Prior PS bottom paint testing focused on saltwater locations in Florida and Massachusetts. This time we’ve moved our testing racks to the brackish waters of the Chesapeake Bay in Deale, Maryland, just south of the sailing mecca of Annapolis. The fouling is generally fairly vigorous due to brown water, agricultural run-off, and summer water temperatures in the 80s, but moderated in the winter due to freshwater influx and near freezing temperatures that knock the soft growth off each winter and slow the leach rate of biocides. Two-year paints typically last just two years, and single year paints do well on the boats that are hauled each winter.

Salinity has a significant effect on antifouling effectiveness. Even saltwater sailors need to consider whether their marina is truly seawater, or whether they are up a river or in a marina basin fed by a freshwater stream. It may be worth testing. For reference, seawater is about 23,000 parts per million (PPM), our Chesapeake Bay marina test site ranges from 4,000-10,000 PPM, and the main stream of the bay, where we sail every 5-15 days, ranges from 6,500 to 14,000 PPM.

LEACH RATES

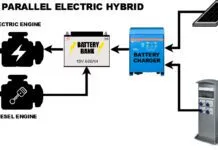

Bottom paint effectiveness and longevity depend on leach rates—the rate at which the biocide is released. This is measured in micrograms per centimeter squared (μg/cm2). We got a glimpse of copper leach rates when we tested prop anodes by placing them on 18-inch copper pipes and leaving them in the water for a year (see “What’s the Best Anode Material?” PS January 2017). The pipes that had anodes experienced virtually no metal loss and were covered with hard growth. The control with no anode lost about 25 μg/cm2 per day of copper, and was quite clean.

If you take into account the water friction of a moving sailboat, and the past performance of antifouling paints with low leach rates, a 9.5 μg/cm2 per day limit would be sufficient to meet our antifouling needs.

If you do the math on the copper load of a mid-level bottom paint with a typical two-coat application, it is about 6-8 grams of copper/ft2. Studies show that about 2/3 of that will be released into the water during its working life. This works out to a theoretical release of about 14 μg/cm2 per day, but perhaps a bit less. California has a copper leach rate restriction of 9.5 μg/cm2 per day, or 3.2 grams/ft2 per year.

This, of course, can vary by how you use the boat, but because sailboats move so slowly, the amount of water friction that a boat is exposed to should not change the math too much.

All of this theory on leach rates and copper content matters as regulators try to settle on what is a tolerable leach rate for copper. It is especially relevant to rich, biodiverse brackish environments like our test site, which are the nurseries for the world’s oceans. By paying careful attention to performance in this environment, we hope to confirm whether regulators are striking the right balance between preventing fouling and protecting our environment.

CENTERBOARD BOATS

In addition to our panel testing, we also applied several paints to our test boat, a Corsair 24, which has a centerboard trunk. Since we’ve not previously dealt with antifouling paints for centerboard trunks, some observations are in order.

Our practice is one coat every 2-3 years, instead of the 2-3 coats every 2-3 years the center board and the rest of the hull receive. This is because the lack of sunlight and water friction. Toward the end of the antifouling’s effective life the centerboard will occasionally stick, as hard growth clogs the edge of the slot.

In this case, dive and cut it loose with a scraper, tracing the edges of the retraced board. Do not try to force it. As long as we paint when jamming first becomes a problem, we have never had growth extend into the case itself, which would be something of a cleaning nightmare. We do keep a course scrub brush screwed to a 30-inch length of ¼” x 1” aluminum bar, which we used to quickly scrub the case midway through the pressure washing process.

WHAT WE TESTED

We’re testing paints from Interlux, Sea Hawk, Pettit, Total Boat, and West Marine. The focus is on two-year paints, but a few single year paints and hard paints are also applied. Most were solvent-based, but several are water bourne.

HOW WE TESTED

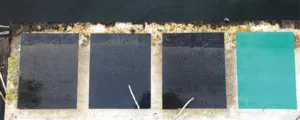

Our test boat was divided into segments, and six ablative paints were applied. All of the paints were applied to fiberglass test panels. For five months through the winter they’ve been hanging on fixed lines—ice pulls too hard on the floats. In the spring they were moved to floats, suspended so the top edge of the panel is just a few inches below the surface. Locations will be rotated to insure even exposure to currents and sunlight. Salinity is tested monthly.

