Photo by Drew Frye

Every day, as the temperature rises and falls, gases inside your fuel tank expand and contract. The gas emissions released during this diurnal breathing have raised concerns at the U.S. Environmental Protection Agency (EPA), and in July 2011, the agency mandated passive carbon-canister filters on all installed gasoline-tank vent lines to collect fuel evaporation emissions (40 CFR Part 1060). While older boats are not required to retrofit, we wondered how such a filter would affect fuel quality and engine performance, so we launched tests in the lab and the field to find out. We also wanted to determine whether carbon is the most effective filter media.

One harmful side effect of the diurnal breathing is moisture build-up within the tank. Water absorbs into fuel at very low levels, but the amount that is stable is temperature dependent. On cool nights, it forms into droplets that settle to the bottom of the tank, where they cannot evaporate-like a minnow trap, where fish can swim in but cannot get out. Such a scenario requires just the right conditions and fuel sitting unused for long periods in the tank, but it does happen-especially on sailboats.

In diesel systems, moisture is the lifeblood of bacteria that feed on the fuel, multiplying in warm weather and fouling filtration and injector lines-a major maintenance headache, often made worse by an idle off-season. In ethanol gasoline (E10) systems, even the smallest amount of moisture can corrode aluminum, copper, steel, and zinc, gumming up passages and needle valves in carburetors.

In larger amounts, water can cause phase separation, dropping gallons of a water/ethanol mix to the bottom of the tank or carburetor bowl and causing all kinds of problems.

Another evaporation bummer is the fuel lost through the process. The EPAs evaporative emissions calculations show that a typical 30-gallon fuel tank will lose 1.5-3 gallons each year due to evaporation during diurnal breathing, depending on fueling practice, gasoline formulation, and climate.

Fuel Vent Filters 101

A canister filter filled with a desiccant is a standard industrial solution to keeping dry liquids dry; water is absorbed into microscopic pores, preventing it from entering the tank, and although the media eventually begins to saturate, it also regenerates some with each breathing cycle. To recover volatile hydrocarbons like gasoline, carbon canisters are commonly used.

Silica gel and carbon filters function similarly: The vapors are adsorbed into micro pores, and although the media eventually saturates, it also regenerates with breathing. Carbon and silica gel both pull water and organic vapors from the air. Silica gel has a high affinity for water, while carbon has a high affinity for organic vapors. However, if exposed to high temperatures and either clean air or an excess of something else, they will release what they had previously adsorbed.

Both media types should keep the tank drier and reduce evaporation, adsorbing and desorbing with each day/night breathing cycle. Both also should reduce oxygen in the tank. The media should last a long time, since every morning, temperatures rise and the tank breathes out, the media regenerates just a bit, and if the filter is adequately sized, that is just enough to get through the next night.

By reducing the loss of volatiles, using a fuel tank vent filter results in less gum formation and better engine starting, particularly in cold weather; its also better for the environment. By reducing evaporation, the vent filters could save a boat owner an estimated $8-$12 annually in gas costs. We also suspect that vent filters may have the unintended, yet beneficial, side effect of reducing fuel oxidation, which can lead to gum and varnish deposits.

Photo by Drew Frye

All vent filter installations must include anti-spitback valves, a splashproof through-hull, and high-mounted, self-draining lines. Without proper installation, a fuel vent filter can be ineffective or dangerous. (Well go more into installation details in Part 2 of this report.)

Carbon vs. Silica Gel

What is the best filter media, activated carbon or silica gel? Silica gel is intended to remove effectively all of the moisture that enters a fuel tank during its daily breathing. After three to six months, and adsorbing all that they can, the silica pellets turn from blue to pink thanks to a special indicating chemical; this is designed to let users know that its time to recharge or replace the pellets. Silica gel adsorbs and desorbs hydrocarbons the same way carbon does, only somewhat less efficiently.

Silica gel-filled breather vents have been protecting drums and tanks containing moisture-sensitive chemicals and petroleum products for at least 50 years. We know these technologies work.

