I love the idea of a preventer that can be engaged by pulling on just one line and that can be eased just as simply if caught aback. As a frequent singlehander, often on performance boats, I find the simplicity appealing.

Boom brake manufacturers state their products can be used as preventers by simply hauling the control line down tight. But we’ve followed reports of this method failing, resulting in broken booms, failed control lines, crash jibes, and ripped out travelers. We’re becoming convinced that the engineering math just doesn’t hold up—and that the manufacturers’ claims are misleading, if not dangerous. And how could it, if boom-end preventers are just barely strong enough in severe conditions? Let’s break it down.

In our last review of boom brakes (see “Tools to Tame the Jibe,” PS July 2017), we collected data on jibe forces using a load cell and doing sloppy jibe after sloppy jibe across the Chesapeake Bay. We must have looked like complete idiots.

In winds up to 15 knots true, the peak force on polyester sails and polyester control lines was roughly 140 percent of the maximum windward mainsheet load. The jibes were noisy and scary, but unless they were a frequent occurrence, not likely to hurt anything.

With laminate sails and Dyneema control lines, the instantaneous load increased to about 250 percent of the maximum load that would be normally applied to the windward sheet. When the wind increased further, to 25-30 knots, the forces increased another 50 percent on both sample lines (polyester and Dacron).

Note there is a disproportionate increase in load because at higher windspeeds, the hull speed limit means more force is transmitted to the sails.

We did only a few tests in stronger winds because they were scary. We’ve also ripped sails jibing off the wind, something that we have never experienced upwind. With laminate sails or high modulus control lines, the forces in moderate winds are likely exceed the safe working load of boom and sheeting components, and in stronger winds this is almost certainly so. In many cases, older boats were not designed with the potential impact loads of high modulus sailcloth and lines in mind.

This is why many riggers are now advising owners of older boats to back up track-mounted mainsheet hardware on their boom. Those small track-mounted shackles are often old, and the repeated loads have weakened the point where they attach to the boom. The remedy is simple, a loop of Dyneema around the boom and shackle to take the strain.

The adjacent table, based on the specifications on the Walder Boom Brake shows how its safe working load compares to those of modern materials. (We’re not picking on Walder, other brands have similar specs.)

HOW WE TESTED

We calculated typical boom-end mainsheet loads at the reefing limit using a Harken on-line calculator, allowing for the fact that big boats typically reef later. They agree with load cell measurements we have taken on a range of boats.

The eighth line in our table “calculated boom-end mainsheet load with 40% impact (crash jibe)” estimates the peak jibe force at the upwind reefing limit. People often carry more sail off the wind, so this will increase the load in proportion. This also does not allow for sailing above hull speed or the use of laminate sails and high modulus rope. The actual force could be more than double this.

Based on these calculations, our conclusion is that when a jibe is caught by a locked-down brake, the load on the hardware is near the working load limit. The load on the brake line is well over its working load limit, but below the breaking strength of the line. This line may hold the first few jibes, but it will eventually fail, most likely by the cover stripping from the core. If the sails are laminate, the lines high modulus, or the winds over the windward reefing limit, it will likely fail the first time.

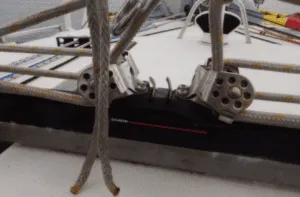

Climbers have long known that cam devices used to grip and hold rope lower the strength of the rope by 30-45 percent, tearing the cover off under high load. This is why we caution against using these as fall arrestors for mast climbing (see “Getting to the Top,” PS October 2014). The same is true of jammers, as demonstrated by this failed boom brake control line.

But can’t we just use high modulus control line in our boom brake? No. The boom brake relies on a certain amount of stretch because even when mounted according to the instructions, the arc described by the boom through a jibe is not a perfect ellipse. As the boom travels through its arc, the control line must stretch 5-10 percent, depending on the exact mounting locations.

On one tack, the load is spread across the full length of the line, all the way back to the cockpit, but on the other tack the load is concentrated on a segment of line between the deck anchor point and the boom. (A double-ended control line that leads back to each end of the cockpit more evenly spreads the load, but this is an uncommon setup.)

So no, you can’t use a high modulus line in your boom brake. It will either jam or provide insufficient friction, depending on the setting. Even more concerning, if the control line is laminate, something more expensive—the boom, for example—may fail in a dangerous way.