Panels will be examined at one year intervals. A good bucket washing from two opposing directions will knock off the loose stuff that sailing would dislodge, and we’ll grade them on a relative scale. PCA Gold—the same formula as our last PS test—was painted on one square as a control.

We will be diving and inspect for the test boat for growth as well. The boat will not be hauled until the three-year mark, or whenever fouling becomes too great . We will likely do some light cleaning past the 20-month mark, with only a glove for soft growth and a thumb to pop off barnacles.

OBSERVATIONS

Since our last in-depth report, the marine coatings industry has undergone a dramatic consolidation, with Dutch chemical giant AkzoNobel swallowing up two of its competitors in the recreational market — Blue Water Paints and Sea Hawk Paints. According to AkzoNobel, these lines will continue to be operated independently with distinct manufacturing plants and brand strategies.

The two entitites will surely benefit from Akzo-Nobel’s purchasing power for raw materials like copper, but don’t hold your breath for bottom paint prices to go down. The consolidation leaves just two companies – Akzo Nobel and Kop Coat (Pettit’s parent company) with the lion’s share of the U.S. recreational marine market.

TOTALBOAT

We tested three paints from Jamestown Distributors, the ablative paint Krypton, the single-season, water-based hard paint JD Select, and solvent-based hard paint Spartan with 38 percent copper biocide, the highest copper percentage of the three. Boosted with tralopyril, and zinc pyrithione, the Krypton is the most expensive of the three at $199. When comparing prices, keep in mind that the Jamestown prices include an application kit—rollers, paint tray, 3M scrub pad (for prep), and a paper paint suit with hood. This extra step is a nice touch that simplifies the application process.

Dry times ranged from 2-8 hours for the Krypton, to 16 hours for the Spartan. JD Select is ready to launch after drying overnight. All three paints are available in black, blue, red, and green. Krypton is also available in white. Krypton dries a little faster, ready to recoat between 1-4 hours after first application, versus 1-6 hours for Spartan and JD Select.

PETTIT

Throughout our nearly three decades of testing bottom in the post-tributyltin era, Pettit’s copper-rich Trinidad line of hard bottom paints has consistently scored near or at the top of the field, while Interlux’s strength has been in the ablative category. Not that Pettit’s soft paints are any slouches. Its Vivid line (available in a rainbow hues) and water-based Hydrocoat have plenty of fans, especially among seasonal sailors.

Since our last in-depth report on antifouling, Pettit has introduced its Odyssey line of ablative bottom paints. The new Odyssey paints are all solvent-based and boosted with zinc. Copper levels range from 40 percent in the Odyssey HD and Odyssey Triton paints to 60 percent in the Odyssey 60, the most expensive paint in our test at $400 per gallon.

Pettit’s copper percentages in Pettit’s Trinidad paints have been scaled back since a decade ago when its most potent blend was advertised as containing 76 percent copper. Today, the most copper-rich blend, Trinidad Pro, contains 65 percent copper. Although its name suggests 75 percent copper, Trinidad 75 contains 60 percent copper.

EPAINT

All of Epaint’s offerings are copper-free paints that are photo-active, meaning they release a biocide when exposed to light, and this chemistry was well-suited for our previous test site in Florida. Three of the paints are water-based paints, and all four have zinc as a booster. The two paints that have consistently done well in past tests—EP 2000, and Epaint ZO, are boosted with zinc omadine. Although EPaints have proven themselves in field testing in northern waters, we are curious to see how these formulas will fair on our panels in the Chesapeake. The biggest challenge with EP-2000 is that it can’t be applied over other conventional paints. In our last test, the Epaint Z0 HP was barnacle free at 20 months.

Epaints are available in a range of colors, including the uniquely available “safety orange,” but the maker recommends the original lighter colors—white or grey—for maximum protection. Epaints go on thinner than the copper-based paints, and at least three coats are recommended for all of the paints. Up to five coats are recommended by the flagship paint, EP-2000. Epaint’s single-season paint, Ecominder, is particularly thin, but it goes on fast. Epaint’s dry times are a little longer than other paints, so you’ll also want to factor that into the application process.

INTERLUX

Interlux’s Micron line of ablative paints have consistently scored well in our past testing, with Micron 66 repeatedly coming out as the most effective paint in South Florida and Long Island Sound in long-term testing. So why isn’t Micron 66 appearing in our brackish water test? The paint’s Achilles heel is freshwater. Micron 66 needs salt water to be active and prolonged exposure to freshwater can greatly diminish its effectiveness.