For gasoline tanks, the EPA recommends using carbon. Carbon will remove some water by adsorption; reduce evaporated ethanol, which is a significant factor in E10 separation; and reduce the loss of other volatile fractions of gasoline that can contribute to hard starting and gum formation. However, at press time, there was no generally marketed marine carbon vent filter available; the units being installed in new boats will not be due for warranty replacement for two years, so we don’t expect to see them in the catalogs for quite some time.

A typical carbon filter for a sailboat with a 30-gallon fuel tank would hold 500-1,000 milliliters of bulk carbon and should last five to 10 years. The carbon actually becomes saturated with fuel vapors within a few months, but it continues to function for many years as a sponge, adsorbing the vapors from the tank during the day, then releasing most of them back into the tank when temperatures drop and vent air flow reverses. Not a terribly efficient process-reducing evaporation by 50 to 65 percent by EPA estimates-but choosing an oversized unit should help. The downside to carbon seems to be that in damp weather, it will saturate with water and become ineffective.

As mentioned, size matters for both carbon and silica-gel filters. You can go small, and plan to replace or refill the unit seasonally when it is spent, or you can go larger, so that the unit can self-regenerate and last longer.

The EPA’s recommended sizes for carbon canisters range from a 1-liter canister for a 25-gallon tank on a trailered boat, to a 4-liter canister for a 250-gallon tank on a boat stored in the water. The sizing follows a formula based on 0.04 liters/gallon of capacity for trailered boats and 0.016 liters/gallon for in-water boats. The recommendations vary based on the boats fuel tank capacity and whether it is stored in the water or on a trailer, because the EPA assumes trailered boats will see a larger diurnal temperature swing than in-water boats, and so require larger canisters. (For more on the EPA mandate, visit the agency website at www.epa.gov.)

We think that the EPA sizing guidelines for carbon canisters may be about right for silica-gel filters, too, and that five to 10 years with no service is very achievable, even though the efficiency will drop.

What We Tested

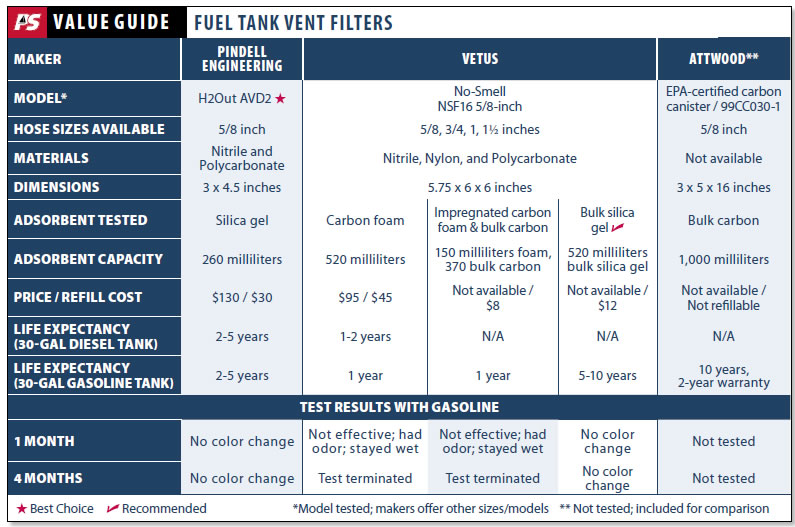

For this round of evaluations, we tested bulk carbon and bulk silica gel, and also compared commercial fuel tank vent filters from Pindell Engineering and Vetus.

The Washington state-based Pindell made a marketing splash this year with its H2Out, which we believe to be the first desiccant breather specifically designed for marine installation. The company makes products that prevent water contamination in fuel, hydraulic fluids, and interior spaces.

From Maryland-based marine manufacturer Vetus, we tested the No-Smell filter, which uses a rigid, carbon-impregnated foam element. While the No-Smell is designed to reduce fumes from fuel-tank breathers in diesel systems, testers were curious to see whether it was a viable option for use as a fuel vent filter since there are so few marine-geared vent filters on the market.