What if we move the boom brake’s attachment point farther aft on the boom? Or put the control line anchors farther aft? Again, the brake functions by describing a semi-circular arc. Any modification away from manufacturer mounting instructions reduces control and increases the forces involved. Every boom brake manufacturer specifies the same basic geometry because it is optimum for this device.

What about upsizing this type of device? If you do this, the performance in lighter winds will be erratic. More importantly, the force on the boom will then become the limiting factor, snapping it like a twig. It is well know that mid-boom preventers can lead to bad outcomes when it is really blowing. A common failure occurs when the boom tip dips into a wave as the boat rolls, resulting in immense forces on the boom end.

Based on our calculations, if the control line fails, the resulting crash jibe may be worse than one that would occur without a jibe tamer. The boat will have rotated a few more degrees past the wind, increasing the forces. Or perhaps the brake will have absorbed some force. In either case, in strong winds, or when the boat is over-canvassed, the impact of the crash jibe can be greater than the working load limit of the traveler and rig, and won’t do it any good.

MISLEADING CLAIMS?

How can manufacturers claim a boom brake, or jibe-tamer is a preventer? Because these devices will in fact prevent a jibe in lighter winds, up to wind speeds when you might tuck a reef in the mainsail. However, if you tension the control line to apply the maximum amount of friction, enough to control a jibe at windspeeds when you might reef the mainsail when beating upwind, the boom will not move in lighter winds. So you must adjust tension to match windspeeds, which partially undermines the main appeal of jibe tamers—their supposed simplicity.

A true preventer must hold up to a more rigorous test—preventing a jibe on an over-canvased boat running downwind in a cross sea, for example. And as our research shows, this appears impossible to accomplish with any jibe preventer on the market without pushing the limits of our cordage and hardware.

Nevertheless, it seems all manufacturers claim their device serves as a preventer—or even eliminates the need for one. Walder says it’s Boom Brake, “. . . eliminates your Preventer.” Dutchman says their product works as a preventer. Captain Don’s Boom Brake describes installation for use as a preventer. Landfall Navigation and West Marine call the Wichard Gyb’Easy a “preventer.”

Is it even possible to use these devices as preventers in extreme conditions? Maybe. But it requires care—and the following guidance applies to conventional preventers as well.

First, never carry more mainsail off the wind than you can carry upwind. Racers will disagree, and I’ve certainly I’ve pushed the limits when sailing fast. But racers also break gear, and the consequences are usually not as serious than they are for someone who is hundreds of miles from help.

Secondly, never set the tension on the boom brake control line higher than you would for a controlled jibe in windspeeds at the reefing limit. If the wind is blowing hard enough for you to reef, then you should reef. If you don’t reef, the brake will likely slow the boom, hopefully enough to prevent damage. The resulting jibe, however, will still be startling and dangerous. But that is far better than a broken boom brake followed by a full-force crash jibe.

Ideally, when running in a heavy sea for long periods, you should rig a bow-to-boom-end preventer. (“The Best Prevention is a Preventer,” PS July 2017.”) If, for some reason the preventer fails, the boom brake will still slow the boom. The boom brake will also be useful if the mainsail is caught aback and you are forced to jibe; it will help relieve part of the load on the preventer as you ease the boom over to the new tack.

FAILURE MODES

Another known failure mode is boom breakage by an over-tensioned boom brake. In one case, in order to calm the boom in lumpy conditions, the brake was over-tensioned for days during an ocean crossing. After weeks of such abuse, the boom failed.

We’re not saying you can’t use a brake as a preventer in lighter conditions. It can greatly simplify things when jibing each while running down a river or channel. Sometimes you are forced to sail slightly by the lee, and a brake can steady the boom. A brake can improve safety when you have a crew member on deck, though rigging a preventer (or sheeting in and locking the down the traveler on multihulls with long travelers) is safer. A boom brake might appeal to singlehanders in settled conditions, when setting a bow-to-boom-end preventer requires extra effort. For a singlehander, pulling a single line from the cockpit can make things safer. If they get caught aback, releasing a single line will jibe the main in control, but this will work only up to the reefing limit.

Some claim a brake can work like a vang. But this is only true when locked down, which makes it impossible to dump the sheet or traveler, so they actually make control worse. No thanks.

CONCLUSION

Don’t lock a boom brake down by using excessive tension on the control line. Never tension the control line more than you would for a heavy air jibe, which with typical winch sizing is probably light hand pressure, like sheeting in 6-8 knots. If you are running wing and wing in strong conditions and need a preventer, rig one from boom end to bow (see “The Best Prevention is a Preventer,” PS July 2017.)