Fortunately, the other paints in the Micron line are not bothered by freshwater. Along with perennial contender Micron CSC and copper-free Micron CF, this year’s entries include two Micron paints that we’ve not previously tested: Micron WA, a water-based ablative boosted with copper and zinc and Micron Navigator, a solvent based copper-free paint boosted with zinc pyrithione. (These two paints, along with Bottomkote Aqua, a water based ablative with 46 percent copper, are not approved for use in California.) The copper-rich Ultra-Kote rounds out the Interlux field. Interlux paints are made by Dutch chemical company AkzoNobel, and many of the paints have compatible equivalents that are marketed abroad under the brand of International Paints.

WEST MARINE

The West Marine’s PCA Gold we’ve applied to our test panel is the same paint we’ve used previously to a test boat used in this location. Although PCA Gold is sold at West Marine, the formula in this particular paint is no longer on the market. Nevertheless, we wanted to include it as a control. Including the older formula of PCA gold will give us an idea of how the new paints stack up to our old standby. It will also allow us to get a better picture of how much of a difference it will make now that Irgarol is no longer available.

Like a number of paints in this test, the older formula of PCA Gold was boosted with Irgarol. The current formula available at West Marine does not include this biocide, instead listing silicone as the anti-slime additive.

The currently available formula of PCA Gold is a budget-priced solvent-based ablative that has performed well in our previous tests up to the one year mark. This blend is made by Kop Coat, the manufacturer of Pettit paints.

SEA HAWK

Sea Hawk is the brand of antifouling paint made by New Nautical Coatings in Largo, Florida. Recently purchased by Akzo Nobel, makers of Interlux paints, Sea Hawk established a reputation for producing potent paints that did especially well in the Caribbean. Over the years, it gained a loyal following on the East Coast. The company’s success hit a speed bump in 2017 when four company officers, including the CEO and president, plead guilty to charges linked to a scheme to knowingly distribute and sell an unregistered pesticide.

We are testing four different Sea Hawk paints. Smart Solution, a solvent-based paint that relies on its slick surface to prevent growth. It is the only metal-free paint in our test. Although an earlier formula did not last more than a year in our saltwater tests, the updated eco-friendly paint will appeal to seasonal sailors in sensitive areas and freshwater lakes. It survived a season of Lake Superior without any hard growth.

Three more Sea Hawk paints round out our test field: Color Kote, a solvent-based copper-free ablative that is available in nearly two dozen colors; Cu Kote, a copper-based paint with 50 percent copper and 10 percent zinc; and Biocop TF, a solvent based paint with 60 percent copper, 10 percent zinc, and boosted with sink pyrithione. Biocop TF and Cu Kote have both provided multi-season protection in past PS tests.

CONCLUSION

At this early stage (5 months), all of our test paints are giving the Chesapeake Bay a run for its money –and are recommended. The temperatures have been fairly frigid and the days have been dark, so we did not expect a lot of growth. In fact, any paint that can’t survive a Chesapeake winter would not earn our recommendation. In terms of applications, the Petit and Totalboat paints seemed to flow the best, but all were acceptable. Some required minor thinning to get the roller to roll, but this was limited, and we aimed for the same coverage rate for all paints.

We painted in September, after which it gets cold on the Chesapeake, slowing growth. We pulled the panels in February for a quick look, at which time the unpainted frames between paints had about 1/8-inch of soft growth and the panels had minimal fouling. To our surprise, the white E-Paint products were completely free of any growth.

As far as future regulations go, after initially scapegoating copper bottom paint on recreational boats for harbor water quality issues, and hearing a lot of talk about banning copper, it seems that resource managers have settled on a sensible limit on leaching rates, and the new paints are being tweaked to meet it.

As these new regulations take hold, we’re not expecting a general drop in performance, because the better two-year paints already met the proposed leaching limit. We should have a clearer picture of performance when we check the paints later this summer.