The bulk carbon we tested was pelletized carbon typically used for humid hydrocarbon recovery systems. (You can also find pelletized carbon at pet stores or aquarium supply stores; it is preferred for gas treatment, is widely available, and is relatively inexpensive at about $10 per 10 ounces.)

The silica gel we tested, Sorbead R, is what industrial supply stores-such as Grainger (www.grainger.com)-sell for use in compressed air driers; it should be of the same quality as factory-fill carbon. A very similar bulk silica gel is also sold at craft stores (for drying flowers), but the quality is variable.

How we tested

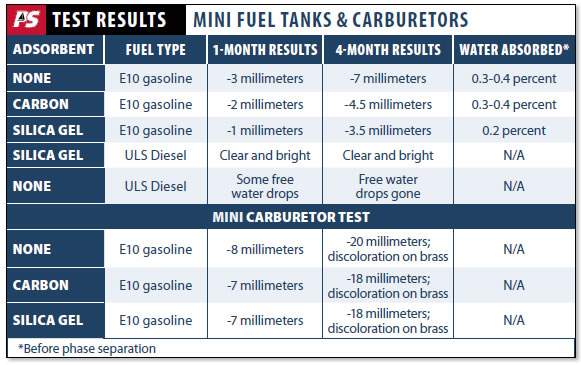

We prefer evaluations that place test products on level ground-although in this case, there are few competing products, and testing all of the interesting permutations at full scale would be impractical. Following the lessons learned with testing miniature holding tanks (PS, February 2012), we set up five miniature E-10 gasoline and diesel tanks. Commercial vent filters were too big for us to use with our mini-tanks, but we were able build matching miniature vent filters and to use the same adsorbents, pelletized carbon and Sorbead R silica gel. The results should be scalable, and at least descriptively accurate.

Each tank was a one-liter jar (filled to 500 milliliters) with a foil-lined cap, and each filter held 10 milliliters of adsorbent. We left them exposed to normal day/night cycling in an open and well-shaded garden shed in the central Chesapeake Bay area for four spring and summer months (March to July). Testers placed the jars in a shallow tray of water, simulating the high humidity typical of marinas and providing realistic temperature stability.

Since carburetor bowls are much smaller than fuel tanks, and they experience much greater temperature extremes, they deserved separate testing. We set up three 100-milliliter jars (filled to 40 milliliters) fitted with galvanically coupled corrosion coupons (steel/aluminum/brass, intended to mimic the metals found in a carburetor). One jar had a carbon filter, one had a silica-gel filter, and the third one had no filter. These were left in full sun for four months, protected only by an outboard motor cowling. This was a very severe test.

To field-test the commercial vent filters, we installed them aboard two identical PDQ 32 catamarans (each with a 27-gallon gasoline tank mounted in an isolated bridge-deck compartment) in two locales, central Chesapeake Bay and south Florida. Both systems include Raycor Lifeguard fuel/air separators.

The Chesapeake Bay installation tested the Vetus carbon canister; we used color-changing humidity test strips to measure the humidity inside the top-loading filters cover. In Florida, we tested the H2Out AVD2 unit; because testing the humidity in-stream is impractical, we relied on the silica gels built-in color indicator to gauge humidity.

Bench Test Findings

Diesel jars: No measurable amount of water accumulated in the diesel test jars, but a light water haze was noticeable in the free-vent jar on cool mornings. The jar with the vent filter always remained clear and bright. Over a few weeks, the haze settled out as small water droplets, which dissolved back into the fuel months later when summer temperatures arrived-proving that droplets of free water can exist in unprotected tanks on an intermittent basis, even in fuel that appears dry. This was enough water to feed microbes and may explain why bugs can grow in seemingly dry tanks; they simply aren’t dry enough. No amount of polishing or recirculation-particularly when the fuel is warm-will remove this dissolved water, and it will always be ready to come out of solution when the temperature cycles.