SPEC GUIDE: CALCULATED BOOM VANG LOADS

Editor’s note: The following story, redacted from an online report and republished with permission of the author, is not meant to highlight or critique seamanship, but to illustrate how gear makers may be putting sailors in danger by advertising jibe tamers as preventers. As illustrated in this and previous reports, all of the “jibe-taming” products we have tested have physical limitations. In extreme conditions, these limitations can inhibit their ability to function reliably as a preventer. Sailors who assume a boom-brake or jibe-tamer will function as a preventer at windspeeds that require reefing may be inviting gear failure or putting themselves at increased risk.

It was night, and Carsten Breuning and his sailing companion were rounding Cape Mendocino, in Capri, a Jeanneau Sun Fast 40.3 as the wind freshened. It was blowing 20-25 knots and the swells were running 8-10 feet. It was still comfortable sailing, their mainsail had two reefs in it and Capri blasted along, making 7-8 knots.

They were most of the way round the cape before the winds began to pick up to above 30 knots. Seas were 10-12 feet. Worse, they had to jibe.

Breuning went to the foredeck to take the poled-out genoa in from the one side and pole the genoa out to the other side. The deck was rolling and pitching in the high waves, the wind was shrieking. But there was no way around it, they had to jibe.

The jibe was uneventful. Breuning’s crew went below for some well-deserved sleep as Breuning takes over the helm. Suddenly, there is a crash jibe. A big wave comes from the side, throwing Capri around so the mainsail is backwinded.

The crew had assumed the boom brake was supposed to either act as a preventer, stopping the jibe or at least act as a brake, slowing the entire process down.

So how did it happen if the boom brake is supposed to prevent it? The line from the boom brake goes through a clutch that keeps the line taut. With the line taut, the boombrake allows no movement of the boom.

When they inspected the boom brake control line, they could see that the outer covering of the line had been peeled back like a banana peel. Once this happened, the clutch couldn’t hold on to the inner core. The line then simply slipped through the clutch and the boom jibed.

So why didn’t they also have a preventer running from the bow back to the end of the boom? First, the boombrake is advertised to function as a preventer, so they assumed that it would. Secondly, they didn’t want to add more tripping hazards on deck. In fact, the boom brake did partially work, but the tremendous forces stripped the cover right off the line.

What could they do? Not only had the boom brake line stripped, the shackle on their traveler was broken in half. This was a serious problem. Without the traveler, there is no place to secure the boom.

REPAIRS

The boom was slammed tight up against the shrouds and held, plastered there, by the wind. Their first priority was to center the boom so they could drop the sail or figure something else out.

The big concern was that another wave might create another crash jibe, just in the other direction. This time there would be no brake at all.

Breuning dove into the cockpit locker and came up with a long line with a carabiner hook in the middle. He clipped into the jackline and crawled out on the deck. He managed to get the carabiner hooked into the block on the mainsail sheet and then ran the each end back to a winch through the genoa car blocks on either side. Now he could crank in the sail to the middle and control it.

Breuning then tied the mainsail block to the remnants of the traveler car with a length of Dyneema. Capri ran downwind. There was no chance to turn into the wind in those seas. There was too much we risk of broaching, or worse, a knockdown.

A freak wave crashed from the side, throwing Capri around. The Dyneema soft-shackle—crimped in a sharp bend—parted. Capri jibed again. Breuning clipped in again, and crawled out on deck to connect a line to the boom that was plastered against the stays. The same procedure as before secured the boom.

The crew got the boom centered again. Breuning mounted a new and heavier soft shackle so there were no sharp edges to cut it. The crew dropped the mainsail and continued under genoa alone. With the genoa rolled halfway out, they were making 6-7 knots. The waves were still enormous, but they finally made safe haven.

The fundamental problem, which no constant-friction device can get around, is that a jibe begins with very little force, but then requires massive braking force as the main jibes and opens to the full force of the wind.

1. The Dutchman Boom Brake’s control line passes around three sheaves in a serpentine fashion. The upper sheaves are fixed while the lower sheave rotates between friction plates. A knob on the side adjusts friction on the lower sheave.

2. Captain Don’s carabiner has four basic recommended friction settings. Shown here is one of the settings that can’t be exactly replicated when using a figure 8.

3. The climber’s figure 8 is a very affordable device compared to marine versions, allowing you to try a DIY boom brake on for size.