CONTACTS

EPAINT

800/258-5998, www.epaint.com

INTERLUX YACHT FINISHES

800/468-7589, www.yachtpaint.com

KOP-COAT (PETTIT)

800/221-4466, www.pettitpaint.com

SEA HAWK

800/528-0997, www.seahawkpaints.com

WEST MARINE

800/262-8464, www.westmarine.com

BUYER'S GUIDE: ANTIFOULING BIOCIDES AND LEACH RATES

| BRAND | TYPE | SOLVENT | COPPER | ZINC | “BOOSTER” BIOCIDES | LEACH RATE (μg/cm2)** | PRICE / GAL. † |

|---|---|---|---|---|---|---|---|

| Total Boat | |||||||

| Krypton | Ablative | Solvent | None | About 7% | Tralopyril, zinc pyrithione | $199 | |

| JD Select | Hard (1 season) | Water borne | 25% | None | None | Not tested or reported. | $134 |

| Spartan | Hard | Solvent | 38% | None | None | Not tested or reported. | $189 |

| Pettit | |||||||

| Odyssey 60 | Ablative | Solvent | 60% | About 7% | None | Not tested or reported. | $264 |

| Odyssey HD | Ablative | Solvent | ~ 40% | About 7% | None | Not tested or reported. | $232 |

| Odyssey Triton | Ablative | Solvent | ~ 40% | About 7% | Econea, copper thiocyanate, zinc pyrithione | Not tested or reported. | $400 |

| Trinidad 75 | Hard | Solvent | 60% | None | None | Not tested or reported. | $268 |

| Trinidad Pro | Hard | Solvent | 65% | None | Irgarol* | $320 | |

| Trinidad HD | Hard | Solvent | 60% | None | Irgarol* | $230 | |

| Epaint | |||||||

| EP 2000 | Hard | Water borne | 0% | 5% | Zinc omadine | $237 | |

| E Paint ZO | Hard | Solvent | 0 | 5% | Zinc omadine | $237 | |

| Ecominder | Hard | Water | 0 | 40% | Zinc pyrithione | $164 | |

| EP-21 | Ablative (1 season) | Water | 0 | 50% | None | $137 | |

| Interlux | |||||||

| Micron CSC | Ablative | Solvent | 37% | 10-25 % | None | $250 | |

| Micron WA *** | Ablative | Water | 48% | 10-25 % | None | Not tested or reported. | $240 |

| Micron CF | Ablative | Solvent | 0 | 10-25 % | None | $290 | |

| Micron Navigator *** | Ablative | Water | 0 | 2-10% | Zinc pyrithione | $275 | |

| Ultra-Kote | Hard | Solvent | 57% | None | None | $260 | |

| Fiberglass Bottomkote Aqua *** | Hard | Water | 46% | None | None | Not tested or reported. | $240 |

| West Marine | |||||||

| PCA Gold | Ablative | Solvent | 40% | None | Irgarol* | $229 | |

| Sea Hawk | |||||||

| Smart Solution | Ablative | Solvent | 0 | None | None | Not tested or reported. | $195 |

| Colorkote *** | Ablative | Solvent | 0 | 10 % | Econea, copper thiocyanate, zinc pyrithione | Not tested or reported. | $245 |

| Cukote | Ablative | Solvent | 47% | 10% | None | $240 | |

| Biocop TF | Ablative | Solvent | 38% | 10% | Zinc pyrithione | Not tested or reported. | $280 |

| *Irgarol is no longer used. **Leach rates per 2015 State of California Water Board study, expressed in micrograms per centimeter squared (μg/cm2). Leach rates may be different in 2022 paints. ***Not approved for use in California (Colorkote approval is pending). †Prices vary by source. |

TECH GUIDE: ANTIFOULING COLORS, DRY TIMES

| BRAND | OVERCOAT* | LAUNCH* | COLORS AVAILABLE |

|---|---|---|---|

| Total Boat | |||

| Krypton | 1-4 hrs. | 2-8 hrs. | Black, white, blue, red, and green |

| JD Select | 1.5-6 hrs. | Overnight | Black, blue, red, and green |

| Spartan | 1.5-6 hrs. | 6-16 hrs. | Black, blue, red, and green |

| Pettit | |||

| Odyssey 60 | 1-6 hrs | 4-16 hrs. | Black, blue, red, and green |

| Odyssey HD | 1-6 hrs | 4-16 hrs. | Black, blue, dark blue, red, and green |

| Odyssey Triton | 1-6 hrs | 4-16 hrs. | Black, white, blue, red, and green |

| Trinidad 75 | 1-6 hrs | 4-16 hrs. | Black, blue, and red |

| Trinidad Pro | 1-6 hrs | 4-16 hrs. | Black, blue, red, and green |

| Trinidad HD | 1-6 hrs | 4-16 hrs. | Black, blue, red, and green |

| Epaint | |||

| EP 2000 | 5-16 hrs. | 1-2 days | Black, white, yellow, safety orange, gray, and blue |