At the end of the testing period, we chilled the jars to 40 degrees. This recreated both the haze and droplets we had seen in the filter-less jar in the spring; the water was still there, just hiding through the warm summer. We did not observe this haze or droplets on the jar with a silica-gel filter.

Gasoline jars: If percent evaporation is the benchmark, the one-month test period was equivalent to six to 12 months in the real world. Evaporation amounts varied; the jar with no filter evaporated the most (9.1 percent), the carbon filter less (5.8 percent), and the silica-gel filter the least (4 percent). The carbon filters recovered about 64 percent of the evaporation, comparing favorably to the EPAs estimate of 50 to 65 percent.

The silica gel appeared to manage high humidity conditions better; it did not saturate with water on foggy mornings. Free water never accumulated, not even when the jars were cooled to 40 degrees at the end of the test. After exposure, we also tested each sample for water tolerance: None had absorbed enough water to suggest that phase separation in a tank is probable, assuming the fuel is replaced at least once each year and no water is leaking into the tank.

Carburetor jars: Evaporation amounts varied among the carburetor test jars. The jar with no filter evaporated the most, and the carbon filter and silica gel filter less. This time, there was much less difference across the board and no difference between the two filter types. Were guessing that under these severe conditions, all of the more volatile materials evaporated through the connecting hose, no matter what the filter.

Corrosion results were confusing at first. The jar without a filter experienced greater staining of the brass coupon. However, all of the corrosion was above the evaporation line and may well have varied only because of splashing when the jars were handled. The degree of staining and depth of corrosion were identical. Additionally, there was no corrosion of the aluminum or steel coupons. We can only assume that in the absence of salt, corrosion inhibitors added during the refining process protected the metals.

Photo by Drew Frye

We also reviewed scholarly research that concluded that the addition of very small amounts of distilled water (0.04 percent water in E10, only 1/10th of the amount required to cause separation) actually inhibits ethanol corrosion by supporting aluminum oxide passivation. We think that chemistry makes sense. However, we did see evidence that vent filters reduce brass corrosion and have started long-term vent filter tests to confirm this; stay tuned for the results.

Water did not accumulate in any jar, not even when the jars were cooled at the end of the test. However, we have observed phase separation in small jars with extreme evaporation ratios in other testing, so we know that phase separation in a carburetor bowl is possible in cool, damp weather.

Photo by Drew Frye

Field Test Findings

What we learned in field testing was that silica-gel adsorbent easily lasted four months and will most likely last more than a year. In fact, testers switched the Chesapeake boats setup from carbon to silica gel (still using the Vetus housing) after two months. We did this for several reasons. The carbon canister became soaked with dew within one week, and stayed that way from February to May, when we terminated the test. While we were assured by the EPA and vendors that the filter media would regenerate in warm weather, we considered the result unacceptable. The saturation never occurred again on the Chesapeake boat once we made the switch to silica gel, and the silica-gel H2Out on the Florida test boat never saturated. Also, at the time, mini test tanks were showing lower evaporation rates with silica gel than with carbon. This seemed counter to conventional wisdom, but we had multiple confirming data points that convinced us to make the switch to silica gel.

Although the activated-carbon water saturation issue appears to be limited to spring/fall in cooler climates, we believe the EPA underestimated the effect of damp weather on carbon filters when they issued their mandate.

H2Out AVD2

Containing 260 milliliters of silica gel, Pindell Engineerings H2Out AVD2 is the only marine desiccant unit that is ready to go right out of the box; all others require some adaptation.

The H2Out comes in two sizes: the AVD2 for tanks up to 60 gallons and the AVD3 for tanks up to 200 gallons. Both are suitable for filtering diesel, gasoline, and E10; they are not compatible with E85. (The company may be introducing a unit specific to gasoline tanks in the future, if they determine there is a more effective media; stay tuned.)

Testers found it easy to remove the silica gel from the 3-inch by 4.5-inch cylindrical housing-simply remove a hose clamp on one end and dump it out-but doing this neatly does require removing the unit from the fuel line in most installations. The silica gels color change is easy to monitor through the clear Lexan housing.

