch Reclosable Fastener

This polyester tape was the top performer within the fabric hook-and-loop category. It retained much of its strength after two years. The adhesive seemed slightly more tenacious than others in this category. There was noticeably less buckling in humidity.

Bottom line: We Recommend this 3M product for bug screens and other light-duty applications calling for fabric hook-and-loop fasteners. It gets the Budget Buy pick thanks to good UV resistance and low price.

Molded Hooks, Fabric Loops

We tested several types of tapes with more rugged molded plastic hooks. Though somewhat more secure, testers found this type of fastener was still prone to creep.

Velcro Industrial Strength

The molded hooks on this product are quite small, impossible to see without a magnifying glass, but the effect on holding power is real. It is not as resistant to a straight pull-out as Scotchs Extreme, but it had the greatest peel and shear strength.

Bottom line: We Recommend this for medium-duty mounting.

Velcro Industrial Strength Extreme

While the hooks on Velcros Industrial Strength Extreme product certainly look aggressive, we were disappointed by its holding ability and its tendency to loosen under variable loads.

Bottom line: The Velcro Industrial Strength Extreme is not as useful onboard use as the Industrial Strength version.

Heavy-duty Molded Hooks

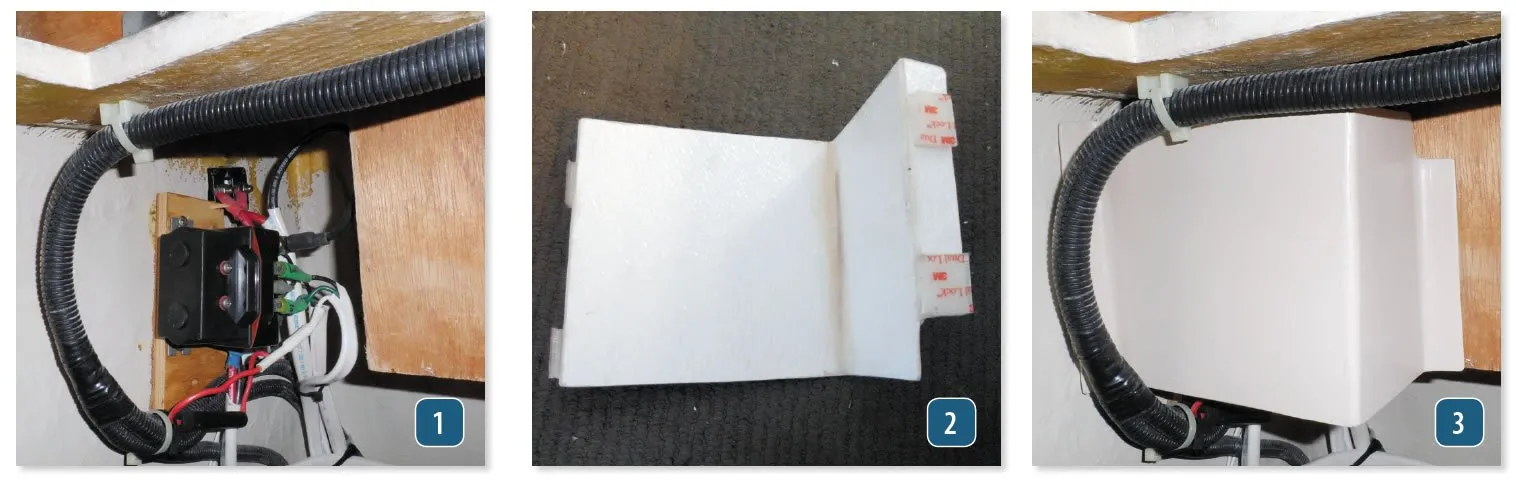

These types of fasteners attach with great security. Although they are rated for 1,000 cycles, we recommend them for items that are not removed frequently. Instead of using fabric loops on one side, both sides have molded plastic hooks that resemble mushrooms and give an audible click when engaged. Developed to hold rigid panels in place (trunk linings, removable office equipment panels), they require different thinking. They are best suited for applications in which you might otherwise use a very small screw, but the panel is thin and you would rather not drill a hole. The best will perform like very high bonding (VHB) tape, but are much easier to remove.

Scotch Extreme / 3M Dual Lock

We have used Scotch Extreme pads to mount solar panels on a Kevlar race boat. Removing the panels five years later required a quick pop with a screw driver under one corner to free the panels, and a few minutes with a pocket knife to remove the pads and adhesive without a trace.

We would not use Scotch Extreme around loop fabrics; it can become badly stuck to carpet, and it can tear bug screens apart. We tried using it to secure a cover to the lens of a deck hatch and it pulled the glazing out of its frame. (It should be noted that the hatch caulking was old and had clearly lost adhesion.)

Scotch Extreme is better suited for mounting rigid objects that are frequently removed, and in which any creep is unacceptable. The adhesive performed exceptionally, adhering tenaciously to many surfaces for years, and it left behind no residue.

Bottom line: Scotch Extreme is not a replacement for velcro, but rather a different product with different strengths. It is our Best Choice for heavy-duty mounting of rigid objects and panels.

Scotch Outdoor Fastener

The Scotch Outdoor Fastener is a low-profile version of Scotch Extreme, and the holding strength is actually better. This is due to the reduced height of the molded mushrooms that interlock. Also, the adhesive is thinner, restricting the product to smooth, flat surfaces. The grip is tenacious, generally requiring a screwdriver to separate the mated pieces.

Bottom line: It is Recommended for heavy-duty mounting on smooth surfaces.

Conclusions

Reclosable fasteners fall into two major groups: those with fabric loops, suitable for use with fabrics, netting, and light-duty attachments that are released frequently; and those with molded plastic loops that provide rock-solid attachment for rigid objects but are incompatible with many fabrics.

We found no shortage of onboard applications for Scotch Extreme and found it particularly handy in situations where we did not want to use a screw because the material we were screwing was fragile or thin.

Avoid nylon hook-and-loop fasteners; they don’t hold up to UV or humidity cycling. Avoid interior products, even on the interior of the boat; again, humidity cycling is the problem. In the end, the trick is to make sure that your choice of products suits the application.

I am going to try and make screen surround for my Island Packet 350. I would like to know specifically which product of scotch mate cold be used to adhere to the cloth Bimini. I would also like to stick it on the cockpit fiberglass. It does not have to last forever.

I was looking at the Scotchmate Hook and Loop Fastening system MP3526N/27N.

I was going to bind the edges of the screening with canvas and adhere the fastener to it and then hopefully use the other side on the Bimini.

This is first time project for me, what do you think?

Thanks, Rick