| E Paint ZO | 3-8 hrs. | Overnight | Black, white, gray, green, and blue |

| Ecominder | 5-16 hrs. | Overnight | Black, white, yellow, safety orange, gray, green, blue, and dark blue |

| EP-21 | 5-16 hrs. | Overnight | Black, white, yellow, safety orange, gray, green, |

| blue, and dark blue | |||

| Interlux | |||

| Micron CSC | 1-4 hrs | 16 hrs. | Black, red, green, shark white, and blue |

| Micron WA | 2-24 hrs | 6-48 hrs. | Black, red, green, and blue |

| Micron CF | 2-12 hrs | 4-18 hrs. | Black, white, red, green, blue |

| Micron Navigator | 1-6 hrs | 1-48 hrs. | Black, red, green, and blue |

| Ultra-Kote | 2-6 hrs | 6-12 hrs. | Black, red, green, and blue (gallons only) |

| Fiberglass Bottomkote Aqua | 2-24 hrs | 6-48 hrs. | Black, shell white, red, green, and blue |

| West Marine | |||

| PCA Gold | 1-6 hrs | 4-16 hrs. | Black, blue, dark blue, red, and Green |

| Sea Hawk | |||

| Smart Solution | 2-6 hrs | 12 hrs. | Black, white, red, green, light blue, dark blue, & light gray |

| Colorkote | 5 hrs | 12 hrs. | Black, white, yellow, red, green and blue, mixable to create 46,656 colors |

| Cu Kote | 2 hrs | 12 hrs. | Black, white, red, green, teal, blue, dark blue |

| Biocop TF | 2 hrs | 12 hrs. | Black, white, red, green, light blue, blue, teal, dark blue, gray |

| *Overcoat & launch times vary by temperature and humidity. Follow maker’s guidelines. |

Over the years we’ve tested antifouling paints in New England (Long Island Sound), and in Florida. For a few years we had simultaneous tests in both areas, but eventually we focused exclusively on Florida, where the fouling was more aggressive. In addition to moving our antifouling test to a new location in the Chesapeake, we made some small modifications to the test panels themselves. In order to better isolate each panel, we expanded the gap between paints. We also left a border around the paints to better contrast the unprotected portions with those protected by paint.

- The new site on a Chesapeake Bay is a tidal creek with a salinity level that will be monitored regularly.

- After a few months, most of the painted panels showed a light layer of slime, while the unpainted areas were already quite thick with slime.

After 30 years of painting bottoms, we’d like to think we’ve learned a few things that make it go faster.

The test boat had a sound coat of West Marine PCA Gold which had been stretched to 3 years, cleaned in-water a few times with a gloved hand and eventually a Berber carpet pad. As part of hauling, the boat was power washed on a dedicated pad with wastewater recovery and treatment. Let the haulout crew know you are painting and to give it a good blast. A scraper is used for any stubborn hard growth and a scrub brush is used inside the centerboard case.

The result is minimal buildup. We sanded the bottom just enough to remove stubborn growth, even up any rough areas, and give it a good tooth, using 60 grit 3M Cubitron paper on a vacuum sander, which was linked to a Dust Deputy trap (see PS March 2022, ”Another Look at Dustless Sanding”) and vacuum with high efficiency bag.

Paint was mixed using single blade turbine mixers. They are superior to common paint mixers for suspending heavy copper and pigment that commonly settle out of antifouling paints. They are also much faster to clean, requiring only a good swipe to remove all residue, an important factor when you have multiple coats of 25 paints to apply. Unfortunately, we’ve been unable to find a good retail source for our preferred flat-blade style (see photo); ours were either recycled from wastewater laboratory flocculation test stands or welded from scrap for practice.

The paints were applied to the test panels and the test boat using 1-inch diameter mini rollers and chip brushes. Normally, our preference is for full-size 9-inch rollers with ¼-to 3/8-inch nap. We used mini-rollers because we had many small areas to paint.