The H2Out can be installed in any orientation, but its best to install it vertically as there is no mechanism to prevent media from settling to one side, allowing some minor bypassing. (The EPA requires this in certified carbon canisters.) Pindell sells a bypass insert to prevent overfills from contaminating the filter; the insert allows for multiple vent hose sizes, including the standard 5/8-inch.

The H2Out performed as advertised, and testers found no problems with installation, leaks, or maintaining the filter. In more than four months, the silica pellets never changed color to indicate they were spent.

The H2Out AVD2 retails for $130 at marine chandleries.

Bottom line: Employing highly adsorbent silica gel, the rugged and trouble-free H2Out keeps humidity out while limiting fuel evaporation. It gets PSs pick for Best Choice in this test, even though it is not an EPA-certified filter.

Vetus No-Smell

The regular Vetus No-Smell contains 520 milliliters of activated carbon in a foam filter pack. It features a mounting foot and bottom-mounted hose fittings that limit installation options. The housing must be bolted at a high-point on a bulkhead, and there must be space above the screw-off lid to service the media. This may be difficult to accommodate on many boats; however, it made for a neat installation on our test boat and was the easiest to service.

When tested with its foam carbon pack, the No-Smell performed poorly in field tests, saturating with dew in just weeks when outside humidity ranged from 60 to 80 percent. Because the No-Smell was not intended for this application, its lackluster performance was understandable. However, testers were still hopeful that the handy, top-loading housing could be retrofitted for duty as a fuel vent filter, so we switched the media to silica gel and added fine stainless-steel perforated plates to the housing to restrain the media.

When filled with silica gel, the Vetus kept humidity on the tank-side of the vent at 20 to 40 percent when outside humidity varied from 40 to 80 percent. This setup worked well-no installation problems, leaks, or maintenance issues-and showed no condensation, despite widely variable temperatures.

We reported the test results to the folks at Vetus, and they responded that although the No-Smell is not marketed as a fuel vent filter, our findings were “very interesting and helpful. They said that they would conduct similar in-house tests using silica gel and that if our results were replicated, they would introduce a silica gel option for the No-Smell.

The carbon No-Smell retails for $95.

Bottom line: Testers liked the Vetus ease of use. We can recommend its housing as a useful starting point for a DIY silica-gel fuel vent filter. We do not suggest using it with its factory carbon foam pack in this application.

Conclusion

Are fuel-tank vent filters necessary in order to have fuel-system reliability? No. Do we have solid data that shows they deliver incremental value exceeding their cost and help maintain fuel quality? Yes.

A little less water in fuel and gasoline systems is always a plus, and the filters we tested offered this for all fuel types. Diesel users should see less free water, and thus less infection and corrosion potential. Gasoline users likely will pay for the unit with fuel savings and may see improved cold-weather starting. Our test to determine whether the filters reduce corrosion in E10 gasoline systems is inconclusive at this point, so we are running additional long-term tests to find out more. (Look for the report in Part 2.)

Which is better, silica gel or activated carbon? In our tests, silica gel did well for both diesel and E10 gasoline. It appears to be the best absorbent for gasoline conservation and for protecting both gas and diesel from atmospheric water absorption.

We would like to see others-and the EPA-take a closer look at fuel evaporation in locations where heavy dew and fog are daily realities. We recognize that local weather is a huge variable, so our results may not be universal. However, if protecting your fuel system from moisture is the primary measure of performance, silica gel is the clear winner for those in cool, damp climates and those who see significant temperature swings.

As far as the EPA mandate, well have to wait and see how it is executed, but there should be both operational and environmental benefits. Were not convinced that the required carbon canisters are the right tools for the job.

At present, there is only one silica gel-based marine product line, the H2Out AVDs, and these appear to be quite effective for gasoline, E-10, and diesel. The H2Out AVD gets our pick for the Best Choice fuel vent filter at this stage of testing. Stay tuned for our followup report.

For a closer look at fuel vent filters in marine systems, check out the resource links posted with this article online.