Having the right tool makes every boat maintenance or repair job that much easier. Having it handy makes an even bigger difference. With that in mind, PS tester Evans Starzinger decided to develop one small tool bag that would cover 85 percent of the jobs by itself. After two years of tinkering with the contents, he settled on a small tool bag that seems to fit the bill. It has four basic categories of tools: standard mechanical tools (screwdrivers and wrenches), electrical, sewing, and consumables. The tool bag was selected to be compact, easy to carry and stow, while just big enough to fit the necessary tools.

***

The oft-repeated chestnut that world cruising is fixing your boat in a series of exotic ports is true, and it implies that a cruising boat should carry a lot of tools to do all that fixing. Over the years, my partner, Beth, and I have added more and more tools to our stash. It got to the point that I had the tools sorted by type into six large Rubbermaid tool boxes and a four-drawer tool chest. I then discovered that to do almost any project required unstrapping and opening at least half of the tool boxes. This created quite a mess, a big cleanup, and a big restowing job when my project was completed. I decided to develop one small tool bag that would cover 85 percent of the jobs by itself and most of the other 15 percent hopefully by opening only one of the larger tool boxes.

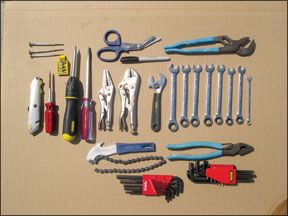

After two years of tinkering with the contents, I have settled on a small tool bag that seems to fit the bill. It has four basic categories of tools: standard mechanical tools (screwdrivers and wrenches), electrical, sewing, and consumables. The tool bag was selected to be compact, easy to carry and stow, while just big enough to fit the necessary tools.

Standard

Mechanical Tools

This category consists of a very conventional collection of tools. I did not want to carry a full set of both metric and standard socket wrenches, so the only real learning point was to figure out exactly which box wrenches were needed to fit the bolts on our boat,

Hawk. Our hose clamps have 7-millimeter nuts, half-inch and 13 millimeter fit the adjustment screws on our two alternators (and also the mainsail batten tension adjustment bolts), 7/16 inch fits the Harken batt cars, and 12 millimeter fits the bleed screw on the engine. The hex wrenches are the only tools that seem to rust, so I keep them in a Ziplock bag sprayed with WD-40. The following tools fall into this category:

Largest flat-blade screwdriver that will fit in the bag, also used as pry bar

Two multi-blade screwdrivers (large ratchet unit and smaller one with specialty blades)

Three small jewelers screwdrivers two flat blades (small and tiny) and one Phillips

Eight ratcheting box wrenches two 7/16 inch, two half-inch, and one each of 9/16 inch,

7 millimeter, 12 millimeter,

and 13 millimeter

An adjustable crescent wrench

Two vice grips (needle nose and standard)

Two sets of hex wrenches (metric and standard)

Pipe wrench

Filter wrench (style with adjustable chain)

Linemans pliers with

heavy-duty wire cutters

Exacto knife

Heavy-duty scissors

Electrical Tools

Through our own experiences and discussions with electrical component experts, we have been convinced that a good crimp connection is the way to go rather than soldering. The key is that it must be a GOOD crimp, which is almost impossible to make with the inexpensive “auto crimper kits.” It requires a high-quality ratchet crimper that will make a perfect, watertight crimp every time. (Practical Sailors favorite crimper is the Klein 1005, Practical Sailor Aug. 15. 2003.) I also use a pair of specialty wire strippers that make a perfect strip to fit the crimp terminals. Ancor (www.ancorproducts.com) makes a quality stripper (a Practical Sailor favorite in the 2003 review) and crimper. They run about $60 each, but are worth it for perfectly trouble-free connections. I keep the multimeter in a Ziplock bag to prevent the display from being scratched by the other tools. Our electrical toolkit includes:

Digital multimeter

Ratchet crimper

Wire stripper

Wire cutters

Sewing Tools

The thread needs to be strong and UV resistant. The Goretex thread (available from Sailrite, www.sailrite.com) meets that bill, as does waxed dental floss, which also holds a knot better. The small needle-nose pliers and vice grips are used to put a needle through thick cloth. We carry the following for sewing needs:

Heavy sailmaker needles

Normal household sewing needles

Goretex sewing thread

Waxed dental floss

Heavy, polyester waxed whipping twine

Small scissors

Needle-nosed pliers

Small vice grips

Lighter

Sailing knife

Fid set

Consumables

We use wire ties on most of our shackles to prevent the pins from vibrating loose. But on two of the shackles (mainsail tack and anchor), we found that the wire ties kept breaking, so we now use stainless wire to seize the pins on those. (Some Practical Sailor editors prefer monel seizing wire over stainless wire and plastic cable ties, which are affected by UV rays.) WD-40 is not much of a lubricant, but it is a terrific cleaning fluid.

While we have many special-purpose lubricants and adhesives, we use LanoCote www.defender.com) as our general purpose stainless-fastener lubricant, blue Loctite (www.loctite.com) as the standard thread lock, and super glue and a two-part epoxy putty as the normal adhesives. In our consumables toolkit youll find:

A small assortment of crimps, terminals, and heat-shrink tubing

Wire ties

Stainless-steel (or monel) seizing wire (to tie shackles closed)

A small jar of LanoCote

WD-40

Electrical tape

Rigging tape

Blue Loctite

Silicone caulk

Super glue

Epoxy

Conclusions

This single, small tool kit, along with a DeWalt (www.dewalt.com) or Makita (www.makita.com) cordless drill and carbide bits, allow me to do most common jobs without unpacking any of our big tool boxes.