The 1/4” to 3/8” solvent-resistant nap rollers are smooth enough for ablative paints, applies the paint faster and more evenly than mini “sausage” rollers. The paint absorption by the roller is minimal when spread across multiple coats. We might keep the roller overnight in a Ziploc bag if it is still good after the first coat, but normally it the fibers have been flattened and the next coat will go on more evenly with a fresh roller.

Applying paint evenly minimizes the amount needed and maximizes the paint’s effectiveness, more than offsetting the cost of a fresh roller and the paint it absorbs. We use a handle about 30 inches long, to reduce stooping and allow the use of two hands for better control, leverage, and reduced fatigue.

To ensure even coverage and dry times on the test boat, we moved the jackstands to paint the bare spots beneath. Normally, we just touch the pad spots up when the boat is in slings just before launching. This works well enough with solvent based paints, since most dry quickly. However, water-borne paints will not finish curing in the water—no matter what the yard says. The result will be a few spots that are not protected very well. As long as the pads are not in exactly the same location at each haulout, you’ll be relying the previous coat of paint for protection in these areas.

This brings up a final critical point. Manufacturers have done a lot of testing to determine ideal application conditions. In particular, pay close attention to recoating recommendations. A paint that is dry to touch does not mean it is ready for overcoating and to jump the gun can impact adhesion.

Over the years we’ve tested some popular theories, non-marine products, and a range of specialized products that claim to keep barnacles at bay. Although most of these suggestions didn’t survive close scrutiny, there have been a few that have caught our attention.

1. The claim that cayenne pepper can boost antifouling paints has been debunked many times (see PS March 2009).

2. None of our tests have been able to prove that darker colors work better.

3. Our search for an inorganic zinc silicate paint for aluminum hulls led us to the water-based zinc primer Dimetcote 21-5, from PPG Amercoat, and it met our modest expectations for a non-copper paint (See PS December 2011).

4. Prop-Glop, a thick grease that you apply to the prop, didn’t stick to our test boat prop and is no longer available. Whenever we’ve tested grease-like products, the grease dissolved shortly after first use or after a few months on a test panel.

5. We’ve tested several expensive prop concoctions, including a baked-on Mussel Buster (shown here). We’ve also noted acceptable protection from less expensive zinc coatings (see PS March 2017).

After considerable study, the Washington State Department of Ecology is delaying on plans to ban copper antifouling paints. Initially copper paints were to have been banned starting January 2021, but this has been postponed until January 2026 to allow study of the effects of replacement antifouling agents. Although the toxicity of copper is reasonably well understood, far less is known about Cybutryne/Irgarol, DCOIT/Sea-Nine, Tralopyril/Econea, and zinc pyrithione.

Washington studies concluded that although copper from boats was measurable, only one marina actually exceeded the state’s water quality targets.

Washington is considering using the proposed EPA 9.5 μg/cm2/day copper leach rate limit, but did not have enough data on the performance of the paints in the marketplace to determine which might be acceptable and what the current leach rates are. Our research indicates nearly all multi-year copper paints can meet this standard, though some single-season paints will not. The Department seems to be leaning in this direction, but in part is waiting for the EPA to finalize their position.

The use of the boosting pesticide Cybutryne/Irgarol has been banned in Europe and all major paint suppliers have stopped formulating with it. It’s gone, and honestly, other than a slight reduction in waterline slime for the first year, it’s benefit was limited.

In California paints are restricted to copper leach rates of less than 9.5 μg/cm2/day and some new paints are pending approval.

Our recommendation is to use multi-year paints when possible, stretch them as far as possible, and keep your ear to the ground for new technical and regulatory developments. We’re not going to second guess a conservative agency.

Want to minimize your copper footprint? This list of California-registered paint copper leach rates can guide you towards potentially less harmful paints. https://www.waterboards.ca.gov/rwqcb9/water_issues/programs/watershed/docs/swu/shelter_island/final_copper_afp_leachrate_list.pdf Keep in mind that the list is out-of-date (2015), and may be inaccurate because major paint formulators are reformulating to meet the 9.5 μg/cm2/day leach rate limit, including most of the paints involved in our brackish water test.

The Washington Department of Ecology’s recommendations to the legislature can be found here: https://apps.ecology.wa.gov/publications/documents/1904020.pdf

Any update after the summer? Thank you